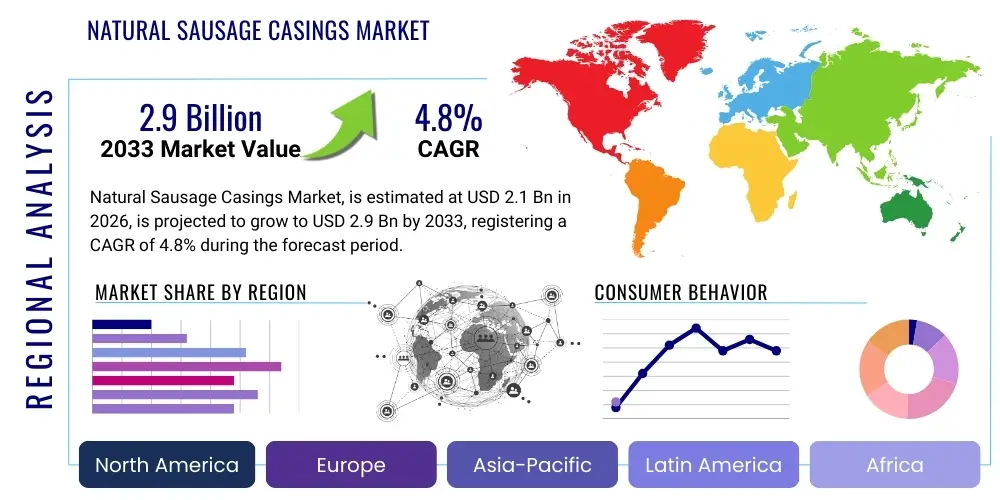

Natural Sausage Casings Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438961 | Date : Dec, 2025 | Pages : 255 | Region : Global | Publisher : MRU

Natural Sausage Casings Market Size

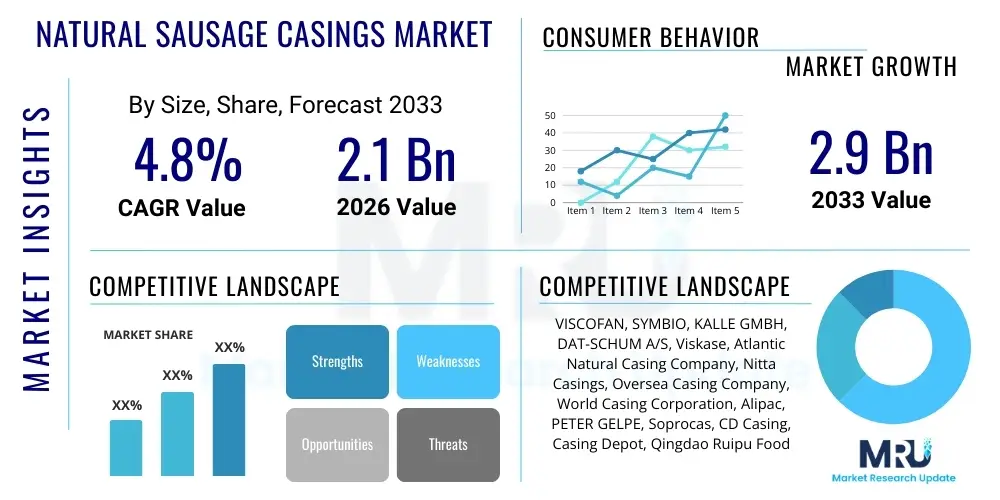

The Natural Sausage Casings Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2026 and 2033. The market is estimated at USD 2.1 Billion in 2026 and is projected to reach USD 2.9 Billion by the end of the forecast period in 2033. This consistent growth trajectory is driven by increasing consumer preference for authentic, traditional meat products and heightened demand for clean-label ingredients across global markets. The perception of natural casings as superior in terms of bite, flavor retention, and cooking performance further solidifies their market position, despite competition from artificial alternatives.

Natural Sausage Casings Market introduction

The Natural Sausage Casings Market encompasses the segment of the food processing industry focused on producing, processing, and distributing tubular membranes derived primarily from the sub-mucosa layer of livestock intestines, predominantly hog, cattle, and sheep. These natural membranes are essential for encasing meat emulsions to produce various types of sausages, providing structure, protection, and enhancing the final product’s culinary characteristics, notably the desirable ‘snap’ or ‘bite’. Major applications span across fresh, smoked, cured, and pre-cooked sausages, forming the backbone of traditional meat processing globally. Benefits include superior cooking properties, excellent smoke permeability, and high flavor transfer, which are crucial for premium sausage production.

Driving factors propelling market expansion include rising meat consumption in developing economies, increasing consumer demand for premium and artisanal meat products, and the persistent preference for clean-label, natural ingredients over synthetic alternatives. Furthermore, the inherent biodegradability of natural casings appeals to environmentally conscious consumers, contributing significantly to their sustained demand. The historical significance and regulatory acceptance of these casings in established culinary practices also provide a stable foundation for market growth, ensuring their continued relevance in high-quality meat production sectors worldwide.

Natural Sausage Casings Market Executive Summary

The Natural Sausage Casings Market is characterized by robust business trends centered on supply chain optimization and quality assurance, given the reliance on by-products from the meat industry. Key players are investing heavily in advanced cleaning, calibration, and preservation technologies to maximize yield and maintain consistent quality standards for global distribution. Business models are shifting towards integrated supply chains, linking slaughterhouses directly with casing processors to ensure freshness and traceability, thereby mitigating risks associated with raw material sourcing volatility. Sustainability and ethical sourcing have also emerged as critical competitive differentiators, influencing procurement decisions among large-scale food manufacturers seeking transparency.

Regionally, Europe and North America remain the dominant markets, attributed to deeply entrenched sausage-making traditions and high per capita consumption of processed meats, particularly premium varieties that necessitate natural casings. However, the Asia Pacific region, driven by urbanization, rising disposable incomes, and the modernization of meat processing infrastructure in countries like China and India, presents the highest growth potential. Regional trends indicate increasing localization of processing facilities to reduce logistics costs and adapt casing specifications to regional sausage types. Segment-wise, hog casings dominate the market due to their versatility and availability, while sheep casings, favored for smaller, specialty sausages, command a premium price point. The pre-cooked and smoked sausage application segment is exhibiting rapid growth, fueled by consumer convenience trends and the superior moisture retention properties offered by natural casings during heat treatment.

AI Impact Analysis on Natural Sausage Casings Market

User inquiries concerning AI's role in the natural sausage casings sector primarily revolve around enhancing raw material quality assessment, optimizing supply chain logistics for perishable goods, and predictive maintenance in processing plants. Common concerns focus on whether AI can accurately grade casings based on diameter and strength faster than manual inspection, and how machine learning can forecast demand volatility linked to meat market fluctuations. Users also show interest in AI-driven traceability systems that can quickly link a batch of finished casings back to the source animal, addressing growing regulatory and consumer demands for provenance and food safety transparency. Essentially, the industry seeks AI solutions that address the inherent variability and perishable nature of the raw material, converting a variable biological input into a standardized industrial product with minimized waste.

The implementation of Artificial Intelligence and machine learning algorithms is set to revolutionize the quality control and supply chain management aspects inherent in the natural casings market. AI-powered optical sorting systems can analyze the physical attributes of cleaned casings—such as diameter consistency, wall thickness, and defect identification—at high throughput speeds, significantly reducing reliance on subjective human grading. This automation leads to improved product standardization, higher processing yields, and a reduction in operational costs. Furthermore, predictive analytics, utilizing historical data on livestock slaughter rates, seasonal demand patterns, and climate conditions, allows processors to better forecast raw material availability and adjust production schedules, minimizing inventory spoilage.

Beyond the factory floor, AI profoundly impacts market strategy and consumer engagement. Machine learning tools are increasingly used to analyze vast datasets of consumer preferences, tracking successful flavor combinations and desired product textures (the ‘snap’ quality), thus assisting sausage manufacturers in developing new products optimally suited for natural casings. In the distribution phase, AI optimizes cold chain logistics by predicting potential delays and adjusting transport routes dynamically, ensuring the integrity of the salted or preserved casings during transit. This transition towards data-driven operations ensures greater efficiency and responsiveness, making the natural casings industry more resilient to external market shocks and material unpredictability.

- AI enhances visual quality inspection, leading to superior grading consistency and reducing manual error in casing selection.

- Predictive modeling optimizes inventory levels and forecasts raw material supply based on agricultural and market data, minimizing spoilage risks.

- Machine learning improves supply chain traceability, providing verifiable provenance data from farm to processor, crucial for food safety compliance.

- AI algorithms contribute to optimizing processing parameters (salting, drying) to achieve specific casing specifications required by different sausage types.

- Automated systems for facility maintenance leverage AI to predict equipment failure, ensuring uninterrupted processing of highly perishable materials.

DRO & Impact Forces Of Natural Sausage Casings Market

The market dynamics are governed by a complex interplay of Drivers, Restraints, Opportunities, and overarching Impact Forces that dictate the growth trajectory and operational challenges for stakeholders. Key drivers predominantly stem from the intrinsic quality advantages of natural casings, including their superior texture, flavor development potential, and consumer preference for natural food ingredients, especially within the premium and artisanal segments of the meat industry. Opportunities lie in expanding into emerging economies with growing middle-class populations, coupled with technological advancements aimed at automating the cleaning and calibration processes to reduce labor intensity and improve yield consistency, thereby addressing inherent operational complexities.

However, the market faces significant restraints. The primary constraint is the dependence on a highly variable raw material supply derived as a by-product of livestock slaughter, making pricing and availability volatile. Furthermore, the extensive manual labor traditionally required for cleaning, sorting, and processing natural casings results in higher production costs compared to synthetic alternatives (like collagen or fibrous casings). Impact forces such as stringent food safety regulations, particularly concerning animal by-products and international trade barriers, necessitate continuous compliance investments and complex logistical frameworks, imposing considerable pressure on smaller processors to maintain global competitiveness and adherence to diverse standards.

The market’s sensitivity to public health scares related to livestock diseases and fluctuating prices of raw animal materials further categorizes external impact forces that shape investment decisions and long-term planning. The growing trend of plant-based sausage alternatives, while currently minimal in direct competition to high-quality meat products using natural casings, represents a potential long-term disruptive force. Consequently, innovation is focused not only on process efficiency but also on enhancing the preservation and shelf life of the casings themselves, ensuring that natural casings remain the gold standard for authentic sausage production in the face of competitive and operational challenges.

Segmentation Analysis

The Natural Sausage Casings market segmentation provides a critical understanding of the product landscape, revealing consumption patterns and application diversity across the food industry. The market is primarily segmented based on the animal source (Hog, Sheep, Beef), which dictates the casing’s size, thickness, and primary application type. Further segmentation occurs based on application (Fresh Sausages, Smoked Sausages, Dried/Cured Sausages), defining the required strength and permeability characteristics. Distribution channels further differentiate the market into direct sales to large processors (B2B) and retail channels for smaller butchers and consumers (B2C), reflecting the varied customer base from large industrial meat companies to specialized artisanal producers. This structured view is essential for strategic market penetration and product development tailored to specific end-user needs.

- By Source: Hog Casings, Sheep Casings, Beef Casings (Rounds, Middles, Bungs)

- By Application: Fresh Sausages (e.g., Breakfast sausage, Bratwurst), Pre-cooked/Boiled Sausages (e.g., Hot dogs, Bologna), Smoked/Dried Sausages (e.g., Salami, Pepperoni)

- By Distribution Channel: B2B (Direct Sales to Meat Processors), B2C (Supermarkets, Specialty Meat Shops, Online Retail)

Value Chain Analysis For Natural Sausage Casings Market

The value chain for natural sausage casings commences with the upstream analysis, which is intrinsically linked to the global livestock slaughter industry. Raw material sourcing involves the collection and preliminary cleaning of intestines from abattoirs, predominantly hog, sheep, and cattle slaughterhouses. Quality control at this initial stage is paramount, as the freshness and handling of the raw guts directly determine the final casing quality. Relationships with slaughterhouses are crucial, often forming long-term contracts to ensure a stable supply of raw materials, which are high-volume, low-margin by-products requiring specialized rapid handling and chilling logistics to prevent microbial degradation and maintain integrity before processing begins.

The midstream processing phase involves intense industrial activities, including meticulous cleaning, degreasing, flushing, and meticulous calibration of the casings. This processing transforms the raw animal intestine into a usable casing product through stages like turning, sliming, sorting, and eventually preservation, typically via heavy salting or brine solutions. Advanced processing technologies are utilized for sizing and classifying casings based on specific market demand for diameter and length, ensuring consistency required by automated sausage stuffing equipment. Efficiency in this stage significantly impacts the final cost and quality, driving continuous investment in labor-saving machinery and stringent hygienic protocols to meet international food safety standards.

Downstream analysis focuses on distribution and sales, covering both direct and indirect channels. Direct distribution (B2B) involves selling large volumes of calibrated and preserved casings directly to major meat processors, industrial sausage makers, and large co-packers globally. Indirect channels (B2C) cater to smaller independent butchers, artisanal producers, and hobbyists through specialized food distributors, wholesalers, and increasingly, e-commerce platforms. Effective distribution requires robust cold chain management, even for salted casings, and localized warehousing to meet just-in-time delivery requirements of meat manufacturers. The market is highly relationship-driven, where technical support and quality consistency are often as important as price competition in securing long-term supply contracts.

Natural Sausage Casings Market Potential Customers

The primary customer base for natural sausage casings is overwhelmingly composed of commercial meat processors, ranging from large multinational corporations specializing in processed meats to smaller, regional artisanal sausage makers. These end-users utilize casings as an indispensable ingredient for manufacturing premium sausages, hot dogs, bologna, and various cured products, relying on natural casings for specific textural qualities and permeability that synthetic options cannot replicate. Large industrial buyers prioritize high-volume consistency, standardized calibration (diameter and length uniformity), and competitive bulk pricing, often purchasing directly from major international casing suppliers through negotiated B2B contracts ensuring steady, long-term supply relationships.

A significant secondary segment consists of specialized, independent butchers and gourmet food producers who prioritize the superior quality, natural appearance, and traditional appeal of sausages encased in natural products. These smaller buyers often purchase through local or specialized distributors, valuing unique casing characteristics, such as specific sheep casings for specialty frankfurters or specific hog casings for regional European sausages. For this segment, the narrative of authenticity and the resulting superior "snap" texture during consumption are key selling points, often enabling them to command higher retail prices for their finished goods, making them less price-sensitive regarding the casing cost.

Furthermore, emerging markets are witnessing a surge in demand from fast-food chains and convenience food manufacturers that are expanding their offering of pre-cooked and packaged sausages. As processing capabilities modernize in developing economies, the demand for calibrated, easy-to-stuff natural casings increases substantially. The customer base also includes private label manufacturers and food service distributors who supply institutional buyers (schools, hospitals, caterers). Overall, the market is characterized by a demanding clientele that views the casing not merely as packaging, but as an integral component of the product's quality, necessitating exacting standards across the entire supply chain, from sourcing raw materials to preservation techniques.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 2.1 Billion |

| Market Forecast in 2033 | USD 2.9 Billion |

| Growth Rate | 4.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | VISCOFAN, SYMBIO, KALLE GMBH, DAT-SCHUM A/S, Viskase, Atlantic Natural Casing Company, Nitta Casings, Oversea Casing Company, World Casing Corporation, Alipac, PETER GELPE, Soprocas, CD Casing, Casing Depot, Qingdao Ruipu Food |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Natural Sausage Casings Market Key Technology Landscape

The core technology in the natural sausage casings market revolves around advanced processing, cleaning, and preservation techniques designed to stabilize a highly perishable biological material. Modern processing plants utilize sophisticated machinery for automated flushing and degreasing of the intestines, drastically reducing manual labor while simultaneously enhancing hygiene and reducing the risk of microbial contamination. Critical advancements include multi-stage high-pressure water jet cleaning systems and enzymatic treatments tailored to efficiently remove unwanted tissues without compromising the integrity of the sub-mucosa layer. These mechanized cleaning lines are essential for scaling production to meet global industrial demand, moving away from labor-intensive traditional methods prevalent in smaller operations.

Perhaps the most significant technological development involves precision calibration and sorting systems. Automated casing calibration machines use optical sensors and laser technology to measure the diameter, thickness, and length of individual strands with extremely high accuracy. This precise sizing is crucial for industrial sausage production, where consistency is necessary for high-speed stuffing lines. Furthermore, advanced preservation techniques, moving beyond simple dry salting, include optimized brine solutions with specific mineral compositions and controlled environment storage (chilling/freezing) to maximize the shelf life and structural integrity of the casings during extended shipping periods across continents. These technologies ensure that the inherent variability of the raw material is minimized, providing a reliable and standardized product to meat processors.

In terms of traceability and quality assurance, digital technologies are playing an increasing role. Implementation of sophisticated Enterprise Resource Planning (ERP) systems allows processors to track casing batches from the specific slaughterhouse lot through every processing stage, facilitating rapid recalls if necessary and providing essential data for regulatory compliance. Emerging technological considerations also encompass sustainable water usage and waste reduction technologies, given the high volume of water required for cleaning. Companies are exploring closed-loop water recycling systems and efficient management of sludge waste, aiming to improve environmental performance while maintaining stringent sanitation standards required for food contact materials, thus future-proofing the industry against tightening environmental regulations.

Regional Highlights

- Europe: Dominates the global market, underpinned by deep-rooted traditions in sausage making (e.g., Germany, Italy, Poland) and a high consumer demand for premium, authentic products. Europe holds the highest processing capabilities, characterized by strict quality standards and significant exports of processed casings globally.

- North America: Represents a mature market characterized by large-scale industrial sausage production and a strong preference for high-quality hog and beef casings. Growth is driven by the robust processed meat industry and continuous demand for specialty sausages utilizing natural casings, particularly in the premium segment.

- Asia Pacific (APAC): Exhibits the fastest growth rate, fueled by expanding meat consumption, rapid modernization of food processing infrastructure, and urbanization. Countries like China and Japan are increasing their reliance on high-quality imported casings as local production scales up and quality requirements become stricter.

- Latin America: A significant region for raw material sourcing, particularly beef casings, given its large cattle population. The market is developing, focusing both on supplying raw material to global processors and catering to domestic demand for traditional meat products.

- Middle East and Africa (MEA): A nascent but growing market, driven by increasing disposable incomes and westernization of food habits. While sheep casing demand is strong due to regional culinary preferences, dependence on imports for high-quality processed casings remains high.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Natural Sausage Casings Market.- VISCOFAN

- SYMBIO (Part of Viskase Companies, Inc.)

- KALLE GMBH

- DAT-SCHUM A/S

- Viskase Companies, Inc.

- Atlantic Natural Casing Company

- Nitta Casings

- Oversea Casing Company

- World Casing Corporation

- Alipac

- PETER GELPE

- Soprocas

- CD Casing

- Casing Depot

- Qingdao Ruipu Food

- Crown Casing, Inc.

- A.C. Legg, Inc.

- DeWied International

- Elshaddai Casings

- Klerk’s Casing Company

Frequently Asked Questions

Analyze common user questions about the Natural Sausage Casings market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the demand for natural sausage casings?

The primary driver is the enduring consumer preference for superior flavor development, traditional texture, and the distinctive 'snap' or bite achievable only with natural casings, particularly in the premium and artisanal sausage segments. The demand for clean-label, natural ingredients also heavily supports market growth.

How does the volatility of raw material supply affect the market?

The market is directly constrained by the availability and price fluctuations of livestock by-products. Since casings are derived from animal intestines, supply is inherently dependent on slaughter rates, leading to price volatility and requiring processors to maintain complex inventory management strategies to stabilize production.

Which type of natural casing dominates the global market?

Hog casings dominate the global market due to their versatility, wide availability, and optimal size range, making them suitable for popular items like bratwurst and fresh Italian sausages. Sheep casings are also highly valued but command a higher price for specialty, small-diameter sausages like frankfurters.

How is technology being used to improve natural casing production?

Technology is focused on advanced automation for cleaning, degreasing, and particularly, precision calibration using optical and laser systems. These innovations reduce reliance on manual labor, increase production consistency, and ensure products meet the strict diameter specifications required by high-speed industrial stuffing machinery.

What are the key differences between natural and collagen casings in commercial use?

Natural casings offer superior smoke permeability, better flavor transfer, and the authentic 'snap' texture. Collagen casings, while cheaper and more uniform, are often perceived as inferior in texture, though they are favored in high-volume production for their consistency and ease of use on automated lines where natural texture is not the primary consumer requirement.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager