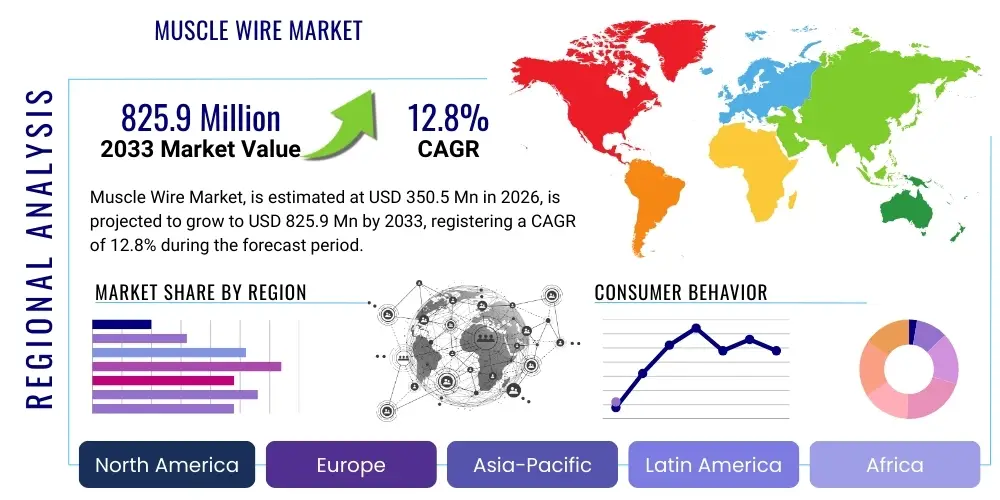

Muscle Wire Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 437798 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Muscle Wire Market Size

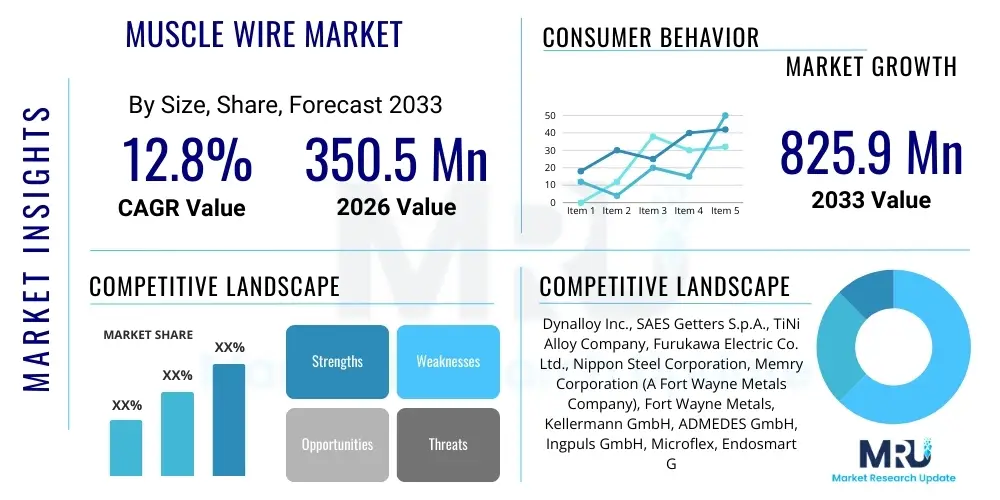

The Muscle Wire Market, driven primarily by advancements in smart materials and micro-actuation technology, is projected to grow at a Compound Annual Growth Rate (CAGR) of 12.8% between 2026 and 2033. This robust growth trajectory is underpinned by increasing adoption across sophisticated sectors such as medical devices and advanced robotics. The market is estimated at USD 350.5 Million in 2026 and is projected to reach USD 825.9 Million by the end of the forecast period in 2033.

Muscle Wire Market introduction

The Muscle Wire Market encompasses the commercialization and deployment of shape memory alloy (SMA) wires, predominantly made of Nickel-Titanium (Nitinol), which exhibit superelasticity and the unique ability to "remember" a predetermined shape. These wires contract and expand upon thermal stimulus (heating and cooling via electrical current), effectively acting as lightweight, compact actuators or artificial muscles. This capability makes muscle wires highly attractive substitutes for conventional electromagnetic motors and pneumatic actuators in applications where size, weight, and silence are critical design parameters, offering high work density relative to their mass.

Major applications of muscle wires span highly sensitive and mission-critical industries. In medical devices, they are essential components in minimally invasive surgical tools, catheter steering mechanisms, and micro-pumps due to their biocompatibility and precision movement. Within aerospace and defense, muscle wires are utilized for deploying small wings or antennae, operating miniature valves, and dampening vibrations. Furthermore, their integration into consumer electronics and advanced robotics facilitates the creation of compact grippers, haptic feedback systems, and silent locking mechanisms, signaling a transition towards smarter, more integrated electromechanical systems.

The primary benefits driving market expansion include their high power-to-weight ratio, intrinsic simplicity (eliminating the need for complex gear trains), silent operation, and high reliability in demanding environments. Key driving factors include the accelerating demand for miniaturization in medical robotics, the increasing complexity of haptic feedback interfaces in virtual reality systems, and supportive governmental initiatives promoting smart material research and development, particularly in nations focused on advanced manufacturing and next-generation defense technologies.

Muscle Wire Market Executive Summary

The Muscle Wire Market is witnessing significant transformation driven by miniaturization trends and increasing research in material science, positioning it as a critical enabler for micro-actuation technologies. Business trends indicate a strong focus on enhancing the fatigue life and response speed of Nitinol alloys, leading to strategic partnerships between alloy manufacturers and medical device innovators. Furthermore, customization is a central theme, as end-users demand wires tailored for specific strain, temperature activation, and electrical resistance profiles, prompting specialized material formulation and surface treatment techniques across the supply chain.

Regionally, North America maintains market dominance, fueled by a robust ecosystem of biomedical engineering firms and high defense spending, especially in the United States, which drives the development of advanced robotic limbs and tactical micro-systems. However, the Asia Pacific (APAC) region is projected to register the highest growth rate, primarily due to expanding medical tourism sectors in countries like India and China, coupled with massive investments in consumer electronics and domestic robotics manufacturing. Europe follows closely, driven by stringent automotive safety standards requiring advanced sensor integration and the region's strong aerospace sector.

Segment trends highlight the dominance of the Nitinol segment due to its superior superelasticity and biocompatibility, making it indispensable in the lucrative medical sector. Application-wise, Medical Devices and Robotics & Automation segments are the primary revenue generators. Within the Robotics segment, the shift from traditional industrial applications to service robotics (e.g., exoskeletons, prosthetic devices) is creating high-volume, high-value opportunities for muscle wire integration, emphasizing the need for reliable, maintenance-free actuation solutions capable of mimicking biological movement patterns efficiently.

AI Impact Analysis on Muscle Wire Market

Common user questions regarding AI's impact on the Muscle Wire Market revolve around how artificial intelligence can optimize the performance, manufacturing processes, and deployment strategies of Shape Memory Alloys (SMAs). Users frequently inquire about AI-driven material discovery—specifically, whether machine learning models can predict superior alloy compositions with better fatigue characteristics or faster activation times than conventional Nitinol. There is also significant interest in the role of AI in complex SMA control systems; users seek to know if AI can manage the non-linear hysteretic behavior of muscle wires more effectively than PID controllers, allowing for smoother, more precise actuation in robotics and surgical instruments. Furthermore, operational questions focus on utilizing AI for predictive maintenance and quality control during the wire drawing and annealing processes to minimize defects and ensure consistent mechanical properties, thereby reducing manufacturing costs and improving overall product reliability in critical applications.

AI's influence is transforming both the upstream manufacturing and downstream application of muscle wires. In manufacturing, AI algorithms process vast amounts of thermodynamic and structural data collected during the production of SMA wires, optimizing annealing temperatures, cooling rates, and deformation parameters to achieve specific transformation temperatures (Af, Mf). This level of control reduces batch variability, significantly improving yield rates and ensuring that muscle wires meet the exacting standards required for medical implantation or precision engineering. By automating quality inspection through computer vision and analyzing real-time sensor data, AI systems can immediately detect subtle metallurgical defects invisible to human inspectors.

In the application phase, AI and machine learning are crucial for implementing sophisticated control strategies. Since the stress-strain relationship and heat dissipation characteristics of muscle wires are highly non-linear, AI models (such as neural networks) are used to predict the exact current required to achieve a desired displacement or force output, compensating dynamically for ambient temperature fluctuations and operational load changes. This capability is paramount in advanced fields like soft robotics, where muscle wires form the backbone of pliable structures, allowing the robot to interact with delicate objects or navigate unpredictable environments with unprecedented adaptability and precision that standard control methods cannot achieve.

- AI-driven material informatics accelerates the discovery of new, high-performance Shape Memory Alloys with enhanced thermal cycling and greater energy density.

- Machine learning optimizes SMA manufacturing processes, leading to superior quality control, reduced defect rates, and consistent transformation temperature profiles.

- AI-based non-linear controllers enhance the precision and responsiveness of muscle wire actuators in complex robotic systems and microsurgical tools.

- Predictive maintenance algorithms utilize operational data to forecast muscle wire fatigue and failure, improving system reliability in aerospace and critical industrial applications.

- Computer vision and machine learning enable automated defect identification during the wire drawing and finishing stages, ensuring material integrity.

DRO & Impact Forces Of Muscle Wire Market

The Muscle Wire Market is propelled by significant technological drivers and constrained by inherent material limitations, creating a dynamic operational environment. Key drivers include the escalating demand for advanced, silent actuation mechanisms in miniaturized systems, particularly within surgical robotics and high-end consumer electronics (such as auto-focus cameras and vibration motors). The global push towards developing human-like prosthetics and exoskeletons also acts as a powerful catalyst, as muscle wires offer the highest power-to-volume ratio suitable for mimicking biological muscle action. These driving forces are strongly aligned with ongoing global trends toward autonomous systems and personalized medicine, underscoring the muscle wire's crucial role as a core component in next-generation devices.

Conversely, the market faces notable restraints, primarily related to the material's operational characteristics. Muscle wires suffer from relatively slow cooling and activation speeds compared to traditional solenoids or motors, limiting their use in high-frequency applications. Furthermore, the limited fatigue life—especially when subjected to high stress and numerous thermal cycles—remains a persistent technical barrier that restricts deployment in ultra-long-life industrial machinery. High manufacturing costs associated with proprietary alloying, purification, and specialized thermo-mechanical processing of Nitinol also act as a constraint, particularly in competitive, low-margin segments like general consumer goods, compelling manufacturers to focus on niche, high-value markets.

Opportunities for market expansion are vast, centering on breakthroughs in composite SMA structures and thin-film muscle wire technology for micro-electromechanical systems (MEMS). The emerging field of soft robotics presents an immediate, massive opportunity, utilizing the wire's flexibility to create adaptable systems. Additionally, the automotive sector offers long-term growth potential through applications in silent door locks, adaptive vents, and shape-changing aerodynamic features. The impact forces affecting the market are primarily regulatory pressure—especially concerning the biocompatibility and long-term reliability of materials used in implantable medical devices—and the constant pressure from substitute technologies, notably piezoelectric actuators and micro-motors, which compete fiercely based on speed and energy efficiency in specific operational niches.

Segmentation Analysis

The Muscle Wire Market is meticulously segmented based on Type, Application, and End-User, reflecting the diverse material science and engineering requirements of modern industries. The segmentation by Type focuses predominantly on the specific alloy composition, defining the wire’s mechanical and thermal properties, which in turn dictate its suitability for particular environments—be it high-temperature aerospace applications or biocompatible medical uses. The Application segmentation clearly differentiates the end-use functionality, allowing for targeted product development, while the End-User segment provides crucial insights into the purchasing power and regulatory hurdles faced by major industrial consumers.

The dominance of Nitinol (Nickel-Titanium) within the Type segment underscores its superior position due to its excellent combination of superelasticity, shape memory effect, and biocompatibility, essential for most high-value commercial applications today. However, specialized alloys like Copper-based SMAs (Cu-Zn-Al and Cu-Al-Ni) maintain relevance in industrial settings where cost-efficiency or higher transformation temperatures are prioritized over the extreme fatigue performance of Nitinol. Analyzing these segments is vital for stakeholders to align their R&D investments with high-growth, technology-intensive areas such as next-generation medical device innovation and sophisticated automation solutions.

- By Type:

- Nitinol (Nickel-Titanium)

- Copper-Zinc-Aluminum (Cu-Zn-Al)

- Copper-Aluminum-Nickel (Cu-Al-Ni)

- Iron-Manganese-Silicon (Fe-Mn-Si)

- Other Alloys (e.g., Nickel-Iron-Gallium)

- By Application:

- Actuation and Movement

- Sensing and Control

- Damping and Vibration Suppression

- Structural Components

- By End-User Industry:

- Medical Devices (Implants, Surgical Tools, Catheters)

- Robotics and Automation (Grippers, Micro-pumps)

- Aerospace and Defense (Actuators, Deployable Structures)

- Automotive (Valves, HVAC Systems, Silent Locks)

- Consumer Electronics and Haptics

- Industrial Manufacturing

Value Chain Analysis For Muscle Wire Market

The value chain for the Muscle Wire Market is complex, beginning with highly specialized upstream processing and culminating in highly integrated downstream applications. Upstream analysis focuses on the sourcing and purification of raw materials, primarily high-grade Nickel and Titanium, followed by specialized vacuum melting (such as Vacuum Induction Melting or Vacuum Arc Remelting) to create the homogeneous Shape Memory Alloy ingot. This phase is capital-intensive and requires stringent quality control, as the purity of the constituent metals directly impacts the final properties, including transformation temperatures and fatigue life, creating a high barrier to entry for new market participants in the raw alloy manufacturing stage.

The midstream process involves thermo-mechanical processing, including hot rolling, cold drawing, and specialized annealing treatments, which are proprietary to leading manufacturers. This is where the bulk SMA material is converted into fine wire or thin film forms, requiring sophisticated machinery and deep metallurgical knowledge to impart the desired shape memory effect and superelasticity. Distribution channels are varied; direct sales channels are common for large-volume, highly customized orders, especially to major defense contractors or medical device OEMs that require direct technical collaboration during the prototyping phase. Indirect channels utilize specialized material distributors and component suppliers who manage inventory and logistics for smaller end-users across diverse industrial segments.

Downstream analysis centers on the integration of the muscle wire components into the final product. End-users, such as surgical instrument manufacturers or robotics companies, receive the wire and integrate it with control circuitry (often employing microcontrollers and power MOSFETs for precise heating/cooling cycles) and mounting hardware. The key focus at this stage is optimizing the control algorithms to manage the wire's hysteretic behavior and ensuring seamless functional integration within the final device. The close collaboration between muscle wire suppliers and downstream integrators is crucial for rapid iteration and commercialization, particularly in fast-paced fields like consumer haptics and minimally invasive surgery.

Muscle Wire Market Potential Customers

Potential customers for muscle wire components are predominantly found in sectors requiring high-precision, silent, and compact actuation or sensing capabilities where traditional motors are impractical due to size or complexity constraints. The largest consuming end-user segment is the Medical Devices industry, encompassing manufacturers of minimally invasive surgical tools (e.g., endoscopic graspers, steerable catheters), orthopedic implants, and sophisticated drug delivery systems like micro-pumps and micro-valves. These customers prioritize biocompatibility, reliability, and precision, making Nitinol-based muscle wires indispensable for advanced procedures and long-term implantation.

The Robotics and Automation sector represents another critical customer base, particularly those developing complex systems such as humanoid robots, industrial grippers for delicate object handling, and prosthetic limbs and exoskeletons. These applications leverage the high force-to-weight ratio and ability of muscle wires to mimic biological motion. Furthermore, major Aerospace and Defense contractors are significant buyers, utilizing muscle wires for lightweight actuation in unmanned aerial vehicles (UAVs), spacecraft deployment mechanisms, and active vibration control systems within sensitive electronic enclosures. The unique characteristics of muscle wires address the severe size and mass constraints inherent in these high-value applications.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 350.5 Million |

| Market Forecast in 2033 | USD 825.9 Million |

| Growth Rate | 12.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Dynalloy Inc., SAES Getters S.p.A., TiNi Alloy Company, Furukawa Electric Co. Ltd., Nippon Steel Corporation, Memry Corporation (A Fort Wayne Metals Company), Fort Wayne Metals, Kellermann GmbH, ADMEDES GmbH, Ingpuls GmbH, Microflex, Endosmart GmbH, Confluent Medical Technologies, AMT, Ati Metal Products |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Muscle Wire Market Key Technology Landscape

The key technology landscape of the Muscle Wire Market is primarily dominated by advancements in Shape Memory Alloy (SMA) metallurgy, specifically focusing on optimizing the composition and thermo-mechanical treatment of Nickel-Titanium (Nitinol). Current technological efforts are concentrated on improving the functional properties of these materials, such as enhancing their resistance to fatigue, especially under high strain cycling, and tailoring the transformation temperatures to match specific application requirements, ensuring reliable performance in both cryogenic (aerospace) and body-temperature (medical) environments. Crucially, research into creating ternary and quaternary SMA systems incorporating elements like Copper, Palladium, or Hafnium aims to achieve faster response times and reduce the dependence on high levels of Nickel, addressing both speed constraints and biocompatibility concerns.

Manufacturing process innovations form another critical pillar of the technology landscape. Specialized techniques like thin-film deposition of SMA materials are crucial for the development of MEMS-based micro-actuators and microscopic sensors, facilitating unprecedented levels of miniaturization essential for advanced microfluidics and integrated electronics. Furthermore, advanced wire drawing and annealing processes utilizing precision laser heating and rapid cooling are employed to control the grain structure at the nano-level, which directly influences the mechanical hysteresis and overall efficiency of the wire actuator. These processes are proprietary and constitute a significant competitive advantage for leading market players, ensuring consistent wire diameter tolerances and surface quality necessary for reliable electrical conductivity and heat transfer.

In terms of system integration, the technological focus is shifting toward smart actuation systems incorporating advanced control electronics. This involves the development of custom drivers and controllers that employ pulse width modulation (PWM) and closed-loop feedback mechanisms to precisely regulate the electrical current supplied to the muscle wire. These smart systems are often integrated with sophisticated sensors to monitor actual displacement and temperature, allowing for real-time compensation of environmental factors. The adoption of AI and machine learning in these control loops is emerging as a disruptive technology, enabling systems to learn and predict the complex non-linear behavior of muscle wires, thereby achieving smoother, more accurate, and energy-efficient movements, a necessity for applications in soft robotics and high-fidelity haptics.

Regional Highlights

Regional dynamics play a crucial role in shaping the Muscle Wire Market, influenced by varying levels of technological maturity, regulatory frameworks, and sector-specific investment across major economic blocs. North America, particularly the United States, stands as the global leader in market value. This dominance is attributed to high expenditure in the aerospace and defense sectors, where muscle wires are integral to sophisticated deployment systems, and a leading position in the medical device industry, which constantly pushes the boundaries of minimally invasive surgical technology. The presence of major R&D centers and universities focusing on advanced materials further consolidates the region’s market share.

The Asia Pacific (APAC) region is forecasted to exhibit the highest Compound Annual Growth Rate (CAGR) throughout the forecast period. This accelerated growth is primarily driven by rapidly expanding manufacturing bases in countries like China, South Korea, and Japan, which are heavily investing in industrial automation and the indigenous development of robotics. Additionally, the proliferation of consumer electronics and the increasing sophistication of healthcare infrastructure in emerging economies within APAC are creating massive new markets for muscle wire applications, particularly in smart wearables and high-volume, cost-effective industrial solutions.

Europe represents a mature yet continually innovating market, with countries such as Germany, Switzerland, and the UK maintaining strong positions. The market here is driven by the robust European automotive industry, focused on implementing lightweight and efficient actuators for internal systems, and a specialized aerospace sector. European regulatory bodies, particularly regarding medical device approvals, set high standards for material reliability and biocompatibility, which indirectly drives technological advancements in high-quality SMA manufacturing. Latin America and the Middle East & Africa (MEA) currently hold smaller market shares but are expected to show steady growth, mainly fueled by localized growth in medical infrastructure and nascent automation initiatives in the energy sector.

- North America: Dominates the market value due to strong R&D funding, high defense spending, and a concentration of major medical device manufacturers focusing on surgical robotics and orthopedic implants.

- Asia Pacific (APAC): Expected to register the fastest growth rate driven by massive investments in domestic robotics, consumer electronics manufacturing, and rapid expansion of medical tourism sectors, particularly in China and India.

- Europe: A key market for high-precision applications in the automotive sector (e.g., silent locks, adaptive aerodynamics) and sophisticated aerospace component manufacturing, supported by stringent quality standards.

- Latin America (LATAM): Exhibits moderate growth, primarily centered on industrial automation upgrades and initial integration of advanced medical technologies in Brazil and Mexico.

- Middle East & Africa (MEA): Emerging market opportunities linked to modernization projects in healthcare infrastructure and early adoption of automation technology in oil and gas and urban development projects.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Muscle Wire Market, covering their product portfolios, recent developments, strategic initiatives, and market positioning.- Dynalloy Inc.

- SAES Getters S.p.A.

- TiNi Alloy Company

- Furukawa Electric Co. Ltd.

- Nippon Steel Corporation

- Memry Corporation (A Fort Wayne Metals Company)

- Fort Wayne Metals

- Kellermann GmbH

- ADMEDES GmbH

- Ingpuls GmbH

- Microflex

- Endosmart GmbH

- Confluent Medical Technologies

- AMT

- Ati Metal Products

- Metalwerks Inc.

- Special Metals Corporation

- Johnson Matthey

- G. Rau GmbH

- GKN Sinter Metals

Frequently Asked Questions

Analyze common user questions about the Muscle Wire market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary material used in commercial muscle wires?

The predominant material utilized in the commercial Muscle Wire Market is Nitinol (Nickel-Titanium), a specific type of Shape Memory Alloy (SMA) prized for its superior superelasticity, strong shape memory effect, and excellent biocompatibility, making it ideal for medical and high-performance actuation applications.

How do muscle wires function as actuators in robotics?

Muscle wires function by contracting when heated (typically via electrical current) and returning to their original, longer shape when cooled. In robotics, this thermal activation allows them to replace conventional motors, providing silent, lightweight, and compact linear or rotational actuation based on precise temperature control.

What are the main limitations of muscle wire technology compared to motors?

The main limitations are slower operational speed due to the required heating and cooling cycles, and limited functional fatigue life, particularly when operating under high strain and frequent cycles. While powerful and small, they are not suitable for high-frequency or continuous rapid-motion applications.

Which end-user industry is the largest consumer of muscle wires?

The Medical Devices industry represents the largest consumer segment. Muscle wires are essential components in advanced minimally invasive surgical tools, catheter guidance systems, and steerable instruments where miniaturization, precision, and biocompatibility are non-negotiable requirements.

How is the market addressing the need for faster muscle wire response times?

The market is addressing speed constraints through several technological approaches: developing thin-film and micro-wire forms (which heat and cool faster), optimizing alloy compositions for lower thermal hysteresis, and implementing AI-driven controllers to manage heat dissipation and cycling efficiency precisely.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager