Mold Oscillation Monitoring Systems Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440457 | Date : Jan, 2026 | Pages : 243 | Region : Global | Publisher : MRU

Mold Oscillation Monitoring Systems Market Size

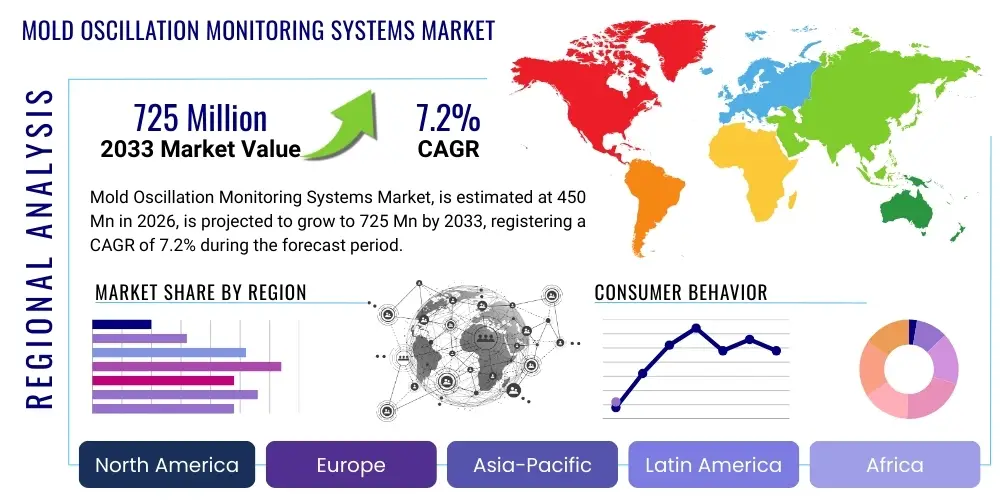

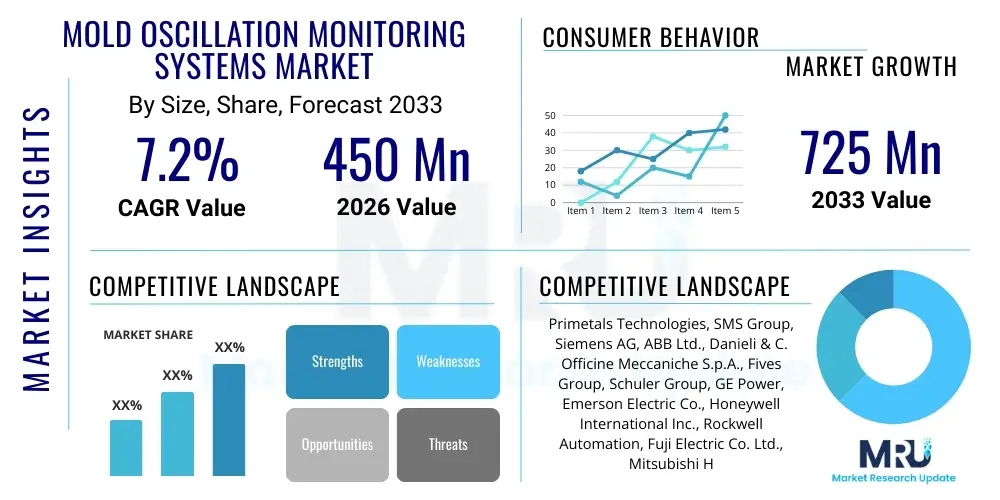

The Mold Oscillation Monitoring Systems Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.2% between 2026 and 2033. The market is estimated at USD 450 Million in 2026 and is projected to reach USD 725 Million by the end of the forecast period in 2033.

Mold Oscillation Monitoring Systems Market introduction

The Mold Oscillation Monitoring Systems Market is a critical segment within the broader industrial automation and process control landscape, specifically tailored for the continuous casting process in steel manufacturing. These systems are engineered to precisely measure and control the oscillation parameters of the mold, which is a fundamental aspect of producing high-quality steel slabs, blooms, and billets. The continuous casting process relies heavily on controlled mold oscillation to prevent molten steel from sticking to the mold walls, ensuring a smooth solidification process, minimizing defects, and optimizing casting speed. The adoption of these sophisticated monitoring systems directly contributes to enhanced product quality, increased operational efficiency, and reduced maintenance costs for steel producers globally. The technological advancements in sensor technology, data analytics, and real-time control systems are propelling the market forward, transforming traditional steel production into a more precise and data-driven operation.

Product description for Mold Oscillation Monitoring Systems typically encompasses a suite of sensors, data acquisition units, and analytical software. These components work in synergy to provide real-time feedback on parameters such as oscillation frequency, amplitude, waveform, and displacement. High-precision sensors, including LVDTs (Linear Variable Differential Transformers), accelerometers, and optical sensors, are strategically placed to capture minute variations in mold movement. The collected data is then processed and analyzed by specialized software that can detect anomalies, predict potential issues, and provide actionable insights to operators. The primary goal is to maintain optimal lubrication conditions between the solidifying shell and the mold, which is crucial for achieving superior surface quality and internal soundness of the cast products. These systems are often integrated with the plant's distributed control system (DCS) or supervisory control and data acquisition (SCADA) systems for centralized monitoring and control, fostering a holistic approach to continuous casting management.

Major applications for Mold Oscillation Monitoring Systems are predominantly found in integrated steel mills and mini-mills involved in continuous casting. Whether producing automotive-grade sheet steel, construction rebars, or specialized alloys, the consistent quality of the cast product starts with a meticulously controlled solidification process in the mold. The benefits derived from implementing these systems are substantial, including significant reductions in surface defects like cracks and breakouts, improved internal quality of the steel, increased casting speed without compromising quality, extended mold life, and a decrease in unexpected downtime dueates to mold-related failures. Driving factors for market growth include the escalating global demand for high-quality steel, the increasing adoption of Industry 4.0 principles in manufacturing, stringent quality standards from end-user industries, and the continuous push towards operational efficiency and cost reduction in a highly competitive steel market. These factors collectively underscore the indispensable role of advanced mold oscillation monitoring in modern steel production.

Mold Oscillation Monitoring Systems Market Executive Summary

The Mold Oscillation Monitoring Systems Market is undergoing a significant transformation, driven by a confluence of business trends that prioritize precision, efficiency, and data-driven decision-making in steel manufacturing. Key business trends include the increasing investment in automation and digital transformation within the steel industry, where continuous casting remains a bottleneck for quality and productivity. Steel producers are recognizing the long-term cost savings and competitive advantages gained by integrating advanced monitoring technologies. This includes a shift towards predictive maintenance strategies, enabled by real-time data from oscillation monitoring systems, which minimizes unplanned downtime and optimizes resource allocation. Furthermore, there is a growing emphasis on sustainability and reducing material waste, with these systems playing a crucial role in improving yield and reducing scrap rates by ensuring consistent product quality from the outset of the casting process. The market also sees a trend towards bundled solutions, where system providers offer comprehensive packages including hardware, software, installation, and ongoing support, simplifying adoption for end-users.

Regional trends significantly influence the market's trajectory, with Asia Pacific (APAC) emerging as the dominant region due to its robust steel production capacity and ongoing industrial expansion. Countries like China, India, and South Korea are at the forefront of adopting advanced steelmaking technologies to meet rapidly growing domestic and export demands. Europe and North America, while having mature steel industries, are focused on modernization and retrofitting existing plants with state-of-the-art monitoring systems to enhance competitiveness, meet stringent quality standards, and improve environmental performance. The emphasis in these regions is often on integrating these systems into broader smart factory initiatives and leveraging data analytics for advanced process control. Emerging economies in Latin America, the Middle East, and Africa are also showing increasing interest, driven by new investments in infrastructure and industrialization, leading to a gradual but steady adoption of mold oscillation monitoring solutions as steel production capabilities expand and mature.

Segment trends highlight several key areas of growth and innovation. The sensor component segment, particularly high-precision LVDTs and accelerometers, continues to evolve with improvements in accuracy, durability, and resistance to harsh industrial environments. The software and analytics segment is experiencing rapid expansion, with solutions incorporating advanced algorithms for pattern recognition, anomaly detection, and predictive modeling. The integration of artificial intelligence and machine learning is a defining trend here, enabling systems to learn from historical data and make increasingly intelligent recommendations or autonomous adjustments. From an application perspective, slab casting, which requires extremely high surface quality for products like automotive sheets, represents a significant growth area for advanced monitoring systems. Furthermore, there the trend of customization, where solutions are tailored to specific caster designs and steel grades, reflects the market's maturity and the diverse needs of steel producers. The drive towards modular, scalable systems that can be easily integrated into existing infrastructure is also a notable trend.

AI Impact Analysis on Mold Oscillation Monitoring Systems Market

The integration of Artificial Intelligence (AI) and Machine Learning (ML) is fundamentally transforming the Mold Oscillation Monitoring Systems Market, moving beyond mere data collection to intelligent data interpretation and predictive capabilities. Common user questions revolve around how AI can enhance the accuracy of defect prediction, whether it can enable autonomous mold parameter adjustments, and what kind of return on investment can be expected from such advanced implementations. Users are keen to understand AI's role in improving overall process stability, reducing human intervention, and providing deeper insights into complex casting phenomena that are often difficult to discern through conventional monitoring. There's also curiosity about the potential for AI to optimize resource consumption, such as reducing the amount of mold powder used, and its ability to learn from various steel grades and casting conditions to refine operational strategies over time. The key themes revolve around enhanced predictive maintenance, superior quality control, and the shift towards more autonomous and self-optimizing casting processes.

AI's influence extends to enabling a more proactive rather than reactive approach to mold oscillation management. By analyzing vast datasets of oscillation parameters, steel properties, casting speeds, and historical defect records, AI algorithms can identify subtle correlations and patterns that indicate impending issues long before they manifest as critical defects or breakouts. This predictive capability allows operators to implement corrective actions in real-time, preventing costly production interruptions and material waste. Moreover, AI-driven systems can dynamically adjust oscillation parameters based on real-time process conditions, metallurgical data, and desired product quality, moving towards truly adaptive casting. This level of intelligent control far surpasses the capabilities of rule-based or statistical process control systems, offering a new paradigm for achieving unparalleled consistency and quality in continuous casting operations. The capacity of AI to continuously learn and improve its models with new data ensures that the monitoring system becomes increasingly robust and accurate over its operational lifespan.

Beyond technical improvements, AI is also driving significant economic benefits for steel producers. The reduction in scrap rates, minimization of costly breakouts, and optimization of mold maintenance schedules translate directly into substantial operational savings and improved profitability. AI-powered diagnostic tools simplify troubleshooting for maintenance teams, accelerating issue resolution and minimizing downtime. Furthermore, the ability of AI to optimize casting speed while maintaining or improving quality means higher throughput and increased production capacity. As the steel industry faces pressures from global competition and environmental regulations, the efficiency gains delivered by AI-enhanced mold oscillation monitoring systems become crucial for maintaining a competitive edge. This shift represents a broader trend within industrial manufacturing towards smart factories, where AI serves as the brain, orchestrating complex processes with unprecedented precision and foresight.

- Enhanced predictive maintenance: AI analyzes oscillation data to forecast potential mold issues, preventing unplanned downtime and reducing maintenance costs.

- Real-time adaptive control: AI algorithms dynamically adjust mold oscillation parameters to optimize casting conditions for various steel grades and production speeds.

- Superior defect detection and prevention: Machine learning models identify subtle patterns indicative of surface and internal defects, improving product quality.

- Optimized resource utilization: AI can fine-tune mold powder consumption and energy usage, leading to operational cost savings and environmental benefits.

- Data-driven decision making: Provides deeper insights into complex casting phenomena, empowering operators with actionable intelligence.

- Autonomous process optimization: Moves towards self-optimizing casting processes by learning from operational data and continuously refining control strategies.

- Reduced human intervention: Automates routine adjustments and anomaly detection, allowing human operators to focus on more complex tasks.

DRO & Impact Forces Of Mold Oscillation Monitoring Systems Market

The Mold Oscillation Monitoring Systems Market is shaped by a complex interplay of drivers, restraints, opportunities, and various impact forces that influence its growth trajectory and competitive landscape. A primary driver for market expansion is the relentless global demand for high-quality steel, particularly from industries such as automotive, construction, and infrastructure, which require materials with superior surface finish and internal integrity. Modern manufacturing standards and increased customer expectations necessitate a consistent and defect-free product, pushing steelmakers to adopt advanced monitoring systems. Furthermore, the imperative for operational efficiency and cost reduction across the steel industry is a significant motivator. These systems reduce scrap rates, minimize costly breakouts, extend mold life, and optimize casting speed, directly contributing to improved profitability. The ongoing digital transformation and the embrace of Industry 4.0 principles, integrating IoT, data analytics, and automation into manufacturing processes, also serve as powerful drivers, positioning mold oscillation monitoring as an indispensable component of smart steel mills. The drive towards predictive maintenance to minimize unplanned downtime is another critical factor compelling adoption.

Despite the compelling benefits, several restraints temper the market's growth. The high initial capital investment required for implementing sophisticated mold oscillation monitoring systems can be a significant barrier for smaller steel producers or those operating with tighter budgets. The complexity of integrating these advanced systems into existing legacy infrastructure, which often involves older machinery and control systems, can pose technical challenges and incur additional costs. There is also a notable restraint related to the availability of skilled personnel capable of operating, maintaining, and interpreting the data generated by these high-tech systems. A shortage of engineers and technicians with expertise in industrial automation, data analytics, and metallurgical processes can hinder effective implementation and utilization. Additionally, economic downturns or fluctuations in the global steel market, which can lead to reduced production volumes or delayed capital expenditures, inevitably impact the demand for new monitoring systems. The perceived risk associated with adopting new technologies and the resistance to change within traditional industrial settings can also act as soft restraints.

Opportunities for growth in this market are abundant, particularly within emerging economies in Asia Pacific, Latin America, and the Middle East and Africa, where new steel plants are being constructed or existing ones modernized to meet burgeoning industrial demands. These regions offer fertile ground for the adoption of new technologies from the outset. Another significant opportunity lies in the retrofitting market, where older steel mills are looking to upgrade their continuous casting facilities without undertaking complete overhauls. Providers of mold oscillation monitoring systems can offer tailored, modular solutions that integrate seamlessly with existing equipment. Technological advancements in sensor development, such as more robust and accurate non-contact sensors, along with increasingly powerful and user-friendly AI/ML-driven analytical software, present further avenues for innovation and market penetration. The trend towards customized solutions, specific to different caster types and steel grades, also creates niches for specialized offerings. The increasing focus on environmental sustainability and reducing carbon footprints offers an opportunity for these systems to demonstrate their value in optimizing processes to minimize energy consumption and waste. The impact forces within the market, such as the bargaining power of buyers (large steel manufacturers) demanding advanced features and competitive pricing, and the bargaining power of suppliers (high-tech sensor and software providers) dictating innovation pace, significantly shape market dynamics. The threat of new entrants is relatively low due to high R&D costs and specialized expertise, while the threat of substitutes is also limited given the critical nature of oscillation monitoring for continuous casting quality. Competitive rivalry among existing players, driven by continuous innovation and service differentiation, remains a strong force.

Segmentation Analysis

The Mold Oscillation Monitoring Systems market is intricately segmented to reflect the diverse technological approaches, application requirements, and end-user characteristics prevalent in the steel industry. Understanding these segments is crucial for stakeholders to identify specific market niches, tailor product offerings, and devise effective market entry strategies. The segmentation often starts with the core components that constitute these systems, moving through the underlying technologies utilized for measurement, to the specific types of continuous casting machines where they are deployed, and finally to the various categories of steel producers that are the primary end-users. This multi-dimensional approach ensures a comprehensive overview of the market's structure and dynamics, highlighting areas of high growth potential and specific challenges. The evolving landscape of steel manufacturing, characterized by a constant drive for higher quality, greater efficiency, and reduced operational costs, continuously refines these segmentation categories.

Further granularity in segmentation allows for a detailed analysis of how different segments contribute to the overall market growth and where innovation is most concentrated. For instance, the distinction between systems designed for billet, bloom, and slab casting is critical, as each casting type presents unique challenges and requires tailored monitoring solutions due to differences in size, shape, and cooling rates of the solidified steel. Similarly, the level of integration and automation offered by these systems can serve as a segmentation criterion, distinguishing between basic data logging systems and advanced, AI-powered predictive and adaptive control solutions. Regional segmentation is also paramount, as the maturity of steel industries, investment capacities, and regulatory environments vary significantly across geographies, impacting adoption rates and technological preferences. The interplay between these segments defines the competitive intensity and market opportunities available for both established players and emerging innovators.

The market's segmentation also accounts for the varying needs of different types of steel producers, from large integrated steel mills that require highly robust and comprehensive systems capable of handling massive production volumes and diverse product portfolios, to smaller mini-mills that may prioritize cost-effectiveness and ease of integration. The rapid pace of technological innovation, particularly in sensor technology and data analytics, continually creates new sub-segments within the market, such as solutions leveraging advanced optical sensors for non-contact measurement or specialized software modules for specific defect detection. This dynamic segmentation underscores the market's responsiveness to technological progress and the specific demands of a highly specialized industrial sector. Strategic planning within this market necessitates a deep understanding of these segmentations to effectively address the complex requirements of continuous casting operations and to capitalize on emerging trends.

- By Component:

- Sensors (LVDT, Accelerometers, Optical Sensors, Strain Gauge Sensors)

- Data Acquisition Systems (DAQ modules, industrial PCs)

- Software (HMI, SCADA integration, data analytics platforms, AI/ML modules)

- Actuators and Control Units

- By Technology:

- Electromagnetic Systems

- Optical Systems

- Mechanical Systems (LVDT-based, Accelerometer-based)

- Hybrid Systems

- By Casting Type:

- Slab Casters

- Billet Casters

- Bloom Casters

- Beam Blank Casters

- By End-User:

- Integrated Steel Mills

- Mini-Mills / Electric Arc Furnace (EAF) Plants

- Specialty Steel Producers

- Foundries (less common, but applicable for certain casting processes)

- By Application:

- Surface Quality Control

- Internal Defect Prevention

- Breakout Prediction

- Process Optimization

- By Deployment:

- New Installations

- Retrofit & Upgrades

Value Chain Analysis For Mold Oscillation Monitoring Systems Market

The value chain for the Mold Oscillation Monitoring Systems Market is characterized by a series of specialized activities, starting from the foundational technology development to the final deployment and post-sales support in steel manufacturing facilities. Upstream analysis reveals a critical reliance on manufacturers of high-precision sensors, microcontrollers, and specialized industrial computing hardware. These suppliers develop and produce components such as LVDTs, accelerometers, fiber optic sensors, and industrial-grade data acquisition units, which are the fundamental building blocks of any monitoring system. Furthermore, specialized software developers providing real-time operating systems, data visualization tools, and advanced analytical algorithms (including AI/ML frameworks) form another crucial upstream segment. The quality and innovation capabilities of these upstream providers directly impact the performance, accuracy, and reliability of the final mold oscillation monitoring system. Strong relationships with these suppliers are essential for ensuring a steady supply of cutting-edge components and for driving continuous product improvement.

Moving further along the value chain, system integrators and equipment manufacturers play a pivotal role. These entities take the individual components from upstream suppliers and combine them into a complete, functioning mold oscillation monitoring system, often customizing it to specific continuous caster designs and client requirements. This stage involves complex engineering, system calibration, and rigorous testing to ensure seamless integration with the existing continuous casting machinery and plant control systems (DCS/SCADA). These companies often possess deep metallurgical and process engineering expertise, allowing them to translate customer needs into effective technological solutions. Their value proposition includes not only the hardware and software integration but also the provision of comprehensive training, installation services, and initial commissioning support, ensuring that the system operates optimally within the challenging environment of a steel plant. Their ability to deliver a robust, integrated solution is paramount to customer satisfaction and system performance.

Downstream analysis focuses on the distribution channels and the ultimate end-users. Distribution channels for mold oscillation monitoring systems are primarily direct, given the high value, complexity, and customization required for these industrial solutions. Manufacturers and system integrators typically engage directly with integrated steel mills, mini-mills, and specialty steel producers. This direct sales model allows for close consultation, detailed technical discussions, and tailored solution development, which are essential for such capital-intensive industrial equipment. Indirect distribution, while less common, might involve regional representatives, authorized distributors, or value-added resellers who provide localized sales and support services, particularly in regions where the primary manufacturers do not have a direct presence. Post-sales services, including maintenance contracts, calibration services, software updates, and ongoing technical support, form a critical part of the downstream value proposition, ensuring the long-term operational efficiency and reliability of the installed systems. These services are often key differentiators in a competitive market, building customer loyalty and ensuring repeat business.

Mold Oscillation Monitoring Systems Market Potential Customers

The primary potential customers for Mold Oscillation Monitoring Systems are industrial entities deeply involved in the production of steel through continuous casting processes. At the forefront are large, integrated steel mills, which are expansive facilities encompassing the entire steelmaking process from raw material preparation to finished product. These mills typically operate multiple continuous casters producing a wide range of products, from thin slabs for flat products to heavy blooms for structural applications. For such customers, maintaining consistent product quality across high production volumes is paramount, and mold oscillation monitoring systems are indispensable tools for achieving this. The substantial investment capabilities of integrated mills also make them prime candidates for adopting advanced, comprehensive monitoring solutions that can be integrated into their sophisticated plant-wide automation systems. Their focus is on maximizing yield, minimizing defects, and optimizing operational efficiency on a grand scale, making precision monitoring a critical strategic investment.

Another significant segment of potential customers comprises mini-mills, which predominantly use electric arc furnaces (EAFs) to melt scrap steel and produce various steel products, often including long products like rebar and wire rod, or specialized alloys. While generally smaller than integrated mills, mini-mills are equally driven by efficiency and quality mandates. For them, mold oscillation monitoring systems are crucial for ensuring the quality of their cast products, reducing energy consumption, and controlling operational costs, which are often more sensitive to fluctuations in the scrap and energy markets. The ability of these systems to reduce breakouts and improve uptime is particularly valuable for mini-mills, where production continuity is key to profitability. As mini-mills increasingly aim for higher value-added products and stricter quality specifications, the adoption of advanced monitoring technologies becomes a competitive necessity, enabling them to produce materials that meet stringent industry standards.

Beyond these major categories, specialty steel producers also represent a valuable customer base. These companies focus on niche markets requiring high-performance alloys and specialized steel grades, such as stainless steel, tool steel, or aerospace-grade alloys, where metallurgical properties and surface integrity are absolutely critical. For these producers, even minute defects can lead to rejection of entire batches, making precision mold oscillation control a non-negotiable requirement. The high value of their end products justifies the investment in the most advanced and accurate monitoring systems available, often with customized features tailored to the unique characteristics of their specialized alloys. Furthermore, foundries that utilize continuous casting processes for specific applications, though less common than in mainstream steelmaking, could also be potential buyers, especially those focusing on high-quality specialized castings where process control is paramount. The underlying commonality across all these potential customers is the critical need for meticulous control over the solidification process to ensure product quality, minimize waste, and optimize production efficiency in demanding industrial environments.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 725 Million |

| Growth Rate | 7.2% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Primetals Technologies, SMS Group, Siemens AG, ABB Ltd., Danieli & C. Officine Meccaniche S.p.A., Fives Group, Schuler Group, GE Power, Emerson Electric Co., Honeywell International Inc., Rockwell Automation, Fuji Electric Co. Ltd., Mitsubishi Heavy Industries Ltd., thyssenkrupp AG, Electro-Nite (AMETEK), ifm electronic GmbH, SICK AG, Balluff GmbH, Pepperl+Fuchs SE, Endress+Hauser Group Services AG |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Mold Oscillation Monitoring Systems Market Key Technology Landscape

The Mold Oscillation Monitoring Systems Market is characterized by a dynamic and evolving technology landscape, driven by the continuous demand for enhanced precision, reliability, and data intelligence in steel manufacturing. At the core of these systems are various sensor technologies designed to capture the minute movements and forces associated with mold oscillation. Linear Variable Differential Transformers (LVDTs) remain a cornerstone due to their high accuracy and robust performance in harsh industrial environments, precisely measuring displacement. Accelerometers are also widely employed to monitor vibration and acceleration patterns, providing insights into the dynamic behavior of the mold. Emerging technologies include advanced optical sensors, which offer non-contact measurement capabilities, reducing wear and tear, and enhancing measurement stability, particularly in high-temperature settings. Strain gauge sensors are used to measure forces and stresses within the mold system, providing another layer of data for comprehensive analysis. The selection of sensor technology often depends on the specific requirements of the caster, the type of steel being produced, and the desired level of precision.

Beyond sensing, the technological landscape is heavily influenced by advancements in data acquisition and processing. High-speed data acquisition (DAQ) systems are crucial for collecting real-time data from multiple sensors simultaneously, ensuring that no critical event is missed. These DAQ systems are typically connected to industrial computers or embedded controllers, which are responsible for initial data processing, filtering, and transmitting the information to higher-level control systems. The development of robust industrial communication protocols, such as industrial Ethernet (Profinet, EtherNet/IP, Modbus TCP) and fieldbus systems, enables seamless data flow and integration with the plant's distributed control system (DCS) or supervisory control and data acquisition (SCADA) systems. This integration is vital for centralized monitoring, control, and archiving of oscillation data, facilitating a holistic approach to continuous casting management and allowing operators to make informed decisions quickly. The reliability and speed of these data pathways are critical for ensuring the real-time responsiveness of the monitoring system.

The most transformative technological advancements in this market are occurring in the realm of software and data analytics, particularly with the integration of Artificial Intelligence (AI) and Machine Learning (ML). These intelligent algorithms move beyond traditional statistical process control by analyzing vast historical and real-time datasets to identify complex patterns, predict potential defects or equipment failures, and even suggest optimal oscillation parameters. Cloud computing and Industrial IoT (IIoT) platforms are facilitating this, enabling remote monitoring, centralized data storage, and advanced analytics that can be accessed from anywhere. Furthermore, sophisticated Human-Machine Interfaces (HMIs) and visualization tools are being developed to present complex data in an intuitive and actionable format for operators and engineers. Predictive maintenance, condition-based monitoring, and adaptive control strategies are becoming standard, reducing unplanned downtime and enhancing overall equipment effectiveness (OEE). The ongoing evolution of these technologies ensures that mold oscillation monitoring systems remain at the cutting edge of industrial automation, continually pushing the boundaries of what is possible in steel production quality and efficiency.

Regional Highlights

The global Mold Oscillation Monitoring Systems Market exhibits distinct regional dynamics, each influenced by varying levels of industrialization, technological adoption rates, steel production capacities, and regulatory environments. Asia Pacific (APAC) stands out as the predominant region, primarily driven by the massive steel production volumes in countries like China, India, Japan, and South Korea. China, being the world's largest steel producer, heavily invests in advanced technologies to enhance quality and efficiency, making it a key market for these monitoring systems. India's rapidly expanding infrastructure and manufacturing sectors are fueling demand for steel, leading to significant investments in new continuous casting facilities and modernization projects. Japanese and South Korean steelmakers, renowned for their technological prowess and focus on high-quality steel, are early adopters of sophisticated monitoring solutions, continuously upgrading their facilities to maintain global competitiveness. The region's growth is also supported by government initiatives promoting industrial automation and smart manufacturing, creating a fertile ground for market expansion.

Europe represents a mature market with a strong emphasis on technological advancement, stringent quality standards, and environmental regulations. Countries such as Germany, Italy, and France are home to leading steel technology providers and steel manufacturers who prioritize precision and efficiency. The European market is characterized by a high adoption rate of sophisticated, integrated monitoring systems, often incorporating AI and advanced analytics, as steelmakers strive to optimize existing plants and meet demanding product specifications. Retrofitting older continuous casters with modern oscillation monitoring solutions is a common trend, driven by the need to extend asset life, improve product quality, and reduce operational costs in a highly competitive market. Furthermore, Europe's commitment to Industry 4.0 and sustainable manufacturing practices encourages the deployment of solutions that offer energy efficiency and waste reduction benefits, making advanced monitoring systems an attractive investment.

North America, particularly the United States and Canada, presents a market focused on modernizing its steel infrastructure and improving the competitiveness of its domestic steel industry. While not as large in production volume as APAC, the region's steelmakers are increasingly investing in advanced automation and digital solutions to enhance efficiency, reduce labor costs, and produce high-quality steel for demanding sectors like automotive and energy. The adoption of mold oscillation monitoring systems in North America is often part of broader capital expenditure projects aimed at improving operational resilience and reducing reliance on imports. Latin America and the Middle East & Africa (MEA) are emerging markets for these systems. In Latin America, countries like Brazil and Mexico are experiencing industrial growth, leading to new investments in steel production facilities. The MEA region, particularly in the Gulf Cooperation Council (GCC) countries, is witnessing significant infrastructure development and industrial diversification, driving the demand for locally produced steel and consequently for advanced steelmaking technologies, including mold oscillation monitoring systems. As these regions continue to industrialize, the demand for high-quality steel and the technologies to produce it efficiently are expected to grow substantially.

- Asia Pacific (APAC): Dominant market due to high steel production volumes, driven by China and India's industrial growth and modernization efforts in Japan and South Korea. Strong focus on new installations and adoption of advanced technologies for mass production and quality.

- Europe: Mature market with emphasis on technological leadership, stringent quality standards, and retrofitting existing plants. Driven by Industry 4.0 initiatives, sustainability goals, and demand for high-performance steel in countries like Germany and Italy.

- North America: Focus on modernizing existing steel infrastructure, improving competitiveness, and enhancing product quality for specialized sectors. Investments are concentrated on efficiency gains and reducing operational costs.

- Latin America: Emerging market with growing industrialization and infrastructure development. Demand for mold oscillation monitoring systems is increasing with new steel plant investments and upgrades in countries like Brazil and Mexico.

- Middle East & Africa (MEA): Growth driven by infrastructure projects, industrial diversification, and increasing local steel production capabilities. Adopting modern technologies to establish competitive local industries.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Mold Oscillation Monitoring Systems Market.- Primetals Technologies

- SMS Group

- Siemens AG

- ABB Ltd.

- Danieli & C. Officine Meccaniche S.p.A.

- Fives Group

- Schuler Group

- GE Power

- Emerson Electric Co.

- Honeywell International Inc.

- Rockwell Automation

- Fuji Electric Co. Ltd.

- Mitsubishi Heavy Industries Ltd.

- thyssenkrupp AG

- Electro-Nite (AMETEK)

- ifm electronic GmbH

- SICK AG

- Balluff GmbH

- Pepperl+Fuchs SE

- Endress+Hauser Group Services AG

Frequently Asked Questions

What is a Mold Oscillation Monitoring System and why is it crucial in steel manufacturing?

A Mold Oscillation Monitoring System is an advanced industrial solution designed to precisely measure and control the oscillating motion of the mold in a continuous casting machine. This oscillation is vital for preventing the solidifying steel shell from sticking to the mold walls, ensuring proper lubrication, and facilitating a smooth casting process. It is crucial because consistent and controlled oscillation directly impacts the surface quality and internal soundness of steel products, preventing defects like cracks and breakouts, thereby enhancing product quality, optimizing casting speed, and reducing operational costs in steel production.

How does AI enhance the capabilities of Mold Oscillation Monitoring Systems?

AI significantly enhances these systems by moving beyond simple data collection to intelligent data analysis and predictive capabilities. AI algorithms can analyze vast datasets to identify subtle patterns and correlations indicating potential defects or equipment malfunctions before they occur, enabling proactive maintenance. Furthermore, AI can dynamically adjust oscillation parameters in real-time, optimizing the casting process for various steel grades and conditions, leading to superior quality control, reduced waste, and more autonomous, efficient operations.

What are the primary benefits of implementing Mold Oscillation Monitoring Systems?

Implementing Mold Oscillation Monitoring Systems offers numerous benefits, including a significant reduction in surface and internal defects in cast steel products, such as cracks and breakouts, leading to improved overall product quality. These systems also enable increased casting speed without compromising quality, optimize mold life, and significantly reduce unplanned downtime by providing early warnings of potential issues. Ultimately, they contribute to enhanced operational efficiency, lower maintenance costs, and improved profitability for steel manufacturers by ensuring consistent and reliable production.

What are the key components of a typical Mold Oscillation Monitoring System?

A typical Mold Oscillation Monitoring System comprises several key components working in synergy. These include high-precision sensors such as Linear Variable Differential Transformers (LVDTs) for displacement measurement, accelerometers for vibration monitoring, and sometimes optical or strain gauge sensors. These sensors are connected to a data acquisition (DAQ) system that collects and digitizes the raw data. The system also includes specialized software for data processing, analysis, visualization, and integration with the plant's control systems (DCS/SCADA), often incorporating advanced algorithms, including AI/ML modules, for predictive insights and adaptive control.

What are the major challenges in adopting Mold Oscillation Monitoring Systems?

The adoption of Mold Oscillation Monitoring Systems faces several challenges. A primary hurdle is the significant initial capital investment required for purchasing and installing these advanced systems. Integrating these new technologies into existing, often older, legacy continuous casting infrastructure can be complex and costly. Furthermore, a shortage of skilled personnel proficient in operating, maintaining, and interpreting the data from these sophisticated systems can hinder effective implementation. Economic downturns affecting the steel industry or fluctuations in raw material prices can also lead to deferred investments, impacting market growth.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager