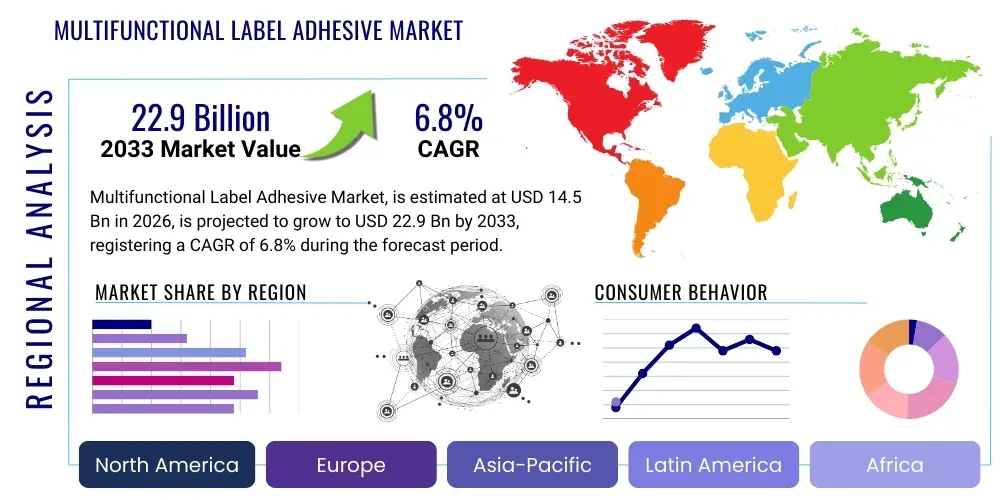

Multifunctional Label Adhesive Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 434750 | Date : Dec, 2025 | Pages : 255 | Region : Global | Publisher : MRU

Multifunctional Label Adhesive Market Size

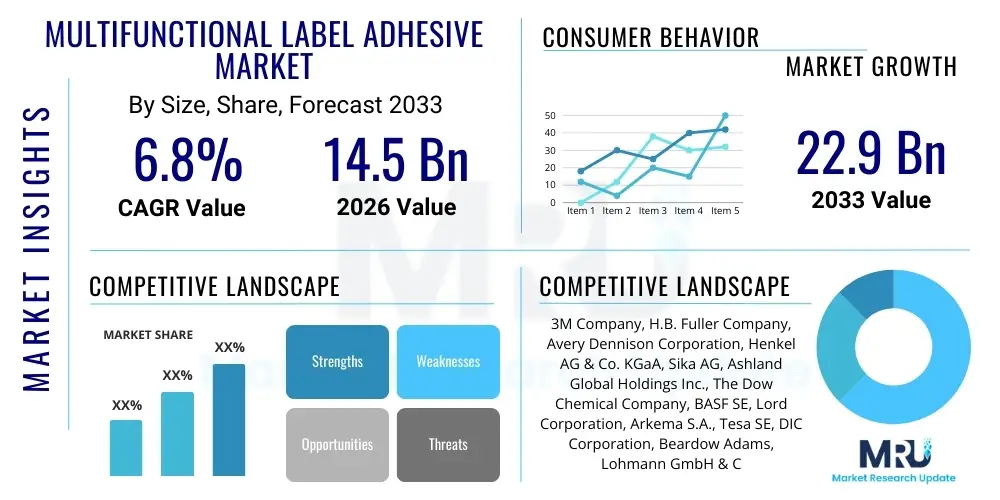

The Multifunctional Label Adhesive Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 14.5 Billion in 2026 and is projected to reach USD 22.9 Billion by the end of the forecast period in 2033. This robust expansion is primarily driven by the increasing complexity of labeling requirements across high-growth sectors such as logistics, food and beverage packaging, and specialized medical device labeling, necessitating adhesives that offer superior performance under diverse environmental stresses.

Multifunctional Label Adhesive Market introduction

The Multifunctional Label Adhesive Market encompasses a specialized range of pressure-sensitive adhesives (PSAs) designed to adhere labels to various substrates, offering performance characteristics beyond basic adhesion. These adhesives are engineered to provide exceptional resilience against factors such as extreme temperatures, moisture, chemical exposure, and UV radiation, often incorporating features like easy removability, high tack, or specific optical clarity requirements. Major applications span demanding industries including specialized packaging, automotive parts identification, pharmaceutical tracking, and electronics component labeling, where label integrity is critical for regulatory compliance and product lifecycle management. The core benefits include enhanced durability, improved operational efficiency through high-speed application, and adaptability to complex or textured surfaces. Key driving factors include the rapid expansion of e-commerce, which demands durable transit labeling, stringent regulatory standards in pharmaceuticals requiring high-performance tracking labels, and continuous innovations in substrate materials (such as low surface energy plastics) which necessitate advanced adhesive formulations.

Multifunctional Label Adhesive Market Executive Summary

The Multifunctional Label Adhesive Market is experiencing significant upward momentum, underpinned by transformative business trends focusing on sustainability and application versatility. Global businesses are shifting towards water-based and UV-cured adhesive technologies to meet environmental mandates and reduce volatile organic compound (VOC) emissions, driving substantial R&D investment among leading manufacturers. Regionally, the Asia Pacific (APAC) continues its dominance, fueled by massive growth in its manufacturing base, particularly in electronics and fast-moving consumer goods (FMCG), though North America and Europe maintain technological leadership and set stringent performance standards, particularly in the healthcare and automotive sectors. Segment trends indicate a pronounced shift towards specialized acrylic-based adhesives due to their superior resistance to heat and chemicals, while the hot melt segment, traditionally application-heavy, is evolving towards reactive hot melts to enhance performance characteristics, thereby securing sustained growth across all geographic and application boundaries.

AI Impact Analysis on Multifunctional Label Adhesive Market

Analysis of common user questions related to the impact of AI on the Multifunctional Label Adhesive Market reveals key user concerns centering around AI's potential to revolutionize material science R&D, optimize complex manufacturing processes, and improve supply chain predictability. Users frequently inquire about how machine learning algorithms can accelerate the discovery of novel adhesive formulations with specialized multifunctionality, particularly those combining environmental sustainability with high-performance characteristics like permanent adhesion on recycled plastics or clean removability from sensitive components. Furthermore, significant interest exists regarding the use of AI-driven vision systems for quality control in high-speed labeling operations and predictive maintenance for adhesive coating machinery. Overall, users anticipate AI will fundamentally enhance both the speed of innovation in adhesive formulation and the efficiency and consistency of label production and application, leading to highly customized, defect-free labeling solutions.

- AI-driven material informatics accelerates the discovery of new bio-based or low-VOC adhesive chemistries.

- Machine learning optimizes curing parameters (UV intensity, temperature) for enhanced adhesive performance and faster production lines.

- Predictive analytics improves demand forecasting for specialized adhesive materials, reducing inventory costs and supply chain disruptions.

- AI-powered vision systems ensure ultra-precise application and defect detection, especially critical for high-tolerance automotive and medical labels.

- Robotics and AI integration optimize automated labeling processes for complex packaging shapes and non-standardized substrates.

DRO & Impact Forces Of Multifunctional Label Adhesive Market

The Multifunctional Label Adhesive Market is shaped by a critical balance of stimulating growth drivers, restricting regulatory hurdles, and expansive opportunities, all interacting as powerful impact forces. Key drivers include the exponential expansion of e-commerce and logistics, necessitating robust, weather-resistant labels for global transit, alongside increasingly stringent governmental regulations, particularly in the pharmaceutical and food industries, demanding tamper-evident and track-and-trace labeling capabilities. Restraints primarily involve the volatile pricing of petrochemical raw materials, which are core components of traditional adhesive polymers, and the technical challenge of developing high-performance adhesives that strictly comply with VOC emission standards and recyclability guidelines. Opportunities lie predominantly in the rapid development of specialized bio-based and smart adhesives (e.g., color-changing indicators, temperature sensors) and the untapped potential in emerging markets for advanced labeling technologies. These factors exert intense impact forces on market dynamics, compelling manufacturers to focus on innovation in sustainable chemistries and efficiency improvements to maintain competitive advantage and meet evolving user demands.

Segmentation Analysis

The Multifunctional Label Adhesive Market is broadly segmented based on its chemical type, technological method, and end-use application, providing a nuanced view of diverse market needs and technological trajectories. Segmentation by chemical type includes high-performance acrylics, versatile rubber-based compounds, and specialized silicones, reflecting variations in required bonding strength, temperature resistance, and substrate compatibility. Technological segmentation highlights the shift towards more sustainable and efficient processes, emphasizing water-based, solvent-based, hot melt, and UV-curable systems, with UV-curing gaining prominence for high-speed, low-VOC applications. The application landscape is crucial, spanning high-volume packaging, rigorous automotive and electronics assembly, and highly regulated healthcare uses. Each segment demands unique adhesive multifunctionality, driving customized product development and specialization across the value chain, ensuring that adhesives meet specific industry performance benchmarks.

- By Chemistry Type:

- Acrylic

- Rubber-based (Synthetic and Natural)

- Silicone

- Polyurethane

- Others (Epoxies, etc.)

- By Technology:

- Water-based

- Solvent-based

- Hot Melt

- UV Curing

- By Application:

- Packaging (Food & Beverage, Consumer Goods)

- Automotive

- Consumer Durables

- Healthcare and Medical

- Electronics and Electrical

- Logistics and Transit

Value Chain Analysis For Multifunctional Label Adhesive Market

The value chain for the Multifunctional Label Adhesive Market is complex, starting with the upstream production of specialized raw materials, including polymers, tackifiers, resins, and solvents, often derived from petrochemical sources. Key upstream activities involve intensive R&D by chemical suppliers to develop next-generation bio-based or functionalized raw ingredients that enhance adhesive properties like temperature resistance and peel strength. The midstream involves adhesive formulators and manufacturers who blend, compound, and coat these raw materials onto various label facestocks and release liners. This formulation stage is highly technology-intensive, focusing on achieving precise viscosity and performance metrics for specific end-use environments. Downstream activities involve label converters and printers who apply the adhesive-coated stock, followed by distributors who channel the final label products to diverse end-user industries such as FMCG, logistics hubs, and pharmaceutical manufacturers. Distribution channels are highly fragmented, leveraging both direct sales for large industrial clients requiring custom formulations and indirect sales through specialized label distributors catering to smaller and medium-sized enterprises, ensuring broad market reach and application support.

Multifunctional Label Adhesive Market Potential Customers

Potential customers for multifunctional label adhesives represent a broad spectrum of industries where label integrity, durability, and specific performance characteristics are non-negotiable requirements for operations and compliance. Primary end-users include large-scale packaging companies (especially in chilled, frozen, or retort food segments), automotive manufacturers requiring durable asset tags resistant to engine heat and oils, and major electronics assemblers needing thin, high-performance labels for tracking components through harsh manufacturing processes. The healthcare sector is a pivotal consumer, utilizing these adhesives for blood bag labeling (withstanding sterilization and extreme cold storage), device tracking, and tamper-evident seals on drug packaging. Furthermore, the burgeoning logistics sector, driven by global e-commerce, represents a massive customer base for transit labels that must maintain adhesion across varied climates and handling conditions, making performance and reliability key purchasing criteria for these sophisticated buyers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 14.5 Billion |

| Market Forecast in 2033 | USD 22.9 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | 3M Company, H.B. Fuller Company, Avery Dennison Corporation, Henkel AG & Co. KGaA, Sika AG, Ashland Global Holdings Inc., The Dow Chemical Company, BASF SE, Lord Corporation, Arkema S.A., Tesa SE, DIC Corporation, Beardow Adams, Lohmann GmbH & Co. KG, Momentive Performance Materials Inc., Wacker Chemie AG, Jowat SE, Evans Adhesive Corporation, Intertape Polymer Group, Cimbar Performance Minerals. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Multifunctional Label Adhesive Market Key Technology Landscape

The technological landscape of the Multifunctional Label Adhesive market is characterized by a push for faster curing speeds, higher environmental performance, and enhanced functional properties tailored for specific end-use conditions. A primary technological driver is the maturation of UV-curable adhesives, which offer rapid curing times and 100% solids formulation, eliminating VOC emissions and significantly improving production efficiency, particularly in pressure-sensitive labeling applications. Simultaneously, water-based acrylic emulsions continue to see significant innovation, focusing on achieving performance comparable to traditional solvent-based systems while remaining environmentally benign. These advancements involve micro-emulsion polymerization techniques that allow for greater control over polymer structure and adhesive properties, crucial for achieving strong adhesion on difficult, low-surface-energy substrates.

Another major area of technological focus involves the development of reactive hot melts (PUR Hot Melts) and high-performance synthetic rubber-based formulations that deliver superior bond strength and temperature resistance required for demanding automotive and industrial applications. These new formulations often incorporate tackifying resins derived from sustainable sources, blending high performance with reduced environmental footprint. Furthermore, the integration of smart technologies is emerging, with research concentrated on developing adhesives that can signal status (e.g., tamper-evidence through color change or peel indicators) or incorporate conductive properties for electronic functionality. These technical leaps ensure that adhesive performance keeps pace with rapid material changes in packaging and product design, particularly the shift towards thinner films and highly recyclable materials.

The market also heavily relies on advanced coating and application technologies, including precision slot die coating and high-speed rotary printing processes. Manufacturers invest heavily in machinery that ensures ultra-uniform adhesive thickness and consistency across large web widths, minimizing material waste and maximizing the functional performance of the final label. The adoption of AI and sensor technology in these coating processes is becoming standard practice, allowing for real-time adjustments and quality assurance, thereby pushing the boundaries of what specialized label adhesives can achieve in terms of reliability and efficiency.

Regional Highlights

The global market for multifunctional label adhesives exhibits distinct regional dynamics driven by varying levels of industrialization, regulatory pressures, and consumer demands across major geographic zones. Asia Pacific (APAC) currently dominates the market both in volume and value, propelled by the immense manufacturing and export activity across countries like China, India, and Southeast Asian nations. The region's robust growth in electronics assembly, automotive production, and the massive expansion of the food and beverage industry necessitate continuous large-scale demand for cost-effective, high-volume labeling solutions. Furthermore, increasing urbanization and the rise of organized retail in APAC amplify the need for sophisticated packaging and logistics labels, making it the central hub for manufacturing and consumption.

North America and Europe represent mature markets characterized by high technological adoption, stringent environmental standards, and a strong focus on specialized, high-margin applications. These regions lead the innovation curve, particularly in the adoption of bio-based, solvent-free, and UV-cured adhesives, driven by regulatory mandates such as the European Union’s REACH regulation and rising consumer preference for sustainable products. North America’s strength lies in the high-tech sectors, including advanced automotive components and complex medical device labeling, demanding adhesives with extreme durability and compliance with FDA regulations. Europe, meanwhile, focuses heavily on pharmaceutical track-and-trace requirements and sustainable packaging initiatives, demanding highly specialized, tamper-evident labels.

Latin America (LATAM), the Middle East, and Africa (MEA) are emerging regions offering significant long-term growth potential, though they currently possess smaller market shares. LATAM's growth is tied to developing industrial capacity, particularly in Brazil and Mexico, focusing initially on standard packaging applications but gradually moving towards more complex industrial needs. The MEA region, particularly the Gulf Cooperation Council (GCC) countries, is investing heavily in infrastructure, construction, and diversified manufacturing, driving demand for industrial and durable goods labeling. As regulatory environments mature and quality standards rise across these emerging regions, the consumption of high-performance multifunctional label adhesives is expected to accelerate dramatically, creating new avenues for market penetration and expansion by global players.

- Asia Pacific (APAC): Dominates the market due to robust manufacturing sectors (Electronics, FMCG), high volume consumption, and rapid e-commerce expansion. Key markets include China, India, and Japan.

- North America: Focuses on high-performance, specialized applications (Medical, Automotive) and leads in technological adoption of sustainable adhesive solutions. Strong emphasis on regulatory compliance and high-value labels.

- Europe: Characterized by stringent environmental regulations (REACH), driving demand for low-VOC and bio-based adhesives. Significant market pull from pharmaceutical traceability requirements and sustainable packaging mandates.

- Latin America (LATAM): Emerging market growth driven by industrialization and increasing modern retail penetration, leading to rising demand for standard and semi-specialized labels, primarily in Brazil and Mexico.

- Middle East and Africa (MEA): Growth tied to infrastructure development and diversification of industrial bases, creating demand for durable industrial and asset tracking labels.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Multifunctional Label Adhesive Market.- 3M Company

- H.B. Fuller Company

- Avery Dennison Corporation

- Henkel AG & Co. KGaA

- Sika AG

- Ashland Global Holdings Inc.

- The Dow Chemical Company

- BASF SE

- Lord Corporation

- Arkema S.A.

- Tesa SE

- DIC Corporation

- Beardow Adams

- Lohmann GmbH & Co. KG

- Momentive Performance Materials Inc.

- Wacker Chemie AG

- Jowat SE

- Evans Adhesive Corporation

- Intertape Polymer Group

- Cimbar Performance Minerals

- Paramelt B.V.

- Mactac, LLC

- ITW Performance Polymers

- Cyberbond LLC

- Toyo Ink SC Holdings Co., Ltd.

- Dymax Corporation

- Franklin International

- Delo Industrial Adhesives

Frequently Asked Questions

Analyze common user questions about the Multifunctional Label Adhesive market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between standard and multifunctional label adhesives?

Standard label adhesives provide basic adhesion to common substrates, whereas multifunctional label adhesives are engineered with specialized chemistries to withstand extreme conditions such as high temperatures, chemical exposure, deep freeze environments, or offer features like clean removability and tamper-evidence, critical for highly regulated industries.

Which technological segment is expected to show the highest growth rate?

The UV Curing technology segment is projected to exhibit the highest growth rate due to its environmental benefits (low-VOC content) and operational advantages, including extremely fast curing speeds, which enhance production throughput in demanding packaging and high-speed labeling applications globally.

How do sustainability mandates impact the development of new label adhesives?

Sustainability mandates, driven by regulatory bodies and consumer preferences, force manufacturers to prioritize the development of bio-based materials, water-based formulations, and low-VOC (volatile organic compound) adhesives. There is also a significant push for adhesives that do not impede the recyclability of labeled packaging materials, such as wash-off or compostable variants.

Which application segment drives the largest demand for multifunctional label adhesives?

The Packaging application segment, particularly covering food and beverage, consumer goods, and the expansive logistics industry, currently accounts for the largest volume of demand. This is driven by the necessity for durable, safe, and regulated labels that maintain integrity throughout the supply chain, from manufacturing to consumer use, including specialized requirements for chilled and frozen goods.

What role does the automotive industry play in the multifunctional label adhesive market?

The automotive sector is a key market for high-performance multifunctional adhesives, requiring durable labels for component tracking, VIN plates, and harsh engine compartment applications. These labels must endure high heat, exposure to oils and solvents, and mechanical abrasion, necessitating advanced acrylic or silicone-based formulations with extreme resistance and longevity.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager