MPCVD Equipment Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439556 | Date : Jan, 2026 | Pages : 242 | Region : Global | Publisher : MRU

MPCVD Equipment Market Size

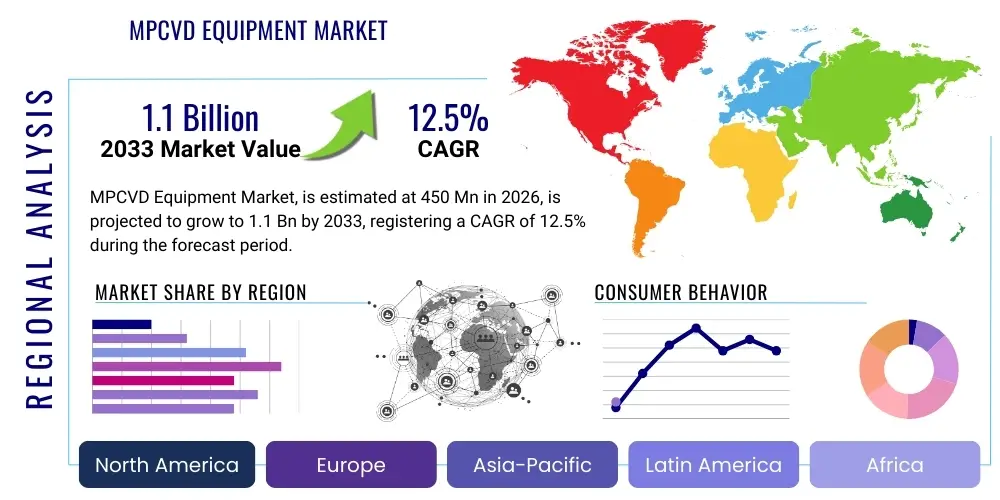

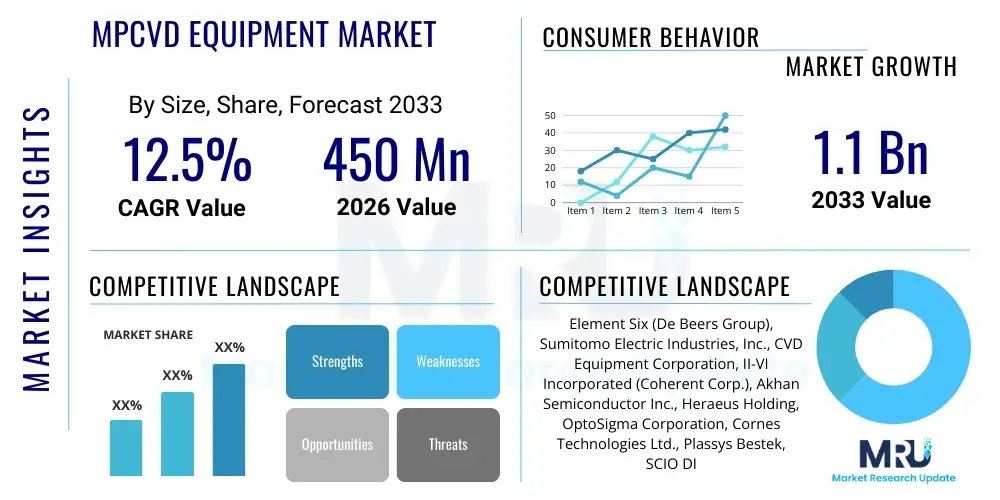

The MPCVD Equipment Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 12.5% between 2026 and 2033. The market is estimated at USD 450 Million in 2026 and is projected to reach USD 1.1 Billion by the end of the forecast period in 2033. This robust growth is primarily fueled by the escalating demand for high-quality synthetic diamonds across diverse industrial, electronic, and gemstone applications. The increasing adoption of advanced materials in semiconductor manufacturing, coupled with significant advancements in MPCVD technology, is creating substantial market expansion opportunities. Furthermore, continuous innovation in reactor design and process optimization techniques is enhancing the efficiency and cost-effectiveness of diamond production, thereby contributing significantly to market value appreciation.

MPCVD Equipment Market introduction

The MPCVD Equipment Market is centered around Microwave Plasma Chemical Vapor Deposition (MPCVD) systems, which are advanced technological solutions primarily utilized for the synthesis of high-quality, single-crystal, and polycrystalline diamonds. MPCVD technology operates by creating a plasma from precursor gases, typically methane and hydrogen, in a microwave chamber, allowing carbon atoms to deposit onto a substrate and grow diamond crystals layer by layer. This sophisticated process offers unparalleled control over diamond purity, crystal structure, and growth rate, making it indispensable for producing diamonds with precise characteristics required for various high-tech applications. The intrinsic benefits of MPCVD include its ability to produce diamonds with superior thermal conductivity, hardness, optical transparency, and electrical insulating properties compared to naturally occurring or other synthetic methods, addressing critical needs across several burgeoning industries.

Major applications for MPCVD-grown diamonds span a wide array of sectors. In the industrial segment, these diamonds are crucial for manufacturing high-performance cutting tools, abrasive materials, and wear-resistant coatings, extending the lifespan and efficiency of machinery. Within the electronics industry, MPCVD diamonds are increasingly utilized as heat spreaders in high-power electronic devices, improving thermal management and device reliability. Furthermore, their unique electrical properties make them ideal for advanced semiconductor substrates, radiation detectors, and quantum computing applications. The gemstone industry also benefits significantly from MPCVD, enabling the creation of optically perfect, lab-grown diamonds that offer an ethical and sustainable alternative to mined stones. The demand for these diamonds is fundamentally driven by the relentless push for materials with extreme properties, alongside the rising consumer acceptance of sustainable alternatives and the ongoing miniaturization and performance enhancement of electronic components.

Key driving factors for the MPCVD Equipment market include the exponential growth in demand for synthetic diamonds in high-tech industries, particularly semiconductors and advanced manufacturing, where their superior properties are critical. Rapid technological advancements, such as larger deposition areas, increased growth rates, and enhanced process control, are making MPCVD systems more efficient and economically viable. The burgeoning market for lab-grown gemstones, fueled by consumer preference for ethical sourcing and transparent origins, also provides a significant impetus. Additionally, substantial investments in research and development for novel diamond applications, including quantum computing, medical devices, and aerospace components, are opening new avenues for market expansion. The continuous quest for materials with extreme physical and chemical properties across diverse industrial landscapes further underpins the sustained growth trajectory of the MPCVD equipment market.

MPCVD Equipment Market Executive Summary

The MPCVD Equipment Market is experiencing dynamic growth, characterized by significant business trends, evolving regional landscapes, and distinct segment shifts. A prominent business trend is the increasing focus on automation and integration of advanced process control systems within MPCVD equipment. Manufacturers are investing heavily in R&D to develop larger chamber sizes, multi-wafer processing capabilities, and in-situ monitoring technologies, aiming to boost throughput, improve yield, and reduce operational costs. There is also a growing emphasis on energy efficiency and modular designs to cater to diverse customer needs, from small-scale research facilities to large-scale industrial production. Strategic collaborations between equipment manufacturers, diamond growers, and end-use industries are becoming more common, fostering innovation and accelerating market penetration of new applications. Furthermore, the market is witnessing consolidation among key players as companies seek to expand their technological portfolios and geographic reach, thereby enhancing their competitive edge.

Regionally, the Asia Pacific (APAC) continues to dominate the MPCVD equipment market, primarily driven by substantial investments in semiconductor manufacturing, robust industrial growth, and the rapidly expanding lab-grown diamond jewelry market, particularly in countries like China and India. This region benefits from lower manufacturing costs and a large consumer base, alongside government initiatives promoting advanced materials research. North America and Europe are significant markets for high-value applications, including R&D for quantum technologies, advanced electronics, and specialized industrial tools. These regions are characterized by a strong presence of research institutions and leading-edge technology companies, which drive demand for highly specialized and advanced MPCVD systems. Latin America, the Middle East, and Africa are emerging markets, showing nascent but growing interest in MPCVD technology, particularly for industrial applications and potential local gemstone production, albeit at a slower pace due to infrastructure and investment challenges.

Segmentation trends within the MPCVD equipment market reveal distinct patterns. The diamond type segment is witnessing accelerated growth in electronic-grade diamonds, driven by their critical role in next-generation power electronics, 5G technology, and quantum computing. While industrial-grade diamonds remain a steady demand driver for cutting and abrasive tools, the gemstone segment is experiencing a significant surge due to shifting consumer preferences towards ethical and sustainable lab-grown diamonds. In terms of reactor types, larger, high-power systems are gaining traction for mass production, especially for industrial and gemstone applications, while compact, versatile systems continue to serve research and niche application markets. End-use industry segments show robust demand from semiconductors, industrial manufacturing, and jewelry, with emerging interest from aerospace, defense, and medical sectors. These trends underscore a market that is diversifying its application base while simultaneously optimizing production capabilities to meet escalating global demand.

AI Impact Analysis on MPCVD Equipment Market

The integration of Artificial Intelligence (AI) into the MPCVD equipment market is poised to revolutionize diamond synthesis, addressing common user concerns regarding process variability, efficiency, and material quality. Users frequently question how AI can lead to more consistent diamond growth, whether it can reduce production costs, and what specific applications of AI are most beneficial in this domain. They are keen to understand if AI can accelerate the discovery of new diamond properties or improve existing ones. The key themes emerging from these inquiries revolve around AI's potential to optimize complex process parameters, enhance predictive maintenance, automate quality control, and facilitate rapid innovation in materials science. The general expectation is that AI will make MPCVD processes smarter, more reliable, and significantly more cost-effective, ultimately expanding the accessibility and utility of synthetic diamonds across a broader range of applications.

AI's influence on the MPCVD equipment market is multi-faceted, primarily focusing on advanced process control and optimization. Traditional MPCVD processes involve numerous variables such as gas flow rates, microwave power, pressure, and substrate temperature, which are difficult to fine-tune manually for optimal results. AI and machine learning algorithms can analyze vast datasets from previous growth runs, identify complex correlations between process parameters and diamond characteristics, and then predict the optimal settings for achieving desired material properties. This capability not only reduces trial-and-error but also ensures higher consistency and reproducibility of diamond growth, significantly mitigating yield losses and improving manufacturing efficiency. Furthermore, AI-driven systems can adapt to real-time process fluctuations, making on-the-fly adjustments to maintain ideal growth conditions, a critical advantage for producing ultra-high-purity electronic-grade diamonds.

Beyond process optimization, AI is set to transform quality assurance and maintenance within MPCVD operations. Machine vision systems powered by AI can perform rapid, non-destructive inspection of grown diamonds, identifying defects, measuring thickness, and assessing surface morphology with far greater accuracy and speed than human operators. This automation of quality control reduces labor costs and ensures that only diamonds meeting stringent specifications proceed to subsequent stages. Predictive maintenance, another powerful AI application, leverages sensor data from MPCVD reactors to anticipate equipment failures before they occur, allowing for proactive servicing and minimizing costly downtime. This analytical capability extends to equipment calibration and performance monitoring, ensuring that MPCVD systems operate at peak efficiency throughout their lifecycle. Moreover, AI can assist in the discovery of new diamond structures or dopants by simulating various growth conditions and predicting material properties, thereby accelerating innovation and expanding the potential applications for MPCVD technology.

- Enhanced Process Optimization: AI algorithms fine-tune complex parameters (gas flow, power, pressure, temperature) for superior diamond growth consistency and desired material properties.

- Automated Quality Control: AI-powered machine vision systems rapidly detect defects, measure dimensions, and assess surface quality, reducing manual inspection and improving yield.

- Predictive Maintenance: AI analyzes sensor data to forecast equipment failures, enabling proactive servicing and minimizing costly operational downtime.

- Accelerated Material Discovery: AI simulations predict optimal growth conditions for novel diamond structures or dopants, speeding up research and development cycles.

- Improved Energy Efficiency: AI optimizes plasma generation and cooling systems, leading to reduced energy consumption per diamond produced.

- Real-time Process Adjustment: AI systems make instantaneous corrections to maintain ideal growth conditions, crucial for high-purity diamond synthesis.

- Data-Driven Decision Making: AI provides actionable insights from historical growth data, empowering operators to make more informed decisions and refine production strategies.

DRO & Impact Forces Of MPCVD Equipment Market

The MPCVD Equipment Market is significantly shaped by a distinct interplay of Drivers, Restraints, Opportunities, and broader Impact Forces that collectively determine its trajectory and potential for expansion. Key drivers propelling this market include the surging global demand for high-quality synthetic diamonds across diverse industrial applications, such as advanced cutting tools, abrasives, and wear-resistant coatings, where their unparalleled hardness and thermal properties offer superior performance. The burgeoning semiconductor industry increasingly relies on MPCVD-grown diamonds for thermal management solutions in high-power electronic devices, driving substantial demand. Furthermore, the growing acceptance and market penetration of lab-grown diamonds in the jewelry sector, driven by ethical sourcing concerns and transparent origins, provide a significant impetus. Continuous technological advancements leading to larger deposition areas, faster growth rates, and reduced production costs are also crucial drivers, making MPCVD technology more attractive and economically viable for a broader range of applications, including automotive, aerospace, and medical device manufacturing.

Despite the robust growth drivers, the MPCVD equipment market faces several notable restraints. The primary impediment is the high initial capital investment required for purchasing and installing advanced MPCVD systems, which can be a significant barrier for new entrants or smaller businesses. The operational complexity of these systems, demanding highly skilled technicians and specialized knowledge for maintenance and process optimization, also acts as a restraint. High energy consumption, particularly for maintaining the microwave plasma and vacuum environment, contributes to operational costs, although ongoing innovations are addressing this. Competition from alternative diamond synthesis methods, such as High-Pressure/High-Temperature (HPHT) and other CVD variants, while not directly comparable in all applications, can still fragment market demand in certain segments. Additionally, the relatively nascent stage of some high-tech applications, like quantum computing, means that while they offer long-term potential, current demand may not fully offset the costs of widespread MPCVD adoption, leading to cautious investment from some quarters.

Opportunities within the MPCVD equipment market are substantial and diverse. The most compelling opportunities lie in emerging applications for diamond materials, particularly in quantum computing, where defect-engineered diamonds serve as qubits, and in advanced medical implants, due to their biocompatibility and hardness. Ongoing research and development efforts in synthesizing new diamond materials with tailored properties, such as nitrogen-vacancy centers for sensing and imaging, are constantly opening new market niches. Furthermore, the relentless pursuit of cost reduction through process innovation, automation, and larger-scale production facilities presents an opportunity to broaden the market reach of MPCVD diamonds into more price-sensitive applications. Regional expansion into developing economies with growing industrial bases and increasing disposable incomes also offers significant untapped potential. Broader impact forces, such as global supply chain disruptions affecting component availability, geopolitical tensions influencing trade policies, and stringent regulatory environments concerning energy efficiency and environmental impact, further shape the market landscape. However, the inherent robustness and superior material quality achievable with MPCVD position it favorably to overcome these challenges and capitalize on long-term growth trends in advanced materials and high-tech manufacturing.

Segmentation Analysis

The MPCVD Equipment Market is meticulously segmented to provide a granular understanding of its diverse components, application areas, and regional dynamics. This segmentation facilitates a comprehensive analysis of market trends, competitive landscapes, and growth opportunities across various categories. The primary segmentation criteria typically include diamond type (industrial, electronic, gemstone), application (cutting tools, heat sinks, semiconductor devices, jewelry), end-use industry (manufacturing, electronics, aerospace & defense, medical, research), reactor type (research-scale, production-scale, multi-wafer), and geographical regions. Understanding these distinct segments is crucial for stakeholders to tailor their product offerings, marketing strategies, and investment decisions, effectively catering to the specific needs and demands of different market verticals. This granular view highlights the specialized nature of demand and innovation driving growth in each segment, from high-volume industrial applications to highly specialized electronic and quantum technology requirements.

- By Diamond Type:

- Industrial Grade Diamond: Used in cutting tools, abrasives, drill bits, and wear-resistant coatings due to extreme hardness.

- Electronic Grade Diamond: High thermal conductivity, electrical insulation, and wide bandgap properties for semiconductors, heat sinks, and power electronics.

- Gemstone Grade Diamond: Optically pure, lab-grown diamonds used in jewelry, offering ethical and sustainable alternatives.

- By Application:

- Cutting and Abrasive Tools: For machining hard materials, polishing, and grinding.

- Heat Sinks and Spreaders: In high-power LEDs, laser diodes, CPUs, and RF devices for thermal management.

- Semiconductor Devices: As substrates, insulators, and active components in advanced electronics.

- Optical Components: For high-power laser windows and lenses due to transparency and thermal stability.

- Medical Devices: Biocompatible coatings, surgical instruments, and prosthetic components.

- Jewelry: Lab-grown diamonds as a sustainable and ethically sourced alternative to mined diamonds.

- Research & Development: For materials science studies, quantum computing, and novel applications.

- By Reactor Type:

- Research-Scale Systems: Smaller, more versatile reactors for R&D and specialized applications.

- Production-Scale Systems: Larger chambers, higher power, designed for high-volume manufacturing.

- Multi-Wafer Systems: Capable of processing multiple substrates simultaneously for increased throughput.

- By End-Use Industry:

- Manufacturing: Tools, coatings, and industrial wear parts.

- Electronics & Semiconductor: Thermal management, power electronics, advanced ICs.

- Aerospace & Defense: High-performance components, sensors.

- Healthcare & Medical: Implants, surgical tools, diagnostic equipment.

- Jewelry: Gemstone production.

- Energy: High-power switches, detectors.

- Research Institutions: Academic and industrial R&D.

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East and Africa (MEA)

Value Chain Analysis For MPCVD Equipment Market

The value chain for the MPCVD Equipment Market is a complex network of interconnected activities, beginning with upstream raw material and component suppliers and extending through to downstream diamond growers and diverse end-use industries. The upstream segment is critical, involving the procurement of specialized gases such as methane and hydrogen, which serve as the carbon source and growth environment for diamond synthesis. Furthermore, it encompasses the supply of high-purity vacuum components, microwave power generators (magnetrons, klystrons), advanced power supply units, temperature control systems, and sophisticated gas delivery and exhaust systems. Manufacturers of these highly technical components play a vital role in ensuring the performance, reliability, and efficiency of MPCVD reactors. Innovations in these upstream technologies, such as more powerful and stable microwave sources or more precise gas control systems, directly impact the capabilities and cost-effectiveness of the final MPCVD equipment, thus influencing the entire value chain.

Midstream activities primarily involve the design, engineering, manufacturing, assembly, and testing of the complete MPCVD equipment systems. This stage requires significant R&D investment to develop proprietary reactor designs, optimize plasma conditions, and integrate advanced automation and process control software. MPCVD equipment manufacturers typically undertake these core activities, drawing upon the specialized components from upstream suppliers. They focus on delivering systems that can achieve high diamond growth rates, superior material quality, and operational stability. Downstream in the value chain, the equipment is purchased by diamond growing companies, which specialize in synthesizing various grades of diamonds—industrial, electronic, or gemstone—to meet specific market demands. These companies then process the raw diamond material, which may involve cutting, polishing, and shaping, before selling them to an even further downstream network of end-use industries, including manufacturers of tools, electronics, jewelry, and medical devices.

The distribution channels for MPCVD equipment are predominantly direct, characterized by highly technical sales processes and direct engagement between equipment manufacturers and diamond growing firms or research institutions. Given the high capital cost and specialized nature of these systems, sales often involve extensive consultation, customization, and post-installation support, including training and maintenance services. Indirect channels, though less common, may involve specialized distributors or system integrators in certain regions, particularly for smaller, more standardized systems or for reaching niche markets. These indirect partners often provide local support and market access for global manufacturers. Effective management of this value chain, from ensuring the quality of upstream components to providing comprehensive downstream support, is crucial for market success. Optimization throughout the direct and indirect channels is key for market penetration, customer satisfaction, and the continuous evolution of MPCVD technology and its applications.

MPCVD Equipment Market Potential Customers

The potential customers for MPCVD equipment are diverse and span a wide array of industries, each seeking the unique properties that MPCVD-grown diamonds offer for their specific applications. Primarily, these customers include industrial diamond manufacturers who produce superabrasives, cutting tools, drilling components, and wear-resistant coatings where extreme hardness, thermal stability, and chemical inertness are paramount. These manufacturers leverage MPCVD technology to produce higher quality, more consistent diamonds than traditional methods, enhancing the performance and longevity of their products. As industries like automotive, aerospace, and construction continue to demand more efficient and durable materials, the need for advanced industrial diamonds from MPCVD systems escalates. This segment represents a foundational and consistently growing customer base, driven by the ongoing modernization and performance optimization across global manufacturing sectors.

Another significant customer segment comprises companies within the electronics and semiconductor industry. These firms utilize MPCVD-grown electronic-grade diamonds for advanced thermal management solutions, such as heat sinks and spreaders in high-power devices, where excellent thermal conductivity is critical for preventing overheating and ensuring device reliability. Beyond thermal applications, semiconductor companies are increasingly exploring diamond as a substrate for next-generation power electronics (e.g., inverters, converters), high-frequency devices, and even quantum computing applications due to its wide bandgap, high breakdown field, and ability to host stable quantum states. Research institutions and university laboratories also constitute a vital customer base, using MPCVD systems for fundamental materials science research, developing novel diamond-based devices, and exploring new frontiers in quantum technologies and advanced sensing, pushing the boundaries of what is possible with diamond materials.

Furthermore, the burgeoning lab-grown gemstone industry represents a rapidly expanding customer segment. Jewelry manufacturers and specialized diamond growers are investing in MPCVD equipment to produce high-quality, aesthetically identical diamonds that offer an ethical and sustainable alternative to mined gemstones. This segment is driven by evolving consumer preferences for transparent sourcing and reduced environmental impact, alongside the ability to produce large, flawless diamonds with precise specifications. Beyond these major segments, emerging applications are bringing new potential customers into the fold, including medical device manufacturers seeking biocompatible diamond coatings for implants and surgical instruments, and defense contractors exploring diamond's properties for specialized optical windows, high-power lasers, and radiation detection systems. The versatility and superior material properties of MPCVD diamonds continue to attract a broadening spectrum of end-users committed to innovation and high-performance material solutions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 1.1 Billion |

| Growth Rate | 12.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Element Six (De Beers Group), Sumitomo Electric Industries, Inc., CVD Equipment Corporation, II-VI Incorporated (Coherent Corp.), Akhan Semiconductor Inc., Heraeus Holding, OptoSigma Corporation, Cornes Technologies Ltd., Plassys Bestek, SCIO DIAMOND Technology Corporation, Diamond Foundry Inc., Washington Applied Physics (WAP), Seki Technotron Corp., Lambda Technologies, Shanghai Daheng Optics and Fine Mechanics Co., Ltd., Advanced Diamond Technologies, Inc., New Diamond Technology, Morgan Advanced Materials, St. Gobain Advanced Ceramics, Sino-Crystal Diamond Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

MPCVD Equipment Market Key Technology Landscape

The MPCVD Equipment Market is defined by a sophisticated technological landscape encompassing several critical innovations and specialized components that collectively enable the precise and efficient synthesis of high-quality diamonds. At its core, the technology relies on highly stable and powerful microwave plasma generation systems, typically operating at frequencies like 2.45 GHz or higher, to dissociate precursor gases into reactive species. The design of the microwave cavity and plasma chamber is paramount for achieving uniform plasma density and temperature distribution, which directly impacts the homogeneity and quality of the growing diamond film or crystal. Recent advancements in plasma coupling efficiency and magnetron technology are enabling larger plasma volumes and more stable growth environments, critical for producing bigger diamonds and for multi-wafer processing. The control over plasma conditions, including microwave power, gas pressure, and substrate temperature, is paramount for tailoring the diamond's properties, from its crystallinity to its impurity levels, which are essential for various applications from industrial cutting to quantum computing.

Beyond plasma generation, the MPCVD technology landscape includes advanced gas delivery systems capable of precise flow control for methane, hydrogen, and various dopant gases (e.g., nitrogen, boron, oxygen). These systems ensure the exact stoichiometry required for high-purity diamond growth and controlled doping, which is crucial for electronic and quantum applications. High-vacuum technology, comprising robust vacuum pumps and leak-tight chambers, is indispensable for maintaining the ultra-pure growth environment, preventing contamination that could degrade diamond quality. Temperature control systems, often utilizing resistive heating or optical pyrometry, are vital for maintaining the substrate at optimal growth temperatures, typically ranging from 700°C to 1200°C. The ability to precisely monitor and control these parameters in real-time is increasingly being integrated through sophisticated sensor arrays and automated feedback loops, enhancing process reproducibility and reducing reliance on manual adjustments. This technological synergy allows for unprecedented control over diamond properties, from hardness and thermal conductivity to optical and electronic characteristics.

Further technological advancements shaping the MPCVD market include in-situ monitoring and diagnostic tools, such as optical emission spectroscopy (OES) and Raman spectroscopy. These techniques allow for real-time analysis of plasma composition and diamond growth characteristics, providing critical data for process optimization and quality assurance without interrupting the growth cycle. Automation and robotic handling systems are also becoming more prevalent, particularly in production-scale MPCVD reactors, to minimize human intervention, reduce contamination risks, and increase throughput efficiency. The development of larger chamber designs and multi-wafer processing capabilities represents a significant step towards industrial-scale production, addressing the growing demand for cost-effective, high-volume diamond synthesis. Research is also ongoing in novel reactor configurations and advanced material precursors to achieve even faster growth rates, lower energy consumption, and the synthesis of new diamond-like materials with unique functionalities. These continuous innovations underscore a dynamic and rapidly evolving technological landscape, driven by the expanding potential of synthetic diamonds across a myriad of high-tech applications.

Regional Highlights

The global MPCVD Equipment Market exhibits distinct regional dynamics, influenced by varying levels of industrialization, technological adoption, investment in research and development, and consumer demand for synthetic diamonds.

- North America: This region is a significant market, characterized by strong R&D activities, particularly in advanced electronics, quantum computing, and aerospace & defense. The presence of leading technology companies and research institutions drives demand for high-end, specialized MPCVD systems. Investment in semiconductor manufacturing and a growing market for lab-grown diamonds further bolster regional growth. Innovation in process control and automation is a key trend, with companies focusing on developing next-generation systems for high-performance applications.

- Europe: Europe is another key market, known for its robust industrial manufacturing sector and significant contributions to materials science research. Countries like Germany, the UK, and France show strong demand for MPCVD diamonds in industrial tools, automotive components, and medical devices. The region also emphasizes sustainable production and ethical sourcing, which supports the growth of the lab-grown diamond segment. European market players are often at the forefront of developing energy-efficient and highly precise MPCVD technologies.

- Asia Pacific (APAC): APAC represents the largest and fastest-growing market for MPCVD equipment. This dominance is driven by massive investments in the semiconductor industry, particularly in China, South Korea, Taiwan, and Japan. Rapid industrialization, a burgeoning consumer market for lab-grown jewelry, and supportive government policies for advanced materials research fuel an accelerating demand. China, in particular, is a major producer and consumer of synthetic diamonds, making it a critical hub for both equipment manufacturing and diamond production.

- Latin America: This region is an emerging market for MPCVD equipment, with nascent but growing interest in industrial applications and potential for local gemstone production. Investment in manufacturing and infrastructure development is gradually increasing, which could drive future demand for advanced materials. However, market growth is currently slower compared to other regions due to economic factors and less established high-tech industries.

- Middle East and Africa (MEA): The MEA region is also an emerging market, showing increasing interest in industrial diamond applications, particularly in the oil & gas sector for drilling tools, and in construction. The region's growing affluence may also contribute to the adoption of lab-grown diamonds in the jewelry market. However, market penetration for MPCVD equipment is still in its early stages, relying largely on imports and a developing local industrial base.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the MPCVD Equipment Market.- Element Six (De Beers Group)

- Sumitomo Electric Industries, Inc.

- CVD Equipment Corporation

- II-VI Incorporated (Coherent Corp.)

- Akhan Semiconductor Inc.

- Heraeus Holding

- OptoSigma Corporation

- Cornes Technologies Ltd.

- Plassys Bestek

- SCIO DIAMOND Technology Corporation

- Diamond Foundry Inc.

- Washington Applied Physics (WAP)

- Seki Technotron Corp.

- Lambda Technologies

- Shanghai Daheng Optics and Fine Mechanics Co., Ltd.

- Advanced Diamond Technologies, Inc.

- New Diamond Technology

- Morgan Advanced Materials

- St. Gobain Advanced Ceramics

- Sino-Crystal Diamond Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the MPCVD Equipment market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is MPCVD technology and how does it work?

MPCVD (Microwave Plasma Chemical Vapor Deposition) is a high-tech process that uses microwave energy to create a plasma from carbon-rich gases (like methane and hydrogen). In this plasma, carbon atoms deposit onto a substrate, layer by layer, to grow high-quality synthetic diamonds with precise properties. It offers superior control over purity and crystal structure compared to other methods.

What are the primary applications of MPCVD-grown diamonds?

MPCVD-grown diamonds are used across diverse sectors: in industrial applications for cutting tools and abrasives, in electronics for heat sinks and semiconductor devices due to their thermal and electrical properties, and in the gemstone industry for creating high-quality, ethically sourced lab-grown diamonds for jewelry.

What are the main drivers for the growth of the MPCVD Equipment Market?

The market is driven by increasing demand for synthetic diamonds in high-tech industries (semiconductors, advanced manufacturing), the rising popularity of lab-grown gemstones, and continuous technological advancements in MPCVD systems that improve efficiency, scalability, and cost-effectiveness of diamond production.

What challenges does the MPCVD Equipment Market face?

Key challenges include the high initial capital investment for MPCVD systems, their operational complexity requiring specialized expertise, and competition from alternative diamond synthesis methods. High energy consumption and the nascent stage of some high-tech applications also present restraints to market expansion.

How is AI impacting the MPCVD Equipment Market?

AI is significantly impacting MPCVD by optimizing complex process parameters for consistent diamond growth, automating quality control through machine vision, enabling predictive maintenance of equipment, and accelerating the discovery of new diamond properties. This leads to increased efficiency, reduced costs, and enhanced material quality.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager