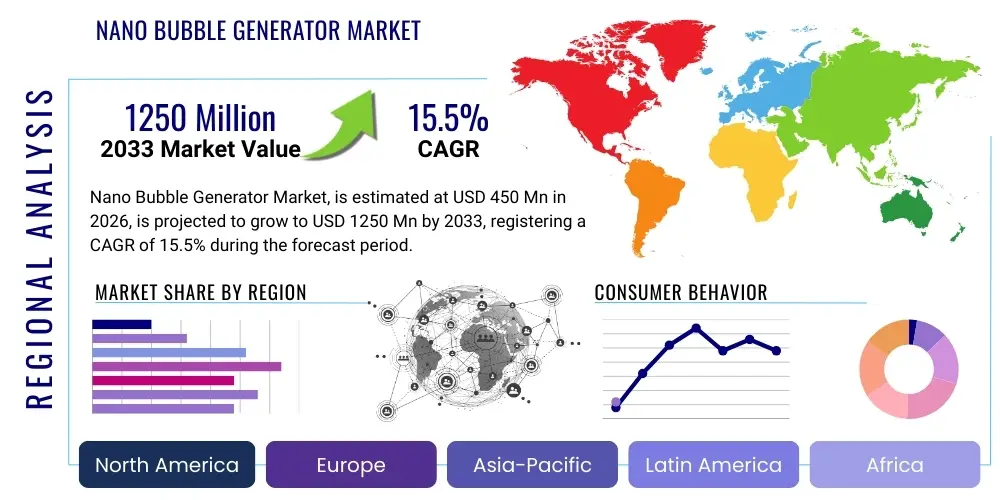

Nano Bubble Generator Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 435279 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Nano Bubble Generator Market Size

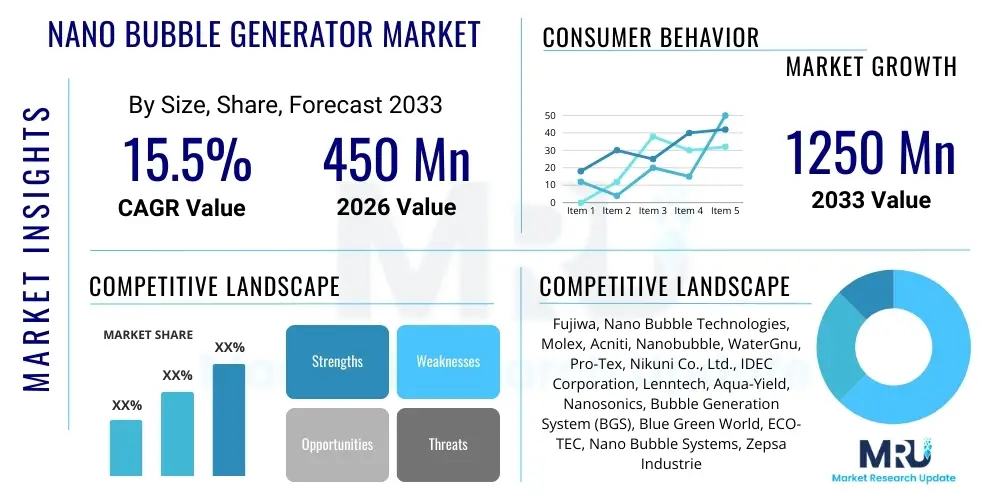

The Nano Bubble Generator Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 15.5% between 2026 and 2033. The market is estimated at USD 450 Million in 2026 and is projected to reach USD 1250 Million by the end of the forecast period in 2033.

Nano Bubble Generator Market introduction

The Nano Bubble Generator Market encompasses advanced systems designed to produce extremely small gaseous cavities, typically less than 200 nanometers in diameter, suspended in liquid media. These nano bubbles exhibit unique physicochemical properties, including high internal pressure, substantial zeta potential, extended longevity in solution due to low buoyancy, and high gas-liquid interfacial area. Unlike macro or micro bubbles, nano bubbles resist coalescence and buoyancy effects, allowing them to remain suspended for months, which is critical for applications requiring sustained chemical or physical reactions. This technology is fundamental to enhancing efficiency across diverse industrial and environmental processes by maximizing gas transfer rates and surface contact.

The core product range includes various generator types such as pressurized dissolution systems, hydrodynamic cavitation generators, static mixers, and electrolytic methods, each tailored for specific industrial scales and target applications. Major applications driving market growth include advanced wastewater treatment (improving aerobic digestion and pathogen inactivation), hydroponics and aquaculture (enhancing dissolved oxygen levels and nutrient absorption), medical sterilization and drug delivery, and microelectronics cleaning. The generators are critical components in systems aimed at sustainable resource management and high-efficiency manufacturing. The primary benefits derived from using nano bubble technology include significant reductions in chemical consumption, improved product yield in biological systems, and the implementation of cleaner, environmentally compliant operational procedures.

The market expansion is fundamentally driven by the escalating global demand for sustainable water management solutions, stringent environmental regulations requiring high-efficiency remediation technologies, and continuous innovation in agricultural practices aimed at maximizing crop yield with reduced water usage. Furthermore, technological advancements in generator design, focusing on energy efficiency and scalability, are making nano bubble systems more accessible to Small and Medium-sized Enterprises (SMEs). The growing adoption in the semiconductor industry for advanced surface cleaning, where particulate matter needs to be removed without causing physical damage, also acts as a significant catalyst for market proliferation.

Nano Bubble Generator Market Executive Summary

The Nano Bubble Generator Market is characterized by robust growth stemming from the integration of this technology into established environmental remediation and high-purity industrial sectors. Current business trends indicate a strong shift towards modular and scalable generator designs, addressing the diverse needs of both large municipal water treatment facilities and localized agricultural setups. Key players are investing heavily in intellectual property related to control systems that optimize bubble size distribution and gas mixture injection, thereby maximizing application efficiency and system stability. The competitive landscape is fragmented, with specialized manufacturers focusing on niche applications, such as medical diagnostics or sophisticated semiconductor cleaning, requiring ultra-precise bubble control, leading to high-value transactions in these verticals.

Regionally, the market exhibits divergent maturity levels. Asia Pacific (APAC), particularly China, Japan, and South Korea, is spearheading adoption, driven by intensive aquaculture activities and critical needs for water conservation and industrial process optimization, especially in electronics manufacturing. North America and Europe demonstrate mature markets, characterized by stringent regulatory environments that favor nano bubble technology for wastewater quality compliance and sustainable farming practices. These regions see high demand for advanced, automated systems that integrate seamlessly into existing infrastructure. Latin America and the Middle East and Africa (MEA) are emerging markets, primarily focused on pilot projects in agriculture and oil and gas sector water management, indicating substantial long-term growth potential once infrastructure investment accelerates.

Segment-wise, the market is highly influenced by the application sector, with water and wastewater treatment consistently dominating revenue share due to the sheer volume of global water processing requirements. However, the food and beverage industry and the medical/biotechnology sectors are projected to register the fastest growth rates. Within the generation method segment, hydrodynamic cavitation generators are gaining prominence due to their lower energy consumption and suitability for high-flow industrial applications, although pressurized dissolution remains the established standard for applications requiring precise gas saturation control. The trend toward using inert gases (like argon or nitrogen) in cleaning and food preservation is diversifying the gas type segment, moving beyond traditional air and oxygen injection.

AI Impact Analysis on Nano Bubble Generator Market

Common user questions regarding AI's impact on the Nano Bubble Generator Market frequently revolve around optimizing generation efficiency, predictive maintenance for complex systems, and the intelligent adaptation of bubble parameters to changing fluid conditions. Users are keen to understand how AI can move the technology beyond simple fixed-setting operation towards dynamic, real-time optimization. Key themes emerging from these inquiries include the potential for Machine Learning (ML) algorithms to accurately predict optimal energy inputs necessary to achieve desired nano bubble concentration and size distribution based on varying water quality (pH, temperature, dissolved solids). Furthermore, there is significant interest in using AI-driven sensor networks for closed-loop control, ensuring maximum effectiveness in high-variability environments like biological wastewater reactors or agricultural irrigation systems. The overarching expectation is that AI integration will substantially reduce operational expenditure (OPEX) and improve the overall reliability and performance consistency of nano bubble installations.

The integration of Artificial Intelligence transforms the operational paradigm of nano bubble generation from reactive control to predictive and prescriptive management. AI algorithms analyze massive datasets derived from flow meters, temperature sensors, gas input controls, and optical measurement tools (for bubble quantification) to establish complex correlations that are impossible to model deterministically. This capability allows the system to autonomously adjust parameters—such as impeller speed in hydrodynamic generators or pressure differentials in dissolution systems—in real-time to maintain optimal performance despite fluctuations in environmental conditions or feedstock purity. This level of precision is critical in high-purity applications, such as pharmaceutical water systems or semiconductor fabrication, where deviation from target parameters can result in significant material loss or process failure.

Furthermore, AI significantly enhances the lifecycle management of nano bubble generator hardware. By continuously monitoring vibration, current consumption, and pressure drops, ML models can predict mechanical wear and schedule preventative maintenance before critical failure occurs, maximizing uptime and reducing costly emergency repairs. This predictive capability is particularly valuable for generators deployed in remote or difficult-to-access locations, such as deep-sea aquaculture farms or underground mining operations. The use of generative AI is also beginning to be explored in the R&D phase, simulating fluid dynamics and chemical interactions to accelerate the design of next-generation, more energy-efficient generator geometries, thus rapidly reducing the time-to-market for novel equipment designs tailored to highly specific industrial needs.

- AI-powered Predictive Maintenance: Forecasting equipment failure and optimizing maintenance schedules based on operational telemetry and historical data.

- Real-time Parameter Optimization: Using ML models for closed-loop control to dynamically adjust pressure, flow, and gas mixture ratios for maximum nano bubble stability and concentration.

- Enhanced Process Efficiency: Deploying prescriptive AI to determine the minimum energy consumption required to achieve target Dissolved Oxygen (DO) levels or oxidation potential in water treatment applications.

- Automated Quality Control: Implementing computer vision and deep learning for instantaneous analysis of bubble size distribution and concentration verification, ensuring consistent output quality in high-stakes environments.

- Remote Diagnostics and System Self-Correction: Enabling autonomous identification and mitigation of operational faults, minimizing human intervention and maximizing system uptime.

DRO & Impact Forces Of Nano Bubble Generator Market

The Nano Bubble Generator Market is driven by environmental necessity, constrained by technological scalability challenges, and holds vast potential in therapeutic and purification sciences. The principal drivers include global water scarcity and the increasing need for high-quality, reusable water sources, alongside regulatory mandates pushing for chemical-free disinfection methods. Restraints primarily involve the high initial capital investment required for industrial-scale generators, the lack of standardized regulatory frameworks specifically addressing nano bubble technology efficiency, and the technical complexity associated with precisely measuring and verifying nano bubble concentration and longevity in diverse matrices. Opportunities lie in expanding adoption across high-value sectors like medical diagnostics, targeted drug delivery, and advanced materials processing, where the unique properties of nano bubbles command a premium price point and solve previously intractable problems. The overall impact force is moderated by the interplay between strong environmental drivers and the necessity for continued technological maturation to overcome adoption hurdles in cost-sensitive industries.

The market dynamics are significantly influenced by specific regional pressures. In developed economies, the impact of forces favoring sustainability (Drivers) outweighs the cost concerns (Restraints), leading to accelerated adoption in municipal water and agriculture. Conversely, emerging markets often prioritize upfront capital expenditure (Restraints), slowing penetration despite acute needs for water treatment. The strongest positive impact force remains the proven capability of nano bubbles to substantially reduce the reliance on conventional, often toxic, chemical treatments (like chlorine or ozone) in various disinfection and oxidation processes. This benefit aligns perfectly with global corporate environmental, social, and governance (ESG) strategies, further accelerating corporate investment.

However, the sustained commercial success of this technology hinges on overcoming standardization issues. Currently, comparisons between different manufacturers’ systems are difficult because of the proprietary nature of bubble measurement techniques. This opacity acts as a moderate restraint, causing hesitation among potential large-scale industrial buyers who require robust, verifiable performance metrics before massive investment. The key opportunity to overcome this is through technological differentiation, specifically in developing generators that can handle highly turbid or chemically heterogeneous inputs without rapid efficiency degradation, thus opening up vast new markets such as oil and gas produced water treatment and remediation of highly contaminated industrial sites.

Segmentation Analysis

The Nano Bubble Generator Market segmentation provides a granular view of application-specific demand patterns and technological preferences. The market is primarily dissected based on the Method of Generation (e.g., pressurized dissolution, hydrodynamic cavitation), the Gas Type utilized (e.g., Oxygen, Ozone, Air, Inert Gases), and crucially, the End-Use Application (e.g., Water Treatment, Aquaculture, Medical). This multi-dimensional segmentation highlights the critical differences in generator design and cost structure required to serve various industries, ranging from high-volume, low-cost water treatment systems to low-volume, high-precision medical devices. Analysis reveals that while traditional methods still hold large market shares, newer, energy-efficient hydrodynamic methods are quickly gaining ground due to industrial scalability requirements.

Segmentation by Gas Type is becoming increasingly important as industries leverage the specific chemical properties of different gases encapsulated in nano bubbles. For instance, ozone nano bubbles are critical in advanced disinfection processes due to their high oxidation potential and long residual life, while inert gas nano bubbles (like Argon or Nitrogen) are gaining traction in semiconductor cleaning and specialized material science applications, providing an ultra-gentle cleaning mechanism. This diversification necessitates manufacturers to produce versatile equipment capable of handling a broader range of gaseous inputs safely and effectively, driving complexity and innovation within the generator design segment.

The segmentation by End-Use Application is the primary driver of market revenue, revealing that municipal and industrial wastewater management accounts for the largest revenue pool due to stringent environmental discharge regulations worldwide. However, specialized sectors like hydroponics and targeted medical therapy are witnessing exponential growth, fueled by the higher return on investment (ROI) offered by nano bubble utilization in these precision-dependent fields. Understanding these nuanced segmentation dynamics is vital for market players to prioritize R&D investment and tailor sales strategies, focusing either on volume (Wastewater) or value (Medical/Biotechnology).

- By Method of Generation:

- Pressurized Dissolution

- Hydrodynamic Cavitation

- Static Mixer

- Electrolytic Methods

- Others (e.g., Acoustic methods)

- By Gas Type:

- Oxygen Nano Bubbles

- Air Nano Bubbles

- Ozone Nano Bubbles

- Inert Gas Nano Bubbles (Nitrogen, Argon, etc.)

- By End-Use Application:

- Water and Wastewater Treatment (Municipal, Industrial)

- Aquaculture and Agriculture (Hydroponics, Crop Yield Enhancement)

- Medical and Biotechnology (Drug Delivery, Diagnostics, Sterilization)

- Food and Beverage Processing (Cleaning, Preservation)

- Cleaning and Semiconductor Manufacturing

- Oil and Gas (Flotation, Produced Water Treatment)

- Chemical and Pharmaceutical

- By Operational Scale:

- Small Scale (Laboratory/Pilot)

- Medium Scale (Commercial/Industrial Modules)

- Large Scale (Municipal/Heavy Industrial Plants)

Value Chain Analysis For Nano Bubble Generator Market

The Value Chain for the Nano Bubble Generator Market begins with upstream activities focused on the sourcing of high-precision components and specialized raw materials. This includes high-grade stainless steel alloys for cavitation chambers, advanced ceramics for nozzles, precision pumps, and sophisticated gas handling and control systems. Manufacturers rely heavily on specialized suppliers for electronic control units (ECUs) and sensors necessary for monitoring flow rates and pressure. A crucial upstream element is the supply of high-purity gases (Oxygen, Ozone, Nitrogen), sourced from industrial gas suppliers, whose quality directly impacts the stability and efficiency of the generated nano bubbles. The integration of advanced computational fluid dynamics (CFD) modeling during the design phase represents a significant value-add in the initial stages.

The core of the value chain is the generator manufacturing and assembly process, which requires highly specialized engineering expertise, particularly in machining components to nanoscale tolerances to ensure consistent bubble size. Distribution channels are highly specialized, often relying on direct sales teams for large industrial projects or collaborating with specialized integrators who focus on specific end-use applications (e.g., wastewater engineering firms or hydroponics consultants). Indirect distribution, through technical distributors, serves smaller clients and regional markets. The complexity of installation and commissioning necessitates strong technical support capabilities from the manufacturers, adding significant value downstream.

Downstream analysis highlights the critical role of installation, maintenance, and ongoing optimization services. Given the complexity of integrating these generators into existing large-scale industrial processes, post-sale service contracts and operational training are essential revenue streams. Potential customers, particularly in the municipal water sector, demand performance guarantees and long-term service agreements, creating strong opportunities for manufacturers to capture recurring maintenance revenue. Direct engagement is common for high-value applications (e.g., medical), ensuring bespoke system tuning and compliance with stringent regulatory requirements, whereas indirect channels handle standardized modules for routine industrial use.

Nano Bubble Generator Market Potential Customers

The primary potential customers and end-users of Nano Bubble Generator technology span industries critically dependent on efficient gas-liquid mass transfer, high-purity environments, and sustainable chemical reduction. The largest volume of buyers comes from the Water and Wastewater Treatment sector, including municipal utility districts seeking to improve aeration efficiency and reduce sludge volumes, and industrial facilities (such as textiles, pulp and paper, and food processing plants) requiring stringent effluent standards before discharge. These buyers prioritize operational expenditure reduction, energy efficiency, and regulatory compliance, making the long-term cost savings of nano bubble aeration highly attractive.

Another significant customer base is found within the high-value Agriculture and Aquaculture industries. Fish farms and intensive shrimp cultivation operations utilize nano bubble generators to maximize dissolved oxygen levels, thereby enhancing the health and density capacity of aquatic life while reducing disease vectors. Hydroponic and vertical farming operators leverage nano bubbles to improve nutrient uptake efficiency in plant roots, leading to faster growth cycles and higher yields. These customers are primarily focused on tangible improvements in biological productivity and resource efficiency (water and fertilizer reduction).

Emerging, high-growth potential customers reside in the Medical, Pharmaceutical, and Semiconductor fields. Semiconductor manufacturers, facing the challenge of removing minute particulate contaminants without surface damage, rely on ultra-clean nano bubble washing processes. In the medical field, researchers and pharmaceutical companies represent high-value customers, exploring the technology for advanced sterilization of surgical tools, improved cell culture viability, and pioneering applications in targeted drug and gene delivery, leveraging the stable, surface-charged nature of the bubbles to encapsulate therapeutic agents and target specific tissues within the body.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 1250 Million |

| Growth Rate | 15.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Fujiwa, Nano Bubble Technologies, Molex, Acniti, Nanobubble, WaterGnu, Pro-Tex, Nikuni Co., Ltd., IDEC Corporation, Lenntech, Aqua-Yield, Nanosonics, Bubble Generation System (BGS), Blue Green World, ECO-TEC, Nano Bubble Systems, Zepsa Industries, Cerlic, Praxair (Linde), Ultra-Fine Bubble Technologies. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Nano Bubble Generator Market Key Technology Landscape

The technology landscape for Nano Bubble Generators is segmented based on the mechanism used to shear gas into nanoscale particles, primarily focusing on energy efficiency and scalability. Pressurized Dissolution remains a prevalent technology, relying on saturating water with gas under high pressure and then releasing it through fine nozzles, forcing the formation of nano bubbles. While reliable and effective for precise bubble size control, this method can be energy-intensive. Conversely, Hydrodynamic Cavitation utilizes specialized rotors, venturi nozzles, or static mixers to induce rapid pressure drops within the fluid flow, causing localized cavitation that shears gas into nano bubbles. This method offers superior scalability for large-volume industrial applications, especially due to its lower relative operational energy cost per cubic meter of treated water, making it a critical area of current R&D focus.

A significant technological advancement involves the shift toward optimizing bubble stability and zeta potential, which dictates the effectiveness of the bubbles in coagulation, flotation, or therapeutic applications. New generations of generators incorporate advanced materials in their fluid contact parts to minimize surface energy losses and enhance bubble charge. Furthermore, the integration of advanced sensor technology, utilizing laser scattering or dynamic light scattering (DLS) techniques, is becoming standard practice. These technologies allow for instantaneous and accurate measurement of bubble metrics, moving away from subjective or unreliable methods, thereby building greater confidence in the efficacy of the installations for high-precision tasks like pharmaceutical cleaning or chemical process enhancement.

Electrolytic methods, though currently niche, represent a cutting-edge segment, particularly for specialized applications where high purity and localized generation are crucial. These systems generate nano bubbles directly through the electrolysis of water, offering extremely clean, localized delivery without the need for external gas supply lines, which is highly desirable in medical and laboratory settings. The overarching trend across all technological methods is the increasing incorporation of IoT and digital twin modeling to simulate, predict, and control performance parameters remotely. Manufacturers are heavily investing in proprietary algorithms that optimize the input variables—pressure, flow, and gas concentration—to maximize the concentration of stable nano bubbles while minimizing energy consumption, positioning the market for smart, interconnected industrial deployment.

Regional Highlights

Regional analysis reveals stark differences in market penetration and application focus, dictated primarily by environmental regulations, industrial concentration, and agricultural intensity.

- Asia Pacific (APAC): APAC is the dominant market region, driven by unparalleled demand in intensive aquaculture and the crucial necessity for industrial water reuse, particularly in rapidly industrializing nations like China and India. Countries such as Japan and South Korea lead in adopting nano bubble technology in advanced microelectronics manufacturing, utilizing it for ultra-clean wafer washing processes. The regional market growth is also significantly fueled by government initiatives promoting sustainable farming and robust infrastructure investment in municipal wastewater treatment facilities, leading to a strong demand for large-scale hydrodynamic cavitation generators.

- North America: North America represents a mature, high-value market characterized by early adoption in the oil and gas sector (produced water treatment) and sophisticated environmental remediation projects. Stringent regulatory standards set by the EPA regarding water quality and chemical discharge drive continuous investment. The region leads in the application of nano bubble technology in agricultural yield enhancement and the establishment of pilot projects integrating AI for operational optimization, focusing on both high-efficiency oxygenation and pathogen control in controlled environments like vertical farms.

- Europe: Europe exhibits strong growth, underpinned by rigorous environmental policies, particularly the Water Framework Directive, which mandates high ecological quality for water bodies. This drives demand for chemical-free disinfection solutions, favoring ozone and oxygen nano bubble applications in water treatment and the food and beverage industry for surface sterilization and preservation. Germany, the Netherlands, and Scandinavia are primary markets, emphasizing R&D collaboration between academic institutions and industry players to develop highly specialized, energy-efficient electrolytic and pressurized dissolution systems tailored for sustainable industrial processes.

- Latin America (LATAM): LATAM is an emerging but fast-growing market, largely focused on large-scale commodity production, particularly mining, agriculture, and aquaculture (e.g., Chile and Brazil). Market penetration is currently concentrated on solving large industrial water quality challenges, such as flotation enhancement in mining operations and treating high volumes of agricultural runoff. Growth is reliant on foreign direct investment and the successful execution of early-stage large industrial projects that demonstrate a clear return on investment (ROI) by minimizing resource consumption and maximizing productivity.

- Middle East and Africa (MEA): The MEA region is characterized by acute water scarcity, driving strong foundational interest in nano bubble technologies for desalination pre-treatment and efficient irrigation in arid environments. The market is nascent, with initial deployments primarily focused on critical infrastructure projects, including municipal wastewater recycling and the optimization of resource usage within the dominant oil and gas sector (e.g., enhanced oil recovery and produced water management). The establishment of regional manufacturing hubs and technical expertise is a key requirement for sustained long-term growth.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Nano Bubble Generator Market.- Fujiwa Co., Ltd.

- Nano Bubble Technologies

- Acniti

- Nanobubble (USA)

- Nikuni Co., Ltd.

- Molex

- IDEC Corporation

- Lenntech B.V.

- Aqua-Yield

- Nanosonics Limited

- Bubble Generation System (BGS)

- Blue Green World Inc.

- ECO-TEC Inc.

- Nano Bubble Systems (NBS)

- Zepsa Industries

- Cerlic Environmental AB

- Praxair (Linde)

- Ultra-Fine Bubble Technologies (UFB Tech)

- Pro-Tex Corporation

- WaterGnu Innovations

Frequently Asked Questions

Analyze common user questions about the Nano Bubble Generator market and generate a concise list of summarized FAQs reflecting key topics and concerns.What specific properties make nano bubbles superior to micro or macro bubbles for industrial use?

Nano bubbles exhibit unique physicochemical properties due to their extremely small size (under 200 nm). Key properties include neutral buoyancy, allowing them to remain suspended in water for extended periods (months), high internal pressure, substantial zeta potential (surface charge), and a vast cumulative gas-liquid interface. These characteristics enable superior gas dissolution, enhanced chemical reaction efficiency, and effective surface cleaning or pathogen disruption without relying on turbulence or large air volumes.

How does nano bubble technology contribute to sustainability in the water treatment sector?

Nano bubble technology drastically improves sustainability by maximizing oxygen transfer efficiency in aeration processes, significantly reducing the energy consumption compared to conventional diffused aeration systems. Furthermore, ozone nano bubbles offer powerful, chemical-free disinfection and oxidation capabilities, minimizing the need for traditional, potentially harmful chemical agents like chlorine, thereby reducing environmental impact and sludge production in wastewater treatment facilities.

What are the primary operational challenges faced during the implementation of large-scale nano bubble generation systems?

Major operational challenges include managing the high initial capital expenditure (CapEx) associated with specialized generation equipment, ensuring consistent system performance when faced with highly variable water quality (e.g., high turbidity or dissolved solids), and the difficulty in real-time, accurate measurement and verification of nano bubble concentration and size distribution using cost-effective, non-laboratory-grade equipment for ongoing process control.

In which emerging application sectors is nano bubble generator technology showing the highest growth potential?

The highest growth potential is observed in the Medical and Biotechnology sectors, specifically in targeted drug delivery systems, advanced medical diagnostics, and enhanced sterilization processes for surgical equipment. The Semiconductor industry also shows rapid growth, utilizing nano bubbles for high-precision, damage-free cleaning of microelectronics and wafers, leveraging the technology's capability to remove minute particles effectively.

What is the difference in application suitability between Hydrodynamic Cavitation and Pressurized Dissolution generators?

Pressurized Dissolution systems are generally preferred for smaller scale, high-precision applications requiring tight control over bubble size and consistent gas saturation (e.g., laboratory use, medical). Hydrodynamic Cavitation generators are better suited for large-scale, high-flow industrial applications such as municipal water treatment or large aquaculture farms, as they offer greater energy efficiency and scalability for processing large volumes of liquid, often at the expense of slight precision in bubble size uniformity.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager