NB Latex Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432485 | Date : Dec, 2025 | Pages : 253 | Region : Global | Publisher : MRU

NB Latex Market Size

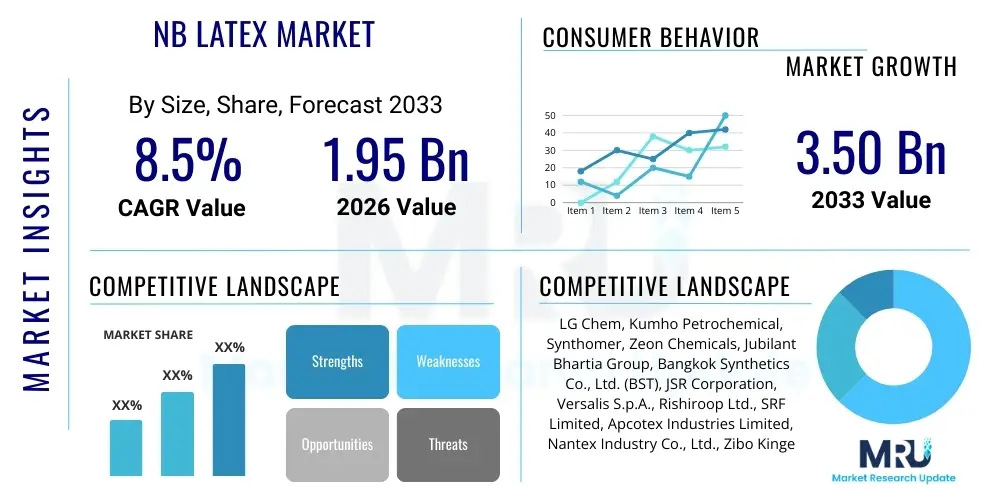

The NB Latex Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2026 and 2033. The market is estimated at USD 1.95 Billion in 2026 and is projected to reach USD 3.50 Billion by the end of the forecast period in 2033. This robust expansion is primarily driven by escalating global healthcare expenditure, coupled with increasingly stringent hygiene and safety regulations across medical and industrial sectors worldwide.

NB Latex Market introduction

Nitrile Butadiene (NB) Latex, a synthetic rubber emulsion produced through the emulsion polymerization of acrylonitrile and butadiene, stands out as a critical material offering superior chemical resistance, puncture resistance, and tensile strength compared to natural rubber latex. Its inherent protein-free nature eliminates Type I latex allergies, making it the preferred material for disposable examination and surgical gloves, which represent its largest and most essential application segment. The unique blend of durability and flexibility ensures optimal performance in high-stakes environments, reinforcing its indispensable role in medical and safety protocols globally.

Beyond the high-demand medical sector, NB Latex finds extensive utilization across diverse industrial applications, including adhesives, paper coating, dipping applications for household goods, and specialty foams. The adaptability of NB Latex formulations allows manufacturers to tailor properties such as particle size, solids content, and cross-linking density to meet specific performance requirements, thereby facilitating its integration into complex manufacturing processes. This versatility broadens the market scope, making the material sensitive to shifts in manufacturing outputs, infrastructure development, and consumer safety standards.

Key driving factors propelling the market include heightened public health awareness following global pandemics, mandatory safety regulations in food processing and chemical handling industries, and continuous technological advancements leading to the development of thinner, stronger, and more comfortable nitrile gloves. Furthermore, the rapid industrialization and growth of the manufacturing sector in emerging economies, particularly in the Asia Pacific region, necessitate increased volumes of protective equipment and specialty adhesives, ensuring sustained long-term growth for NB Latex producers.

NB Latex Market Executive Summary

The NB Latex market is characterized by significant momentum, driven predominantly by non-discretionary demand from the global healthcare sector and enhanced industrial safety standards. Business trends indicate a strong focus on capacity expansion by major manufacturers, particularly in Southeast Asia, to mitigate supply chain volatility and capitalize on low-cost production advantages. Technological advancements are centered on optimizing polymerization processes to achieve lower modulus and higher tensile strength, fulfilling the market requirement for lighter yet more durable nitrile gloves, thereby improving user dexterity and reducing material usage per unit. Strategic partnerships between raw material suppliers and glove manufacturers are becoming common to stabilize input costs and ensure consistent quality.

Regionally, Asia Pacific (APAC) maintains its dominant position, serving as the world’s primary manufacturing hub for NB Latex and derived end-products, fueled by supportive government policies, abundant labor, and escalating domestic healthcare needs in countries like China, India, and Malaysia. North America and Europe, while mature markets, are experiencing growth driven by strict regulatory mandates (such as OSHA and EU directives) requiring high-quality personal protective equipment (PPE). The shift toward localized manufacturing in the West, spurred by geopolitical risks and supply shortages experienced during recent crises, presents a crucial long-term trend influencing future regional distribution patterns.

Segmentation trends highlight the overwhelming dominance of the medical grade segment, which continues to command the largest market share due to its essential nature and high consumption rates in hospitals and clinics. Within product types, high solids content latex is gaining traction due to its efficiency in dipping processes and reduced energy requirements for drying. Furthermore, increased environmental consciousness is pushing the development of sustainable and biodegradable NB Latex alternatives, although current adoption remains niche, representing a future growth opportunity across all application segments.

AI Impact Analysis on NB Latex Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the NB Latex market overwhelmingly center on three core themes: predictive operational efficiency, advanced material formulation, and dynamic supply chain resilience. Users are keenly interested in how AI can optimize the highly complex and energy-intensive emulsion polymerization process, specifically through predicting reactor conditions and optimizing batch consistency to reduce defects and waste. A primary concern is whether AI-driven quality control systems can effectively manage the subtle variations in raw material inputs (butadiene and acrylonitrile) to maintain the stringent quality required for medical-grade products. Furthermore, expectations are high regarding AI’s ability to accelerate R&D by simulating new NB Latex formulations with improved barrier properties or reduced modulus without extensive physical prototyping, thus shortening the time-to-market for next-generation products.

- AI-driven predictive maintenance optimizes polymerization reactor performance, minimizing unplanned downtime and maximizing asset utilization across production facilities.

- Advanced algorithms analyze complex raw material fluctuations (Butadiene and Acrylonitrile pricing and quality) to ensure optimal procurement timing and blending strategies, mitigating cost volatility.

- Machine learning models enhance Quality Control (QC) by identifying subtle deviations in latex particle size and distribution in real-time, ensuring stringent medical-grade specifications are met consistently.

- AI simulation accelerates the development of novel, low-ammonia, or high-tenacity NB Latex formulations, reducing reliance on lengthy physical trials and lowering R&D expenditure.

- Dynamic supply chain mapping and risk assessment utilize AI to forecast demand peaks (e.g., during health crises) and optimize inventory deployment, enhancing market responsiveness and resilience.

DRO & Impact Forces Of NB Latex Market

The NB Latex market dynamics are shaped by a powerful confluence of drivers, constraints, and inherent opportunities that dictate long-term strategic planning. Key drivers include the ever-increasing global demand for enhanced hygiene standards, mandatory implementation of personal protective equipment (PPE) across sensitive industries, and the persistent threat of infectious disease outbreaks, necessitating constant stockpiling of medical gloves. Restraints primarily revolve around the high volatility and non-renewable nature of petrochemical raw materials, specifically butadiene, which exerts significant pressure on manufacturing costs and profit margins. Furthermore, intense competition from alternative synthetic polymers and the high capital investment required for new polymerization facilities act as barriers to entry.

Opportunities for growth are significant, particularly in expanding NB Latex applications beyond traditional medical gloves into highly specialized industrial gloves, high-performance coatings, and sustainable adhesive formulations. The development of bio-based or partially sustainable NB Latex, potentially leveraging bio-butadiene, represents a major avenue for future market differentiation and compliance with stricter environmental regulations in developed economies. The increasing sophistication of dipping technology also allows manufacturers to create products with superior tactile sensitivity and comfort, driving consumer preference over less comfortable alternatives.

The principal impact forces shaping the market include strict regulatory environments (e.g., FDA, REACH compliance), which favor the consistent, high quality of NB Latex, and macroeconomic factors such as global oil price movements, which directly influence raw material costs. Geopolitical stability is another critical force, as the concentration of manufacturing capacity in Southeast Asia makes the global supply chain susceptible to trade disputes and regional lockdowns. These interwoven forces demand that market players prioritize operational flexibility, robust risk management strategies, and vertical integration to maintain competitive advantage and ensure supply continuity to essential end-users.

Segmentation Analysis

The NB Latex market segmentation provides a granular view of demand distribution based on composition and end-use application, enabling strategic market targeting. The primary segmentation is based on end-use application, where the medical sector remains the largest and fastest-growing category, followed by industrial protective wear, and then specialty segments like adhesives and sealants. Compositionally, the market is differentiated by solids content—high solids content latex is preferred for high-speed dipping processes due to quicker coagulation and drying times, offering cost-efficiency, while medium solids content latex caters to specific industrial coating requirements. Understanding these segments is crucial as product quality specifications, regulatory compliance, and pricing structures vary significantly between medical, industrial, and consumer grades.

- By Application:

- Medical (Disposable Examination Gloves, Surgical Gloves)

- Industrial (Protective Industrial Gloves, Chemical Handling)

- Adhesives and Sealants

- Paper and Board Coatings

- Others (Foams, Dipped Goods)

- By Type/Product Grade:

- High Solid Content NB Latex (Typically >45% Solids)

- Medium Solid Content NB Latex (Typically 40%-45% Solids)

- Low Solids Content NB Latex

- By Geography:

- North America (U.S., Canada)

- Europe (Germany, U.K., France)

- Asia Pacific (China, Malaysia, Thailand, India)

- Latin America (Brazil, Mexico)

- Middle East and Africa (UAE, Saudi Arabia)

Value Chain Analysis For NB Latex Market

The NB Latex value chain initiates with the upstream sourcing of key petrochemical monomers: butadiene and acrylonitrile, which are heavily influenced by crude oil prices and the global refining capacity. Butadiene supply, in particular, often dictates the operational costs for latex manufacturers, necessitating sophisticated hedging and procurement strategies. The conversion of these monomers into NB Latex occurs in the midstream, involving complex emulsion polymerization processes conducted in large chemical plants. This phase is capital-intensive and requires stringent quality control to ensure the resulting latex emulsion meets the required consistency, particle size, and stability specifications for its intended downstream application, especially medical dipping.

The downstream activities involve the distribution of the liquid latex to secondary manufacturers. Direct distribution channels are often employed for large-volume customers, such as multinational glove manufacturers or major adhesive producers, ensuring quality control and technical support are maintained throughout the supply relationship. Indirect channels, utilizing specialized chemical distributors and regional agents, cater to smaller industrial customers and geographically diverse markets. Efficiency in transportation and storage is critical, as NB Latex is a temperature-sensitive emulsion requiring careful handling to prevent destabilization or coagulation.

The final stage involves the end-product manufacturing, where the latex is utilized in dipping processes (gloves, balloons) or formulation processes (adhesives, coatings). Glove manufacturers, being the dominant end-users, transform the latex into finished goods that must comply with rigorous medical standards (ASTM, EN, ISO). This final step adds significant value through packaging, sterilization, and branding. The profitability across the chain is heavily weighted towards the upstream raw material suppliers and the highly efficient, large-scale downstream glove producers, placing midstream latex producers under continuous pressure to optimize operational efficiency and secure long-term raw material contracts.

NB Latex Market Potential Customers

The primary potential customers for NB Latex are centered within industries requiring high-level barrier protection, sterilization, and chemical resistance. The largest single customer segment comprises global manufacturers of disposable gloves, ranging from specialized surgical glove producers to high-volume examination glove manufacturers. These companies view NB Latex as a strategic, non-substitutable input for meeting regulatory requirements and high-volume demand from healthcare systems, laboratories, and pharmaceutical companies globally. The high consumption rate of disposable gloves, exacerbated by increased hygiene awareness, ensures this segment remains the central driver of market volume and innovation in quality specifications.

The secondary segment involves industrial protective equipment manufacturers that produce robust industrial gloves, safety sleeves, and specialized coatings for chemical processing, automotive manufacturing, and food handling sectors. These customers prioritize the superior chemical abrasion resistance offered by NB Latex formulations, often demanding bespoke formulations optimized for contact with specific solvents or oils. The shift towards automated production lines also requires industrial gloves with specialized grip patterns and durability, presenting continuous customization opportunities for latex suppliers.

Furthermore, specialty chemical formulators and producers of adhesives, sealants, and paper coatings constitute a vital customer base. In these applications, NB Latex is valued for its strong adhesion properties, low curing temperature, and mechanical stability. Specifically, the construction and packaging industries utilize NB Latex-based adhesives that offer environmental benefits, such as low Volatile Organic Compounds (VOCs), driving sustained demand as industries seek compliant, high-performance bonding solutions. These diverse applications ensure market resilience against fluctuations in any single end-user sector.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.95 Billion |

| Market Forecast in 2033 | USD 3.50 Billion |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | LG Chem, Kumho Petrochemical, Synthomer, Zeon Chemicals, Jubilant Bhartia Group, Bangkok Synthetics Co., Ltd. (BST), JSR Corporation, Versalis S.p.A., Rishiroop Ltd., SRF Limited, Apcotex Industries Limited, Nantex Industry Co., Ltd., Zibo Kingen Industry Co., Ltd., China Petrochemical Corporation (Sinopec), PetroChina Company Limited, TSRC Corporation, ARLANXEO. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

NB Latex Market Key Technology Landscape

The technological landscape of the NB Latex market is primarily focused on enhancing product performance, improving production efficiency, and addressing environmental concerns. A major innovation area is the refinement of emulsion polymerization techniques to achieve highly monodisperse latex particles with uniform size and distribution. This precision control over particle morphology is critical for developing high-performance dipping compounds that yield thinner gloves with superior barrier protection, lower modulus (for improved comfort and tactile sensitivity), and reduced risk of pinholes, which is essential for compliance with evolving medical standards and user demand for greater dexterity.

Another pivotal area of research involves modifying the chemical structure and compounding agents to improve the mechanical properties of the final product while reducing processing time and energy consumption. This includes the use of advanced cross-linking systems and specialized surfactants that allow for stable, low-ammonia NB Latex formulations. Low-ammonia formulations are increasingly sought after due to reduced toxicity during processing and improved environmental profiles. Furthermore, the industry is heavily investing in technologies that facilitate higher solids content while maintaining low viscosity, enabling faster dipping speeds and significantly lowering the energy required for the extensive drying process typically involved in glove manufacturing.

Looking forward, sustainable technology is emerging as a critical competitive differentiator. Research efforts are underway to incorporate bio-based raw materials, such as bio-acrylonitrile or bio-butadiene, into the polymerization process to create greener NB Latex alternatives. While currently complex and costly, this move aligns with corporate sustainability mandates and anticipated regulatory pressure to minimize the petrochemical footprint. Continuous process optimization, often leveraging digital twinning and advanced process control (APC) systems, further characterizes the technological push, aiming to solidify NB Latex's position as the material of choice over competing synthetic rubber options.

Regional Highlights

- Asia Pacific (APAC): APAC dominates the global NB Latex market both in terms of consumption and production capacity. Countries like Malaysia and Thailand house the world’s largest glove manufacturing facilities, ensuring high, sustained regional demand for the raw latex. China and India are major consumers in non-medical sectors (adhesives, construction, automotive) due to rapid industrialization and escalating domestic healthcare investment. The region benefits from competitive manufacturing costs, favorable governmental support for export-oriented industries, and proximity to raw material sources.

- North America: North America represents a mature, high-value market characterized by stringent regulatory oversight (FDA requirements for medical devices) and a high degree of technological sophistication. Demand is primarily concentrated in the premium medical and specialized industrial sectors. Growth is steady, driven by stockpiling initiatives, replacement demand, and a preference for high-quality, specialized protective wear. Regional stability is a key procurement driver for end-users seeking alternatives to potentially volatile supply chains.

- Europe: Similar to North America, the European market is highly regulated (REACH, CE marking) and focused on high-specification products, particularly surgical and chemotherapy-grade gloves. Germany, the UK, and France are major consumers. Although production capacity is limited compared to APAC, the region focuses on R&D for sustainable NB Latex formulations and niche applications, driven by strong environmental consciousness and the need for localized technical support.

- Latin America and MEA: These regions represent emerging markets exhibiting high growth potential, fueled by improving healthcare infrastructure and growing awareness of occupational safety standards. While current consumption is smaller, increased foreign direct investment in manufacturing and localized public health initiatives are expected to rapidly increase the demand for imported or locally produced NB Latex products throughout the forecast period.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the NB Latex Market.- LG Chem

- Kumho Petrochemical Co., Ltd.

- Synthomer plc

- Zeon Chemicals L.P.

- JSR Corporation

- Bangkok Synthetics Co., Ltd. (BST)

- Jubilant Bhartia Group (Jubilant Life Sciences)

- Versalis S.p.A.

- Rishiroop Ltd.

- SRF Limited

- Apcotex Industries Limited

- Nantex Industry Co., Ltd.

- Zibo Kingen Industry Co., Ltd.

- China Petrochemical Corporation (Sinopec)

- TSRC Corporation

- ARLANXEO

- PetroChina Company Limited

- Shanxi Sanwei Group Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the NB Latex market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is driving the high demand for NB Latex in the medical sector?

The demand is primarily driven by the superior puncture resistance, chemical impermeability, and critically, the protein-free composition of NB Latex, which eliminates the risk of Type I latex allergies prevalent with natural rubber, making it the mandated material for disposable medical gloves globally.

How do fluctuating raw material prices impact the profitability of NB Latex producers?

Raw material volatility, particularly in butadiene and acrylonitrile markets, significantly impacts producer profitability. Since these petrochemical derivatives constitute a major portion of production costs, rapid price increases often necessitate strategic raw material hedging and forward pricing contracts to stabilize margins and ensure supply continuity.

Which geographical region dominates the manufacturing and supply of NB Latex?

Asia Pacific (APAC), specifically Southeast Asian nations like Malaysia and Thailand, dominates the global NB Latex supply chain. This dominance is due to established, high-volume production capacities, favorable logistics for shipping finished goods, and cost advantages in manufacturing and labor.

What are the key technical advantages of High Solid Content (HSC) NB Latex?

HSC NB Latex offers advantages in dipping processes, requiring less energy for drying due to the reduced water content. This leads to faster manufacturing cycles, higher throughput, and ultimately, lower operational costs for large-scale producers of nitrile gloves and industrial dipped goods.

What future innovations are expected to shape the NB Latex market?

Future innovations will focus on sustainability, including the integration of bio-based monomers (bio-butadiene) and the development of biodegradable formulations. Furthermore, technology aimed at producing ultra-low modulus, high-tenacity latex will enhance glove comfort and tactile sensitivity without compromising barrier protection, fulfilling premium market requirements.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager