Nanotextiles Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432210 | Date : Dec, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Nanotextiles Market Size

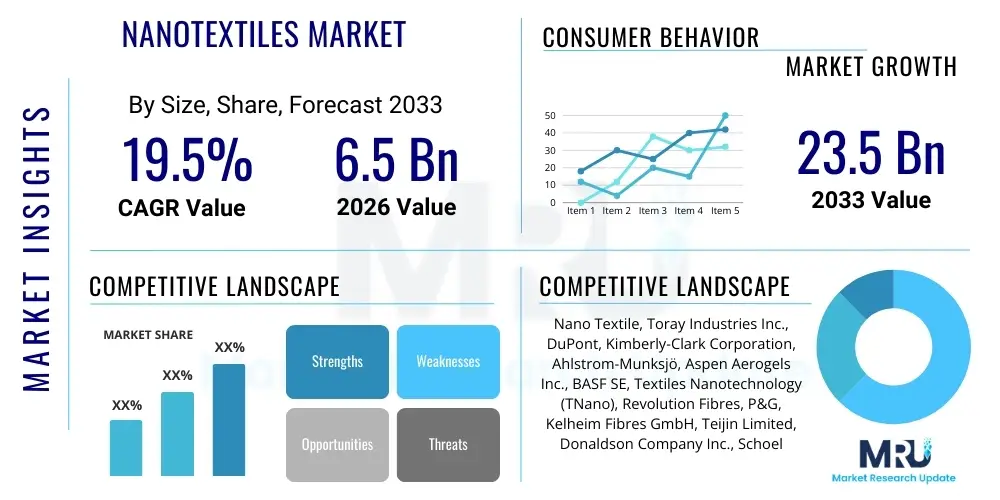

The Nanotextiles Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 19.5% between 2026 and 2033. The market is estimated at USD 6.5 Billion in 2026 and is projected to reach USD 23.5 Billion by the end of the forecast period in 2033.

Nanotextiles Market introduction

The Nanotextiles Market encompasses the development, production, and distribution of textile materials engineered using nanoscale components or structures. These textiles exhibit enhanced functional properties far surpassing conventional materials, including superior strength, self-cleaning capabilities, high UV resistance, antimicrobial properties, and advanced electrical conductivity. Nanotextiles leverage technologies such as electrospinning, chemical vapor deposition (CVD), and sol-gel processing to integrate nanoparticles, nanowires, or carbon nanotubes (CNTs) into fiber substrates, fundamentally altering surface morphology and performance characteristics. The driving force behind the adoption of nanotextiles is the increasing demand for high-performance materials across critical sectors like healthcare, military, and extreme sports apparel, where material failure or performance limitations can have severe consequences. This technological advancement represents a paradigm shift from passive textiles to active, intelligent fabrics capable of sensing, regulating, and responding to external environments.

Major applications for nanotextiles are diverse and expanding rapidly. In the medical field, they are crucial for producing advanced wound dressings, tissue engineering scaffolds, and high-efficacy surgical masks due to their antimicrobial nature and biocompatibility. For the defense and aerospace industries, nanotextiles offer lightweight solutions for ballistic protection, stealth coatings, and radiation shielding. Furthermore, the consumer goods sector utilizes these materials to create smart wearables that monitor vital signs, self-cleaning clothing, and durable, stain-resistant upholstery. The primary benefit derived from these materials is the combination of miniaturization and multifunctionality, enabling the creation of fabrics that are inherently lighter, stronger, and more versatile than traditional alternatives, thereby opening new avenues for product innovation and differentiation across the global manufacturing landscape.

Key factors driving market expansion include extensive research and development initiatives focused on sustainable and bio-based nanomaterials, coupled with supportive regulatory frameworks promoting material innovation in high-tech manufacturing economies. The declining cost of nanotechnology integration, improved production scalability, and the growing consumer preference for functional apparel further propel market growth. However, addressing concerns related to the long-term environmental impact and consumer safety of specific nanomaterials remains a critical challenge that influences product development and market acceptance. Successful commercialization is heavily reliant on demonstrating reliable, cost-effective, and environmentally benign manufacturing processes that maintain the integrity and functional performance of the nanoscale modifications throughout the textile life cycle.

Nanotextiles Market Executive Summary

The global Nanotextiles Market is experiencing robust acceleration, fueled by continuous innovation in polymer science and nanotechnology integration, positioning it as one of the fastest-growing segments within advanced materials. Business trends indicate a strong move toward strategic collaborations between academic institutions, specialized nanotechnology firms, and large textile manufacturers to accelerate commercialization and standardize production protocols. Investment is heavily concentrated in developing electrospinning techniques for mass production of nanofibers, especially those targeting biomedical applications and high-end protective gear. Furthermore, there is a distinct business emphasis on sustainable nanotextile solutions, driven by corporate social responsibility mandates and evolving consumer demand for eco-friendly products, pushing companies to explore non-toxic, biodegradable, and recycled nanofiber precursors. The competitive landscape is characterized by intense intellectual property development, highlighting the importance of patented manufacturing processes and proprietary surface treatments.

Regional trends reveal Asia Pacific (APAC) as the dominant force in both production and consumption, primarily due to established textile manufacturing hubs in China and India, coupled with increasing government funding for nanotechnology research in South Korea and Japan. North America and Europe remain key markets for high-value-added applications, particularly in smart textiles, defense, and high-performance medical devices, commanding premium pricing due to stringent quality standards and advanced regulatory oversight. Emerging economies in Latin America and the Middle East and Africa (MEA) are showing increasing demand, particularly in protective workwear and industrial filtration segments, signaling future growth potential as manufacturing capabilities mature in these regions. The geographical distribution of innovation capacity is highly concentrated, with centers of excellence often linked to major university research parks and industrial clusters specializing in materials science.

Segmentation trends highlight the rapid expansion of the materials segment, with carbon nanotubes (CNTs) and metallic nanoparticles (e.g., silver, gold) leading in terms of revenue, primarily due to their superior conductivity and antimicrobial efficacy, respectively. By application, the medical and healthcare sector is poised for the highest growth rate, driven by the immediate need for advanced wound care and sophisticated diagnostics embedded in wearable fabric sensors. Conversely, the defense and security segment, though smaller in volume, demands highly specialized and customized nanotextiles, ensuring high average selling prices (ASPs). The future market structure is expected to shift towards convergence, where single fabric platforms incorporate multiple nanomaterial functionalities, such as simultaneous self-cleaning, energy harvesting, and vital sign monitoring, demanding integrated manufacturing and processing capabilities across the value chain.

AI Impact Analysis on Nanotextiles Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Nanotextiles Market center primarily on optimizing material discovery, accelerating quality control, and customizing manufacturing processes. Common questions revolve around how AI can shorten the research cycle for novel nanofiber compositions, predicting the performance characteristics (like durability or conductivity) before physical synthesis, and implementing predictive maintenance in electrospinning machinery. Users are keen to understand AI's role in scaling up production from laboratory bench to industrial volume while maintaining nanoscale precision, a historically difficult challenge. The overarching theme is the expectation that AI and Machine Learning (ML) algorithms will be crucial for overcoming current research bottlenecks, minimizing material waste, and ensuring the consistent quality required for regulatory approval, particularly in highly sensitive medical and aerospace applications.

AI's integration is expected to revolutionize material informatics within the nanotextiles sector. By leveraging vast databases of material properties, processing parameters, and resulting textile characteristics, ML models can rapidly screen thousands of potential nanomaterial combinations and synthesis routes. This predictive modeling capability significantly reduces the need for expensive and time-consuming physical experimentation, allowing researchers to home in on optimal formulations for specific functional requirements, such as maximal energy storage capacity or tailored thermal regulation performance. Furthermore, AI is critical in simulating the long-term behavior and degradation patterns of nanotextiles under various environmental stresses, providing manufacturers with crucial data for product lifecycle management and warranty provisions, enhancing overall reliability and market trust.

In the manufacturing phase, AI facilitates Generative Design principles and advanced process control. AI-driven monitoring systems analyze real-time data from production lines—including variables like humidity, voltage, and flow rate in electrospinning—to dynamically adjust parameters, ensuring uniform fiber diameter and distribution, which is essential for textile functionality. This precision minimizes defects and maximizes yield, directly addressing the scalability and cost challenges previously associated with nanomanufacturing. As the market moves toward personalized functional apparel, AI algorithms will be essential for managing complex customization demands, ensuring that specific batches of fabric are manufactured efficiently to meet unique client specifications concerning embedded sensors, coatings, or specific protective properties.

- AI accelerates the discovery of novel nanofiber compositions by simulating molecular interactions and predicting performance metrics.

- Machine Learning optimizes electrospinning parameters in real-time, drastically reducing process variability and improving fiber quality consistency.

- Predictive maintenance algorithms minimize downtime for complex nanomanufacturing equipment, increasing operational efficiency and throughput.

- AI-driven image analysis enhances quality control by rapidly identifying nanoscale defects or non-uniformities in fiber structures.

- Generative design tools assist engineers in creating optimized textile geometries for specific applications, such as lightweight ballistic protection.

- Data analytics derived from AI support regulatory compliance by providing comprehensive traceability and quality documentation for advanced medical textiles.

- AI enables highly customized manufacturing runs for smart textiles, managing complex sensor integration and circuitry layouts within the fabric structure.

DRO & Impact Forces Of Nanotextiles Market

The Nanotextiles Market is fundamentally shaped by a confluence of accelerating drivers (D), significant restraints (R), and compelling opportunities (O), creating powerful impact forces that influence strategic decisions. Key drivers include the escalating demand for high-performance protective textiles in military, law enforcement, and industrial environments, coupled with rapid advancements in wearable electronics and smart clothing technology which necessitates electrically conductive and flexible substrates. Furthermore, global awareness regarding hygiene and safety, particularly in the post-pandemic era, has boosted the market for antimicrobial and viral-barrier nanotextiles in healthcare and consumer segments. These drivers exert a strong positive force, encouraging massive R&D spending and infrastructural investments in advanced materials science worldwide.

Conversely, the market faces considerable restraints, primarily concerning regulatory uncertainty and public perception issues surrounding the potential toxicity and long-term environmental fate of certain nanoparticles. Standardizing the classification, labeling, and disposal of materials incorporating metal nanoparticles or carbon nanotubes remains a significant regulatory hurdle, slowing down mass-market adoption and increasing compliance costs for manufacturers. Additionally, the high cost associated with sophisticated nanomanufacturing equipment (like specialized electrospinning machines) and the need for highly skilled labor contribute to elevated production expenses, making the end products relatively expensive compared to conventional textiles, thus limiting penetration into price-sensitive consumer markets. These restraints generate resistance forces, demanding innovative cost-reduction strategies and clear, unified global regulatory guidelines.

Tremendous opportunities exist within the development of fully biodegradable and biocompatible nanotextiles, aligning with global sustainability goals and expanding the addressable market within regenerative medicine, surgical implants, and environmentally friendly filtration systems. The convergence of nanotechnology with 3D printing (additive manufacturing) presents new ways to create intricate and highly functional textile structures on demand. Moreover, untapped potential lies in utilizing nanotextiles for large-scale environmental remediation, such as advanced air and water purification filters capable of capturing ultra-fine pollutants. These opportunities act as powerful directional forces, guiding future research focus toward personalized healthcare applications and addressing global environmental challenges through advanced material innovation, promising high returns on investment for companies that successfully navigate the regulatory and scaling complexities inherent in this domain.

Segmentation Analysis

The Nanotextiles Market is structurally segmented based on crucial factors including the type of nanomaterial used, the specific manufacturing technology employed, the functionality achieved, and the various end-use applications served. This segmentation is essential for understanding market dynamics, identifying high-growth niches, and formulating precise commercial strategies. The core segmentation by material highlights the dominance of carbon-based nanomaterials and metallic compounds, crucial for electrical and biological functionality, respectively. The technology segment differentiates between methods like electrospinning (favored for high-surface area structures) and coating techniques (cost-effective for bulk textile modification). Understanding these splits allows market players to specialize in areas where their proprietary technology provides a distinct competitive advantage, enabling targeted product development and market penetration efforts.

The segmentation by functionality provides the clearest view of product differentiation and market value. Key functionalities include antimicrobial textiles, highly conductive fabrics (for sensors and energy storage), UV protection, flame retardancy, and water repellency (superhydrophobicity). The demand for multifunctional textiles, which combine several of these attributes (e.g., antimicrobial and water-repellent protective clothing), is rapidly increasing, creating complex product development challenges but offering superior revenue potential. Analyzing the market through this functional lens confirms the high-value nature of specialized applications, particularly in defense and medicine, where performance specifications are non-negotiable and justify premium pricing structures.

The end-use application segment—comprising Medical & Healthcare, Automotive, Defense & Security, Sports & Outdoors, and Consumer Textiles—reveals the ultimate destination of the nanoproducts and the scale of demand. The Medical & Healthcare segment, driven by advanced wound care and implantable devices, exhibits strong growth and stable demand, whereas the Consumer Textiles segment, while large, is highly sensitive to cost and aesthetics. Strategic analysis indicates that companies focusing on niche, high-requirement sectors (like aerospace components or military uniforms) benefit from higher margins and longer contract cycles, contrasting with the high-volume, lower-margin dynamics of general protective apparel and everyday clothing segments. This comprehensive segmentation informs manufacturing scalability decisions and target market prioritization.

- By Nanomaterial Type:

- Carbon Nanotubes (CNTs)

- Nanoparticles (Silver, Titanium Dioxide, Gold, Zinc Oxide)

- Nanofibers (Polymer-based, Ceramic-based)

- Nanowires

- By Technology:

- Electrospinning

- Coating and Finishing (Sol-gel, Layer-by-layer)

- Nanofiber Composites

- Plasma Treatment

- Chemical Vapor Deposition (CVD)

- By Functionality:

- Antimicrobial and Anti-viral

- Electrical and Thermal Conductive

- UV Protection and Flame Retardancy

- Water and Stain Repellent (Superhydrophobic)

- Self-Cleaning (Photocatalytic)

- By Application:

- Medical and Healthcare (Wound Dressings, Implants, Hygienic Masks)

- Defense and Security (Ballistic Protection, Stealth Textiles)

- Sports and Outdoor Wear (Thermal Regulation, Performance Monitoring)

- Automotive and Aerospace (Lightweight Composites, Interior Fabrics)

- Environmental (Filtration Systems, Water Purification)

- Consumer and Apparel (Smart Wearables, General Clothing)

Value Chain Analysis For Nanotextiles Market

The value chain for the Nanotextiles Market begins with the upstream sourcing and synthesis of raw materials, specifically the base polymers (e.g., nylon, polyester, polypropylene) and the nanoscale additives (CNTs, metallic nanoparticles, ceramic precursors). This initial stage is crucial as the quality and purity of the nanoscale components directly dictate the final textile performance and safety profile. Key players in this upstream segment include specialized chemical producers and nanotechnology synthesis companies, which require high levels of technical expertise and stringent quality control protocols. Efficiency in this stage relies on cost-effective mass production techniques for uniform nanoparticles and the secure handling of potentially hazardous nanoscale materials, influencing the overall production cost structure for downstream manufacturers.

The mid-stream encompasses the core transformation process: integrating nanomaterials into the textile structure through specialized manufacturing technologies such as electrospinning, melt-blowing, or various coating and finishing techniques. This is the stage where the textile's functional characteristics are fundamentally engineered. Manufacturers at this level invest heavily in proprietary machinery and process optimization to achieve scalability while maintaining nanofiber consistency and adhesion to the substrate. Successful midstream operations require close collaboration with upstream suppliers to tailor nanomaterial specifications and downstream partners to ensure the functional textiles meet precise application requirements, often involving customized weaving or knitting processes followed by advanced post-processing treatments.

The downstream distribution channel involves moving the finished nanotextiles to end-use sectors, utilizing both direct and indirect channels. Direct sales are common for high-value, highly customized applications, such as supplying specialized medical device companies or defense contractors, where technical consultation and stringent quality assurance documentation are required. Indirect channels, involving specialized textile distributors or integrated apparel manufacturers, handle higher volumes of consumer or standard industrial protective textiles. The proximity to end-use customers and efficient supply chain logistics are critical for timely delivery and market responsiveness. Ultimately, the successful monetization of nanotextiles relies on effective marketing that clearly communicates the superior functionality and verified safety of the materials to the final buyers and consumers, often necessitating educational campaigns to overcome technological unfamiliarity.

Nanotextiles Market Potential Customers

The primary potential customers for the Nanotextiles Market are diverse industrial and institutional buyers requiring materials with exceptional performance characteristics that conventional textiles cannot provide. Within the Medical & Healthcare sector, major purchasers include hospitals, pharmaceutical companies, and specialized medical device manufacturers who procure advanced wound dressings, sterile antimicrobial textiles for operating rooms, and flexible substrates for wearable patient monitoring devices. These customers prioritize biocompatibility, sterilization efficacy, and verifiable long-term stability, making them high-value, quality-sensitive clients. The demand is structurally inelastic due to the critical nature of these applications, ensuring continuous market uptake for certified products.

Another significant customer base resides within the Defense & Security and Industrial Safety sectors. Government agencies, military contractors, and large industrial corporations operating in hazardous environments (e.g., chemical plants, oil refineries, mining) purchase nanotextiles for ballistic protection, chemical warfare protection suits, and advanced flame-retardant workwear. These customers require materials that meet extremely rigorous performance standards, often involving official certification processes and long-term supply contracts. The key purchasing criteria here revolve around weight reduction, enhanced durability, and verifiable protective performance against specific threats, driving demand for specialized, high-cost composite nanotextile solutions.

Furthermore, the high-end Consumer and Sports & Outdoor segments represent a rapidly growing customer demographic. Premium sportswear brands, automotive manufacturers (for advanced interior materials and lightweight composites), and tech companies developing smart wearables are significant buyers. These customers seek nanotextiles that offer enhanced consumer appeal, such as moisture-wicking capability, odor control, UV protection, and integrated sensing functionality. Their purchasing decisions are influenced not only by performance but also by aesthetic appeal, brand reputation, and willingness to pay a premium for technological differentiation, pushing manufacturers to balance performance engineering with consumer-grade finish and scalability. The convergence of fashion and technology further solidifies this segment as a crucial future revenue source for specialized nanotextile products.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 6.5 Billion |

| Market Forecast in 2033 | USD 23.5 Billion |

| Growth Rate | CAGR 19.5% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Nano Textile, Toray Industries Inc., DuPont, Kimberly-Clark Corporation, Ahlstrom-Munksjö, Aspen Aerogels Inc., BASF SE, Textiles Nanotechnology (TNano), Revolution Fibres, P&G, Kelheim Fibres GmbH, Teijin Limited, Donaldson Company Inc., Schoeller Textiles AG, Nanotex, FibeRio Technology Corporation, Baltex, Elmarco s.r.o., Hollingsworth & Vose Company, Lydall Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Nanotextiles Market Key Technology Landscape

The Nanotextiles Market is defined by several cutting-edge manufacturing and finishing technologies that enable the integration of nanoscale features into textile fibers and surfaces. Electrospinning remains the flagship technology, allowing the creation of highly uniform, continuous nanofibers with extremely high surface area-to-volume ratios. This method is crucial for applications demanding superior filtration, tissue engineering scaffolds, and high-capacity battery separators within flexible textile formats. Ongoing research focuses on improving the scalability and speed of industrial electrospinning processes, including multi-jet and nozzle-free systems, to drive down manufacturing costs and meet large-volume industrial demands. The precision of electrospinning is essential for controlling pore size and morphology, directly impacting the functional performance of the resulting fabric, whether for filtration or biomedical applications.

Coating and functional finishing techniques represent the second major technological pillar. These include methods like Sol-gel processing, which applies liquid precursors containing nanoparticles that solidify on the fabric surface, and Chemical Vapor Deposition (CVD), often used to deposit thin, highly uniform conductive or protective layers onto textile substrates. Layer-by-Layer (LbL) assembly is gaining traction for creating highly controlled, multi-functional coatings by sequential deposition of complementary nanoscale materials, enabling precise control over thickness and chemical composition. These coating techniques are typically more cost-effective for modifying conventional textiles in bulk compared to creating nanofiber mats entirely through electrospinning, making them highly relevant for consumer and general industrial markets seeking enhanced features like stain resistance or UV protection.

Furthermore, novel integration technologies, such as advanced compounding and in-situ polymerization, are vital for ensuring the durable integration of nanomaterials directly within the polymer matrix of the fiber during extrusion or spinning. This internal integration enhances the material's long-term stability and washability compared to surface coatings, addressing a major durability concern in consumer apparel. The adoption of additive manufacturing (3D printing) is also beginning to influence the sector, allowing for the precise construction of complex 3D textile structures incorporating nanofillers, especially valuable in creating customized, intricate scaffolds for advanced tissue engineering or specialized sensor integration within functional fabrics. Collectively, these technologies drive the transition from passive textiles to sophisticated, active smart fabrics capable of complex interactions with their environment.

Regional Highlights

- Asia Pacific (APAC): APAC commands the largest market share, driven by its unparalleled textile manufacturing capacity, particularly in countries like China, India, and South Korea. Strong governmental support for nanotechnology research and rapid industrialization across the region contribute to its leadership. APAC is a key hub for mass production of commodity nanotextiles (e.g., antimicrobial masks, filtration media) and is quickly accelerating investment in high-end applications like smart wearables and advanced defense textiles. Japan and South Korea lead in intellectual property generation and commercialization of next-generation nano-coating technologies, positioning the region for sustained rapid growth.

- North America: This region is characterized by high spending on R&D, stringent defense standards, and rapid adoption of high-value smart textiles and medical applications. The United States is a global leader in both nanotech innovation and end-use application, particularly within the military (advanced combat uniforms, ballistic protection) and medical fields (FDA-approved nanofiber wound dressings). The market here demands high performance and is less price-sensitive than consumer markets, focusing primarily on proprietary functional textiles and embedded sensor technologies.

- Europe: Europe represents a mature market emphasizing sustainability, safety, and regulatory compliance (e.g., REACH regulations). Countries like Germany, Switzerland, and the UK are strong centers for advanced industrial textiles, high-performance protective workwear, and specialized filtration systems. European manufacturers are heavily focused on developing bio-based and biodegradable nanotextiles, driven by strong consumer and institutional demand for eco-friendly materials and ethical sourcing practices.

- Latin America (LATAM): The LATAM market is currently characterized by moderate growth, primarily focused on adopting imported nanotextiles for industrial protective clothing (PPE) in the mining and construction sectors. Brazil and Mexico show the highest potential due to developing manufacturing bases and increasing regional investment in infrastructure and textile production. Market penetration remains constrained by economic factors and higher reliance on conventional textile solutions, though opportunities for specialized filtration media are expanding.

- Middle East and Africa (MEA): Growth in MEA is primarily driven by defense modernization programs in the Gulf Cooperation Council (GCC) countries and increased investment in industrial safety standards across the region, particularly in oil and gas extraction. The high demand for durable, thermally regulated, and UV-resistant textiles due to harsh climatic conditions makes it a receptive market for high-quality functional materials. Investment is often concentrated through government procurement for military and critical infrastructure projects.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Nanotextiles Market.- Toray Industries Inc.

- DuPont

- Kimberly-Clark Corporation

- Ahlstrom-Munksjö

- Aspen Aerogels Inc.

- BASF SE

- Textiles Nanotechnology (TNano)

- Revolution Fibres

- P&G

- Kelheim Fibres GmbH

- Teijin Limited

- Donaldson Company Inc.

- Schoeller Textiles AG

- Nanotex

- FibeRio Technology Corporation

- Baltex

- Elmarco s.r.o.

- Hollingsworth & Vose Company

- Lydall Inc.

Frequently Asked Questions

Analyze common user questions about the Nanotextiles market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary technology driving the production of high-performance nanofibers?

The predominant technology is electrospinning, which utilizes an electric field to draw nanoscale fibers from a liquid polymer solution. This technique allows for precise control over fiber diameter and morphology, essential for applications requiring high surface area, such as advanced filtration and biomedical scaffolds.

Which application segment holds the largest potential for revenue generation in the Nanotextiles Market?

The Medical and Healthcare segment is projected to show the highest growth rate and substantial revenue potential. This is driven by the critical need for advanced antimicrobial wound dressings, sophisticated tissue engineering materials, and flexible, sensor-integrated diagnostic wearable devices.

What are the main regulatory and safety concerns impacting the mass market adoption of nanotextiles?

The primary concern is the potential for environmental release and long-term health effects of free-floating nanoparticles, particularly metal-based ones. Regulatory bodies are working to standardize safety protocols, testing methods, and clear labeling guidelines to address public and governmental concerns regarding nanoparticle toxicity.

How do carbon nanotubes (CNTs) enhance textile functionality?

CNTs primarily enhance textiles by providing exceptional electrical conductivity, mechanical strength, and thermal stability. This enables the creation of smart textiles for energy harvesting, sensing, and reliable thermal regulation in high-performance or extreme environment apparel.

Which geographical region currently dominates the Nanotextiles manufacturing landscape?

Asia Pacific (APAC), particularly driven by major textile manufacturing economies such as China, India, and South Korea, dominates the global manufacturing volume. This dominance is supported by favorable government policies and large-scale industrial infrastructure for both raw material synthesis and textile finishing.

The Nanotextiles Market is undergoing a revolutionary transformation driven by material science breakthroughs and escalating demand for multifunctional, high-performance fabrics across critical industries globally. The convergence of nanotechnology with traditional textile engineering creates materials that offer superior mechanical, electrical, and biological properties, fundamentally changing what fabrics are capable of achieving. This market analysis confirms the robust compound annual growth trajectory, fueled largely by innovation cycles in biomedical engineering and the pervasive adoption of smart wearable technology. Key drivers include government investment in defense modernization, increasing consumer awareness regarding health and hygiene, and the necessity for lighter, stronger materials in aerospace and automotive applications. The integration of advanced computational tools, particularly Artificial Intelligence and Machine Learning, is crucial for overcoming inherent manufacturing constraints related to scalability and quality control at the nanoscale, ensuring that the production processes can efficiently support the growing market demand. AI models optimize precursor selection, predict fiber performance, and manage complex electrospinning parameters in real-time, significantly accelerating the commercialization timeline for novel nanotextile products. While the market faces challenges related to high capital expenditure for specialized machinery and the complex regulatory landscape surrounding nanoparticle toxicity, vast opportunities exist in developing sustainable, biodegradable nanotextiles and integrating these materials with additive manufacturing techniques like 3D printing. The competitive environment is marked by strong intellectual property protection and strategic partnerships among chemical suppliers, research institutes, and large-scale textile producers to leverage proprietary technological advantages. Regionally, Asia Pacific leads in volume production due to extensive manufacturing infrastructure, while North America and Europe retain leadership in high-value, research-intensive segments such as military and advanced medical devices, setting the pace for functional material innovation. The segmentation analysis underscores the rapid expansion in functional categories, specifically antimicrobial and conductive textiles, highlighting the future focus on convergence to deliver multifunctional fabric platforms. Stakeholders must strategically navigate the value chain, ensuring high-purity upstream material supply and efficient downstream distribution, particularly through direct channels for customized high-performance solutions. The financial outlook remains exceptionally strong, affirming nanotextiles as a pivotal enabling technology for the future of smart and protective materials across the entire industrial spectrum. Continued dedication to safety research and the standardization of manufacturing processes will be vital for achieving widespread consumer acceptance and maximizing the projected market valuation by 2033. The comprehensive understanding of DRO factors—focusing on mitigating regulatory risks while capitalizing on sustainability and technological convergence opportunities—will define market success over the forecast period. The increasing sophistication of textile finishing techniques, combined with advancements in conductive polymer science, promises a future where fabrics are integral components of connected, responsive, and protective systems rather than merely passive barriers. The continuous refinement of production methodologies, such as nozzle-free electrospinning and advanced surface deposition, is poised to democratize access to these advanced materials, pushing them beyond niche high-cost applications toward broader industrial and consumer adoption globally. This technological progression is irreversible and establishes nanotextiles as a fundamental pillar of the next generation of material engineering.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager