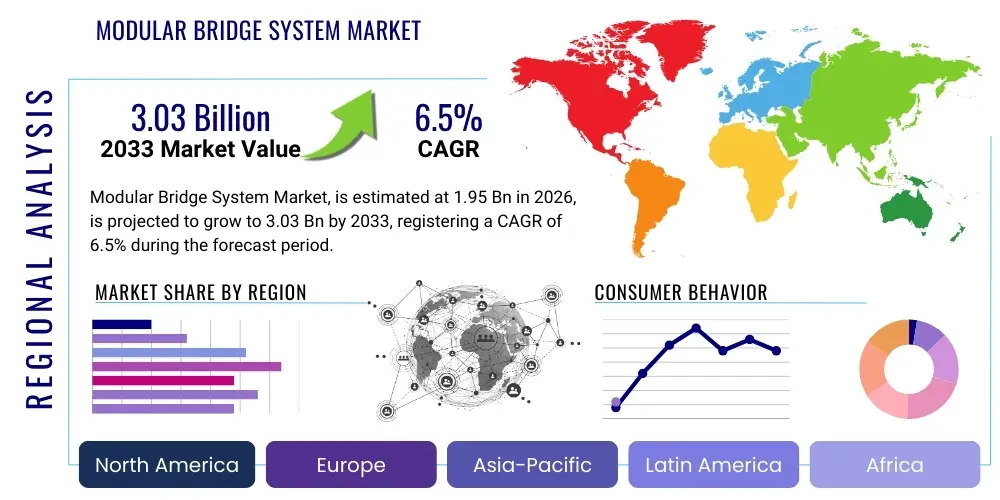

Modular Bridge System Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439542 | Date : Jan, 2026 | Pages : 242 | Region : Global | Publisher : MRU

Modular Bridge System Market Size

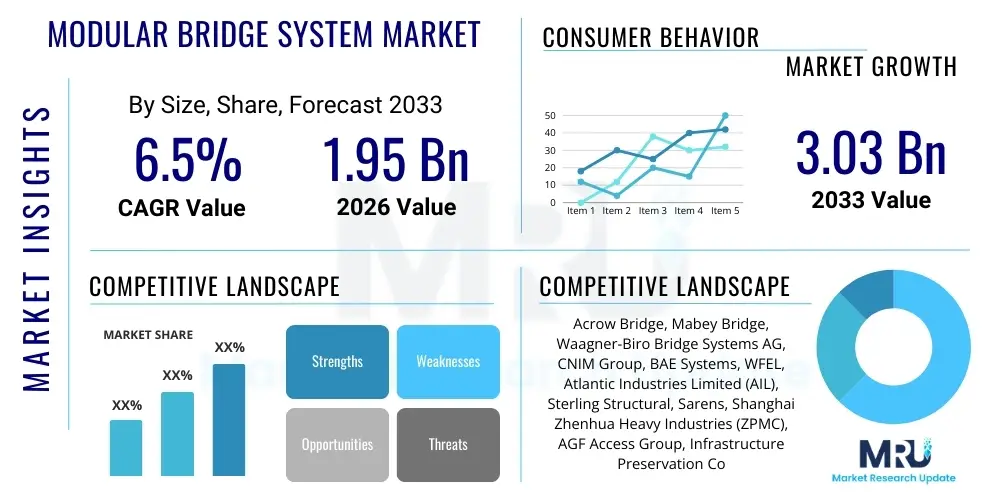

The Modular Bridge System Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 1.95 Billion in 2026 and is projected to reach USD 3.03 Billion by the end of the forecast period in 2033.

Modular Bridge System Market introduction

The Modular Bridge System Market encompasses the design, manufacturing, and deployment of prefabricated bridge components that can be rapidly assembled to form complete bridge structures. These systems are characterized by their standardization, interchangeability of parts, and ease of transport and erection, making them highly versatile for a wide range of applications. Modular bridges are typically constructed from materials such as steel, aluminum, or composite materials, offering robust solutions for temporary or permanent infrastructure needs. Their inherent flexibility allows for various configurations, including panel bridges, beam bridges, and truss bridges, catering to diverse span lengths and load requirements.

Major applications for modular bridge systems span critical sectors including military logistics, disaster relief efforts, emergency access, and civil infrastructure development. They are invaluable for creating temporary detours during conventional bridge construction or repair, providing rapid crossings over challenging terrains, or establishing essential links after natural calamities like floods or earthquakes. The systems are also extensively used in resource industries such as mining and oil and gas for temporary access roads and heavy equipment crossings, as well as in urban development for pedestrian bridges and utility crossings where speed and minimal disruption are paramount.

The primary benefits driving the adoption of modular bridge systems include accelerated project timelines due to off-site fabrication and quick on-site assembly, significant cost efficiencies derived from reduced labor and equipment requirements, and enhanced safety by minimizing on-site work at height. Furthermore, their reusability and adaptability to various sites and scenarios contribute to a sustainable and economical solution. Key driving factors for market growth include increasing global infrastructure spending, a heightened focus on disaster preparedness and rapid response capabilities, the expansion of military logistical operations, and the continuous demand for efficient, adaptable, and temporary access solutions in burgeoning urban and industrial landscapes worldwide.

Modular Bridge System Market Executive Summary

The Modular Bridge System Market is witnessing robust expansion, propelled by significant global business trends towards accelerated construction, enhanced logistical efficiency, and resilience in infrastructure development. Manufacturers are increasingly focusing on innovations in materials, design methodologies, and fabrication techniques to offer lighter, stronger, and more rapidly deployable systems. A notable business trend is the growing integration of digital technologies, such as Building Information Modeling (BIM) and advanced simulation software, into the design and planning phases, leading to optimized modular solutions and streamlined project execution. Furthermore, there is an increasing demand for sustainable and reusable bridge components, influencing supply chain practices and material selection within the industry.

Regionally, the market exhibits dynamic growth patterns. North America and Europe continue to be significant markets, driven by ongoing infrastructure maintenance, replacement projects, and military expenditure. However, the Asia Pacific region is emerging as a primary growth engine, fueled by rapid urbanization, extensive infrastructure development initiatives in countries like China and India, and increasing investments in disaster response infrastructure. Latin America, the Middle East, and Africa are also poised for substantial growth, largely due to investments in mining, oil and gas, and transport infrastructure, coupled with a rising need for robust and quickly deployable solutions in areas prone to natural disasters or undergoing significant development.

Segmentation trends within the market highlight increasing demand for specific bridge types and materials. Steel remains a dominant material choice due to its strength and durability, but there is a growing interest in lightweight materials such as aluminum and advanced composites, particularly for applications requiring rapid deployment and reduced transportation costs. The market for emergency and disaster relief applications is expanding significantly, reflecting global climate change impacts and geopolitical instability. Simultaneously, the road and highway segment continues to dominate in terms of market share, driven by a persistent need for efficient traffic management solutions during construction and repair phases, alongside the expansion of new transportation networks. The military and defense sector also represents a stable and high-value segment, with ongoing investments in tactical bridging solutions.

AI Impact Analysis on Modular Bridge System Market

Artificial Intelligence (AI) is poised to revolutionize the Modular Bridge System Market by enhancing various stages from design and manufacturing to deployment and maintenance. Users frequently inquire about how AI can optimize structural integrity, streamline project timelines, and predict maintenance needs for these critical infrastructure components. Common questions revolve around AI's ability to automate design processes, improve material utilization, reduce overall project costs, and increase the safety of both construction and operational phases. The overarching theme is the expectation that AI will introduce unprecedented levels of efficiency, precision, and intelligence into the lifecycle of modular bridge systems, addressing traditional challenges such as complex load calculations, resource allocation, and timely fault detection.

- AI-driven generative design can rapidly produce optimized bridge geometries and material layouts, considering various environmental and load conditions, significantly reducing design time and material waste.

- Predictive analytics powered by AI can analyze real-time sensor data from deployed modular bridges to forecast maintenance requirements, identify potential structural weaknesses before failure, and extend the operational lifespan.

- AI algorithms can optimize logistics and supply chain management for modular bridge components, ensuring timely delivery, minimizing transportation costs, and reducing on-site inventory.

- Automated quality control systems leveraging computer vision and machine learning can inspect fabricated bridge modules for defects with high accuracy, ensuring adherence to stringent quality standards during manufacturing.

- AI-enhanced project management tools can provide real-time insights into construction progress, resource allocation, and potential bottlenecks, improving decision-making and project efficiency for modular bridge installations.

- Robotics and AI can facilitate automated assembly processes for modular components, particularly in controlled factory environments, enhancing precision and reducing reliance on manual labor for repetitive tasks.

DRO & Impact Forces Of Modular Bridge System Market

The Modular Bridge System Market is primarily driven by escalating global infrastructure development, rapid urbanization, and an increased frequency of natural disasters, necessitating quick-response, deployable crossing solutions. Government investments in transport infrastructure, coupled with the expansion of military and defense capabilities requiring tactical bridging, significantly fuel market demand. Furthermore, the inherent benefits of modular systems, such as their rapid deployment, cost-effectiveness, and reusability, make them an attractive option for both temporary and permanent applications, especially in remote or challenging terrains where traditional construction methods are impractical or time-consuming. The burgeoning demand for temporary access solutions in the construction, mining, and oil and gas industries also acts as a powerful driver for market expansion.

Despite these drivers, the market faces several restraints. High initial capital investment required for specialized manufacturing facilities and robust inventory of modular components can deter new entrants and limit smaller players. Logistical challenges associated with transporting large or heavy modular sections to remote project sites, coupled with the need for specialized heavy lifting equipment, can add to project complexity and cost. Additionally, a lack of standardized design codes and regulations across different regions can sometimes hinder market penetration and necessitate custom engineering, thus increasing lead times and expenses. The availability of skilled labor for assembly and specialized equipment operation also presents a persistent challenge in some geographies.

Opportunities for growth are abundant, particularly in emerging economies where extensive infrastructure gaps and rapid development initiatives create substantial demand. The adoption of smart city concepts and the integration of IoT sensors for real-time bridge monitoring present avenues for value-added services and technological differentiation. Furthermore, the development and integration of advanced, lightweight, and sustainable materials, such as high-strength composites, offer opportunities to enhance performance, reduce transportation costs, and improve environmental footprints. The increasing focus on resilience planning and disaster preparedness globally also opens up significant avenues for modular bridge solutions in pre-positioned emergency stocks and rapid response frameworks. Impact forces shaping the market include technological advancements, particularly in material science and digital construction, which continually improve product performance and deployment efficiency. Government policies and regulatory frameworks concerning infrastructure spending, environmental protection, and disaster management exert significant influence. Economic cycles, including global recessions or booms, directly affect construction and infrastructure investment, impacting market demand. Lastly, environmental concerns drive innovation towards more sustainable and less disruptive construction practices, further favoring modular solutions.

Segmentation Analysis

The Modular Bridge System Market is comprehensively segmented to provide a detailed understanding of its diverse components and their respective market dynamics. This segmentation facilitates targeted strategic planning and allows stakeholders to identify key growth areas and customer needs. The market is primarily segmented by type, material, application, and end-user, reflecting the varied requirements across different industries and geographical regions. Each segment represents distinct technological considerations, operational demands, and economic factors, contributing uniquely to the overall market landscape. Analyzing these segments helps in understanding the competitive dynamics and consumer preferences within the specialized field of rapid bridge construction.

- By Type

- Panel Bridges

- Beam Bridges

- Truss Bridges

- Arch Bridges

- Suspension Bridges

- Cable-Stayed Bridges

- Floating Bridges

- By Material

- Steel

- Aluminum

- Composites

- Hybrid Materials

- By Application

- Road & Highway Construction

- Railway Infrastructure

- Military & Defense

- Emergency & Disaster Relief

- Construction & Industrial Access

- Mining & Oil & Gas Operations

- Pedestrian & Utility Crossings

- By End-User

- Government & Public Agencies

- Construction Companies

- Mining & Energy Sector

- Military & Defense Organizations

- Humanitarian & Aid Organizations

- Private Developers

Value Chain Analysis For Modular Bridge System Market

The value chain for the Modular Bridge System Market begins with upstream activities centered on raw material procurement and component manufacturing. This initial stage involves the sourcing of high-grade steel, aluminum, and advanced composite materials from suppliers, followed by the fabrication of standardized modules and components such as girders, deck panels, and connection systems. Key upstream players include specialized metal producers, composite material manufacturers, and engineering firms focusing on precision component manufacturing. Quality control and material science research are critical at this stage to ensure the durability, strength, and lightweight properties of the modular bridge elements.

Midstream activities primarily encompass the design, engineering, and assembly of these modular components into complete bridge systems. This involves specialized bridge engineering companies and manufacturers who configure and test the modules according to specific project requirements. Logistics and transportation play a pivotal role in moving these large and often heavy components from manufacturing facilities to construction sites, requiring specialized heavy-haul equipment and careful planning. The direct distribution channel typically involves direct sales from manufacturers to large government bodies, military organizations, or major construction firms for substantial projects, offering a bespoke service package including design, delivery, and often, on-site technical support.

Downstream activities involve the installation, deployment, and ongoing maintenance of modular bridge systems, often performed by general contractors, specialized bridge construction companies, or military engineering units. This phase also includes rental services for temporary bridges, where companies lease modular systems for specific project durations, providing a flexible solution for short-term access needs. The indirect distribution channel primarily involves a network of regional distributors, agents, and rental equipment providers who facilitate access to modular bridge systems for smaller projects or provide localized support. These intermediaries often handle sales, rental, and basic maintenance services, extending market reach and providing comprehensive solutions to a broader customer base, including private developers and industrial clients.

Modular Bridge System Market Potential Customers

The Modular Bridge System Market caters to a diverse range of end-users and buyers, each with specific requirements driven by their operational mandates and infrastructure needs. Government agencies, particularly those responsible for national and local infrastructure development, highway maintenance, and public works, represent a significant customer base. These entities frequently procure modular bridges for rapid repair of existing infrastructure, emergency bypasses during natural disasters, or as cost-effective solutions for new construction projects in challenging environments. Their purchasing decisions are often influenced by public safety, long-term durability, and adherence to regulatory standards, alongside budget constraints.

Another crucial segment comprises construction companies and general contractors, who utilize modular bridge systems to facilitate access to project sites, establish temporary crossings over rivers or difficult terrain, or create detours to minimize disruption during conventional bridge construction. These customers prioritize ease of assembly, speed of deployment, and the ability to quickly reconfigure or relocate systems for multiple projects, enhancing their operational efficiency and project timelines. The mining and oil & gas industries are also substantial buyers, requiring heavy-duty modular bridges for transporting equipment and materials across vast, often remote, and rugged landscapes, where permanent infrastructure might be economically unfeasible or environmentally sensitive.

The military and defense sector constitutes a critical segment, demanding robust, rapidly deployable, and tactical bridging solutions for logistical support in operational theaters, disaster relief missions, and training exercises. Their needs emphasize portability, high load-bearing capacity, and resilience under extreme conditions. Furthermore, humanitarian organizations and emergency services are increasingly recognizing the value of modular bridges for establishing vital lifelines and access routes in post-disaster scenarios, where speed and reliability are paramount. Private developers and industrial clients, needing temporary or semi-permanent access solutions for their facilities or development projects, also form a growing segment, valuing the flexibility and cost-effectiveness offered by modular systems over traditional construction.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.95 Billion |

| Market Forecast in 2033 | USD 3.03 Billion |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Acrow Bridge, Mabey Bridge, Waagner-Biro Bridge Systems AG, CNIM Group, BAE Systems, WFEL, Atlantic Industries Limited (AIL), Sterling Structural, Sarens, Shanghai Zhenhua Heavy Industries (ZPMC), AGF Access Group, Infrastructure Preservation Corporation, Parsons Corporation, Atkins, AECOM, HDR, Skanska, VINCI, Bechtel, Fluor Corporation |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Modular Bridge System Market Key Technology Landscape

The Modular Bridge System Market is continuously evolving with the integration of cutting-edge technologies aimed at enhancing efficiency, durability, and deployment speed. One of the most significant technological advancements is the development and utilization of high-performance materials, including advanced high-strength steels, lightweight aluminum alloys, and fiber-reinforced polymer (FRP) composites. These materials offer superior strength-to-weight ratios, corrosion resistance, and extended lifespans, contributing to more robust yet easier-to-transport bridge modules. The adoption of hybrid material systems further optimizes performance by leveraging the specific advantages of different materials for various bridge components, balancing strength, weight, and cost considerations.

Digitalization plays a pivotal role in the modern modular bridge system landscape, with Building Information Modeling (BIM) and advanced computational design software being extensively used for precise planning, virtual prototyping, and clash detection. These digital tools facilitate seamless collaboration among designers, manufacturers, and installers, significantly reducing errors and rework. Furthermore, the integration of 3D printing for complex connection components and customized parts is gaining traction, allowing for greater design freedom and rapid fabrication of intricate geometries that would be challenging with traditional manufacturing methods. Automated and robotic fabrication techniques in controlled factory environments ensure high precision and consistent quality in module production.

Emerging technologies like the Internet of Things (IoT) and sensor-based monitoring systems are transforming the operational phase of modular bridges. These systems embed sensors within bridge structures to collect real-time data on load distribution, structural integrity, environmental conditions, and material fatigue. This data, analyzed through AI and machine learning algorithms, enables predictive maintenance, early detection of potential issues, and optimized operational management, extending the service life of bridges and ensuring safety. Additionally, augmented reality (AR) and virtual reality (VR) technologies are being explored for training personnel, visualizing complex assembly sequences, and providing remote technical assistance during the deployment of modular bridges, further enhancing efficiency and safety on site.

Regional Highlights

- North America: A mature market driven by significant investments in infrastructure upgrades, replacement of aging bridges, and robust military spending. The region benefits from established manufacturers and a strong emphasis on rapid deployment for emergency response.

- Europe: Characterized by stringent safety standards and a focus on sustainable infrastructure. Demand is fueled by extensive road and rail networks requiring continuous maintenance and expansion, alongside growing needs for disaster relief and temporary access solutions.

- Asia Pacific (APAC): The fastest-growing region, propelled by rapid urbanization, massive infrastructure development projects in countries like China and India, and increasing awareness and investment in disaster preparedness for frequently impacted areas.

- Latin America: An emerging market with significant potential due to ongoing development of mining, oil & gas, and transportation infrastructure. Investment in disaster resilience and temporary access in remote areas is also a key driver.

- Middle East and Africa (MEA): Growth is primarily driven by large-scale infrastructure projects, expansion of the oil and gas sector, and military investments. The region presents opportunities for both temporary and permanent modular solutions in developing economies.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Modular Bridge System Market.- Acrow Bridge

- Mabey Bridge

- Waagner-Biro Bridge Systems AG

- CNIM Group

- BAE Systems

- WFEL

- Atlantic Industries Limited (AIL)

- Sterling Structural

- Sarens

- Shanghai Zhenhua Heavy Industries (ZPMC)

- AGF Access Group

- Infrastructure Preservation Corporation

- Parsons Corporation

- Atkins (SNC-Lavalin)

- AECOM

- HDR

- Skanska

- VINCI

- Bechtel

- Fluor Corporation

Frequently Asked Questions

Analyze common user questions about the Modular Bridge System market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary benefits of using modular bridge systems over traditional construction?

Modular bridge systems offer rapid deployment, significant cost savings through reduced labor and equipment, enhanced safety due to off-site fabrication, and flexibility for temporary or permanent applications, making them highly efficient and adaptable.

What materials are commonly used in the construction of modular bridges?

Modular bridges are predominantly constructed from high-strength steel, lightweight aluminum alloys, and advanced composite materials, often utilizing hybrid designs to optimize strength, weight, and corrosion resistance for specific project requirements.

In which applications are modular bridge systems most effectively utilized?

Modular bridge systems are most effectively utilized in emergency and disaster relief, military operations, temporary access for construction and industrial sites, road and highway bypasses, and in remote or challenging terrains where rapid installation is crucial.

How does AI impact the modular bridge system market?

AI impacts the market by enabling generative design for optimized structures, predictive maintenance through sensor data analysis, enhanced logistics, automated quality control, and improved project management, leading to greater efficiency and safety.

What are the key factors driving the growth of the Modular Bridge System Market?

Key growth drivers include increasing global infrastructure spending, the rising frequency of natural disasters necessitating rapid response, continuous military and defense investments, and the global trend towards urbanization demanding efficient temporary and permanent access solutions.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager