Molecular Beam Epitaxy System Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432639 | Date : Dec, 2025 | Pages : 241 | Region : Global | Publisher : MRU

Molecular Beam Epitaxy System Market Size

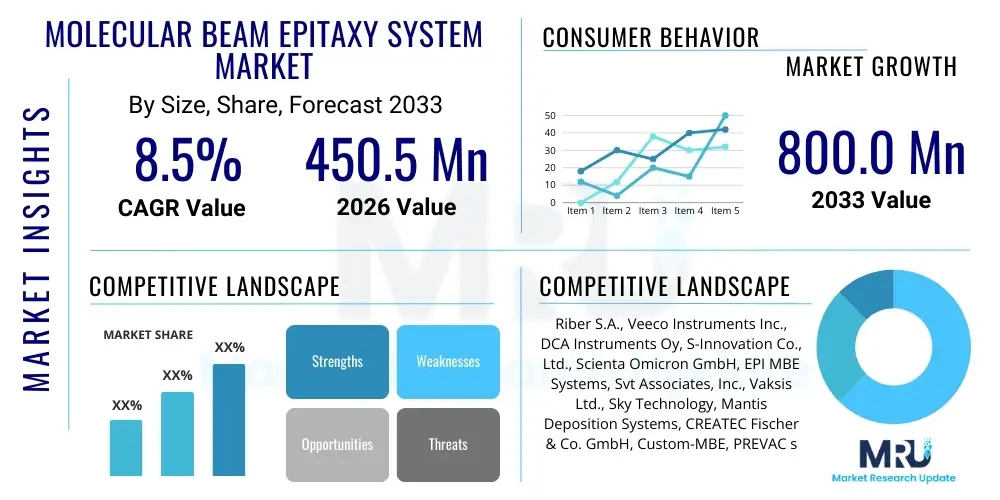

The Molecular Beam Epitaxy System Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2026 and 2033. The market is estimated at USD 450.5 Million in 2026 and is projected to reach USD 800.0 Million by the end of the forecast period in 2033.

Molecular Beam Epitaxy System Market introduction

The Molecular Beam Epitaxy (MBE) System Market centers on highly sophisticated vacuum deposition equipment utilized for growing crystalline thin films with atomic-layer precision. MBE is a critical technology in advanced semiconductor manufacturing, offering unparalleled control over the stoichiometry and thickness of deposited layers, which is essential for developing high-performance electronic and optoelectronic devices. These systems operate under Ultra-High Vacuum (UHV) conditions, ensuring minimal contamination and enabling the deposition of high-purity materials, particularly complex compound semiconductors like III-V and II-VI materials, silicon, and specialized oxides.

The primary applications of MBE systems span across revolutionary technological domains, including the fabrication of high electron mobility transistors (HEMTs), laser diodes, quantum cascade lasers (QCLs), advanced solar cells, and sophisticated sensors. The superior material quality achieved via MBE is indispensable for devices requiring precise control over quantum mechanical effects, such as quantum dots and quantum wells used in advanced photonics and quantum computing hardware. Furthermore, MBE plays a fundamental role in academic and industrial research, serving as the benchmark for synthesizing new metastable materials and exploring novel heterostructures.

Key driving factors accelerating market expansion include the global proliferation of 5G and 6G infrastructure, which demands high-speed, high-frequency components manufactured using III-V materials (like GaAs and InP). The growing investment in quantum technology research by governments and private entities worldwide necessitates highly controlled material growth methods unique to MBE systems. Additionally, continuous technological refinements in MBE system design—such as increased automation, improved uniformity across larger wafer sizes, and the integration of in-situ monitoring tools—are making these systems more attractive for high-volume production applications, moving beyond their traditional role solely in fundamental research.

Molecular Beam Epitaxy System Market Executive Summary

The Molecular Beam Epitaxy System market is characterized by robust growth driven primarily by advancements in compound semiconductor technology and the commercialization of specialized electronic components crucial for next-generation communication and computing. Business trends indicate a shift towards fully automated, production-scale MBE systems, particularly those tailored for nitride materials (GaN and AlN), essential for power electronics and high-frequency radio frequency (RF) applications. Strategic alliances between system manufacturers and end-users, especially in Asia Pacific, are defining the competitive landscape, focusing on customized system configurations optimized for specific material growth requirements and large-diameter wafer processing capabilities.

Regionally, Asia Pacific maintains its dominance, spurred by massive investments in domestic semiconductor fabrication facilities and dedicated research centers in China, South Korea, and Taiwan. North America and Europe, while representing mature markets, are experiencing heightened demand driven by government-backed research initiatives in quantum computing, defense applications, and advanced microelectronics fabrication, maintaining a strong focus on high-precision R&D-grade systems. The growth trajectory is significantly impacted by geopolitical factors influencing global semiconductor supply chains, pushing localized manufacturing capacity expansion in various regions, thereby driving the sale of new MBE installations.

Segmentation trends highlight the increasing importance of production-grade MBE systems over research-grade systems, reflecting the maturity of certain III-V device technologies transitioning from lab prototypes to commercial products. The segment for Arsenide and Phosphide MBE systems remains foundational for optoelectronics, while the demand for specialized Oxide and Nitride MBE systems is witnessing the fastest growth due to their essential role in energy-efficient devices and high-power applications. Subsegment growth in ancillary equipment, such as effusion cells and in-situ characterization tools, is also substantial, as users seek greater process control and reliability to maximize material quality and throughput.

AI Impact Analysis on Molecular Beam Epitaxy System Market

User queries regarding the impact of Artificial Intelligence (AI) on the Molecular Beam Epitaxy System market frequently revolve around process optimization, predictive maintenance, and autonomous material synthesis. Users are keen to understand how AI-driven algorithms can monitor complex, multi-variable growth processes in real-time—specifically parameters like beam flux, substrate temperature, and shutter timing—to achieve enhanced layer uniformity and defect minimization, far surpassing the capabilities of traditional feedback loops. A key concern is the integration complexity and the requirement for substantial, high-quality historical MBE data to train robust AI models. Expectations center on AI enabling "self-driving" MBE systems capable of synthesizing novel materials or heterostructures automatically, drastically reducing the time and expert knowledge required for experimental optimization and accelerating research and development cycles in fields like quantum materials and advanced semiconductors.

- AI integration streamlines real-time monitoring of complex growth parameters (flux ratios, temperature gradients) within the UHV chamber.

- Predictive modeling and machine learning algorithms optimize shutter sequences and growth temperatures, resulting in superior material quality and reduced waste.

- AI enables autonomous optimization of experimental parameters, drastically shortening the R&D cycle for novel semiconductor structures and materials.

- Advanced data analysis via AI facilitates defect detection and classification in epitaxial layers during growth (in-situ), improving yield in high-volume production systems.

- Integration of AI-powered process control improves the reproducibility and transferability of growth recipes across different MBE systems globally.

DRO & Impact Forces Of Molecular Beam Epitaxy System Market

The Molecular Beam Epitaxy System Market is influenced by a dynamic interplay of stimulating growth drivers, restricting operational challenges, and significant long-term opportunities, all shaped by overarching impact forces related to technological necessity and capital investment cycles. The primary drivers include the exponential demand for high-speed, energy-efficient compound semiconductors crucial for 5G/6G, data centers, and specialized defense electronics. Restraints are primarily tied to the extremely high initial capital cost of MBE systems, their complex maintenance requirements necessitating highly trained personnel, and the relatively low throughput compared to competing technologies like Metal-Organic Chemical Vapor Deposition (MOCVD) for specific applications. Opportunities are vast, focused on the emerging fields of quantum technology, advanced micro-LED displays, and the increasing industry shift toward larger wafer diameters (e.g., 6-inch and 8-inch) for cost efficiency, necessitating new, high-capacity MBE installations.

Impact forces significantly affecting this market include the global geopolitical tension surrounding semiconductor self-sufficiency, compelling nations to invest heavily in domestic research and manufacturing capabilities, directly boosting MBE system procurement. Technological impact forces are characterized by rapid innovation in adjacent fields, such as in-situ monitoring systems (e.g., Reflection High-Energy Electron Diffraction - RHEED) and precursor material purity, which collectively enhance MBE performance. Economic impact is crucial, as the highly specialized nature of the equipment makes the market sensitive to fluctuations in R&D budgets of major technology firms and government funding cycles for foundational science and defense projects. Social impact forces, though indirect, relate to the global push for sustainability and energy efficiency, driving demand for advanced III-N materials synthesized by MBE for power management solutions.

Segmentation Analysis

The Molecular Beam Epitaxy System market is comprehensively segmented based on the type of material being grown, the classification of the system itself (based on function and size), and the primary application sector. Understanding these segments is vital for assessing market growth vectors, as system requirements vary significantly between research environments demanding flexibility and industrial settings prioritizing throughput and reliability. The key distinguishing factors in segmentation include the ultra-high vacuum chamber design, the type and number of effusion cells (sources), the incorporation of specialized gas sources for volatile elements, and the degree of automation implemented in the wafer handling and processing sequences. The material type segmentation (III-V, III-N, Silicon, etc.) is the most impactful, dictating the required configuration and target end-users.

- By System Type:

- Research and Development Grade MBE Systems

- Production Grade MBE Systems

- By Material Grown:

- III-V Semiconductor Systems (GaAs, InP)

- III-Nitride Semiconductor Systems (GaN, AlN)

- Silicon/Germanium Systems

- Oxide and Complex Material Systems

- Others (e.g., II-VI compounds, topological insulators)

- By Application:

- Optoelectronics (Lasers, LEDs, Photodetectors)

- Microelectronics (HEMTs, Transistors, ICs)

- Solar Energy Devices

- Quantum Computing and Advanced Materials Research

- Sensors and Defense Technology

Value Chain Analysis For Molecular Beam Epitaxy System Market

The value chain for the Molecular Beam Epitaxy System market is highly specialized and requires stringent control at every stage, commencing with the upstream supply of ultra-high purity materials and components. Upstream analysis focuses heavily on the procurement of high-quality effusion cell components (e.g., crucibles, filaments), specialized vacuum pumps (turbo molecular and cryopumps), precise temperature control units, and, crucially, the elemental sources themselves—Gallium, Arsenic, Indium, etc., which must meet extremely low impurity standards to ensure defect-free epitaxial growth. Suppliers capable of meeting these demanding specifications hold significant leverage. Innovation in upstream is centered on developing robust, contamination-resistant source materials and increasingly larger capacity sources for production systems.

The core manufacturing stage involves the system integrators, who design, assemble, and test the complex UHV chambers and associated process controls. Due to the custom nature of many high-end MBE systems, this stage requires profound expertise in vacuum engineering, crystal growth physics, and automation software. Downstream analysis focuses on the distribution and end-use application. Direct channels dominate the market, as systems often require extensive customization, installation, and post-sale service provided directly by the manufacturer or highly specialized local representatives. Indirect channels are rarely used for the full system but may involve third-party suppliers for spare parts, specific monitoring tools, or advanced software modules.

The downstream customers are primarily specialized research institutions, academic laboratories, government defense facilities, and high-tech semiconductor fabrication plants (fabs). The relationship between the system provider and the end-user is typically long-term, involving technical training, application support, and scheduled maintenance. The value derived at the downstream end is the ability to produce high-value components—such as VCSELs for data transmission or HEMTs for 5G base stations—that command premium prices due to the performance characteristics enabled solely by the high quality of MBE-grown materials. This structure reinforces the highly technical, low-volume, high-value nature of the MBE system market, emphasizing service and technological partnership over simple transactional sales.

Molecular Beam Epitaxy System Market Potential Customers

The potential customers for Molecular Beam Epitaxy Systems are institutions and commercial entities engaged in the development, research, and fabrication of advanced electronic and photonic devices where atomic-layer precision is paramount. These customers are highly sophisticated, typically possessing significant capital resources and a critical requirement for cutting-edge material science capabilities. The largest segment of buyers includes academic and national research laboratories globally, particularly those focusing on condensed matter physics, quantum technologies, and advanced materials engineering, utilizing R&D grade systems for exploring fundamental phenomena and synthesizing novel compounds.

The commercial sector constitutes another major buying group, dominated by Integrated Device Manufacturers (IDMs) and specialized compound semiconductor foundries. These firms purchase production-grade MBE systems primarily for the mass fabrication of high-performance components, such as high-frequency integrated circuits required for radar systems and 5G/6G communication infrastructure, as well as complex laser diodes and optical components used in fiber optics and consumer electronics (e.g., facial recognition sensors). The defense and aerospace industries represent a critical, albeit smaller, customer segment, requiring MBE systems for producing highly reliable, radiation-hardened devices and advanced infrared detectors for surveillance and targeting systems.

Furthermore, emerging technology companies focused on quantum computing hardware—specifically those developing qubits based on complex semiconductor heterostructures or topological insulators—are becoming increasingly important customers. These buyers require customized MBE systems capable of maintaining extremely low growth rates and pristine interfaces. The buying decision in this market is not merely based on cost but heavily relies on the vendor's reputation, technical support capabilities, process guarantees (material uniformity and defect density), and the ability to integrate advanced in-situ characterization tools critical for controlling sensitive material growth processes.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450.5 Million |

| Market Forecast in 2033 | USD 800.0 Million |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Riber S.A., Veeco Instruments Inc., DCA Instruments Oy, S-Innovation Co., Ltd., Scienta Omicron GmbH, EPI MBE Systems, Svt Associates, Inc., Vaksis Ltd., Sky Technology, Mantis Deposition Systems, CREATEC Fischer & Co. GmbH, Custom-MBE, PREVAC sp. z o.o., Tectra GmbH, Evatec AG, Angstrom Engineering, PVD Products Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Molecular Beam Epitaxy System Market Key Technology Landscape

The technological landscape of the Molecular Beam Epitaxy System market is defined by continuous evolution aimed at enhancing material quality, throughput, and system reliability, while maintaining the fundamental principle of atomic-layer deposition in an Ultra-High Vacuum (UHV) environment. A critical aspect of modern MBE technology is the refinement of source technology, specifically the transition from traditional thermal effusion cells to sophisticated valve-based crackers and plasma sources. These advancements are essential for safely and efficiently handling volatile elements (like Phosphorus and Arsenic) and achieving the highly reactive species required for growing high-quality III-Nitride (GaN) materials, which are crucial for high-power electronics and blue/UV optoelectronics. The shift toward solid-source materials, combined with precise temperature control and beam flux uniformity, remains a core technological focus to minimize contamination and maximize stability over extended production runs.

Another major area of technological innovation involves the integration of advanced in-situ monitoring and control systems. Reflection High-Energy Electron Diffraction (RHEED) is foundational for monitoring the crystal surface structure and growth rate in real-time, but new technologies, such as pyrometric interferometry and sophisticated flux monitors (e.g., beam flux gauges), are being incorporated to provide comprehensive feedback during the deposition process. The goal is to move towards fully automated, closed-loop control systems where growth parameters can be adjusted dynamically based on real-time material diagnostics, critical for maintaining uniformity across larger wafer sizes (up to 8 inches) now required by commercial semiconductor foundries. This push towards automation and precise diagnostic capabilities directly supports the scalability of MBE from research environments to industrial mass production.

Furthermore, the development of specialized hybrid MBE techniques is broadening the application scope. For instance, Gas Source MBE (GSMBE) utilizes gas precursors instead of solid sources for certain elements, offering better compositional control and reduced particulate contamination, especially beneficial for III-V applications. Oxide MBE, often incorporating ozone or activated oxygen sources, is rapidly advancing to meet the needs of complex functional materials used in superconducting circuits and neuromorphic computing. This technological diversification, coupled with the drive toward modular, multi-chamber systems that allow for sequential processing without breaking the vacuum, underscores the market's commitment to delivering high-performance, customized solutions for the most demanding electronic and quantum applications.

Regional Highlights

The global Molecular Beam Epitaxy System market exhibits distinct regional dynamics driven by varying levels of investment in semiconductor manufacturing, research infrastructure, and governmental strategic priorities in communication and defense technology.

- Asia Pacific (APAC): Dominates the global market share, largely fueled by aggressive government and private sector investment in compound semiconductor fabrication facilities, particularly in China, South Korea, and Taiwan. These regions are primary hubs for high-volume manufacturing of optoelectronics (VCSELs, LEDs) and components for 5G infrastructure, driving the highest demand for production-grade MBE systems. Japan remains a strong market for fundamental materials research and specialized component manufacturing.

- North America: Characterized by strong government funding focused on defense applications, advanced photonics, and foundational research into quantum computing and novel materials. The US market is highly demanding regarding customized, R&D-grade MBE systems used in academic institutions and major national laboratories, coupled with growing commercial adoption for specialized high-frequency RF devices.

- Europe: Exhibits steady growth driven by collaborative research initiatives funded by the European Union, focusing on silicon photonics, high-efficiency solar cells, and specific segments of quantum technology. Countries like Germany and the UK maintain a strong presence in both MBE system manufacturing and high-end material research.

- Latin America & Middle East and Africa (LAMEA): These regions represent nascent markets, primarily focused on academic research applications. Growth potential is linked to localized efforts to develop indigenous technological capabilities, especially in energy and telecommunications sectors, leading to sporadic demand for specialized R&D units.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Molecular Beam Epitaxy System Market.- Riber S.A.

- Veeco Instruments Inc.

- DCA Instruments Oy

- S-Innovation Co., Ltd.

- Scienta Omicron GmbH

- EPI MBE Systems

- Svt Associates, Inc.

- Vaksis Ltd.

- Sky Technology

- Mantis Deposition Systems

- CREATEC Fischer & Co. GmbH

- Custom-MBE

- PREVAC sp. z o.o.

- Tectra GmbH

- Evatec AG

- Angstrom Engineering

- PVD Products Inc.

- Kurt J. Lesker Company

- Ferrotec Corporation

Frequently Asked Questions

Analyze common user questions about the Molecular Beam Epitaxy System market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary technical advantage of MBE over alternative deposition techniques?

MBE provides atomic-layer precision control over film thickness, composition, and interface abruptness under Ultra-High Vacuum (UHV), resulting in the highest crystalline quality required for advanced quantum and high-frequency semiconductor devices, unlike methods such as MOCVD which lack this level of kinetic control.

Which applications are driving the highest demand for production-grade MBE systems?

The highest current demand for production-grade systems is driven by the optoelectronics sector (specifically Vertical-Cavity Surface-Emitting Lasers or VCSELs used in 3D sensing and data communications) and the microelectronics sector for High Electron Mobility Transistors (HEMTs) essential for 5G and radar technologies.

How is the adoption of larger wafer sizes impacting the MBE system market?

The transition toward 6-inch and 8-inch wafer processing is pushing system manufacturers to develop new, highly automated production MBE systems that ensure exceptional material uniformity and flux stability across wider deposition areas, accelerating the scalability and commercial viability of MBE-grown devices.

What role do III-Nitride materials play in the future growth of the MBE market?

III-Nitride semiconductors (GaN, AlN) are crucial for high-power electronics and specialized blue/UV optoelectronics. Demand for specialized Nitride MBE systems, often utilizing plasma sources, is growing rapidly due to the need for high-quality, defect-minimized layers used in power devices and rugged environment sensors.

What is the current challenge regarding the cost-effectiveness of Molecular Beam Epitaxy?

The primary cost challenge is the extremely high initial capital investment required for UHV equipment and the relatively slower growth rate compared to atmospheric pressure techniques like MOCVD. However, the superior performance and yield enabled by MBE often justify the total cost of ownership for highly specialized components where material quality is non-negotiable.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager