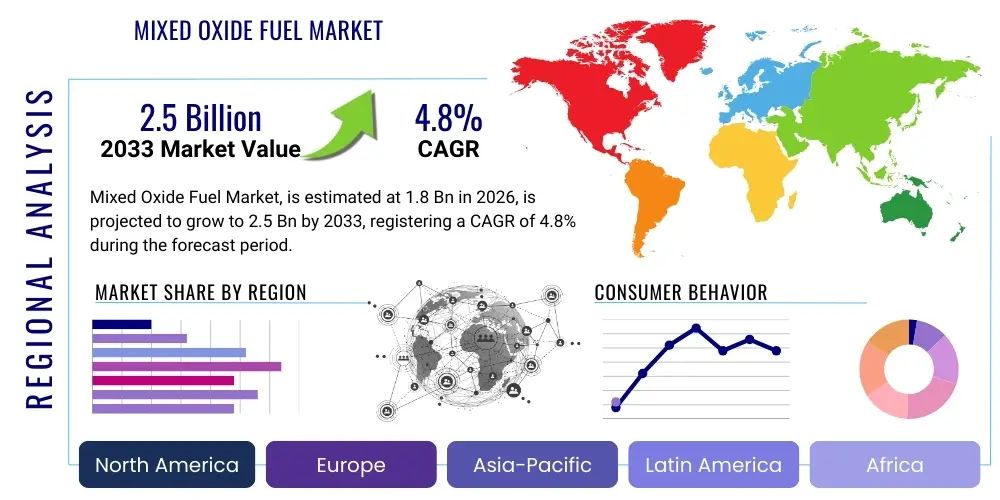

Mixed Oxide Fuel Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439907 | Date : Jan, 2026 | Pages : 253 | Region : Global | Publisher : MRU

Mixed Oxide Fuel Market Size

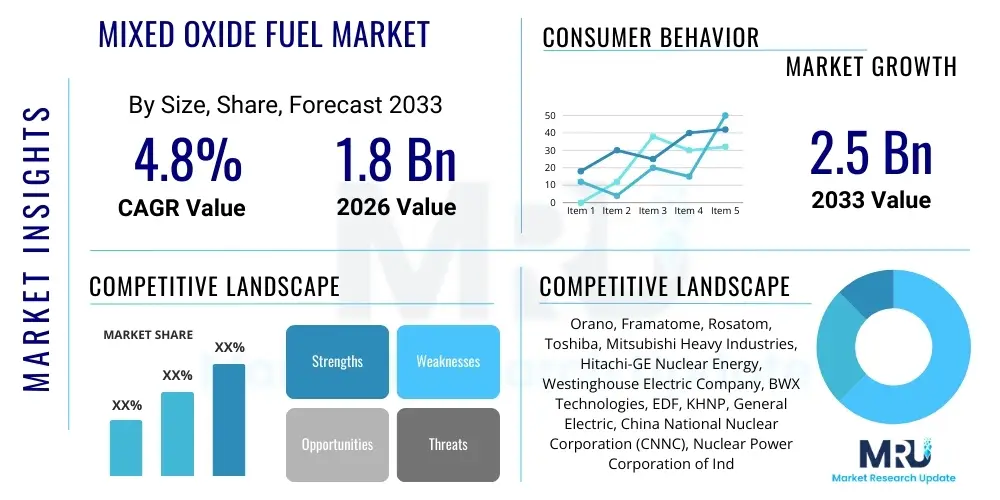

The Mixed Oxide Fuel Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2026 and 2033. The market is estimated at USD 1.8 billion in 2026 and is projected to reach USD 2.5 billion by the end of the forecast period in 2033.

Mixed Oxide Fuel Market introduction

The Mixed Oxide (MOX) fuel market represents a pivotal segment within the global nuclear energy landscape, primarily driven by the imperative to manage plutonium stockpiles derived from reprocessing spent nuclear fuel and to enhance energy security through diversified fuel sources. MOX fuel is a blend of plutonium and natural or depleted uranium, which is used in nuclear reactors instead of low-enriched uranium (LEU) fuel. This innovative fuel allows for the recycling of plutonium, a byproduct of nuclear power generation, into new fuel, thereby reducing the volume and radiotoxicity of high-level nuclear waste while extracting additional energy.

The product, MOX fuel, is typically fabricated as ceramic pellets, similar to conventional uranium fuel, which are then assembled into fuel rods and bundles for use in light water reactors (LWRs), including Pressurized Water Reactors (PWRs) and Boiling Water Reactors (BWRs), as well as in Fast Breeder Reactors (FBRs). Its composition and manufacturing process are highly specialized, requiring advanced radiological protection and stringent quality controls due to the presence of plutonium. The primary benefit of MOX fuel lies in its capability to close the nuclear fuel cycle partially, optimizing resource utilization and mitigating the environmental burden associated with nuclear waste management.

Major applications of MOX fuel include electricity generation in commercial nuclear power plants and the strategic disposition of excess weapons-grade plutonium, converting it into a less proliferation-sensitive form. Key driving factors for market growth encompass the increasing global demand for clean energy, governmental policies supporting nuclear power expansion, the need for efficient plutonium management, and advancements in nuclear fuel cycle technologies. These elements collectively underscore MOX fuel's critical role in the sustainable future of nuclear energy, addressing both resource efficiency and waste reduction challenges.

Mixed Oxide Fuel Market Executive Summary

The Mixed Oxide Fuel Market is characterized by intricate business trends, significant regional variations, and evolving segmental dynamics, all contributing to its strategic importance in the nuclear industry. Business trends are largely shaped by long-term governmental energy policies, substantial capital investments in nuclear infrastructure, and the highly specialized, vertically integrated nature of key industry players. The market is also influenced by global efforts towards nuclear disarmament and non-proliferation, which necessitate the secure and effective disposition of plutonium, often through its conversion into MOX fuel for energy production. Technological advancements in reprocessing and fuel fabrication continue to refine efficiency and safety profiles, driving specialized investments and collaborative research initiatives.

Regionally, the market exhibits distinct operational philosophies and levels of maturity. Europe, particularly France and Belgium, has historically led in MOX fuel utilization and reprocessing capabilities, driven by established closed-fuel cycle policies. Asia Pacific, spearheaded by Japan, India, and China, is emerging as a significant growth region, propelled by ambitious nuclear power expansion programs and the strategic imperative of energy security. In contrast, North America has historically focused on a once-through fuel cycle, although discussions around the future of spent fuel management and potential MOX utilization continue to evolve, reflecting shifting policy landscapes and public discourse on nuclear waste. These regional variances are critical for understanding market demand and supply dynamics.

Segmentation trends within the MOX fuel market highlight the dominance of light water reactors (LWRs) as the primary application platform, given their widespread global deployment. However, increasing research and development in Fast Breeder Reactors (FBRs) signifies a potential future growth segment, offering even greater resource utilization. Fabrication processes, predominantly dry routes, are continually being optimized for efficiency and safety. The market also sees differentiation in its end-use applications, spanning from base-load electricity generation to crucial plutonium management programs, each requiring tailored approaches and regulatory compliance, further defining the market's complex structure and growth trajectory.

AI Impact Analysis on Mixed Oxide Fuel Market

Common user questions regarding AI's impact on the Mixed Oxide Fuel Market frequently center on how artificial intelligence can enhance the safety, efficiency, and cost-effectiveness of MOX fuel production and utilization. Users are keen to understand AI's role in optimizing complex fuel cycle processes, from material handling and quality control during fabrication to reactor performance monitoring and predictive maintenance for MOX-fueled reactors. There is significant interest in AI's potential to improve decision-making in highly regulated environments, mitigate human error, and accelerate research and development of advanced MOX fuel designs. Concerns also exist around data security, the reliability of AI algorithms in critical safety applications, and the necessary regulatory frameworks to govern AI integration in such a sensitive industry. Overall, the expectation is that AI will introduce unprecedented levels of precision and automation, transforming operational paradigms while demanding robust verification and validation strategies.

- AI can significantly optimize MOX fuel fabrication processes by improving quality control through automated inspection systems, predicting material defects, and enhancing process efficiency, thereby reducing operational costs and waste generation.

- Predictive analytics driven by AI can monitor reactor core performance more accurately, enabling real-time adjustments for MOX fuel assemblies, optimizing burnup, and extending operational cycles while ensuring safety margins are maintained.

- AI-powered simulations and modeling tools can accelerate the design and testing of new MOX fuel compositions and cladding materials, leading to more robust and accident-tolerant fuels with enhanced performance characteristics.

- Enhanced security and non-proliferation measures can be achieved through AI by analyzing vast datasets from surveillance systems, tracking nuclear materials, and identifying anomalous activities in MOX production facilities or storage sites.

- AI can support regulatory compliance and safety assessments by processing complex operational data, identifying potential risks, and providing predictive insights for preventative maintenance and safety protocol adherence, streamlining licensing procedures.

DRO & Impact Forces Of Mixed Oxide Fuel Market

The Mixed Oxide Fuel Market is significantly shaped by a dynamic interplay of drivers, restraints, opportunities, and broader impact forces, each exerting considerable influence on its growth trajectory and operational landscape. Key drivers include the global imperative for sustainable energy solutions, where nuclear power offers a low-carbon alternative to fossil fuels, coupled with the strategic necessity to manage growing stockpiles of plutonium resulting from reprocessing spent nuclear fuel. Many nations view MOX as a valuable tool for plutonium disposition, transforming a waste product with proliferation concerns into a valuable energy resource, thereby contributing to national energy security and environmental sustainability goals. Furthermore, the expansion of nuclear reactor fleets in emerging economies, alongside the long-term operation of existing reactors, creates a consistent demand for reliable and efficient fuel sources, positioning MOX as a viable alternative or supplementary fuel.

Conversely, the market faces substantial restraints that temper its growth. The high capital costs associated with establishing and maintaining MOX fuel fabrication facilities and reprocessing plants are a significant barrier, often requiring extensive governmental support and long-term financial commitments. Public perception and concerns surrounding nuclear safety, waste management, and proliferation risks also impose considerable political and social hurdles, influencing regulatory stringency and project timelines. Moreover, the complex and stringent regulatory frameworks governing nuclear materials, particularly plutonium, add layers of operational complexity and compliance costs. The limited global reprocessing capacity and specialized logistical challenges for transporting plutonium further constrain the widespread adoption and expansion of MOX fuel utilization.

Opportunities for market growth primarily stem from technological advancements in MOX fuel fabrication, such as advanced dry processes that can enhance efficiency and reduce waste, and the development of new reactor designs like Small Modular Reactors (SMRs) which may offer more flexible and potentially cost-effective platforms for MOX utilization. International collaborations and agreements aimed at addressing global plutonium management and non-proliferation objectives also present avenues for market expansion. The impact forces acting on the market are broad and multifaceted, including geopolitical stability, which can affect supply chains and international cooperation; evolving public policies on nuclear energy and waste; economic competitiveness of nuclear power relative to other energy sources; and continuous technological innovation across the entire nuclear fuel cycle. These forces collectively dictate the market's direction, resilience, and potential for transformation in the coming years.

Segmentation Analysis

The Mixed Oxide Fuel Market is segmented to provide a granular understanding of its diverse components, allowing for targeted analysis of market dynamics and strategic planning. These segmentations categorize the market based on various critical attributes, including the type of reactor utilizing MOX fuel, the specific fabrication processes employed, the end-use applications, and different stages of the fuel cycle. Each segment reflects unique technological requirements, regulatory considerations, and market demand drivers. This systematic breakdown helps identify key areas of growth, technological advancements, and operational challenges within the intricate landscape of nuclear fuel management and energy production.

- By Reactor Type

- Pressurized Water Reactors (PWR): Dominant segment due to widespread global deployment.

- Boiling Water Reactors (BWR): Utilized in specific regions with established nuclear fleets.

- Fast Breeder Reactors (FBR): Emerging segment with potential for enhanced resource utilization and waste reduction.

- Other Advanced Reactors: Includes experimental reactors and next-generation designs exploring MOX applications.

- By Fabrication Process

- Dry Process: Involves blending powders of plutonium and uranium oxides, often favored for its efficiency and waste minimization.

- Wet Process: Utilizes solutions of plutonium and uranium, followed by co-precipitation, less common but used historically.

- By End-Use Application

- Electricity Generation: Primary application in commercial nuclear power plants to produce electricity.

- Plutonium Management: Strategic use for the disposition of surplus weapons-grade plutonium, converting it into reactor fuel.

- Research & Development: Applications in experimental reactors for studying fuel behavior and advanced fuel cycle concepts.

- By Fuel Cycle Stage

- Front-End: Involves the sourcing, fabrication, and preparation of MOX fuel before reactor loading.

- Back-End: Encompasses the management of spent MOX fuel, including storage, potential further reprocessing, or disposal.

Value Chain Analysis For Mixed Oxide Fuel Market

The value chain for the Mixed Oxide Fuel Market is a complex and highly specialized sequence of activities, beginning with the acquisition of raw materials and extending through fuel fabrication, reactor operation, and the ultimate management of spent fuel. Upstream analysis focuses on the sourcing of key components: uranium, typically in natural or depleted form, and plutonium, which is primarily obtained from the reprocessing of spent nuclear fuel generated by existing reactors. This reprocessing, often a government-controlled or heavily regulated activity, separates plutonium from other fission products and residual uranium. The purity and isotopic composition of both uranium and plutonium are critical, dictating the subsequent fabrication steps and the performance characteristics of the final MOX fuel. Securing these materials involves long-term contracts, geopolitical considerations, and stringent non-proliferation safeguards, underscoring the strategic nature of the upstream segment.

The midstream of the value chain involves the intricate process of MOX fuel fabrication. This stage entails the precise mixing of plutonium and uranium oxides, pelletization, sintering, and encapsulation into fuel rods, which are then assembled into fuel bundles. This highly specialized manufacturing requires advanced facilities, remote handling capabilities, robust quality assurance protocols, and strict adherence to radiological safety standards. Companies involved in this stage typically possess deep expertise in nuclear materials science and engineering. Downstream analysis primarily involves the utilization of MOX fuel in nuclear power reactors for electricity generation, followed by the management of spent MOX fuel. Spent MOX fuel, with its unique isotopic composition and higher actinide content, requires specialized handling, interim storage, and eventual disposal in geological repositories, or potentially further reprocessing in a closed fuel cycle.

The distribution channel for MOX fuel is highly controlled and direct, owing to the strategic and sensitive nature of the product. Nuclear power plant operators typically establish direct contractual relationships with MOX fuel fabricators or integrated nuclear fuel cycle companies. Logistics involve highly secure transportation protocols, often coordinated with national and international regulatory bodies to ensure safety, security, and non-proliferation compliance. Indirect influences on the value chain include research institutions driving technological advancements, regulatory bodies setting safety and environmental standards, and international organizations promoting non-proliferation. The entire value chain is characterized by significant capital intensity, long lead times, stringent security measures, and a limited number of highly specialized global players, reflecting the unique challenges and strategic importance of the Mixed Oxide Fuel Market.

Mixed Oxide Fuel Market Potential Customers

The primary potential customers and end-users of Mixed Oxide Fuel are entities operating commercial nuclear power plants, as well as national nuclear agencies and, in some specific instances, defense ministries involved in plutonium disposition programs. Nuclear power plant operators, whether state-owned utilities or private corporations, represent the largest segment of potential buyers. Their demand is driven by the operational requirements of their existing Light Water Reactors (LWRs) or, increasingly, advanced reactor designs, where MOX fuel can be implemented to optimize fuel cycle economics, manage plutonium inventories, and contribute to national energy security objectives. These operators typically enter into long-term supply agreements with specialized fuel fabricators, emphasizing reliability, safety, and compliance with stringent regulatory standards. The decision to use MOX fuel is often a strategic one, influenced by national energy policy, reprocessing capabilities, and the availability of plutonium.

National nuclear agencies and research institutions also constitute a significant customer base, albeit often for specialized applications rather than large-scale commercial use. These entities may utilize MOX fuel in experimental or research reactors to study advanced fuel cycle concepts, test new reactor technologies, or develop improved fuel designs. Their interest lies in understanding the material properties, burnup characteristics, and safety performance of MOX under various conditions, contributing to the broader knowledge base of nuclear science and engineering. Furthermore, governmental bodies responsible for nuclear waste management and non-proliferation initiatives are key stakeholders, as MOX fuel serves as a critical pathway for the disposition of surplus weapons-grade plutonium, converting it into reactor fuel and reducing its proliferation risk. These programs often involve significant government funding and international cooperation.

Ultimately, the decision to procure and utilize MOX fuel is complex, involving a delicate balance of economic viability, political considerations, regulatory approval, and public acceptance. Customers in this market are highly sophisticated, requiring deep technical expertise, robust safety cultures, and a commitment to long-term operational sustainability. The limited number of suppliers capable of fabricating MOX fuel further defines the buyer-supplier relationship, making it one of strategic partnerships and mutual reliance. The evolving global energy landscape and increasing focus on nuclear fuel cycle sustainability mean that the pool of potential customers, particularly in nations expanding their nuclear power programs, is likely to grow, albeit cautiously and under strict international oversight.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.8 billion |

| Market Forecast in 2033 | USD 2.5 billion |

| Growth Rate | 4.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Orano, Framatome, Rosatom, Toshiba, Mitsubishi Heavy Industries, Hitachi-GE Nuclear Energy, Westinghouse Electric Company, BWX Technologies, EDF, KHNP, General Electric, China National Nuclear Corporation (CNNC), Nuclear Power Corporation of India Limited (NPCIL), Cameco, Urenco, Centrus Energy, TVEL Fuel Company |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Mixed Oxide Fuel Market Key Technology Landscape

The Mixed Oxide Fuel Market is underpinned by a highly sophisticated and continuously evolving technology landscape, essential for the safe, efficient, and secure handling of plutonium and uranium. A cornerstone of this landscape is the reprocessing technology, which extracts plutonium from spent nuclear fuel, making it available for MOX fabrication. Technologies such as PUREX (Plutonium Uranium Redox EXtraction) are mature, but ongoing research focuses on advanced aqueous and pyroprocessing methods to enhance efficiency, reduce waste volumes, and improve proliferation resistance. These reprocessing advancements directly influence the quality and availability of the plutonium feedstock for MOX, dictating the economic and technical viability of the entire MOX fuel cycle. The development of more robust and compact reprocessing facilities could significantly alter the market dynamics, expanding the number of countries capable of closing their fuel cycle.

MOX fuel fabrication itself relies on specialized and highly automated processes, primarily categorized into dry and wet routes. The dry route, exemplified by the MIMAS (MIcronized MASter blend) process, involves mechanically blending fine powders of plutonium dioxide and uranium dioxide, followed by pressing into pellets and sintering. This method is favored for its flexibility, lower liquid waste generation, and ability to handle various plutonium isotopic compositions. Advanced fabrication techniques are continuously being explored, including vibro-packing of fuel particles and inert matrix fuels, aiming to improve fuel performance, increase plutonium loading, and enhance resistance to reactor transients. These innovations are critical for reducing fabrication costs, improving fuel integrity under irradiation, and expanding the applicability of MOX to a wider range of reactor types and operational scenarios.

Beyond fabrication, the technological landscape includes advanced materials science for cladding and fuel matrix development, aimed at improving accident tolerance and extending fuel burnup. Simulation and modeling tools, powered by high-performance computing, are indispensable for designing new MOX fuel assemblies, predicting their in-reactor behavior, and performing detailed safety analyses. Remote handling and automation technologies are paramount in MOX facilities due to the radiological hazards of plutonium, ensuring worker safety and operational efficiency. Furthermore, advanced instrumentation for real-time monitoring, material accounting, and non-destructive assay techniques are vital for stringent international safeguards and security protocols. The continuous integration of these diverse technologies, often supported by international collaborative research, is crucial for the sustainable growth and enhanced safety of the Mixed Oxide Fuel Market, ensuring that it remains at the forefront of nuclear fuel cycle innovation.

Regional Highlights

- Europe: Europe, particularly France and Belgium, has been a pioneer and a significant user of MOX fuel for decades, driven by established reprocessing capabilities and a closed-fuel cycle policy. France operates several nuclear power plants routinely using MOX fuel and has a robust infrastructure for reprocessing and fabrication, making it a leading market in terms of operational experience and installed capacity. The region's commitment to reducing nuclear waste and maximizing resource utilization underpins its continued, albeit steady, engagement with MOX technology.

- Asia Pacific (APAC): The APAC region is poised for substantial growth in the MOX fuel market, primarily led by Japan, India, and China. Japan, despite recent challenges, maintains a strong long-term strategy for a closed fuel cycle, with plans for MOX utilization in its fleet. India is actively pursuing advanced heavy water reactors and Fast Breeder Reactors, with a clear strategy for plutonium utilization. China, with its ambitious nuclear power expansion program, is developing its own reprocessing and MOX fabrication capabilities, signaling significant future demand and a strategic shift towards fuel cycle independence.

- North America: Historically, the United States has largely followed a once-through fuel cycle, with limited commercial MOX fuel utilization. However, discussions around the future of spent fuel management and the potential for plutonium disposition continue. While large-scale commercial MOX deployment has faced setbacks, research and development efforts, especially concerning advanced reactor concepts and non-proliferation objectives, maintain a level of interest in the underlying technologies. Canada also operates a once-through fuel cycle, with no current plans for MOX, but contributes to global nuclear R&D.

- Middle East and Africa (MEA): This region is characterized by emerging nuclear power programs, particularly in countries like the UAE and Saudi Arabia, which are in the early stages of establishing their nuclear infrastructure. While current focus is on conventional uranium fuel, the long-term potential for MOX fuel utilization depends on the development of reprocessing capabilities and strategic decisions regarding spent fuel management. South Africa also has a nascent nuclear program that could explore MOX in the distant future.

- Latin America: Countries like Argentina and Brazil have active nuclear power programs, with Argentina having a closed fuel cycle approach in some aspects. However, MOX fuel utilization is not currently a widespread practice in the region. Future adoption would depend on factors such as the growth of nuclear energy, the establishment of reprocessing facilities, and international cooperation frameworks.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Mixed Oxide Fuel Market.- Orano

- Framatome

- Rosatom

- Toshiba

- Mitsubishi Heavy Industries

- Hitachi-GE Nuclear Energy

- Westinghouse Electric Company

- BWX Technologies

- EDF

- KHNP (Korea Hydro & Nuclear Power)

- General Electric

- China National Nuclear Corporation (CNNC)

- Nuclear Power Corporation of India Limited (NPCIL)

- Cameco

- Urenco

- Centrus Energy

- TVEL Fuel Company (Rosatom subsidiary)

- Japan Atomic Energy Agency (JAEA)

- Belgonucleaire (historically significant, now part of ENGIE)

- AREVA (now Orano and Framatome entities)

Frequently Asked Questions

Analyze common user questions about the Mixed Oxide Fuel market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is Mixed Oxide (MOX) fuel?

Mixed Oxide (MOX) fuel is a type of nuclear fuel used in nuclear reactors that contains plutonium, mixed with natural or depleted uranium, rather than solely enriched uranium. It is fabricated from plutonium recovered during the reprocessing of spent nuclear fuel, along with uranium. This innovative fuel allows for the recycling of plutonium, a byproduct of nuclear power generation and potentially excess weapons material, into new fuel, thereby extracting additional energy and reducing the volume of high-level nuclear waste.

The composition of MOX fuel, typically around 5-10% plutonium dioxide (PuO2) mixed with uranium dioxide (UO2), makes it a valuable alternative to traditional low-enriched uranium (LEU) fuel. It helps to close the nuclear fuel cycle partially, optimizing resource utilization and contributing to a more sustainable management of nuclear materials. Its use is a strategic decision for many countries aiming to enhance energy security and manage their plutonium inventories effectively.

Why is MOX fuel used in nuclear power plants?

MOX fuel is used in nuclear power plants for several compelling reasons, primarily centered on resource efficiency, waste reduction, and strategic plutonium management. Firstly, it enables the recycling of plutonium that would otherwise be considered a waste product from reprocessing spent uranium fuel. This recycling reduces the amount of high-level radioactive waste requiring long-term disposal and extracts more energy from the original uranium resource.

Secondly, MOX fuel serves as a critical tool for the disposition of surplus weapons-grade plutonium, converting it into reactor fuel and thus reducing global proliferation risks by rendering it less accessible for weapons programs. Thirdly, its utilization contributes to national energy security by diversifying fuel sources and reducing reliance on freshly mined uranium. By using plutonium already available within the fuel cycle, countries can enhance their self-sufficiency in nuclear fuel supply. Lastly, for countries with established reprocessing capabilities, MOX fuel forms an integral part of their closed nuclear fuel cycle policy, aiming for maximum energy extraction and minimum waste generation.

What are the main challenges associated with MOX fuel?

The Mixed Oxide Fuel Market faces several significant challenges that impede its broader adoption and economic competitiveness. A primary challenge is the exceptionally high capital cost required to establish and operate MOX fuel fabrication plants and associated reprocessing facilities. These facilities demand specialized infrastructure, stringent security, and advanced radiological protection, leading to substantial investment requirements.

Another major hurdle is public perception and acceptance. Concerns surrounding nuclear safety, the transportation of plutonium, and the long-term management of MOX spent fuel often lead to strong public opposition and complicate regulatory approvals. Furthermore, MOX fuel carries increased proliferation concerns due to its plutonium content, necessitating robust international safeguards and security measures, which add complexity and cost to its lifecycle. Finally, the technical complexity of fabricating MOX fuel, dealing with the diverse isotopic compositions of plutonium, and its slightly different neutronic characteristics compared to uranium fuel, require advanced expertise and contribute to higher operational costs, making it less economically competitive than conventional uranium fuel in many markets.

Which countries are currently using or planning to use MOX fuel?

Several countries globally have either actively utilized or are significantly planning for the use of Mixed Oxide (MOX) fuel in their nuclear power programs. Historically, France has been a leading proponent and user of MOX fuel, operating multiple Pressurized Water Reactors (PWRs) with MOX assemblies, underpinned by its well-established reprocessing facility at La Hague and MOX fabrication plant at Melox. Belgium has also used MOX fuel in its reactors, leveraging its partnership with French facilities.

Japan has a long-standing policy for a closed nuclear fuel cycle, including MOX fuel utilization, though its programs have faced delays and political challenges. Nevertheless, several of its nuclear power plants are designed for MOX use, and there are long-term plans to proceed with its implementation. India is actively pursuing an advanced nuclear fuel cycle, including the use of MOX fuel, particularly in its Fast Breeder Reactor program, as part of its strategy to maximize energy independence. China, with its rapidly expanding nuclear fleet, is also investing heavily in developing its own reprocessing and MOX fabrication capabilities, positioning itself as a major future user to manage its growing plutonium inventories and enhance energy security. Russia, through Rosatom, is another key player with active MOX fabrication and utilization in its fast neutron reactors (BN-600 and BN-800), demonstrating a fully closed fuel cycle capability.

How does MOX fuel impact nuclear waste management?

MOX fuel significantly impacts nuclear waste management by altering the volume, composition, and radiotoxicity of the waste stream. By using plutonium derived from reprocessed spent nuclear fuel, MOX technology effectively recycles a highly radioactive and long-lived component that would otherwise contribute to the bulk of high-level waste from a once-through fuel cycle. This recycling reduces the overall volume of long-lived actinides requiring geological disposal, thereby extending the capacity of future repositories and potentially reducing their overall footprint.

However, while MOX use reduces the plutonium content in the final waste, MOX spent fuel itself has a different isotopic composition and typically contains a higher concentration of minor actinides compared to spent uranium fuel. These minor actinides contribute to the long-term radiotoxicity and heat generation of the waste, presenting unique challenges for disposal. Therefore, MOX impacts waste management not by eliminating the need for disposal, but by transforming the nature of the waste, which requires specific considerations in repository design and safety assessments. The ultimate goal is to optimize the entire fuel cycle to minimize the long-term environmental burden of nuclear energy.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager