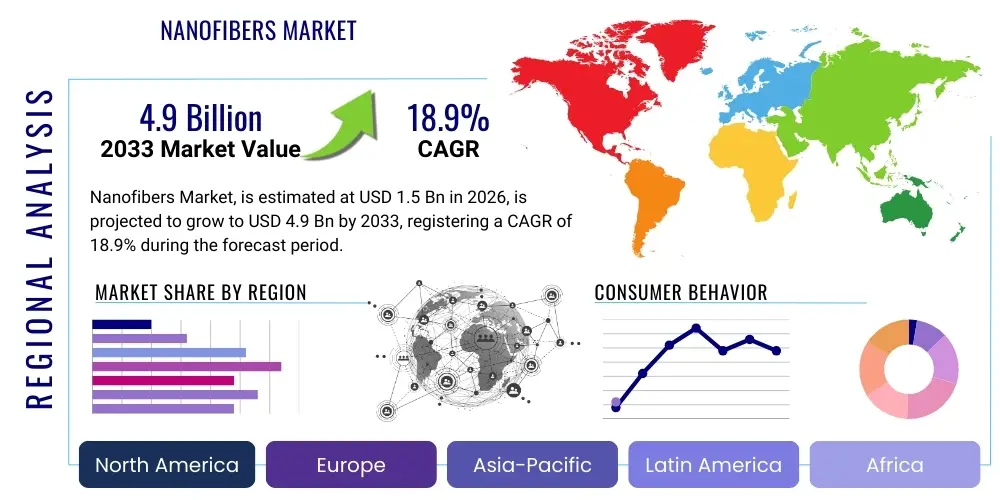

Nanofibers Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438609 | Date : Dec, 2025 | Pages : 253 | Region : Global | Publisher : MRU

Nanofibers Market Size

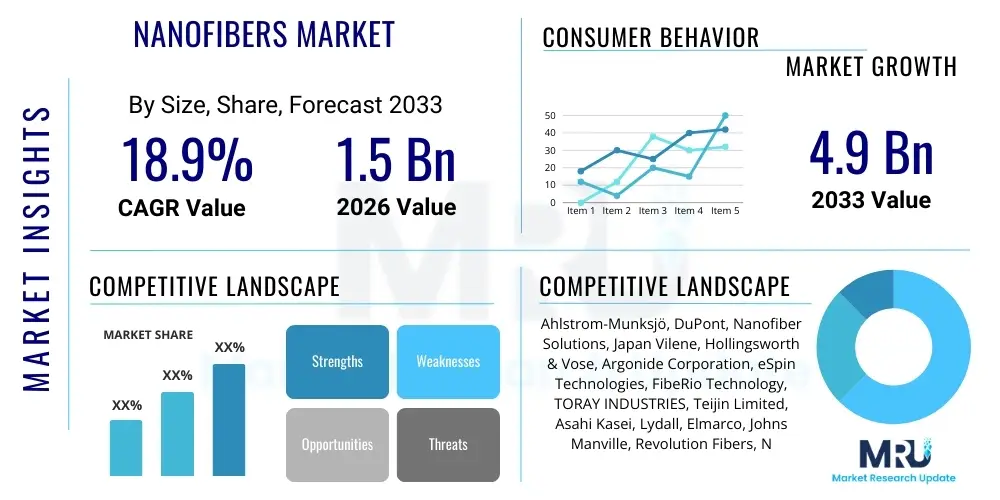

The Nanofibers Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 18.9% between 2026 and 2033. The market is estimated at USD 1.5 Billion in 2026 and is projected to reach USD 4.9 Billion by the end of the forecast period in 2033.

Nanofibers Market introduction

The Nanofibers Market encompasses the production, distribution, and application of fibers with diameters typically less than 100 nanometers. These materials exhibit unique characteristics such as extremely high surface-area-to-volume ratio, high porosity, and superior mechanical strength, making them indispensable in advanced technological fields. The primary product descriptions span across materials like polymer nanofibers (e.g., PVA, Nylon, Polyimide), carbon nanofibers, and composite nanofibers, synthesized predominantly through electrospinning, drawing, and template-based methods. These fibers are characterized by their ability to significantly enhance the performance of end products, offering functionalities not achievable with conventional materials. Their microscopic dimensions allow for remarkable molecular filtration capabilities and highly efficient energy storage kinetics.

Major applications of nanofibers are concentrated in critical sectors, including high-efficiency air and liquid filtration systems, biomedical and healthcare products such as wound dressings and tissue engineering scaffolds, and energy devices like batteries and fuel cells. In filtration, nanofibers provide enhanced barrier properties without sacrificing flux, leading to cleaner air and water purification solutions. In the medical field, their biocompatibility and structure mimic the extracellular matrix, facilitating regenerative medicine breakthroughs. The inherent benefits driving market adoption include improved performance parameters, miniaturization capabilities, and the development of lightweight, sustainable materials across diverse industries. Furthermore, the capacity of nanofibers to be functionalized with specific chemical groups opens avenues for smart materials and sensing applications.

The driving factors for market growth are profoundly linked to stringent environmental regulations demanding superior air and water filtration, the accelerating global investment in regenerative medicine and advanced drug delivery systems, and the imperative for high-performance energy storage solutions required by the electric vehicle and consumer electronics industries. Specifically, the rising prevalence of airborne diseases and pollution necessitates advanced protective equipment and filtration media, while the quest for lighter and more efficient electrodes in lithium-ion batteries fuels demand for carbon and composite nanofibers. The convergence of material science innovation and industrial scale-up efforts continues to propel nanofibers from research laboratories into mainstream commercial products.

Nanofibers Market Executive Summary

The global Nanofibers Market is undergoing rapid transformation, marked by significant technological advancements in scalable manufacturing processes, particularly in high-throughput electrospinning techniques. Business trends show a strategic shift toward vertical integration, where raw material suppliers are forming partnerships with nanofiber producers to optimize material quality and reduce production costs, thereby enhancing market accessibility. Key industry players are focusing on patenting novel applications in specialized fields such as defense and aerospace, where the lightweight and strong characteristics of nanofibers offer competitive advantages. Investment in automation and AI-driven quality control is becoming paramount to ensure product uniformity and meet rigorous regulatory standards, especially those governing medical devices and environmental safety.

Regionally, the Asia Pacific (APAC) region is projected to dominate the market in terms of volume and consumption due to its robust manufacturing base, rapidly industrializing economies, and increasing adoption of advanced filtration technologies in heavily polluted urban centers. North America and Europe, while having lower production volumes compared to APAC, lead the market in terms of value, driven by high-value applications in biomedical research, advanced wound care, and cutting-edge energy storage R&D. These mature markets are characterized by demanding regulatory frameworks that favor high-quality, certified nanofiber products. Furthermore, governments in these regions are actively funding research initiatives focused on integrating nanofibers into smart textiles and wearable technology, further cementing their position in high-end segments.

Segment trends indicate that the Polymer Nanofibers segment maintains the largest market share owing to their versatility, low cost of production, and established use in filtration media and general consumer goods. However, the Carbon Nanofibers segment is exhibiting the fastest growth rate, fueled by its unparalleled electrical conductivity and mechanical stability crucial for battery electrodes, supercapacitors, and structural composites. Application-wise, the Filtration segment remains the primary revenue generator due to universal demand for HVAC and industrial purification systems. Concurrently, the Biomedical segment, encompassing tissue scaffolds and targeted drug delivery, represents the most lucrative opportunity, poised for explosive growth as clinical trials mature and regulatory approvals accelerate for nanofiber-enabled medical treatments.

AI Impact Analysis on Nanofibers Market

The integration of Artificial Intelligence (AI) and Machine Learning (ML) platforms is revolutionizing the Nanofibers Market by optimizing complex synthesis processes and accelerating the discovery of novel materials. Users frequently inquire about how AI can mitigate the primary challenge of nanofiber production: scalability and consistency. Common concerns revolve around predictive quality control, real-time process tuning, and the modeling of structure-property relationships. Users expect AI algorithms to analyze vast datasets generated during electrospinning and melt blowing, allowing producers to instantaneously adjust parameters (voltage, flow rate, collector distance) to maintain desired fiber diameter and morphology, thereby significantly reducing waste and ensuring batch-to-batch uniformity. The expectation is that AI will transform nanofiber manufacturing from an empirical process into a predictable, optimized engineering discipline.

A second critical theme in user queries relates to AI's role in computational material science and accelerating innovation. Researchers are keen to leverage ML to screen potential polymer combinations and solvent systems that could yield nanofibers with specific, tailored characteristics—such as enhanced tensile strength for composites or improved biocompatibility for medical implants—without exhaustive laboratory experimentation. This computational approach drastically cuts down R&D cycles, allowing companies to respond faster to niche market demands. The ability of neural networks to identify subtle patterns in material structures that correlate with macroscopic performance properties is a key driver for investment in AI tools within R&D departments across the nanofiber industry value chain.

Ultimately, the impact of AI is viewed as instrumental in democratizing high-quality nanofiber production. By automating complex material characterization and quality assurance procedures, smaller firms can achieve the performance standards previously reserved for large research institutions. User interest also focuses on AI-driven supply chain management, optimizing the procurement of precursor materials and streamlining logistics for sensitive products like sterile nanofiber wound dressings. The consensus is that AI provides the computational backbone necessary to transition nanofiber technology from a laboratory curiosity to a widely industrialized, cost-effective advanced material platform, directly addressing historical limitations related to cost and manufacturing bottlenecks.

- AI-Driven Process Optimization: Real-time adjustment of electrospinning parameters (voltage, temperature, flow rate) to ensure consistent fiber diameter and morphology, minimizing batch variability.

- Predictive Quality Control (PQC): Utilization of machine learning models to analyze microscopic images and production data for anomaly detection and defect prediction before material failure occurs.

- Accelerated Material Discovery: Employment of generative AI models and high-throughput virtual screening to identify optimal precursor polymers and solvent combinations for targeted nanofiber properties (e.g., conductivity, strength).

- Enhanced Simulation and Modeling: Use of AI to accurately model fluid dynamics and electric field distribution in synthesis techniques, improving the design and scalability of manufacturing equipment.

- Supply Chain Resilience: Optimizing raw material sourcing and inventory management for specialty chemicals necessary for nanofiber production, ensuring continuity and cost efficiency.

DRO & Impact Forces Of Nanofibers Market

The Nanofibers Market is primarily driven by mounting global environmental concerns, particularly the urgent need for high-performance filtration solutions capable of capturing sub-micron particulate matter (PM2.5) and neutralizing biological contaminants. Simultaneously, the accelerating demand from the healthcare sector for advanced regenerative medicine platforms, including scaffolds that precisely mimic the body's native extracellular matrix, acts as a powerful economic catalyst. However, growth is significantly restrained by the high capital expenditure required to set up large-scale, consistent nanofiber production facilities, and the persistent technical challenges related to achieving high throughput without compromising fiber quality, particularly for sensitive materials. These factors create inherent barriers to entry for new market participants and place significant pressure on existing players to rapidly scale their operations and reduce unit costs.

Opportunities for disruptive market expansion exist primarily within next-generation energy storage and smart textile applications. The potential for carbon and metal oxide nanofibers to significantly boost the energy density and charging speed of lithium-ion batteries and supercapacitors presents a substantial revenue stream. Furthermore, the development of functionalized nanofibers for integration into wearable sensors, defense materials (NBC protection), and personalized health monitoring fabrics represents a burgeoning opportunity. The complex interplay of these factors defines the market's trajectory; while demand pull is strong across multiple sectors, the technology push is constrained by the need for commercially viable, large-scale synthesis methods that can meet rigorous industrial standards and regulatory requirements globally.

The impact forces within the nanofiber market are primarily centered on technological momentum, regulatory stringency, and competitive dynamics. Technological advancements in nozzle design and solvent-free production methods (like melt electrospinning) exert a strong positive force, promising cost reduction and increased throughput. Conversely, strict regulatory oversight, especially in medical and pharmaceutical applications, acts as a restrictive force, delaying time-to-market for new products. The intense competitive landscape, characterized by numerous patents and specialized production expertise, compels key players to continuously innovate and diversify their application portfolio to maintain market relevance and secure long-term commercial contracts with major end-users in the highly consolidated filtration and biomedical sectors.

Segmentation Analysis

The Nanofibers Market is systematically analyzed based on material type, technology, and application, providing a granular view of market dynamics and growth potential across various dimensions. Material type segmentation, which includes polymer, carbon, ceramic, and composite nanofibers, is critical as the choice of precursor directly dictates the final material's performance characteristics (e.g., flexibility, conductivity, thermal resistance). Polymer nanofibers, due to their ease of processing and cost-effectiveness, dominate the volume segment, while carbon and ceramic nanofibers command higher value due to their superior performance in electrical and thermal applications. Understanding the material breakdown helps stakeholders identify strategic sourcing needs and target specific high-value end-user markets.

The technology segmentation highlights the primary manufacturing methods, with electrospinning being the most established and versatile technique, allowing for fine control over fiber dimensions and morphology. However, emerging and more scalable technologies like melt blowing, drawing, and template synthesis are gaining traction as the industry moves toward mass production for industrial filtration and textile integration. The technological landscape reveals ongoing efforts to shift away from solvent-heavy processes towards more environmentally friendly and cost-efficient manufacturing practices, which will significantly influence future market dynamics and competitive pricing strategies. Adoption rates of new technologies are highly dependent on achieving consistent quality at high volume.

The Application segmentation is the most direct indicator of market demand, categorized primarily into Filtration, Biomedical, Electronics/Semiconductors, Energy, and Composites. Filtration holds the largest share due to global regulatory drivers and environmental necessity, demanding high-efficiency particulate air (HEPA) and ultra-filtration systems. The Biomedical sector, though smaller in volume, represents the highest growth potential, driven by clinical successes in tissue regeneration and advanced drug delivery. This detailed segmentation allows producers to optimize their product portfolio for specific sectors, allocate R&D resources effectively, and formulate targeted marketing campaigns based on the unique regulatory and performance demands of each industry vertical.

- By Material Type:

- Polymer Nanofibers (e.g., PVA, Nylon, Polyimide, PAN)

- Carbon Nanofibers (CNFs)

- Ceramic Nanofibers

- Composite Nanofibers

- By Technology:

- Electrospinning

- Drawing

- Melt Blowing

- Template Synthesis

- Force Spinning

- By Application:

- Filtration (Air, Liquid, Oil-Water Separation)

- Biomedical (Tissue Engineering, Drug Delivery, Wound Dressings)

- Energy Storage (Batteries, Supercapacitors, Fuel Cells)

- Electronics and Semiconductors

- Textiles and Apparel (Smart Textiles, Protective Gear)

- Composites and Structural Materials

Value Chain Analysis For Nanofibers Market

The Nanofibers Market value chain begins with the upstream analysis, which focuses on the sourcing and supply of precursor raw materials, primarily high-grade polymers, specialized carbon sources, and metal oxides. This stage is crucial as the purity and consistency of these starting materials directly dictate the quality and performance of the final nanofiber product. Key suppliers include large petrochemical companies and specialty chemical manufacturers. Cost volatility and supply chain stability for these precursors, particularly exotic polymers and highly purified solvents necessary for electrospinning, are major factors influencing production costs. Efficiency in this upstream segment is achieved through long-term supply agreements and stringent quality control protocols, which ensure that materials meet the demanding specifications required for nanotechnology applications.

The midstream segment involves the core manufacturing process, encompassing the conversion of raw materials into nanofibers using various technologies such as electrospinning, melt blowing, or drawing. This stage includes sophisticated equipment manufacturing (e.g., multi-nozzle electrospinning machines) and the establishment of high-volume production facilities. Differentiation at this stage is achieved through proprietary technological advancements that increase throughput, reduce solvent usage, and maintain fiber uniformity at scale. Following production, the fibers often undergo post-processing steps like functionalization, coating, or integration into final forms such as nonwoven membranes or composite sheets. Distribution channels play a critical role, involving direct sales to large original equipment manufacturers (OEMs) in the filtration or automotive industries, or indirect sales through specialized distributors who handle smaller, niche orders, particularly in the research and development sector.

The downstream analysis focuses on the end-user integration, where the nanofiber components are incorporated into finished products across various applications, including medical devices, air filters, and composite structures. Direct distribution is common for high-value, customized products like tissue engineering scaffolds sold to research institutions or hospitals. Indirect distribution, leveraging a network of specialized materials distributors, is more prevalent for commodity applications like industrial filtration media. The complexity of the value chain requires close collaboration between nanofiber producers and end-product integrators to ensure optimal material selection and processing compatibility, especially given the stringent performance and regulatory requirements in sectors like aerospace and biomedicine. Profitability throughout the chain is highly dependent on effective intellectual property management and the ability to demonstrate superior performance value over traditional materials.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.5 Billion |

| Market Forecast in 2033 | USD 4.9 Billion |

| Growth Rate | 18.9% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Ahlstrom-Munksjö, DuPont, Nanofiber Solutions, Japan Vilene, Hollingsworth & Vose, Argonide Corporation, eSpin Technologies, FibeRio Technology, TORAY INDUSTRIES, Teijin Limited, Asahi Kasei, Lydall, Elmarco, Johns Manville, Revolution Fibers, Nanothinx S.A., TDA Research, Inc., Aspen Aerogels, UPM-Kymmene Corporation, LG Chem. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Nanofibers Market Key Technology Landscape

The technological landscape of the Nanofibers Market is dominated by solution-based processing techniques, with Electrospinning standing as the foundational and most widely adopted method. Electrospinning utilizes an electrical field to draw charged polymer jets from a liquid reservoir onto a grounded collector, producing fibers with diameters often well below 100 nanometers. This technique is highly versatile, capable of handling a wide range of polymers and solvent systems, and is particularly favored in research and high-precision applications like tissue scaffolds and drug encapsulation where morphology control is paramount. Recent innovations in electrospinning focus on scaling up production through multi-nozzle arrays and needleless systems, dramatically improving throughput and addressing the historical limitation of low productivity compared to conventional textile manufacturing processes.

Beyond electrospinning, several other key technologies are crucial for specific market segments. Melt Blowing, a technique traditionally used for microfibers, has been adapted to produce thicker nanofibers by optimizing processing parameters, offering a more cost-effective and solvent-free pathway particularly beneficial for industrial filtration media and nonwoven fabrics. Template Synthesis involves creating nanofibers within the pores of a material, such as anodized aluminum oxide (AAO), and is invaluable for producing highly ordered, uniform ceramic or metallic nanofibers required in advanced sensor and electronic applications. Furthermore, novel techniques like Centrifugal Spinning (or Force Spinning) are emerging, utilizing rotational force rather than electric fields to eject fibers, offering a high-volume, continuous production method suitable for manufacturing large quantities of polymer nanofibers for composite reinforcement and bulk materials.

The strategic differentiation among market players often rests on their intellectual property portfolio surrounding these manufacturing techniques. Companies are heavily investing in proprietary modifications to standard techniques, such as incorporating coaxial or blend electrospinning to create core-shell structures or composite nanofibers with enhanced functionalities (e.g., sustained drug release, or encapsulated thermal insulation). The shift is moving towards high-speed, automated production lines integrated with real-time monitoring sensors, which is essential for penetrating cost-sensitive high-volume markets. The long-term goal for the industry's technology roadmap is the mass production of defect-free nanofibers at costs competitive with traditional commodity materials, thereby unlocking potential in the automotive, construction, and consumer goods sectors.

Regional Highlights

The Nanofibers Market exhibits distinct regional dynamics driven by varying regulatory environments, levels of industrialization, and R&D investment landscapes.

- North America: This region maintains a leading position in terms of market value and technological innovation, primarily due to robust government funding for nanotechnology research (e.g., NIH, NSF grants) and the strong presence of major medical device and aerospace manufacturers. The United States is the central hub for high-value applications, particularly in regenerative medicine, advanced wound care, and specialized military filtration systems. Strict FDA regulations necessitate high-quality, traceable materials, favoring premium nanofiber producers.

- Europe: Characterized by stringent environmental standards (e.g., REACH regulations), Europe demonstrates high demand for nanofiber-based air and water purification technologies. Germany, France, and the UK are key markets, focusing heavily on integrating nanofibers into automotive air filters and high-efficiency industrial membranes. The region also shows significant growth in sustainable packaging and smart textile development, leveraging nanofibers for enhanced material functionality and reduced environmental footprint.

- Asia Pacific (APAC): APAC is anticipated to be the fastest-growing region both in terms of volume consumption and production capacity, driven by rapid industrialization, increasing pollution levels (especially in China and India), and growing disposable incomes leading to higher healthcare spending. China is a major manufacturing base for affordable nanofiber filtration media, while countries like Japan and South Korea lead in sophisticated applications, notably in flexible electronics, battery electrodes (LG Chem, Samsung), and high-performance technical textiles.

- Latin America (LATAM): The LATAM market is nascent but growing steadily, largely focused on importing high-end nanofiber products for localized applications in water treatment and agricultural filtration. Brazil and Mexico represent the largest markets, driven by infrastructure projects and increasing healthcare modernization efforts. Local production is minimal, creating opportunities for international exporters to establish distribution networks.

- Middle East and Africa (MEA): Growth in MEA is primarily spurred by investments in desalination and water management technologies, particularly in the Gulf Cooperation Council (GCC) countries where water scarcity is critical. Nanofiber membranes offer highly efficient and potentially lower energy-intensive water purification solutions. The application in advanced oil and gas filtration also constitutes a significant, specialized market segment in this region.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Nanofibers Market.- Ahlstrom-Munksjö

- DuPont

- Nanofiber Solutions

- Japan Vilene

- Hollingsworth & Vose

- Argonide Corporation

- eSpin Technologies

- FibeRio Technology

- TORAY INDUSTRIES

- Teijin Limited

- Asahi Kasei

- Lydall

- Elmarco

- Johns Manville

- Revolution Fibers

- Nanothinx S.A.

- TDA Research, Inc.

- Aspen Aerogels

- UPM-Kymmene Corporation

- LG Chem

- Nanopareil

- Donaldson Company

- Kuraray Co. Ltd.

- Unitika Ltd.

- Membrane Solutions LLC

Frequently Asked Questions

Analyze common user questions about the Nanofibers market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the demand for nanofibers in industrial applications?

The primary driver is the stringent global regulatory environment concerning air and water quality. Nanofibers offer superior filtration efficiency compared to conventional materials, capturing sub-micron particles and pollutants, which is essential for compliance in industries such as automotive, HVAC, and industrial processing, providing a high surface area for enhanced separation performance.

Which manufacturing technology is currently the most scalable and cost-effective for mass production of nanofibers?

While traditional electrospinning offers the highest precision for research and specialized medical applications, technologies like melt blowing and centrifugal/force spinning are proving to be the most scalable and cost-effective for mass production. These high-throughput methods reduce solvent dependency and are optimized for generating large volumes of nonwoven nanofiber mats required by the filtration and composite industries, addressing the market's need for lower unit costs.

How are nanofibers transforming the energy storage sector, particularly in battery technology?

Nanofibers, especially those made of carbon or ceramics, are transforming energy storage by serving as highly conductive and robust electrode materials (anodes and cathodes) in lithium-ion batteries and supercapacitors. Their high surface area significantly increases ion transfer kinetics and power density, while their structural integrity helps mitigate volume expansion issues, leading to faster charging cycles and extended battery life crucial for electric vehicles and portable electronics.

What are the major challenges restraining the widespread commercialization of nanofibers?

The major challenges restraining commercialization include the high initial capital investment required for establishing industrial-scale production equipment (e.g., multi-nozzle electrospinning apparatus), the inherent technical difficulty in ensuring batch-to-batch consistency and uniformity at high speed, and the relatively high cost of precursor materials (specialized polymers and solvents) compared to traditional fiber sources.

Which geographical region holds the highest growth potential for nanofiber applications in the next decade?

The Asia Pacific (APAC) region is projected to hold the highest growth potential. This growth is underpinned by rapid industrial expansion, escalating environmental pollution necessitating advanced filtration, and massive government and private investment in electronics manufacturing and high-end automotive production, particularly in China, South Korea, and India, creating a huge addressable market for high-performance materials.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager