Milking Hose Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436578 | Date : Dec, 2025 | Pages : 255 | Region : Global | Publisher : MRU

Milking Hose Market Size

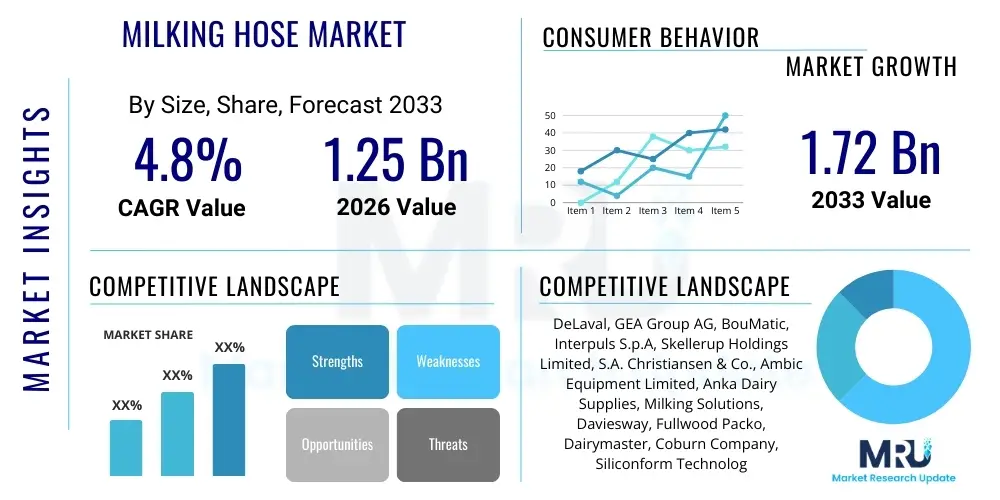

The Milking Hose Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2026 and 2033. The market is estimated at USD 1.25 Billion in 2026 and is projected to reach USD 1.72 Billion by the end of the forecast period in 2033. This consistent growth trajectory is primarily underpinned by the global trend toward dairy farm modernization and increased adoption of automated milking systems, which inherently rely on high-quality, durable milking hoses for efficient operation and maintaining rigorous hygiene standards. The market valuation reflects steady replacement demand coupled with new installations across emerging economies.

Milking Hose Market introduction

The Milking Hose Market encompasses the production and distribution of specialized flexible tubing crucial for transporting milk and facilitating vacuum processes within automated and semi-automated milking systems. These hoses, often manufactured from materials like silicone, natural rubber, or specialized thermoplastics, must withstand harsh chemical cleaning regimes, extreme temperature fluctuations, and constant mechanical stress while ensuring the integrity and hygiene of the milk product. The inherent role of these components in minimizing contamination risk makes material quality and longevity paramount, driving demand for premium products that comply with stringent international food safety regulations, such as those established by the FDA and equivalent regional bodies.

Major applications of milking hoses span large commercial dairy operations, smaller family-owned farms investing in automation, and specialized livestock breeding centers. Beyond transporting the raw milk from the teat cup to the bulk tank, certain hoses manage the pulsation and vacuum lines necessary for the physiological function of the milking cluster, emphasizing their critical, multifaceted nature within the dairy supply chain infrastructure. The increasing average herd size in industrialized agricultural regions necessitates more robust and reliable equipment, propelling the adoption of advanced hose technologies designed for extended operational cycles and enhanced resistance to acidic environments created by Cleaning-in-Place (CIP) systems.

Key driving factors supporting market expansion include the urgent need for dairy farmers globally to improve operational efficiency and reduce labor dependency through automation. Furthermore, escalating consumer awareness regarding food safety and traceability mandates that dairy producers invest continuously in non-porous, easily sanitized equipment components, guaranteeing product quality and reducing the prevalence of mastitis in dairy cattle. The beneficial impact of high-specification hoses includes minimized downtime due to equipment failure, lower maintenance costs over the equipment lifecycle, and, most importantly, the preservation of milk quality, ultimately commanding higher prices in competitive global dairy markets.

Milking Hose Market Executive Summary

The Milking Hose Market is characterized by a stable but competitive landscape, highly dependent on the cyclical investment patterns within the global dairy sector and driven significantly by advancements in material science focused on hygiene and durability. Current business trends indicate a strong shift towards silicone hoses, favored for their superior thermal resistance and inert properties compared to traditional rubber options, though rubber remains competitive in cost-sensitive segments. Regionally, growth is bifurcated, with mature markets like North America and Europe focusing primarily on high-specification replacement demand and regulatory compliance, while the Asia Pacific region, particularly India and China, experiences explosive growth driven by foundational mechanization and the transition from manual to automated milking practices on a massive scale.

Segment trends highlight the growing dominance of specialized cluster and twin hoses designed specifically for high-capacity rotary and parallel milking parlors, reflecting the industrialization of dairy farming. Furthermore, the segmentation by end-user shows that large commercial farms, those housing thousands of cattle, are the primary purchasers of premium, sensor-integrated, and long-life hose systems, demanding specialized vendor contracts and maintenance agreements. Material segmentation analysis reveals persistent innovation in antimicrobial additives integrated within hose polymers, designed to proactively combat biofilm formation and ensure milk purity throughout the transportation process, thereby aligning with global health objectives and stricter sanitation protocols enforced by regulatory bodies worldwide.

This market requires constant vendor innovation, not merely in product durability but also in the provision of comprehensive servicing and predictive maintenance protocols that minimize unexpected failures, which can be devastating to high-throughput dairy operations. The integration of maintenance contracts alongside product sales is becoming a critical competitive differentiator. The market’s future is intrinsically linked to the successful deployment of Industry 4.0 concepts in agriculture, where components like hoses are viewed not just as consumables but as integrated, intelligent parts of the entire dairy monitoring ecosystem, necessitating traceability mechanisms and enhanced material certification standards.

AI Impact Analysis on Milking Hose Market

User inquiries regarding the influence of Artificial Intelligence (AI) on the Milking Hose Market primarily center on predictive maintenance, sensor integration for anomaly detection, and optimizing Cleaning-in-Place (CIP) cycles. Users are keen to understand how AI-driven systems can monitor the physical state (wear, micro-fissures, chemical degradation) of hoses in real-time, thereby preventing catastrophic failures, which lead to significant production losses and quality control issues. Key concerns revolve around the cost-effectiveness of implementing smart sensors within relatively low-cost consumables like hoses and the interoperability of specialized monitoring systems with existing farm management software platforms. Expectations include reduced operational downtime, extended component life through optimized usage, and verifiable digital records of hose performance and sanitation compliance, supporting enhanced operational transparency and regulatory reporting.

The impact of AI, while not directly influencing the chemical composition or physical manufacture of the hose itself, fundamentally alters the maintenance lifecycle and inventory management associated with these components. AI algorithms, leveraging data collected from integrated flow sensors, vacuum pressure monitors, and temperature probes located near or within the hose lines, can identify subtle deviations from optimal performance parameters, signaling potential degradation or biofilm buildup far before human inspection would detect it. This preventative capability shifts the maintenance model from reactive replacement based on fixed schedules to predictive replacement based on actual component condition, significantly optimizing procurement and reducing operational waste associated with premature disposal.

Furthermore, AI-powered systems are crucial for validating the efficacy of CIP procedures, which are vital for hose longevity and hygiene. By analyzing data on detergent concentration, water temperature fluctuations, and cycle duration through the hosing network, AI can confirm successful sanitization, flagging any sections of the pipeline, including the hoses, that may have insufficient cleaning exposure. This capability ensures that premium materials, such as medical-grade silicone, maintain their structural integrity and hygienic performance throughout their intended lifespan, solidifying the value proposition of high-end milking equipment components and contributing to higher milk quality standards across the industry.

- AI drives predictive maintenance schedules, minimizing unexpected hose failures and related production halts.

- Integration of flow and pressure sensors allows AI systems to monitor hose integrity and detect internal blockages or wear.

- AI optimizes CIP cycles, ensuring effective sanitation and extending the hygienic life of the milking hoses.

- Farm management systems utilize AI analytics to forecast future replacement needs, improving inventory efficiency.

- Automated monitoring of vacuum stability through AI helps identify micro-leaks or cracks in the hosing before they impact milking performance.

DRO & Impact Forces Of Milking Hose Market

The Milking Hose Market is primarily driven by the mandatory shift toward dairy automation globally and the non-negotiable enforcement of high hygienic standards, demanding frequent replacement of aging or degraded hoses. Restraints predominantly stem from the volatility in raw material costs, particularly synthetic polymers and specialized silicone, which directly impacts manufacturing margins, alongside the cyclical nature of capital expenditure in the agricultural sector, often tied to global dairy commodity prices. Opportunities lie in the development and patenting of highly specialized, antimicrobial-integrated hose materials and expanding penetration into rapidly mechanizing Asian and South American dairy sectors. The convergence of these factors creates significant impact forces, particularly the pressure for vendors to provide extended warranties and guaranteed operational lifetimes for their products, necessitating continuous R&D investment in material durability and chemical resistance.

A key driver is the stringent regulatory environment in developed markets, which dictates precise material specifications and replacement intervals to maintain milk quality and prevent microbial contamination. As global dairy production intensifies, the necessity of maintaining reliable vacuum integrity across vast milking parlor networks elevates the importance of high-performance hoses capable of enduring continuous mechanical and thermal stress. Conversely, a major restraining force is the price sensitivity exhibited by small and medium-sized farms, especially in developing regions, leading them to often choose cheaper, less durable PVC or rubber hoses over premium silicone options, potentially compromising long-term efficiency and increasing the frequency of failures and replacements.

The foremost opportunity for market differentiation involves integrating smart features into hose systems, such as RFID tags or chemically reactive indicators, that signal the optimal time for replacement or cleaning, thereby merging traditional material technology with modern IoT capabilities. The impact forces are further amplified by the sustainability agenda, wherein dairy farmers are increasingly seeking longer-lasting materials that minimize plastic waste and components that facilitate more efficient use of water and cleaning chemicals during CIP. Manufacturers responding effectively to the convergence of hygiene demands, technological integration, and environmental stewardship are poised for substantial market gains and leadership positioning in the coming decade.

Segmentation Analysis

The Milking Hose Market segmentation provides critical insights into purchasing behaviors, material preferences, and technological adoption across various end-user profiles. The market is primarily differentiated based on the core material used, reflecting varying demands for durability, chemical resistance, and cost-effectiveness; the application, which dictates the necessary pressure ratings and flexibility; and the farm size, which influences procurement volume and quality specification requirements. Understanding these segments allows manufacturers to tailor product development, focusing on high-margin silicone hoses for commercial operations or cost-effective rubber options for aftermarket replacement in older systems, ensuring comprehensive market coverage and optimized strategic resource allocation across disparate global geographies.

- By Material:

- Silicone

- Natural Rubber

- Synthetic Rubber (EPDM, Butyl)

- Thermoplastics (PVC, Polyurethane)

- By Application:

- Milk Transfer Hoses

- Pulsation Hoses (Vacuum Lines)

- Cleaning-in-Place (CIP) Hoses

- By End-User/Farm Size:

- Small Farms (Less than 100 Head)

- Commercial Farms (100–1,000 Head)

- Industrial Dairy Farms (More than 1,000 Head)

- By Sales Channel:

- Original Equipment Manufacturers (OEM)

- Aftermarket/Replacement Sales

- By Type:

- Single-Tube Hoses

- Twin Hoses

- Cluster/Assembly Hoses

Value Chain Analysis For Milking Hose Market

The value chain for the Milking Hose Market begins with the upstream procurement of specialized raw materials, primarily high-grade polymers, silicone compounds, and various chemical additives necessary for imparting resistance to heat, chemicals, and abrasion. Suppliers of these base materials, often large chemical and specialty elastomer companies, hold significant bargaining power, especially for FDA-approved and food-contact-compliant silicone necessary for premium hoses. The core manufacturing stage involves extrusion, curing, and rigorous quality control testing to meet specific pressure ratings and hygienic standards. Efficiency at this stage, particularly minimizing material waste and optimizing cure times, is critical for competitive pricing, establishing the fundamental cost structure of the end product before distribution and retail markup are applied.

The downstream segment is dominated by two primary distribution channels: sales directly to Original Equipment Manufacturers (OEMs) of milking equipment (e.g., DeLaval, GEA, BouMatic) and aftermarket sales distributed through specialized agricultural distributors, dealer networks, and veterinary supply houses. Sales to OEMs involve large-volume, low-margin, contract-based supply for new parlor installations, demanding consistent quality and just-in-time delivery. Conversely, aftermarket sales, constituting the majority of the market volume due to the necessity of periodic replacement, are characterized by higher margins and greater dependence on strong relationships with local distributors who provide critical inventory and installation services directly to dairy farms, often providing crucial technical support and maintenance advice.

The shift towards indirect channels, especially through centralized equipment dealers, is prominent, as these distributors often bundle hoses with other replacement parts and services, becoming crucial intermediaries for brand recognition and customer loyalty. Direct sales, though less common, are usually reserved for large industrial dairy farms that purchase in bulk directly from the manufacturer or utilize highly specialized, custom-engineered hose assemblies for unique parlor configurations. Effective management of this distribution nexus requires robust inventory tracking, rapid fulfillment capabilities, and a global logistics network to ensure timely delivery of perishable components, which are essential for uninterrupted dairy operations worldwide and maximizing the product's value delivery to the end-user.

Milking Hose Market Potential Customers

The primary consumers and buyers in the Milking Hose Market are diverse organizations and entities operating across the dairy production spectrum, ranging from multinational corporate farming operations to localized equipment maintenance professionals. Foremost among the potential customers are the Industrial Dairy Farms, defined by large herd sizes (often exceeding 1,000 head) and a high degree of automation. These entities demand the highest quality, most durable, and often custom-specified silicone or synthetic rubber hoses, prioritizing longevity and reliability to minimize operational interruptions, often securing bulk purchasing agreements directly with major manufacturers or their regional representatives.

A crucial secondary customer group comprises the Original Equipment Manufacturers (OEMs) of milking machinery, such as manufacturers of milking robots, conventional milking parlors, and mobile milking units. These companies purchase hoses in massive volumes for integration into their initial system builds. Their purchasing criteria are centered on standardized dimensions, rigorous compliance certifications (e.g., EU food contact regulations, FDA standards), competitive pricing for mass production, and assured supply chain reliability. The quality of the hose integrated into the OEM product directly impacts the perceived overall quality and reliability of the complete milking system, making the OEM segment a critical strategic target for hose suppliers seeking stable, high-volume contracts.

Furthermore, specialized Agricultural Equipment Dealers and Veterinary Supply Services represent a vital segment, acting as necessary intermediaries for the vast aftermarket segment. These entities serve as the direct point of purchase for millions of replacement hoses bought by small and commercial farms (100–1,000 head) throughout the year. These customers require a diverse inventory encompassing various materials (from cost-effective rubber to premium silicone), ensuring local availability and technical support for installation and maintenance, solidifying their role as indispensable components of the overall market demand structure and crucial points for targeted marketing efforts.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.25 Billion |

| Market Forecast in 2033 | USD 1.72 Billion |

| Growth Rate | 4.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | DeLaval, GEA Group AG, BouMatic, Interpuls S.p.A, Skellerup Holdings Limited, S.A. Christiansen & Co., Ambic Equipment Limited, Anka Dairy Supplies, Milking Solutions, Daviesway, Fullwood Packo, Dairymaster, Coburn Company, Siliconform Technology GmbH, Trelleborg AB, Tetra Pak, Agpro Inc., Conewango Products, Puli-Sistem S.r.l., Mueller Company |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Milking Hose Market Key Technology Landscape

The Milking Hose Market's technology landscape is heavily influenced by material science innovation, focusing on maximizing service life, enhancing hygienic properties, and improving resistance to aggressive CIP chemicals, which are crucial for maintaining regulatory compliance. A key technological trend is the shift towards advanced food-grade silicone and proprietary synthetic rubbers (like EPDM modified compounds) that offer superior flexibility and minimal porosity compared to conventional materials, significantly reducing the risk of bacterial adherence and biofilm formation—a major concern in dairy operations. Manufacturers are increasingly utilizing multi-layer co-extrusion techniques to produce hoses with specialized internal linings that are highly smooth and chemical-resistant, surrounded by durable external layers designed to withstand mechanical abuse and UV exposure within the milking parlor environment.

Another significant technological advancement involves the integration of smart features into the hosing and connecting components. This includes embedding passive technologies such as RFID chips into the connectors or near the end of the hose for simplified asset tracking, maintenance logging, and ensuring quick identification during mandatory replacement cycles, facilitating seamless integration with centralized farm management software. Furthermore, ongoing research focuses on developing materials that visibly degrade or change color when their integrity is compromised or when they approach the end of their hygienic lifespan, providing simple, visual cues to farm operators for preventative maintenance interventions, thereby reducing reliance solely on scheduled replacement intervals.

The most advanced technological front involves incorporating antimicrobial additives, often silver ions or other proprietary inorganic compounds, directly into the polymer matrix during manufacturing. While maintaining compliance with food contact safety standards, these additives provide an active barrier against microbial growth on the inner surface of the hose, greatly augmenting the effectiveness of standard CIP procedures. Coupled with improvements in fitting and connection technologies—such as specialized clamp designs and compression fittings that eliminate dead spaces and potential harborage areas for bacteria—these material and mechanical innovations collectively enhance the overall biosecurity and operational reliability of modern automated milking systems, solidifying the market's technical progression and meeting evolving industry requirements for enhanced productivity.

Regional Highlights

- North America: North America, led by the United States and Canada, represents a mature and technologically sophisticated market segment characterized by large-scale industrial dairy operations and a high adoption rate of rotary and robotic milking systems. The market demand here is predominantly driven by replacement sales of high-performance hoses, particularly premium silicone and specialized synthetic rubber variants, where compliance with FDA standards and rigorous farm audits necessitate frequent component renewal. Significant focus is placed on durability and integration capabilities, as farmers seek components compatible with advanced sensor monitoring systems to optimize parlor efficiency. Regulatory pressure regarding milk quality and increasing labor costs further cement the demand for highly reliable, long-life hose systems, making it a critical market for technological innovators and premium product suppliers.

- Europe: Europe maintains a strong position in the global Milking Hose Market, largely influenced by the stringent regulations set forth by the European Food Safety Authority (EFSA) and the strong presence of major milking equipment OEMs such as GEA and DeLaval. Western European countries exhibit high automation rates, similar to North America, focusing on minimizing environmental impact and maximizing animal welfare through superior equipment. Eastern Europe is experiencing moderate growth driven by farm consolidation and modernization efforts supported by EU agricultural subsidies, leading to increasing demand for medium-to-high specification hoses. The region is a key testbed for sustainable materials and advanced cleaning technologies, often leading global trends in hygienic design and material transparency, contributing significantly to both OEM supply and a highly active aftermarket segment.

- Asia Pacific (APAC): The APAC region is projected to register the fastest growth rate throughout the forecast period, primarily due to the rapid industrialization of the dairy sector in countries like China, India, and Australia. India, with its massive but historically fragmented dairy structure, is transitioning rapidly toward mechanized milking, driving foundational demand for basic and cost-effective rubber and PVC hoses, creating immense opportunities for local and international manufacturers. Australia and New Zealand, major global dairy exporters, operate highly efficient, large-scale farms that mirror the demand characteristics of North America, requiring high-grade, durable components to sustain intensive production cycles. The region's growth is heavily influenced by government initiatives promoting food security and modern agricultural practices, fostering an environment ripe for substantial market penetration and expansion.

- Latin America (LATAM): Latin America presents a dynamic market profile, with robust growth in key dairy-producing nations such as Brazil, Argentina, and Mexico. Market penetration is characterized by increasing foreign investment in large-scale commercial dairy operations alongside persistent presence of small to medium-sized traditional farms. Demand is increasing for robust, easy-to-maintain hoses that can withstand the diverse environmental conditions found across the continent. While price sensitivity is higher than in Europe or North America, there is a distinct move toward quality hoses as dairy exports increase, necessitating compliance with international quality standards. The aftermarket is particularly strong, driven by replacement cycles on existing machinery and ongoing modernization projects.

- Middle East and Africa (MEA): The MEA market, while smaller in absolute terms, offers specific, high-value opportunities, particularly in the Gulf Cooperation Council (GCC) countries where large, technically sophisticated mega-farms operate in arid environments. These specialized operations require extremely resilient, temperature-stable hoses (often high-grade silicone) that can withstand high ambient temperatures and intensive cleaning cycles necessary to maintain stringent hygiene standards under challenging conditions. African markets, such as South Africa and parts of East Africa, are initiating mechanization efforts, driving baseline demand, though distribution challenges and economic volatility remain significant factors affecting widespread adoption of premium hosing solutions in the near term.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Milking Hose Market.- DeLaval

- GEA Group AG

- BouMatic

- Interpuls S.p.A

- Skellerup Holdings Limited

- S.A. Christiansen & Co.

- Ambic Equipment Limited

- Anka Dairy Supplies

- Milking Solutions

- Daviesway

- Fullwood Packo

- Dairymaster

- Coburn Company

- Siliconform Technology GmbH

- Trelleborg AB

- Tetra Pak

- Agpro Inc.

- Conewango Products

- Puli-Sistem S.r.l.

- Mueller Company

Frequently Asked Questions

Analyze common user questions about the Milking Hose market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary material driving growth in the Milking Hose Market?

The primary material driving market growth is high-grade silicone, favored for its superior inertness, chemical resistance, and thermal stability, which significantly extends the product's lifespan and maintains strict hygienic standards crucial for food contact applications, surpassing traditional rubber in high-specification commercial dairy environments.

How frequently should milking hoses be replaced to maintain optimal milk quality?

Milking hose replacement frequency depends on material type and usage; typically, natural rubber hoses require replacement every 6 months, while high-quality silicone hoses can last 12 months or longer. Farms must adhere to manufacturer guidelines and monitor for signs of cracking, hardening, or contamination to prevent negative impacts on vacuum stability and milk hygiene.

What role does automation play in the demand for specialized milking hoses?

Automation, specifically the widespread adoption of robotic and rotary parlors, drives demand for specialized twin and cluster hoses that must operate continuously under high stress. These systems require extremely durable, high-specification materials capable of withstanding intensive mechanical pulsation and aggressive Cleaning-in-Place (CIP) regimes without premature failure, thus fueling the premium segment.

Which geographical region exhibits the highest projected growth rate for milking hose sales?

The Asia Pacific (APAC) region, specifically emerging economies like India and China, is projected to register the highest growth rate. This accelerated expansion is driven by the massive transition from manual milking methods to mechanized dairy farming, necessitating the foundational procurement of thousands of hose assemblies for new and modernized parlor installations.

What is the impact of rising raw material costs on the Milking Hose Market?

Rising costs of specialized raw materials, particularly synthetic polymers, rubber compounds, and food-grade silicone, increase manufacturing costs and often translate to higher end-user prices. This volatility acts as a restraint, especially influencing price-sensitive small farms to delay replacement or opt for less durable, cheaper thermoplastic alternatives, thereby impacting overall market profitability and replacement cycles.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager