Multitube Heat Exchanger Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439243 | Date : Jan, 2026 | Pages : 251 | Region : Global | Publisher : MRU

Multitube Heat Exchanger Market Size

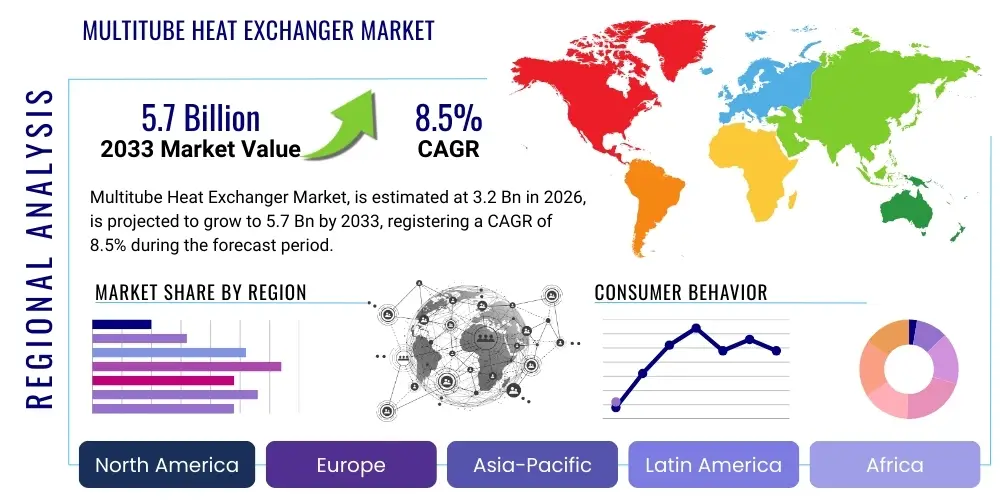

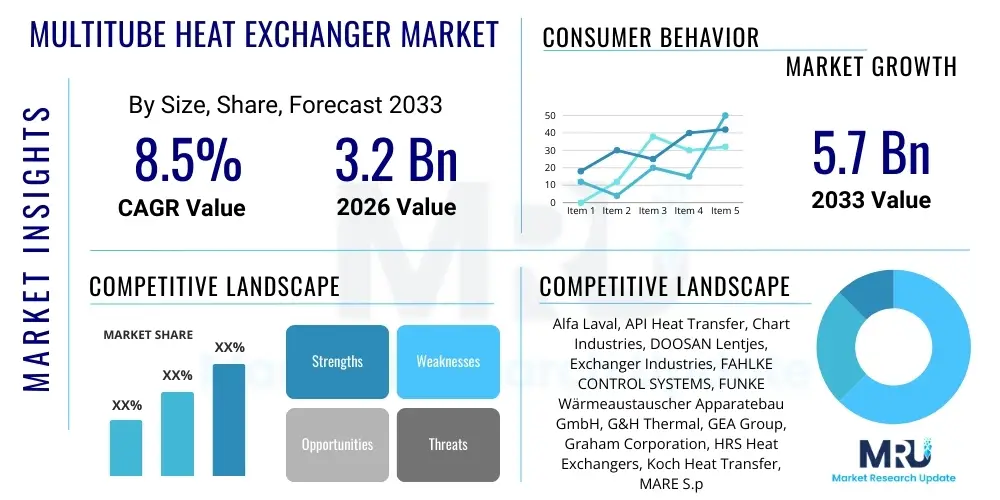

The Multitube Heat Exchanger Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2026 and 2033. The market is estimated at USD 3.2 Billion in 2026 and is projected to reach USD 5.7 Billion by the end of the forecast period in 2033.

Multitube Heat Exchanger Market introduction

Multitube heat exchangers are critical components in numerous industrial processes, facilitating efficient heat transfer between two or more fluids at different temperatures. These devices, characterized by a bundle of tubes encased within a cylindrical shell, are engineered to optimize thermal exchange while minimizing energy consumption. Their robust design allows for handling diverse fluids, including liquids, gases, and steam, across a wide range of operating pressures and temperatures. The market for multitube heat exchangers is primarily driven by the continuous demand for energy-efficient solutions and process optimization in heavy industries.

Major applications span across the chemical and petrochemical sectors, oil and gas processing, power generation, HVAC and refrigeration, and the food and beverage industry. In chemical plants, they are indispensable for reactions, condensation, and evaporation processes. In oil and gas, they play a vital role in crude oil refining, gas processing, and liquefaction. Benefits of multitube heat exchangers include their high thermal efficiency, durability, flexibility in design to accommodate various fluid properties, and relatively compact footprint compared to other heat exchange technologies. Their ability to manage corrosive and high-pressure fluids further enhances their utility in demanding industrial environments.

Driving factors for market growth include the global push for industrialization, particularly in emerging economies, alongside stringent environmental regulations mandating reduced energy consumption and emissions. Advancements in material science and manufacturing techniques are also contributing to the development of more efficient and durable multitube heat exchangers, expanding their application scope. The increasing complexity of industrial processes and the need for reliable, high-performance equipment continue to fuel innovation and adoption within this specialized market segment.

Multitube Heat Exchanger Market Executive Summary

The Multitube Heat Exchanger Market is experiencing robust growth, propelled by sustained expansion in industrial sectors globally and an escalating demand for energy efficiency. Business trends indicate a strong focus on customization and the integration of advanced materials to enhance performance and longevity. Manufacturers are increasingly investing in research and development to offer specialized solutions tailored to specific industry requirements, such as those in cryogenic applications or high-fouling environments. The shift towards sustainable industrial practices is also driving innovation in designs that optimize energy recovery and minimize environmental impact. Consolidation among key players and strategic partnerships are becoming more prevalent, aimed at expanding market reach and technological capabilities.

Regional trends highlight the Asia Pacific (APAC) as a dominant and rapidly growing market, driven by rapid industrialization, burgeoning chemical and petrochemical industries, and extensive infrastructure development, particularly in countries like China and India. North America and Europe, while mature, demonstrate steady growth fueled by the modernization of existing industrial facilities, strict energy efficiency mandates, and a strong emphasis on technological advancements and automation. The Middle East and Africa (MEA) region shows significant potential due to ongoing investments in oil and gas exploration and production, as well as the diversification of their industrial bases. Latin America also presents growth opportunities, particularly in its expanding mining, food processing, and chemical sectors.

Segmentation trends reveal a continued preference for fixed tubesheet and U-tube heat exchangers due to their reliability and cost-effectiveness. However, the demand for more specialized types like floating head and kettle type exchangers is rising in applications requiring frequent cleaning or handling of thermal expansion. In terms of material, stainless steel remains a primary choice for its corrosion resistance and durability, but there is a growing interest in high-performance alloys like titanium and nickel alloys for extreme operating conditions. Application-wise, the chemical and petrochemical industries consistently represent the largest segment, with significant growth also observed in power generation and the burgeoning pharmaceutical sector, driven by increasing regulatory scrutiny and production demands for high-purity processes.

AI Impact Analysis on Multitube Heat Exchanger Market

The integration of Artificial Intelligence (AI) is set to revolutionize the Multitube Heat Exchanger Market by addressing common user questions related to operational efficiency, predictive maintenance, and optimal design. Users frequently inquire about how to reduce unplanned downtime, extend equipment lifespan, and fine-tune heat transfer performance in dynamic operating conditions. They also seek methods to accelerate design cycles and optimize material selection for enhanced durability and cost-effectiveness. AI-driven solutions offer direct answers to these challenges, promising a paradigm shift from reactive to proactive management and design processes. The key themes revolve around maximizing uptime, minimizing energy consumption, and achieving unprecedented levels of precision in both manufacturing and operation, thereby significantly enhancing the return on investment for end-users.

- Predictive maintenance analytics: AI algorithms analyze sensor data to forecast potential failures, enabling proactive repairs and reducing costly downtime.

- Operational optimization: Machine learning models continuously adjust operating parameters for maximum thermal efficiency and energy savings in real-time.

- Advanced design and simulation: AI-powered tools accelerate the design process by optimizing tube configurations, materials, and flow paths for specific applications, reducing prototyping costs.

- Material science innovation: AI assists in discovering and developing new high-performance materials suitable for extreme temperature and corrosive environments, enhancing durability.

- Automated quality control: AI-driven vision systems can detect manufacturing defects with high precision, ensuring consistent product quality and reliability.

- Demand forecasting and supply chain optimization: AI algorithms improve forecasting accuracy for spare parts and new unit demand, streamlining inventory and production.

- Energy footprint reduction: AI identifies opportunities for heat recovery and integration into broader plant energy management systems, contributing to sustainability goals.

DRO & Impact Forces Of Multitube Heat Exchanger Market

The Multitube Heat Exchanger Market is significantly influenced by a complex interplay of drivers, restraints, and opportunities, all shaped by various impact forces. Key drivers include the escalating global demand for energy-efficient industrial solutions, stringent environmental regulations mandating reduced emissions and optimized resource utilization, and the robust expansion of process industries such as chemical, petrochemical, oil and gas, and power generation, particularly in emerging economies. The continuous need for upgrading and modernizing aging infrastructure in developed regions also contributes to sustained market demand. Furthermore, the inherent reliability and versatility of multitube heat exchangers across diverse applications solidify their position as essential industrial equipment, ensuring a stable foundation for market growth.

However, the market also faces notable restraints. The high initial capital investment required for multitube heat exchangers, especially for specialized materials and complex designs, can deter potential buyers, particularly small and medium-sized enterprises. The complexity of maintenance, which often requires specialized skills and tools, along with potential issues like fouling, corrosion, and leakage, adds to operational costs and can impact adoption rates. Volatility in raw material prices, such as steel, copper, and specialized alloys, directly affects manufacturing costs and, consequently, the final product pricing, leading to market uncertainties. Furthermore, the availability of alternative heat exchange technologies, though perhaps less versatile, presents competitive pressure in certain application niches.

Despite these challenges, significant opportunities exist for market expansion. The growing focus on customization and the development of advanced heat exchanger designs tailored for specific, high-performance applications offer lucrative avenues. The integration of smart technologies, such as IoT sensors and AI for predictive maintenance and operational optimization, represents a substantial growth area, enhancing efficiency and reducing lifecycle costs. Emerging economies, with their rapid industrialization and increasing energy demands, offer untapped potential. The rising adoption of renewable energy sources and waste heat recovery systems also creates new applications for multitube heat exchangers, driving demand for innovative and sustainable solutions. Strategic collaborations and technological advancements in material science will further unlock new market frontiers.

Segmentation Analysis

The Multitube Heat Exchanger Market is comprehensively segmented by various criteria, including product type, material of construction, application, and end-use industry. This segmentation provides a granular view of market dynamics, revealing key trends, growth pockets, and competitive landscapes within specific categories. Understanding these segments is crucial for stakeholders to identify target markets, develop tailored product offerings, and formulate effective business strategies. The market's diverse applications across a multitude of industries necessitate such detailed segmentation, reflecting the wide range of operational requirements and material compatibilities demanded by different process environments. Each segment contributes uniquely to the overall market growth, influenced by specific technological advancements, regulatory frameworks, and economic factors.

- By Type

- Fixed Tubesheet Heat Exchangers

- U-Tube Heat Exchangers

- Floating Head Heat Exchangers

- Kettle Type Heat Exchangers

- Bayonet Type Heat Exchangers

- Others (e.g., Double Pipe, Plate and Shell)

- By Material

- Stainless Steel

- Carbon Steel

- Titanium

- Nickel Alloys

- Copper & Copper Alloys

- Exotic Materials (e.g., Hastelloy, Inconel)

- Others

- By Application

- Chemical & Petrochemical Processing

- Oil & Gas Industry

- Power Generation (Conventional & Nuclear)

- HVAC & Refrigeration

- Food & Beverage Processing

- Pharmaceutical & Biotechnology

- Pulp & Paper Industry

- Water & Wastewater Treatment

- Marine Industry

- Others

- By End-Use Industry

- Manufacturing Sector

- Processing Sector

- Energy Sector

- Utilities

- Construction

Value Chain Analysis For Multitube Heat Exchanger Market

The value chain for the Multitube Heat Exchanger Market encompasses a series of interconnected activities, beginning from raw material sourcing and extending to end-user utilization and after-sales services. Upstream analysis involves the procurement of essential raw materials such as various grades of steel (stainless, carbon), titanium, nickel alloys, and copper, which are sourced from primary metal producers. Component manufacturers then transform these raw materials into tubes, shells, baffles, and other specialized parts required for heat exchanger assembly. The quality and availability of these raw materials and components directly impact manufacturing costs and product performance. Innovation in metallurgy and material science at this stage can significantly influence the final product's efficiency and longevity, fostering differentiation within the market.

Midstream activities involve the design, manufacturing, and assembly of the multitube heat exchangers. This stage requires specialized engineering expertise for thermal and mechanical design, adherence to industry standards (e.g., ASME, TEMA), and advanced manufacturing processes including welding, fabrication, and quality assurance testing. Manufacturers may range from large multinational corporations to specialized regional players, each focusing on different scales of production and levels of customization. The adoption of advanced manufacturing technologies, such as automation and precision machining, can improve production efficiency, reduce lead times, and enhance product quality, thereby strengthening a manufacturer's competitive position.

Downstream analysis covers distribution channels and engagement with end-users. Multitube heat exchangers are typically distributed through a combination of direct sales channels, where manufacturers engage directly with large industrial clients, and indirect channels, involving a network of distributors, agents, and engineering procurement and construction (EPC) firms. EPC companies often integrate heat exchangers into larger industrial projects, serving as key intermediaries. After-sales services, including installation, commissioning, maintenance, repair, and spare parts supply, are crucial for customer satisfaction and long-term relationships. Direct sales offer closer customer relationships and customization opportunities, while indirect channels provide broader market reach. Both are vital for effective market penetration and sustaining competitive advantage in this capital-intensive industry.

Multitube Heat Exchanger Market Potential Customers

The primary end-users and buyers of multitube heat exchangers span a broad spectrum of industrial sectors, all requiring efficient heat transfer solutions for their processes. Chemical and petrochemical plants constitute a significant customer base, utilizing these exchangers for various operations such as reaction cooling, solvent condensation, reboiling, and feed preheating. Similarly, the oil and gas industry relies heavily on multitube heat exchangers for refining crude oil, gas processing, liquefaction of natural gas, and offshore platform operations, where robust and reliable equipment is paramount for continuous operation in harsh environments. These industries typically demand large-scale, high-pressure, and often custom-designed units.

Beyond the heavy process industries, power generation facilities, including conventional thermal power plants, nuclear power plants, and renewable energy installations, are crucial customers. They employ multitube heat exchangers for steam generation, turbine exhaust condensation, and cooling systems. The HVAC and refrigeration sector also represents a substantial market, particularly for industrial cooling and heating applications, although the scale and specific designs may differ from process industries. Food and beverage processing companies utilize these exchangers for pasteurization, sterilization, chilling, and heating various food products, where hygiene and material compatibility are critical considerations for food safety.

Furthermore, the pharmaceutical and biotechnology industries require highly specialized multitube heat exchangers, often made from exotic materials, for aseptic processing, sterilization, and temperature control of sensitive compounds, adhering to stringent regulatory standards. The pulp and paper industry, metal processing plants, and water and wastewater treatment facilities also form part of the diverse customer ecosystem, each having unique demands for heat transfer efficiency, corrosion resistance, and operational reliability. The increasing complexity and specialization within these industries drive the demand for tailored multitube heat exchanger solutions, emphasizing performance, energy efficiency, and compliance with industry-specific regulations.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 3.2 Billion |

| Market Forecast in 2033 | USD 5.7 Billion |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Alfa Laval, API Heat Transfer, Chart Industries, DOOSAN Lentjes, Exchanger Industries, FAHLKE CONTROL SYSTEMS, FUNKE Wärmeaustauscher Apparatebau GmbH, G&H Thermal, GEA Group, Graham Corporation, HRS Heat Exchangers, Koch Heat Transfer, MARE S.p.A., Manning & Lewis, Mersen, Mueller Industries, NIBE Industrier AB, OHM Group, S.A., Secespol, SPX Flow. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Multitube Heat Exchanger Market Key Technology Landscape

The Multitube Heat Exchanger Market is continuously evolving with significant technological advancements aimed at enhancing efficiency, durability, and operational flexibility. One critical area is the development and application of advanced materials. This includes high-performance alloys such as titanium, Hastelloy, and Inconel, which offer superior corrosion resistance and strength at elevated temperatures, thereby extending the lifespan and application range of heat exchangers in harsh chemical and petrochemical environments. Research into novel coating technologies also plays a vital role in mitigating fouling and erosion, which are common operational challenges that impact efficiency and maintenance costs. These material innovations are crucial for meeting increasingly stringent performance and reliability demands across various industrial sectors.

Another significant technological trend involves the increasing adoption of sophisticated design and simulation software. Computational Fluid Dynamics (CFD) and Finite Element Analysis (FEA) tools enable engineers to accurately model fluid flow, heat transfer, and structural integrity under diverse operating conditions, optimizing designs for maximum thermal efficiency and mechanical robustness before physical prototyping. This reduces development cycles and costs while improving predictive capabilities for performance. Furthermore, the integration of Additive Manufacturing (3D printing) is beginning to revolutionize the production of complex internal geometries and specialized components, allowing for customized heat transfer surfaces that were previously impossible to achieve through traditional manufacturing methods, leading to higher efficiency and more compact designs.

The convergence of Multitube Heat Exchangers with Industry 4.0 technologies is also transforming the market. This includes the incorporation of advanced sensors for real-time monitoring of temperature, pressure, flow rates, and vibration, providing critical operational data. These sensors, coupled with the Internet of Things (IoT), enable remote monitoring and data collection. The collected data is then fed into Artificial Intelligence (AI) and Machine Learning (ML) algorithms, which facilitate predictive maintenance, anomaly detection, and real-time operational optimization. This intelligent integration enhances equipment reliability, minimizes unplanned downtime, and optimizes energy consumption, paving the way for smart, self-optimizing heat transfer systems that are crucial for modern industrial efficiency and sustainability goals.

Regional Highlights

- North America: This region showcases a mature market, driven by robust industrial infrastructure, a strong focus on energy efficiency, and stringent environmental regulations. Key countries like the United States and Canada are witnessing significant investments in upgrading existing facilities in the chemical, oil & gas, and power generation sectors, fostering demand for high-performance and customized multitube heat exchangers. Technological adoption and R&D activities are also prominent, leading to innovation in smart and efficient designs.

- Europe: Similar to North America, Europe is characterized by mature industrial sectors with a strong emphasis on sustainability and energy conservation. Germany, the UK, France, and Italy are leading markets, driven by stringent EU directives on energy efficiency and emissions reduction. The region also boasts a strong presence of specialized heat exchanger manufacturers and a growing demand for advanced materials and compact designs for renewable energy integration and pharmaceutical applications.

- Asia Pacific (APAC): APAC is the fastest-growing market globally, propelled by rapid industrialization, massive infrastructure development, and burgeoning chemical, petrochemical, and manufacturing industries in China, India, and Southeast Asian countries. The region benefits from increasing foreign direct investment, expanding industrial capacities, and a growing energy demand, leading to high adoption rates of multitube heat exchangers for various process applications.

- Latin America: This region presents significant growth potential, primarily driven by expanding mining operations, a growing chemical industry, and investments in oil & gas exploration and production, particularly in Brazil and Mexico. The need for modernizing industrial processes and improving energy efficiency is a key driver, although economic volatility can sometimes impact investment cycles.

- Middle East and Africa (MEA): The MEA region's market is heavily influenced by its extensive oil and gas industry, with Saudi Arabia, UAE, and Qatar being major contributors. Large-scale investments in refineries, petrochemical complexes, and power generation projects are fueling demand for robust and high-capacity multitube heat exchangers. Industrial diversification initiatives in countries like Saudi Arabia are also opening new avenues for market growth beyond traditional hydrocarbon sectors.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Multitube Heat Exchanger Market.- Alfa Laval

- API Heat Transfer

- Chart Industries

- DOOSAN Lentjes

- Exchanger Industries Ltd.

- FAHLKE CONTROL SYSTEMS

- FUNKE Wärmeaustauscher Apparatebau GmbH

- G&H Thermal

- GEA Group Aktiengesellschaft

- Graham Corporation

- HRS Heat Exchangers Ltd.

- Koch Heat Transfer Company

- MARE S.p.A.

- Manning & Lewis

- Mersen S.A.

- Mueller Industries, Inc.

- NIBE Industrier AB

- OHM Group, S.A.

- Secespol

- SPX Flow, Inc.

Frequently Asked Questions

What is a multitube heat exchanger and how does it work?

A multitube heat exchanger, also known as a shell and tube heat exchanger, consists of a bundle of tubes housed within a cylindrical shell. Heat transfer occurs as one fluid flows through the tubes and another fluid flows around the tubes within the shell, exchanging thermal energy without direct contact. Baffles are often used to direct the shell-side fluid flow, enhancing heat transfer efficiency.

What are the primary applications of multitube heat exchangers?

Multitube heat exchangers are widely used in industrial processes for heating, cooling, condensation, and evaporation. Key applications include chemical and petrochemical processing, oil and gas refining, power generation, HVAC systems, food and beverage processing, and pharmaceutical manufacturing.

What are the main advantages of using multitube heat exchangers?

Their advantages include high thermal efficiency, robustness for high-pressure and high-temperature applications, flexibility in design for various fluids and operating conditions, ease of maintenance (especially U-tube and floating head types), and a relatively long operational lifespan compared to other heat exchanger types.

What factors influence the cost of a multitube heat exchanger?

The cost is primarily influenced by material selection (e.g., stainless steel, titanium, exotic alloys), design complexity, operating pressure and temperature requirements, size and heat transfer area, and specific industry standards or certifications needed for the application. Customization and specialized features also add to the overall cost.

How is AI impacting the future of multitube heat exchangers?

AI is transforming the market through predictive maintenance, optimizing operational parameters for energy efficiency, accelerating and refining design processes, and aiding in the discovery of advanced materials. These advancements lead to reduced downtime, lower operational costs, and enhanced performance throughout the equipment lifecycle.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager