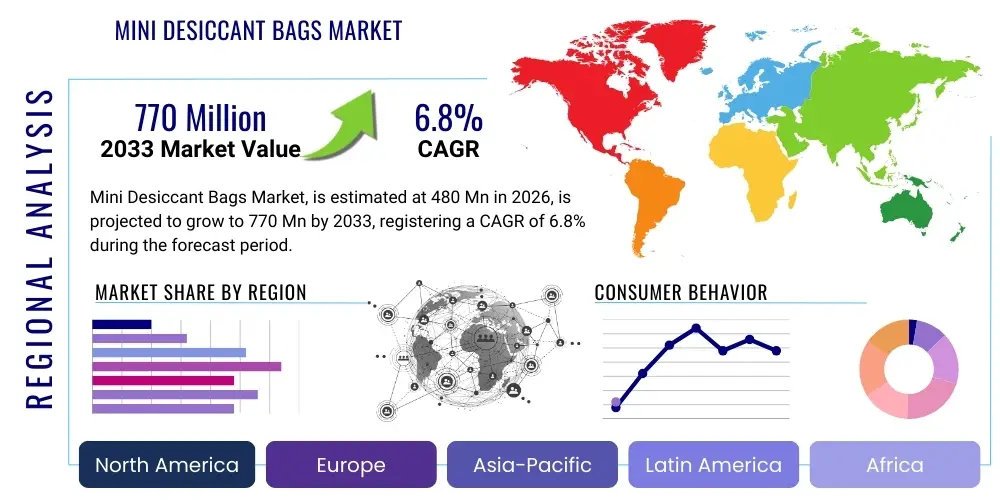

Mini Desiccant Bags Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440150 | Date : Jan, 2026 | Pages : 243 | Region : Global | Publisher : MRU

Mini Desiccant Bags Market Size

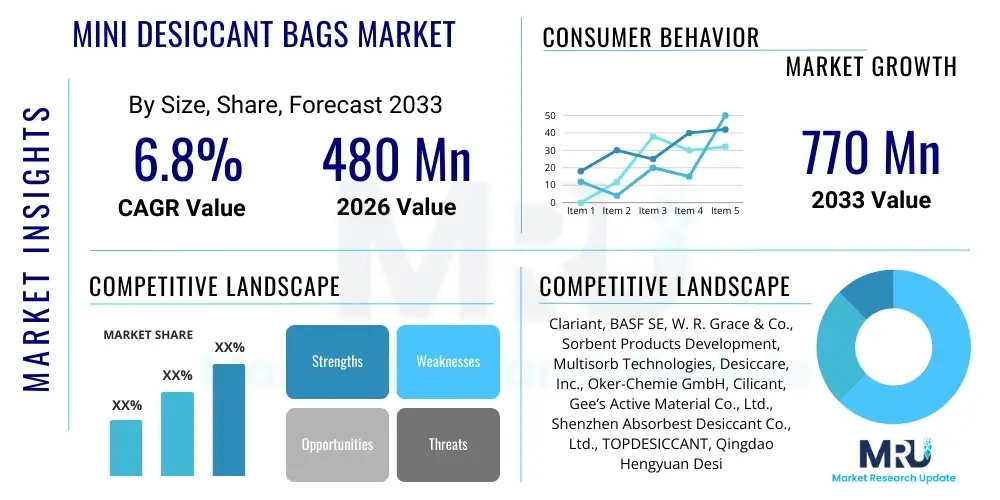

The Mini Desiccant Bags Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 480 million in 2026 and is projected to reach USD 770 million by the end of the forecast period in 2033. This robust growth trajectory is primarily driven by the escalating demand for protection of moisture-sensitive goods across a multitude of industries, coupled with advancements in material science enhancing desiccant efficacy and sustainability. The increasing global trade, stringent quality control regulations, and the rapid expansion of e-commerce platforms further fuel market expansion, creating a critical need for reliable moisture adsorption solutions to preserve product integrity and extend shelf life, thus minimizing economic losses due to spoilage and damage. This growth is also underpinned by a heightened awareness among manufacturers and consumers regarding the long-term benefits of moisture control in preserving product quality and extending functional lifespan.

Mini Desiccant Bags Market introduction

Mini desiccant bags are small, absorbent packets designed to protect moisture-sensitive products from humidity and condensation. These bags typically contain desiccant materials such as high-grade silica gel, activated clay (bentonite or montmorillonite), or molecular sieves, all of which possess inherent hygroscopic properties, allowing them to actively adsorb water vapor from the surrounding environment. Their primary function is to maintain a low-humidity atmosphere within a sealed or semi-sealed package, thereby preventing detrimental effects such as corrosion of metals, mold growth on organic materials, mildew on textiles, degradation of active pharmaceutical ingredients, and other forms of moisture-induced spoilage or functional impairment. The compact and discreet size of these bags makes them ideally suited for inclusion in a wide range of product packaging configurations, from small electronic components and delicate optical instruments to pharmaceutical vials, food containers, and intricate medical devices.

Major applications for mini desiccant bags span across incredibly diverse and critical sectors. In electronics, they are indispensable for protecting semiconductors, circuit boards, consumer gadgets, and sensitive optical equipment from performance-degrading moisture. Within the pharmaceutical industry, they are vital for preserving drug stability and efficacy, ensuring medications retain their potency and safety throughout their shelf life. The food and beverage sector utilizes them extensively to extend the freshness and prevent spoilage, caking, or mold in dry goods, packaged snacks, spices, coffee, and powdered ingredients. Furthermore, medical devices rely on these bags to maintain sterility and functionality, while the automotive industry employs them to prevent corrosion of spare parts and electronic modules. The textile and leather industry uses them to safeguard against mildew and odor, and logistics and shipping companies incorporate them into cargo containers to protect goods during long-haul transit across varying climates.

The benefits of utilizing these specialized desiccant solutions are manifold and highly impactful. They directly contribute to enhanced product longevity, significantly reduced spoilage rates, and a marked improvement in overall product quality and reliability. For businesses, this translates into minimized returns, fewer warranty claims, and greater customer satisfaction, ultimately reinforcing brand reputation. The use of mini desiccant bags also facilitates compliance with increasingly stringent industry-specific quality and safety standards, particularly in highly regulated sectors like pharmaceuticals and food processing. Several driving factors underpin the market's sustained growth, including the continuous innovation in moisture-sensitive technologies, the burgeoning e-commerce sector necessitating robust protection during complex supply chains, and a global rise in awareness regarding the economic and functional imperative of effective moisture control in preserving product integrity from manufacturing to end-user consumption.

Mini Desiccant Bags Market Executive Summary

The Mini Desiccant Bags Market is navigating a landscape shaped by dynamic business trends, distinct regional market characteristics, and evolving preferences across its various segments. A prominent business trend is the increasing emphasis on sustainable packaging solutions. Manufacturers are actively responding to consumer demand and regulatory pressures by developing eco-friendly desiccant materials, such as bio-based and regenerated desiccants, and utilizing biodegradable or recyclable bag packaging. Automation is another critical trend, with advanced machinery improving the efficiency, precision, and consistency of desiccant bag production, as well as their seamless integration into automated packaging lines. Furthermore, the emergence of smart packaging technologies, which incorporate moisture indicators or even RFID-enabled sensors, represents a nascent yet impactful trend poised to offer real-time monitoring and advanced product protection, thereby enhancing the overall value proposition of desiccation solutions.

Regionally, the Asia Pacific (APAC) market unequivocally leads in terms of both market size and growth trajectory. This dominance is primarily attributable to the region's colossal manufacturing base for electronics, textiles, pharmaceuticals, and consumer goods, particularly in economies such as China, India, and Southeast Asian nations. The rapid industrialization, expanding export activities, and a burgeoning middle class in APAC further amplify the demand for reliable moisture protection. North America and Europe, while representing more mature markets, exhibit stable and consistent demand, driven by stringent quality standards in high-value sectors like aerospace, medical devices, and advanced electronics, where product integrity is non-negotiable. Emerging economies in Latin America, the Middle East, and Africa are demonstrating accelerated adoption rates, fueled by improving logistics infrastructure, increased foreign investment in manufacturing, and a growing understanding of the economic benefits of effective product preservation.

From a segmentation perspective, silica gel continues to be the most prevalent and versatile desiccant type, favored for its high absorption capacity and chemical inertness across a broad range of applications. However, activated clay desiccants are experiencing a resurgence, driven by their natural origins, cost-effectiveness, and lower environmental footprint, making them attractive for less sensitive goods and industrial uses. Molecular sieves, while more expensive, maintain their indispensable role in highly specialized applications demanding extremely low humidity levels, such as in optics and specific pharmaceutical formulations. The food and pharmaceutical sectors remain paramount end-use segments, propelled by rigorous regulatory compliance and the critical need to prevent spoilage, maintain efficacy, and extend the shelf life of perishable and sensitive products. There is also a discernible trend towards customized and optimized desiccant solutions, with demand increasing for smaller, more efficient bags precisely tailored to specific product volumes and packaging designs, reflecting a shift towards precision moisture control.

AI Impact Analysis on Mini Desiccant Bags Market

The integration of Artificial Intelligence (AI) holds substantial promise for revolutionizing the Mini Desiccant Bags Market, directly addressing prevalent user questions and concerns regarding optimization, quality assurance, and supply chain efficiency. Users are increasingly curious about AI's potential to move beyond traditional, static desiccant deployment towards more dynamic and predictive moisture management. Common inquiries center on how AI algorithms can analyze complex environmental data, historical shipping conditions, and specific product vulnerabilities to recommend the optimal type, quantity, and placement of desiccants, thereby preventing moisture damage more effectively and cost-efficiently. There is also significant interest in leveraging AI for enhanced quality control within manufacturing, from ensuring the consistency of desiccant material properties to verifying the integrity and fill accuracy of finished bags at high speeds. Furthermore, users are exploring AI's capacity to streamline supply chain logistics, predict demand fluctuations, and optimize inventory levels for various desiccant products, thereby reducing waste and ensuring timely availability. These collective expectations underscore a clear industry desire for more intelligent, precise, and automated solutions in the realm of moisture protection.

- Predictive Moisture Analytics: AI algorithms can analyze vast datasets including climatic conditions, transit routes, packaging permeability, and product hygroscopy to predict moisture ingress risks and recommend precise desiccant dosages, transitioning from generalized to data-driven moisture control strategies.

- Enhanced Quality Control and Inspection: AI-powered computer vision systems can perform real-time, high-speed inspection of desiccant bags during manufacturing, detecting minute defects in sealing, material consistency, and fill accuracy, significantly improving product reliability and reducing production errors.

- Supply Chain Optimization and Demand Forecasting: AI can analyze historical sales data, seasonal patterns, geopolitical events, and macroeconomic indicators to generate highly accurate demand forecasts for different desiccant types and sizes, leading to optimized inventory management, reduced warehousing costs, and improved supply chain resilience.

- Manufacturing Process Efficiency: AI can monitor and analyze operational parameters of desiccant bag production lines, identifying bottlenecks, predicting equipment failures, and suggesting process adjustments to maximize throughput, minimize material waste, and reduce energy consumption.

- Smart Packaging Integration and Data Analysis: When integrated with smart packaging solutions featuring moisture sensors, AI can process and interpret real-time humidity data, providing actionable insights into package conditions, alerting stakeholders to potential breaches, and enabling preventative measures before damage occurs.

- Material Innovation and Formulation: AI-driven simulations and machine learning models can accelerate the research and development of novel desiccant materials with superior absorption capacities, faster adsorption rates, and enhanced environmental sustainability by predicting molecular interactions and material properties.

- Customized Solution Design: AI tools can help desiccant manufacturers rapidly design and prototype custom desiccant solutions for specific client needs by analyzing product specifications, packaging designs, and environmental exposure profiles, offering tailored and highly effective moisture protection strategies.

DRO & Impact Forces Of Mini Desiccant Bags Market

The Mini Desiccant Bags Market is profoundly influenced by a complex interplay of internal and external forces, categorized as Drivers, Restraints, and Opportunities (DRO), which collectively shape its trajectory and competitive landscape. A primary driver propelling market growth is the relentless expansion and increasing sophistication of the electronics industry, which continuously develops more sensitive and compact components that are highly vulnerable to moisture-induced damage. Simultaneously, the burgeoning pharmaceutical sector, driven by an aging global population and advancements in biotechnology, necessitates stringent moisture control to maintain drug stability, efficacy, and regulatory compliance, thereby fueling desiccant demand. The dramatic global rise in e-commerce, leading to products traversing varied and often unpredictable climatic conditions during extended transit, further amplifies the critical need for robust protective packaging solutions. Additionally, heightened consumer expectations for product quality and longevity across a wide array of goods, from packaged foods to luxury items, compel manufacturers to adopt effective desiccation strategies, making mini desiccant bags an indispensable component in preserving product integrity and reducing economic losses due to spoilage or damage.

Conversely, the market faces significant restraints that necessitate innovative solutions. Paramount among these are environmental concerns related to the disposal of single-use plastic components and non-biodegradable desiccant materials, which contribute to landfill waste and microplastic pollution. This pushes the industry towards developing more sustainable and eco-friendly alternatives, often at a higher production cost. The availability of substitute moisture control solutions, such as active packaging films, modified atmosphere packaging (MAP), or specialized barrier coatings, presents competitive pressures that could impact desiccant market share in certain applications. Furthermore, volatility in the prices of key raw materials, including specific grades of silica gel, bentonite clay, and specialized packaging fabrics, can lead to increased manufacturing costs and squeezed profit margins. Lastly, a persistent lack of comprehensive awareness regarding the specific benefits and proper application of desiccants in some emerging industries or among smaller enterprises can hinder broader market adoption, creating pockets of untapped potential that require targeted educational initiatives.

Despite these challenges, numerous opportunities are poised to fuel future growth and innovation within the market. A significant opportunity lies in the intensified research and development of eco-friendly and biodegradable desiccant materials, along with sustainable packaging solutions, aligning with global environmental regulations and growing consumer preference for green products. The seamless integration of mini desiccant bags into smart packaging solutions, potentially incorporating advanced RFID or moisture-sensing technologies, offers a compelling value proposition by enabling real-time product monitoring, enhanced traceability, and proactive intervention capabilities. Furthermore, the expansion into rapidly industrializing emerging markets, where awareness of product protection is increasing and logistics infrastructure is improving, presents substantial untapped growth avenues. Continuous technological innovation in desiccant materials, focusing on achieving higher absorption capacities, faster adsorption rates, and specialized formulations for novel applications (e.g., cold chain logistics or advanced manufacturing), will open new market niches and reinforce the indispensable role of mini desiccant bags in contemporary global supply chains, ensuring product quality and safety across diverse environments.

Segmentation Analysis

The Mini Desiccant Bags Market is meticulously segmented across various critical dimensions, providing a granular and comprehensive understanding of its intricate dynamics, growth avenues, and competitive landscape. This detailed segmentation allows market participants to identify specific trends, discern evolving consumer preferences, analyze technological adoptions, and pinpoint high-growth areas within distinct sub-markets. By categorizing the market based on key attributes such as the type of desiccant material, the end-use industry, the physical size or capacity of the bag, and the material used for the bag's packaging, stakeholders gain invaluable insights. This structured approach facilitates the development of highly targeted marketing strategies, product innovation initiatives, and supply chain optimizations that precisely meet the diverse and often unique requirements of various applications and customer bases. Understanding these segments is paramount for strategic planning, resource allocation, and maintaining a competitive edge in a dynamic global market.

- By Type:

- Silica Gel Desiccants: This segment dominates the market due to silica gel's high adsorption capacity across a wide range of temperatures and humidity levels, its chemical inertness, and non-toxic nature. Available in both indicating (color-changing to denote saturation) and non-indicating forms, it is highly versatile and widely adopted across electronics, pharmaceuticals, and food packaging.

- Clay Desiccants: Primarily composed of calcium bentonite or montmorillonite clay, these desiccants are natural, cost-effective, and environmentally friendly. They are preferred for less sensitive goods, bulk industrial applications, and in situations where cost-efficiency is a primary concern, offering good moisture absorption at moderate humidity levels.

- Molecular Sieve Desiccants: Characterized by their highly porous crystalline aluminosilicates, molecular sieves offer superior moisture absorption capacity, particularly at very low humidity levels and high temperatures. Their ability to selectively adsorb specific molecules makes them ideal for highly specialized and demanding applications such as in optical instruments, advanced electronics, and specific pharmaceutical formulations requiring extreme dryness.

- Activated Alumina Desiccants: These highly porous, granular forms of aluminum oxide are excellent adsorbents for water vapor, widely used in compressed air dryers, gas purification systems, and for dehydrating various liquids and gases. They possess high crush strength and resistance to thermal shock.

- Other Desiccants: This category includes less common or specialty desiccants such as calcium chloride (known for its aggressive moisture absorption), natural plant fibers, and various blended formulations engineered to achieve specific performance characteristics like extended lifespan or enhanced absorption under particular environmental conditions.

- By End-Use Industry:

- Electronics: A critical application for protecting sensitive components like semiconductors, integrated circuits, printed circuit boards, and consumer electronics from moisture-induced corrosion, short circuits, and performance degradation during storage and transit.

- Pharmaceuticals: Essential for preserving the stability, efficacy, and shelf life of medicines, vitamins, diagnostic kits, and medical device components by preventing moisture-induced degradation of active ingredients, thereby ensuring patient safety and product compliance.

- Food & Beverages: Used extensively to safeguard dry foods, snacks, cereals, coffee, spices, and powdered ingredients from moisture absorption, which can lead to caking, microbial growth, flavor degradation, and overall spoilage, extending product freshness and appeal.

- Automotive: Employed to protect spare parts, delicate electronic modules, and interior components from rust, corrosion, and mildew during manufacturing, storage, and shipping, especially for vehicles or parts transported across varying climatic zones.

- Logistics & Shipping: Broadly utilized within shipping containers, crates, and individual product packaging for general cargo to prevent moisture damage, condensation, and "container rain" during long-distance transportation, particularly across oceans.

- Medical Devices: Crucial for maintaining the sterility, functionality, and integrity of sensitive medical instruments, implants, diagnostic equipment, and surgical kits, where moisture can compromise performance and patient safety.

- Textile & Leather: Protects garments, footwear, handbags, and other leather products from mold, mildew, unpleasant odors, and moisture stains that can occur during storage or transit in humid conditions.

- Defense & Aerospace: Essential for preserving the reliability and functionality of high-value, sensitive equipment, weaponry, and aerospace components that require stringent environmental control during long-term storage and operational deployment.

- Other Industries: Includes a wide array of niche applications such as museums & archives (for preserving artifacts and documents), optics (for preventing fogging), chemicals (for protecting hygroscopic substances), and industrial machinery.

- By Bag Size/Capacity:

- 1 Gram: The smallest standard size, typically used for very compact packaging, individual electronic components, small pharmaceutical vials, and moisture-sensitive consumer goods.

- 2 Gram: Slightly larger, suitable for small to medium-sized packages, common in electronics, medical device kits, and some food product packaging.

- 5 Gram: A versatile size often employed for medium-sized packages, footwear boxes, smaller automotive parts, and bulkier food items.

- 10 Gram: Used for larger items, bulk packaging, industrial components, and situations requiring greater moisture absorption capacity over longer durations.

- Above 10 Gram / Customized: Includes larger packets up to several kilograms, specifically designed for industrial applications, large containers, or unique product dimensions requiring bespoke moisture control solutions.

- By Packaging Material:

- Tyvek: A highly favored material, known for its high strength, tear resistance, lint-free and dust-proof properties, and excellent breathability for moisture vapor. It is frequently used for pharmaceutical, medical device, and high-tech electronics applications due to its clean room compatibility and durability.

- Non-Woven Fabric: A cost-effective and breathable material widely used for general industrial applications, consumer goods, and scenarios where Tyvek's specific properties are not strictly required. It offers good moisture permeability and sufficient strength for most uses.

- Cotton: A natural, biodegradable, and breathable material that is occasionally used for desiccant bags, particularly in niche applications where natural fibers are preferred, or for products sensitive to synthetic materials.

- Clear Film/Plastic: Used in specific instances where visual inspection of the desiccant (e.g., indicating silica gel changing color) is desired. This material requires specialized perforation or design to allow for sufficient moisture absorption while maintaining product visibility.

- Others: Encompasses a range of specialized materials including laminated films for enhanced barrier properties, various composites designed for specific environmental conditions, and sustainable bio-plastics under development to address environmental concerns.

Value Chain Analysis For Mini Desiccant Bags Market

The value chain for the Mini Desiccant Bags Market delineates a structured progression of activities, commencing from the sourcing of fundamental raw materials and extending through the intricate stages of manufacturing, distribution, and ultimately, the diverse end-use applications. This interconnected sequence meticulously illustrates how value is added at each step to transform basic components into highly functional moisture protection solutions. At the upstream end of the value chain, the process begins with the critical procurement of essential raw materials. This involves acquiring high-quality desiccant substances such as synthetic amorphous silicon dioxide for silica gel, various grades of bentonite or montmorillonite clay from mining operations, and specialized crystalline aluminosilicates for molecular sieves. Concurrently, a crucial element is the sourcing of advanced packaging materials, which include technical fabrics like Tyvek, diverse non-woven materials, cotton fibers, and specialized films. The consistency, purity, and cost-effectiveness of these foundational inputs are paramount, as they directly influence the final product's performance, safety profile, and overall market competitiveness, requiring robust supplier relationships and quality control.

Moving further downstream in the value chain, these meticulously sourced raw materials are then transported to desiccant bag manufacturers. This manufacturing stage involves sophisticated industrial processes utilizing specialized machinery for precise weighing, accurate filling of the desiccant material into the chosen bag fabric, and hermetic sealing to ensure package integrity. Advanced automation and stringent quality control protocols, including leak detection and absorption capacity testing, are critical at this stage to guarantee that each mini desiccant bag meets specified performance standards and regulatory requirements. Post-manufacturing, the finished products enter the various distribution channels. These channels can be broadly categorized into direct and indirect routes. Direct sales typically involve manufacturers supplying large industrial end-users, such as major electronics or pharmaceutical companies, with bulk orders and often customized solutions, fostering direct relationships and technical support. This approach allows for greater control over the sales process and direct feedback from customers.

Indirect distribution, conversely, leverages a network of specialized distributors, wholesalers, and increasingly, online e-commerce platforms. These intermediaries play a vital role in making desiccant bags accessible to a broader and more fragmented customer base, including smaller businesses, niche industries, and individual consumers globally. E-commerce platforms, in particular, have emerged as a significant channel, enabling wider market reach, streamlined purchasing, and efficient logistics. The efficiency and reliability of this entire distribution network are paramount for ensuring timely delivery and maintaining the quality and effectiveness of the desiccant products, especially given the global nature of supply chains and the sensitivity of the products being protected. The final stage involves the utilization by diverse end-use industries, including electronics, pharmaceuticals, food & beverages, automotive, and logistics. The success of the entire value chain is therefore predicated on seamless collaboration, continuous innovation, and rigorous quality assurance across all stages, from raw material procurement to end-user application, ultimately delivering superior product protection and enhancing customer satisfaction.

Mini Desiccant Bags Market Potential Customers

The potential customer base for mini desiccant bags is extraordinarily diverse and expansive, encompassing virtually any industry or entity involved in the production, storage, or transportation of moisture-sensitive goods. At its core, the primary buyers are manufacturers whose products are susceptible to damage, degradation, or diminished functionality due to ambient humidity or condensation. This includes a vast spectrum of companies within the electronics sector, ranging from semiconductor foundries and component manufacturers to producers of consumer electronics, optical devices, and advanced circuit boards. These entities critically rely on desiccants to prevent irreversible damage such as corrosion, short-circuiting, and compromised performance, thereby ensuring product reliability and extending operational lifespan. Similarly, pharmaceutical and biotech companies represent a cornerstone of the customer base, utilizing desiccant bags to rigorously preserve the stability, efficacy, and shelf life of active pharmaceutical ingredients, finished medications, diagnostic kits, and sensitive medical devices, strictly adhering to stringent regulatory standards and patient safety protocols.

Beyond these high-tech and regulated industries, the food and beverage sector constitutes another significant segment of potential customers. Manufacturers of dry goods, packaged snacks, cereals, spices, coffee, powdered ingredients, and even pet foods consistently employ desiccant bags to prevent moisture absorption, which can lead to undesirable caking, microbial growth, flavor degradation, staleness, and ultimately spoilage. By maintaining optimal low-humidity environments, desiccants play a crucial role in extending product freshness, enhancing consumer appeal, and minimizing food waste. The automotive industry, including component suppliers and vehicle manufacturers, also forms a substantial customer group. They utilize desiccant bags to protect spare parts, electronic modules, and sensitive interior materials from rust, corrosion, and mildew during long-term storage, assembly, and global shipping, ensuring the integrity of complex supply chains and final product quality.

Furthermore, the rapidly expanding e-commerce and logistics sectors are increasingly vital customers for mini desiccant bags. As products traverse complex global supply chains, often experiencing varied climatic conditions and extended transit times, reliable moisture protection within packaging is indispensable to ensure goods arrive at their destination in pristine condition, significantly reducing product returns and enhancing overall customer satisfaction. Other significant end-users include manufacturers in the textile and leather industry, who deploy desiccants to prevent mold, mildew, and unpleasant odors in apparel, footwear, and accessories. Defense and aerospace organizations are critical buyers for protecting high-value, sensitive equipment and components during long-term storage and deployment. Even specialized institutions like museums, archives, and fine art handlers utilize these bags for the preservation of historical artifacts and valuable documents. In essence, any organization with an imperative to protect product quality, functionality, or longevity from the detrimental effects of moisture, across both high-value and commodity markets, is a direct potential customer for mini desiccant bags, underscoring their broad and fundamental utility in modern commerce.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 480 Million |

| Market Forecast in 2033 | USD 770 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Clariant, BASF SE, W. R. Grace & Co., Sorbent Products Development, Multisorb Technologies, Desiccare, Inc., Oker-Chemie GmbH, Cilicant, Gee’s Active Material Co., Ltd., Shenzhen Absorbest Desiccant Co., Ltd., TOPDESICCANT, Qingdao Hengyuan Desiccant Technology Co., Ltd., Sanwa Chemical Industry Co., Ltd., Fuji Silysia Chemical Ltd., Süd-Chemie India Pvt. Ltd. (a Clariant Group company), Shanghai Minrui Industry Co., Ltd., Dongguan Dingxing Industry Co., Ltd., Ailipack, Hengyuan Desiccant, Xiamen Zhaohui Purification Material Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Mini Desiccant Bags Market Key Technology Landscape

The Mini Desiccant Bags Market is characterized by a dynamic and evolving technology landscape, continuously propelled by advancements in material science, sophisticated packaging technologies, and optimized manufacturing processes. These innovations collectively aim to enhance the efficacy, sustainability, and seamless integration of moisture control solutions within modern supply chains. At the forefront of technological development are significant strides in desiccant materials themselves. Research and development efforts are intensely focused on creating new generations of silica gel with markedly higher absorption capacities and faster adsorption rates, often tailored for specific humidity ranges. Concurrently, there is a strong emphasis on exploring and commercializing alternative natural and sustainable absorbents, such as advanced forms of activated clay or bio-based polymers, which offer comparable or superior performance to traditional desiccants while significantly reducing environmental impact. Furthermore, the ongoing refinement of molecular sieve technology allows for the precise engineering of pore sizes and chemical compositions to target specific moisture levels and gas adsorption, catering to ultra-sensitive and high-value applications requiring exceptional dryness.

Packaging technology plays an equally pivotal role in determining the overall efficacy, durability, and market appeal of mini desiccant bags. Manufacturers are increasingly adopting advanced, breathable yet highly durable materials, including enhanced non-woven fabrics and specialized grades of Tyvek. These materials are engineered to ensure optimal moisture vapor transmission rates while rigorously preventing desiccant dust leakage, a critical factor for cleanroom environments and sensitive product packaging. Innovations extend to the development of transparent or semi-transparent films that allow for convenient visual inspection of indicating desiccants, such as color-changing silica gel, providing immediate feedback on saturation levels. Beyond traditional materials, the burgeoning trend towards smart packaging is leading to the integration of desiccants with intelligent features, such as embedded RFID tags for tracking and authentication, or miniature moisture sensors that provide real-time data on humidity levels within a package. These advanced features enable proactive interventions and offer an unprecedented level of product protection and traceability throughout the supply chain.

Manufacturing processes for mini desiccant bags are also undergoing significant technological advancements to meet the escalating demand for precision, efficiency, and scalability. Modern production lines incorporate fully automated filling and high-speed sealing machines, ensuring consistent desiccant quantities and hermetic seals, which are paramount for maintaining product integrity and performance. Sophisticated quality control systems, often leveraging Artificial Intelligence and advanced machine vision technologies, are deployed to meticulously detect even minute defects, verify precise fill levels, and ensure proper bag integrity at incredibly high production speeds. These systems not only enhance product reliability but also significantly reduce waste and production costs. Collectively, these technological advancements are driving the development of more reliable, efficient, and environmentally responsible mini desiccant bag solutions, pushing the boundaries of moisture protection and adding substantial value across various end-use industries by meticulously preserving product quality and extending shelf life, thereby strengthening market leadership and fostering continued innovation.

Regional Highlights

- North America: This region constitutes a mature yet highly innovative market for mini desiccant bags, characterized by stringent quality control standards, particularly prevalent in the pharmaceutical, medical device, aerospace, and high-tech electronics sectors. The demand here is primarily driven by the imperative to preserve high-value goods, alongside sophisticated manufacturing processes and a robust focus on product integrity and regulatory compliance. Continuous innovation in smart packaging solutions, including integrated sensors, and a strong push towards sustainable and environmentally friendly desiccant options are key emerging trends shaping the market in this region.

- Europe: Similar to North America, Europe represents a significant market with highly stringent regulatory frameworks governing product quality and safety, especially within its well-developed pharmaceutical, food, and automotive industries. Countries like Germany, France, the UK, and Switzerland contribute substantially to market demand, driven by their advanced manufacturing capabilities and export-oriented economies. The region places a strong emphasis on environmental sustainability, which is fueling increased research, development, and adoption of eco-friendly desiccant materials and biodegradable packaging solutions, reflecting a commitment to circular economy principles.

- Asia Pacific (APAC): APAC stands as the largest and most rapidly growing market for mini desiccant bags globally. This robust expansion is primarily fueled by the region's colossal and expanding manufacturing base across diverse sectors, including electronics, textiles, food processing, and pharmaceuticals, particularly evident in economic powerhouses like China, India, Japan, and South Korea. Rapid industrialization, increasing export volumes, and a booming e-commerce sector are significant drivers. The region also offers substantial potential for further market expansion due to its vast population, rising disposable incomes, and the ongoing development of logistics and cold chain infrastructure.

- Latin America: This region is experiencing steady and consistent market growth, largely driven by increasing industrialization, expanding cross-border trade activities, and a heightened awareness regarding the importance of product protection in economies such as Brazil, Mexico, and Argentina. Investments in improving logistics and supply chain infrastructure, coupled with the growth of local manufacturing capabilities, are significantly contributing to the rising demand for reliable moisture control solutions to safeguard both domestically produced and imported goods, fostering new market penetration opportunities.

- Middle East and Africa (MEA): The MEA region is emerging as a market with considerable growth potential, primarily propelled by substantial investments in manufacturing diversification, healthcare infrastructure development, and overall economic expansion. The often harsh and arid climatic conditions in many parts of the region make desiccant bags an essential and non-negotiable component for protecting goods during storage and transit, particularly for imported products sensitive to moisture and for supporting the growth of local industrial and consumer goods manufacturing. Increased regional trade and economic integration also play a role in driving demand.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Mini Desiccant Bags Market.- Clariant

- BASF SE

- W. R. Grace & Co.

- Sorbent Products Development

- Multisorb Technologies

- Desiccare, Inc.

- Oker-Chemie GmbH

- Cilicant

- Gee’s Active Material Co., Ltd.

- Shenzhen Absorbest Desiccant Co., Ltd.

- TOPDESICCANT

- Qingdao Hengyuan Desiccant Technology Co., Ltd.

- Sanwa Chemical Industry Co., Ltd.

- Fuji Silysia Chemical Ltd.

- Süd-Chemie India Pvt. Ltd. (a Clariant Group company)

- Shanghai Minrui Industry Co., Ltd.

- Dongguan Dingxing Industry Co., Ltd.

- Ailipack

- Hengyuan Desiccant

- Xiamen Zhaohui Purification Material Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Mini Desiccant Bags market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are mini desiccant bags and how do they function?

Mini desiccant bags are small packets containing hygroscopic materials like silica gel or activated clay, designed to absorb moisture from the surrounding environment. They function by creating and maintaining a dry, low-humidity atmosphere within a sealed package, thereby preventing moisture-induced damage such as corrosion, mold, mildew, and degradation of moisture-sensitive products, which significantly extends their shelf life and preserves their quality and functionality.

Which industries primarily use mini desiccant bags?

These bags are indispensable across a wide array of industries, including electronics, pharmaceuticals, food & beverages, medical devices, automotive, and logistics. Key applications involve protecting sensitive electronic components, maintaining drug stability, preserving food freshness, safeguarding medical instruments, preventing rust on automotive parts, and ensuring cargo integrity during global shipping and storage.

What are the main types of desiccant materials found in these bags?

The primary types of desiccant materials used are silica gel, known for its versatility and high absorption capacity; activated clay, valued for its cost-effectiveness and natural origin; and molecular sieves, which are employed for highly specialized applications requiring extremely low humidity levels. Other types include activated alumina and calcium chloride, each offering distinct performance characteristics tailored to specific moisture control requirements.

Are mini desiccant bags reusable or environmentally friendly?

Many desiccant materials, especially silica gel, are regenerable by heating, allowing for reuse in certain contexts, though most are marketed for single-use due to practicalities. The industry is actively developing more environmentally friendly options, focusing on biodegradable packaging materials and sustainable desiccant substances like natural clays and bio-based desiccants to mitigate environmental impact and align with global sustainability goals.

How does the size of a desiccant bag relate to its effectiveness and application?

The effectiveness of a desiccant bag is directly proportional to its size and the quantity of desiccant material it contains, which dictates its total moisture absorption capacity. Optimal sizing is crucial and depends on several factors: the volume of the enclosed space, the inherent moisture content of the product, the desired humidity level to be maintained, the anticipated exposure to external humidity, and the required duration of protection. Proper sizing ensures efficient and prolonged moisture control for specific applications.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager