Nanoindentation and Scratch Test Instruments Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432685 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Nanoindentation and Scratch Test Instruments Market Size

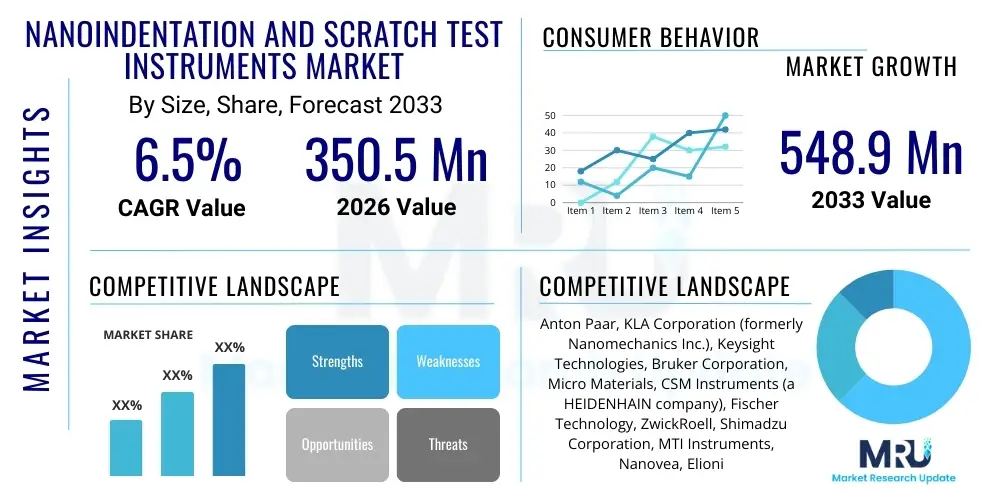

The Nanoindentation and Scratch Test Instruments Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 350.5 Million in 2026 and is projected to reach USD 548.9 Million by the end of the forecast period in 2033.

The consistent growth trajectory of the market is primarily attributed to the increasing demand for advanced material characterization techniques across various high-tech industries. Nanoindentation instruments, which measure hardness and elastic modulus at the nanoscale, are critical in developing new materials, particularly thin films, coatings, and semiconductor structures. The precision and high sensitivity offered by modern instruments, coupled with standardized testing procedures, are accelerating adoption within both R&D settings and quality control environments.

Furthermore, the integration of scratch testing capabilities alongside nanoindentation provides comprehensive insights into tribological properties, adhesion, and wear resistance. This combined capability is highly valued in aerospace, automotive, and microelectronics sectors where material longevity and performance under stress are paramount. Market expansion is also supported by continuous technological advancements, including improved tip geometries, higher loading capacities, and enhanced software algorithms for complex data analysis, driving overall market value upward over the forecast period.

Nanoindentation and Scratch Test Instruments Market introduction

The Nanoindentation and Scratch Test Instruments Market encompasses advanced precision measurement systems designed to quantify the mechanical properties of materials at the micro and nanoscale. These instruments are crucial for characterizing the surface hardness, elastic modulus, yield strength, adhesion, and wear resistance of thin films, coatings, bulk materials, and delicate biological samples. Nanoindentation, often referred to as depth-sensing indentation, uses an ultra-sharp tip to penetrate the material surface while continuously monitoring the load and displacement, generating detailed mechanical property profiles essential for materials engineering and quality assurance.

Major applications span materials science research, where new alloys and composites are tested; the microelectronics industry, for evaluating semiconductor device components and interconnects; and the biomedical field, for analyzing biomaterials and tissue mechanics. Key benefits driving market adoption include the ability to perform localized testing with high spatial resolution, minimal material damage, and the provision of quantitative data essential for predictive modeling and structural integrity assessments. These instruments facilitate the development of superior performing products by ensuring that materials meet stringent performance criteria in critical applications.

Driving factors for this market include the global expansion of the microelectronics sector, particularly in advanced packaging and flexible electronics, which necessitates precise characterization of thin-layer mechanics. Moreover, increasing investments in nanotechnology research by governmental and private entities, coupled with stringent regulatory standards for material quality in aerospace and automotive industries, further stimulate demand for accurate and reliable testing instrumentation. The push towards developing smarter, lighter, and more durable materials across all manufacturing sectors remains a primary market catalyst.

Nanoindentation and Scratch Test Instruments Market Executive Summary

The Nanoindentation and Scratch Test Instruments Market is poised for robust growth, driven by escalating R&D activities in advanced materials and the miniaturization trend in electronics. Business trends indicate a strong move toward integrated, multi-functional testing platforms that combine nanoindentation, scratch testing, and atomic force microscopy (AFM) capabilities to offer comprehensive material analysis solutions. Key companies are focusing on developing automated systems with enhanced throughput and improved software analytics to cater to industrial quality control demands, shifting the market emphasis from purely academic research tools to sophisticated industrial metrology equipment.

Regionally, Asia Pacific is anticipated to exhibit the highest growth rate, fueled by massive government funding in nanotechnology infrastructure, the rapid expansion of semiconductor manufacturing hubs in China, South Korea, and Taiwan, and increasing collaboration between academic institutions and industrial partners. North America and Europe, while mature markets, continue to lead in technological innovation, specifically in high-end dynamic testing and elevated temperature testing capabilities necessary for aerospace and energy applications. The competitive landscape is characterized by strategic mergers and acquisitions aimed at consolidating expertise and expanding global distribution networks.

Segment trends highlight the dominance of quasi-static nanoindentation due to its foundational role in material mechanics, although dynamic mechanical analysis (DMA) techniques are gaining traction for viscoelastic materials characterization. In terms of end-users, industrial laboratories are becoming increasingly important buyers, moving beyond the traditional stronghold of academic and government research institutions. Furthermore, the rising adoption of specialized instruments for testing biomedical materials, such as hydrogels and tissue scaffolds, represents a significant emerging opportunity, pushing manufacturers to develop instruments capable of operating in biologically relevant environments.

AI Impact Analysis on Nanoindentation and Scratch Test Instruments Market

Common user questions regarding AI's influence in the Nanoindentation and Scratch Test Instruments Market center on how artificial intelligence can accelerate material discovery, enhance data processing efficiency, and improve testing reliability. Users are keen to understand if AI can automate the notoriously complex processes of tip-area function calibration, drift correction, and anomalous data point identification. There is significant expectation that machine learning (ML) algorithms will be applied to predict material properties based on indentation curves, thereby reducing the need for extensive experimental trials. Concerns often revolve around data governance, the integration complexity of AI software with existing hardware, and the reliability of AI-driven material predictions in novel, untested compositions. The consensus points towards AI becoming an indispensable tool for maximizing the value extracted from high-volume, multi-parameter mechanical testing data.

- AI algorithms enable faster, more accurate interpretation of complex load-displacement curves, particularly for layered or anisotropic materials.

- Machine Learning facilitates predictive maintenance of instrumentation by analyzing sensor data for potential mechanical failures or tip degradation.

- Automated experimental design and optimization using AI dramatically reduces the time required for material screening and development (Accelerated Materials Discovery).

- AI enhances data quality control by automatically detecting and correcting thermal drift, system compliance variations, and outliers in large datasets.

- Integration of Neural Networks allows for the rapid classification of material behavior (e.g., plastic vs. viscoelastic response) without requiring manual curve fitting models.

- AI assists in correlating microstructural features identified via microscopy with local mechanical properties derived from nanoindentation maps.

DRO & Impact Forces Of Nanoindentation and Scratch Test Instruments Market

The market dynamics are significantly shaped by the confluence of robust technological drivers, high instrumentation costs acting as restraints, and substantial opportunities arising from emerging industrial applications. Key drivers include the exponential growth in global semiconductor fabrication and the associated demand for precise quality control of wafer coatings and interconnects, alongside increased global R&D spending on durable and functional thin films for renewable energy and electric vehicle technologies. Conversely, the market faces restraints such as the initial high capital investment required for these instruments, the necessity for highly skilled technical personnel to operate and interpret complex data, and the challenges associated with standardizing testing procedures across diverse material types and operating environments.

Opportunities are abundant in the customization of instruments for extreme environmental testing, such as high-temperature nanoindentation for turbine blade materials and in-situ liquid testing for biological samples. Furthermore, the expansion of additive manufacturing (3D printing) requires specialized mechanical testing of resulting microstructures, presenting a novel application space. The primary impact forces influencing this market include the bargaining power of buyers, which is moderate due to the availability of established vendors but constrained by the technical specificity of the instruments, and the high threat of new technologies, primarily sophisticated computational modeling (e.g., Finite Element Analysis) that might substitute some physical testing needs, though generally, modeling still relies on physical measurement inputs for validation.

The threat of substitutes is relatively low because physical nanoindentation remains the gold standard for direct mechanical characterization at the nanoscale, unmatched by alternative techniques in precision and scope. However, the bargaining power of suppliers is moderate to high, especially for proprietary components like high-precision actuators and diamond tips, leading to sustained operational costs. Overall, the market remains driven by necessity—the continuous push for improved material performance in high-stakes applications—outweighing the restraining factor of cost, especially in industrialized nations where material failure carries significant economic and safety implications.

Segmentation Analysis

The Nanoindentation and Scratch Test Instruments Market is comprehensively segmented based on the type of instrument, the underlying measurement technique utilized, the specific application area, and the primary end-user sector. This segmentation allows for targeted market analysis, highlighting variations in demand and growth potential across different technological and industrial niches. The product type segmentation distinguishes between highly sensitive, fixed benchtop systems suitable for high-precision R&D, and more compact, potentially portable systems designed for industrial quality control or field-based testing, each catering to different operational requirements.

Measurement technique segmentation is critical, dividing the market based on the method of data acquisition and analysis, encompassing established quasi-static methods and more complex dynamic techniques used for viscoelastic material characterization. Application-wise, the market is heavily influenced by the demands of microelectronics and advanced coatings, which require routine, high-resolution mechanical property mapping. Understanding these segments is vital for manufacturers to tailor their product offerings, focusing R&D efforts on specific high-growth areas, such as instruments capable of handling high-aspect-ratio structures or measuring ultra-low force interactions crucial for next-generation devices.

The end-user segmentation clearly separates institutional buyers (academia and government labs) from commercial industrial consumers (manufacturers and contract testing laboratories). While academia drives the need for cutting-edge, highly flexible research tools, industrial end-users prioritize automation, speed, reliability, and integration into existing quality assurance pipelines. This bifurcation necessitates different sales and support strategies, with academic sales focusing on specification and technical capability, and industrial sales centered on throughput and return on investment (ROI).

- By Product Type:

- Benchtop Systems (High Precision, R&D focused)

- Portable/Handheld Systems (Quality Control, Industrial focused)

- By Measurement Technique:

- Quasi-Static Nanoindentation (Traditional Load-Displacement)

- Dynamic Nanoindentation (Continuous Stiffness Measurement - CSM)

- Scratch Testing (Adhesion, Wear)

- Lateral Force Microscopy Integration

- By Application:

- Material Science Research

- Microelectronics and Semiconductors

- Coatings and Thin Films

- Automotive and Aerospace

- Biomedical Materials and Devices

- By End-User:

- Academia and Research Institutions

- Industrial Laboratories (Manufacturing QA/QC)

- Contract Testing and Service Providers

Value Chain Analysis For Nanoindentation and Scratch Test Instruments Market

The value chain for the Nanoindentation and Scratch Test Instruments Market begins with the highly specialized upstream component suppliers, particularly manufacturers of high-precision actuators, displacement sensors (e.g., capacitive or optical), and the critical diamond indenter tips. These components require specialized knowledge and manufacturing processes, granting suppliers significant leverage due to the limited number of high-quality sources globally. Instrument manufacturers then integrate these components, adding proprietary control software, sophisticated environmental isolation chambers, and data analysis packages, defining the core value proposition and differentiation in the market.

Downstream analysis focuses on distribution and end-user adoption. Distribution channels are typically a mix of direct sales teams for major global accounts and highly technical, specialized regional distributors capable of providing installation, calibration, and long-term service support. Due to the complexity and high cost of the equipment, the sales cycle often involves significant technical consultation and demonstration. Direct channels are preferred for servicing major industrial or government accounts, ensuring intellectual property control and immediate customer feedback, whereas indirect channels leverage local market expertise and established relationships in smaller or geographically distant regions.

The final value realization occurs at the end-user stage, where the instrument is deployed for materials characterization. Value-added services such as certified calibration, customized application support, and training programs are crucial for maintaining customer loyalty and ensuring accurate data generation. The entire chain is heavily dependent on maintaining technological superiority and providing robust, reliable after-sales service, given the delicate nature and precision requirements of nanoscale testing.

Nanoindentation and Scratch Test Instruments Market Potential Customers

The primary potential customers for Nanoindentation and Scratch Test Instruments are multifaceted, spanning high-technology manufacturing and fundamental research environments. End-users typically include research scientists, materials engineers, and quality assurance specialists who require quantitative, localized mechanical property data unavailable through conventional macro-scale testing. Industrial buyers, particularly in the semiconductor, aerospace, and medical device sectors, use these instruments to ensure the performance and durability of critical thin films, protective coatings, and integrated micro-components.

Academic and government research laboratories represent another cornerstone of the customer base. University material science departments, national laboratories focused on advanced manufacturing, and specialized government testing facilities utilize these tools for basic scientific discovery, new material synthesis validation, and establishing international material standards. These users require instruments with maximum flexibility, capability for non-standard testing geometries, and open-architecture software for custom experimental programming.

Moreover, the rise of specialized contract testing laboratories presents a growing segment of buyers. These service providers offer mechanical testing services to smaller companies that cannot afford the high capital expenditure of owning an instrument. This segment seeks high-throughput, automated, and reliable systems capable of meeting diverse client testing demands efficiently, underscoring the shift towards commercialized testing services as the technology matures.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 350.5 Million |

| Market Forecast in 2033 | USD 548.9 Million |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Anton Paar, KLA Corporation (formerly Nanomechanics Inc.), Keysight Technologies, Bruker Corporation, Micro Materials, CSM Instruments (a HEIDENHAIN company), Fischer Technology, ZwickRoell, Shimadzu Corporation, MTI Instruments, Nanovea, Elionix Inc., Piuma Nanoindentation, Testometric, Mitutoyo Corporation, Tinius Olsen, Agilent Technologies, Gatan Inc., Rtec Instruments, CETR (Center for Tribology). |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Nanoindentation and Scratch Test Instruments Market Key Technology Landscape

The technological backbone of the Nanoindentation and Scratch Test Instruments Market relies heavily on ultra-high precision mechanical and optical engineering coupled with sophisticated computational control. Key technologies include the Continuous Stiffness Measurement (CSM) technique, which applies an oscillating force superimposed on the main loading curve to continuously measure stiffness and, consequently, the elastic modulus and hardness as a function of depth. This dynamic technique provides far more detail than traditional quasi-static methods, especially for depth-dependent properties in thin films. Furthermore, instruments utilize highly advanced displacement measurement systems, often employing capacitive sensors or interferometry, capable of resolving displacements in the picometer range, which is essential for accurate nanoscale mechanical characterization.

Another pivotal technological advancement involves the integration of environmental control systems. Modern instruments are frequently equipped with heating and cooling stages, enabling high-temperature nanoindentation (critical for aerospace alloy testing) and sub-ambient testing, as well as liquid cells for testing biological samples or polymer hydrogels under hydrated conditions. Scratch testing instruments leverage precise lateral force sensors and motorized stages to control the applied normal force and sliding velocity, accurately quantifying adhesion strength and scratch resistance through real-time monitoring of frictional forces and acoustic emissions. These technologies allow researchers and engineers to simulate real-world service conditions with unparalleled fidelity.

Software and data processing constitute an increasingly vital part of the technology landscape. Advanced software packages incorporate ISO and ASTM standard analysis methods (e.g., the Oliver-Pharr method) and feature automation scripts for high-throughput testing, crucial for industrial quality control. There is a growing trend toward integrating machine vision and automated tip positioning using fiducial markers to ensure repeatable testing on complex microstructures. Furthermore, the convergence of nanoindentation with Scanning Probe Microscopy (SPM) or Atomic Force Microscopy (AFM) allows for precise pre- and post-test imaging of the indent or scratch area, providing crucial contextual information about surface deformation and failure mechanisms, reinforcing the multi-modal approach to material characterization.

Regional Highlights

- North America: North America holds a substantial share of the Nanoindentation and Scratch Test Instruments Market, driven by robust funding for fundamental material science research and the presence of leading technology developers in the aerospace, defense, and semiconductor industries. The US market specifically benefits from established research infrastructure and the early adoption of highly specialized instruments for advanced coating analysis and extreme environment testing. Demand here is characterized by the need for high-end, customized solutions tailored for niche applications like nuclear material testing and biomedical device characterization.

- Europe: Europe is a key innovation hub, particularly in Germany, the UK, and France, with strong emphasis on automotive component performance, advanced polymers, and renewable energy material testing. European regulations often mandate stringent quality testing for material durability and lifespan, fueling continuous demand for high-precision scratch and wear resistance testing equipment. Academic-industrial partnerships and collaborative research projects funded by the European Union further solidify market growth and technological diffusion across the continent.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing region, dominated by increasing investments in semiconductor fabrication plants, particularly in Taiwan, South Korea, and China. The rapid expansion of electronics manufacturing, coupled with escalating government investments in national nanotechnology initiatives (e.g., China's Made in China 2025), significantly boosts the need for reliable, high-throughput instruments for quality assurance of thin films and microelectronic packaging materials. Japan remains a strong market for established, high-quality instrumentation, particularly in high-reliability applications.

- Latin America, Middle East, and Africa (MEA): These regions represent emerging markets. Growth in Latin America is primarily tied to academic expansion and government investment in resource extraction and materials processing R&D. The Middle East, particularly the GCC nations, is seeing increased adoption linked to diversification efforts in petrochemicals, infrastructure development, and establishing regional research centers focused on materials engineering, necessitating modern testing facilities for characterizing new construction and protective coating materials.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Nanoindentation and Scratch Test Instruments Market.- Anton Paar

- KLA Corporation (formerly Nanomechanics Inc.)

- Keysight Technologies

- Bruker Corporation

- Micro Materials

- CSM Instruments (a HEIDENHAIN company)

- Fischer Technology

- ZwickRoell

- Shimadzu Corporation

- MTI Instruments

- Nanovea

- Elionix Inc.

- Piuma Nanoindentation

- Testometric

- Mitutoyo Corporation

- Tinius Olsen

- Agilent Technologies

- Gatan Inc.

- Rtec Instruments

- CETR (Center for Tribology)

Frequently Asked Questions

Analyze common user questions about the Nanoindentation and Scratch Test Instruments market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of nanoindentation instruments in materials science?

Nanoindentation instruments are primarily used to measure fundamental mechanical properties, such as hardness and elastic modulus, of materials at extremely localized, nanoscale dimensions, particularly essential for characterizing thin films, coatings, and individual microstructural phases.

How is the growth of the semiconductor industry influencing the demand for these instruments?

The semiconductor industry’s constant push for miniaturization and the reliance on complex multilayer thin films necessitates ultra-precise mechanical characterization. This drives high demand for nanoindentation tools to ensure the reliability and mechanical integrity of advanced semiconductor devices and packaging materials.

What is the difference between quasi-static and dynamic nanoindentation techniques?

Quasi-static nanoindentation measures mechanical properties based on a single, continuous load-displacement cycle. Dynamic nanoindentation, such as Continuous Stiffness Measurement (CSM), applies an oscillating force during loading to continuously measure stiffness and properties as a function of indentation depth, providing richer data for viscoelastic materials.

Which geographical region exhibits the highest growth potential in this market?

The Asia Pacific (APAC) region, led by China, South Korea, and Taiwan, is expected to exhibit the highest growth rate due to massive governmental and private investments in nanotechnology research, semiconductor fabrication, and advanced materials manufacturing infrastructure across the region.

What are the key technological advancements driving market innovation?

Key technological advancements include the integration of artificial intelligence (AI) for automated data analysis and experimental design, the development of in-situ environmental testing stages (e.g., high temperature and liquid cells), and improved software for high-throughput, standardized industrial quality control testing.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager