Neoprene Sponge Cord Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438301 | Date : Dec, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Neoprene Sponge Cord Market Size

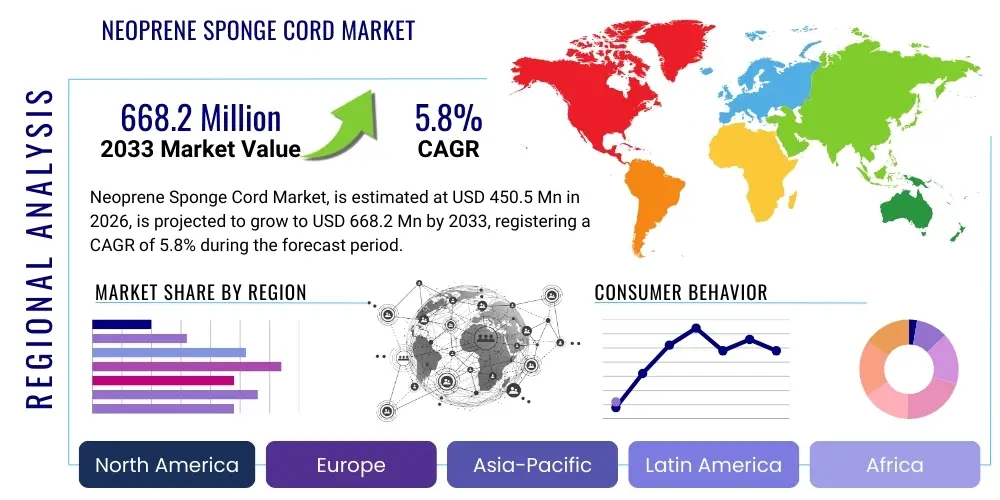

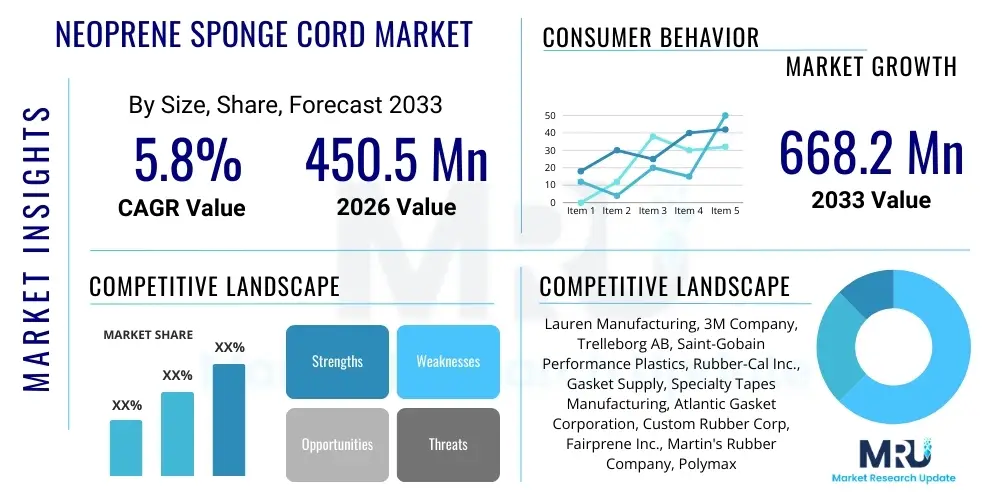

The Neoprene Sponge Cord Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 450.5 Million in 2026 and is projected to reach USD 668.2 Million by the end of the forecast period in 2033.

Neoprene Sponge Cord Market introduction

The Neoprene Sponge Cord Market encompasses the manufacturing, distribution, and sale of sealing and cushioning materials made from closed-cell polychloroprene (Neoprene) rubber. These cords are highly valued across industrial sectors due to their exceptional resilience, weather resistance, oil and chemical resistance, and ability to perform reliably across a broad temperature range. Neoprene sponge cords are predominantly utilized in applications requiring effective sealing against dust, moisture, and air, or where vibration damping is critical. Key manufacturing processes involve extrusion and vulcanization, resulting in flexible, durable cords available in various densities and diameters.

The primary applications of Neoprene Sponge Cords span several high-growth industries. In the automotive sector, they are indispensable for creating seals in doors, windows, and engine compartments, ensuring noise reduction and weatherproofing. The construction and HVAC industries rely on these cords for gasketing, insulation, and expansion joint fillers, particularly where fire retardancy and durability are prerequisites. Furthermore, their application extends into the electronics sector for shock absorption and environmental protection of sensitive components, highlighting their versatility and critical function in maintaining operational integrity across diverse mechanical and structural assemblies.

Market growth is substantially driven by the accelerating demand from the global automotive industry, particularly in electric vehicle manufacturing, where high-performance sealing materials are essential for battery enclosures and thermal management systems. Additionally, stringent regulatory requirements concerning energy efficiency and noise reduction in construction are fueling the adoption of high-quality sealing solutions like Neoprene sponge cords. The inherent benefits, including excellent compression set resistance and superior durability compared to open-cell alternatives, solidify their position as a preferred material in demanding industrial environments, ensuring sustained market expansion throughout the forecast period.

Neoprene Sponge Cord Market Executive Summary

The Neoprene Sponge Cord Market is characterized by robust growth, primarily driven by increasing industrial automation and escalating demand for high-performance sealing materials in specialized applications such as aerospace, mass transit, and renewable energy infrastructure. Key business trends indicate a shift towards customized, high-density cords capable of withstanding extreme temperatures and harsh chemical exposures, pushing manufacturers to invest heavily in advanced extrusion technologies and material science research to improve product specifications. Strategic mergers and acquisitions among established players are also prevalent, aimed at consolidating market share and expanding specialized product portfolios, particularly in highly regulated regional markets like North America and Europe.

Regional dynamics reveal that the Asia Pacific (APAC) region remains the dominant growth engine, fueled by rapid industrialization, large-scale infrastructure projects in countries like China and India, and the explosive growth of the regional automotive manufacturing base. North America and Europe maintain strong market positions, driven by high adoption rates in replacement markets and stringent quality standards that favor premium, certified Neoprene products. Segmentation trends emphasize the increasing adoption of closed-cell variants over semi-closed options due to superior impermeability, and the rising prominence of specific diameter cords, particularly those used for intricate gasketing in complex machinery.

Overall, the market trajectory is positive, underpinned by continuous technological advancements in material compounding and a diversified application base that mitigates risks associated with cyclical industry downturns. Manufacturers are strategically focusing on sustainable production methods and exploring bio-based alternatives, albeit slowly, to address increasing environmental concerns. The competitive landscape is moderately fragmented, with specialized manufacturers vying for niche applications by offering superior material blends and customized service models, ensuring innovation remains central to market competitiveness and sustainable growth.

AI Impact Analysis on Neoprene Sponge Cord Market

Users frequently inquire about how Artificial Intelligence (AI) and associated technologies like machine learning (ML) and predictive analytics will transform the traditional manufacturing of elastomer products. Common concerns center on whether AI can optimize the highly specific process of Neoprene compounding, predict material degradation under various stress conditions, and automate quality control without compromising the physical properties essential for high-performance sealing. Users are keenly interested in the potential for AI-driven demand forecasting, which could stabilize volatile raw material procurement and optimize inventory management for highly custom product lines, alongside questions about robotic process automation enhancing extrusion consistency and reducing manufacturing waste, ultimately seeking efficiency gains and improved material quality predictability.

The implementation of AI is expected to revolutionize several core aspects of Neoprene Sponge Cord production and distribution, moving the industry towards Industry 4.0 standards. In the manufacturing phase, AI algorithms are being deployed to monitor real-time data from extrusion machines, adjusting temperature, pressure, and flow rates instantaneously to ensure uniform cell structure and density, thereby minimizing batch variations and significantly reducing scrap material. Furthermore, machine learning models are proving crucial in optimizing the complex chemical formulation processes, predicting the optimal mix ratios for desired attributes such as compression set, tensile strength, and oil resistance based on minor variations in raw polymer batches, leading to unparalleled consistency and performance improvement.

Beyond the factory floor, AI profoundly impacts supply chain robustness and market strategy. Predictive maintenance enabled by AI monitors equipment health, dramatically cutting downtime and ensuring higher overall operational efficiency. In the commercial sphere, sophisticated ML models analyze vast quantities of end-user performance data to inform R&D, identifying unmet needs for specific industrial applications, such as high-temperature environments in aerospace or demanding shock absorption requirements in specialized electronics. This data-driven approach allows manufacturers to rapidly prototype and launch highly specialized Neoprene sponge cord products that precisely match evolving market requirements, enhancing customer satisfaction and market responsiveness.

- AI-driven optimization of polymer compounding formulas for enhanced performance characteristics.

- Predictive maintenance schedules for extrusion equipment reducing unplanned manufacturing downtime.

- Automated quality inspection systems utilizing computer vision to detect subtle surface flaws and inconsistencies.

- Machine learning models for highly accurate demand forecasting and raw material procurement stabilization.

- Optimization of energy consumption during vulcanization processes through real-time AI parameter adjustments.

- Enhanced customization capabilities through rapid analysis of application-specific performance feedback loops.

- Implementation of robotic automation in material handling and packaging, improving operational safety and speed.

DRO & Impact Forces Of Neoprene Sponge Cord Market

The Neoprene Sponge Cord Market dynamics are governed by a complex interplay of Drivers, Restraints, and Opportunities, which collectively form the Impact Forces shaping its growth trajectory. Key drivers include robust demand from the expanding global automotive sector, particularly the rapid transition toward electric vehicles (EVs) which require highly durable and fire-resistant sealing solutions for battery packs and chassis. Simultaneously, escalating infrastructure development in emerging economies, alongside stringent regulatory mandates in developed markets concerning noise reduction and thermal insulation in construction, strongly propel the need for high-quality elastomeric seals. The versatility and inherent superiority of Neoprene in terms of chemical stability and ozone resistance further establish its preferred status over general-purpose rubber alternatives, reinforcing its market penetration across critical industrial applications.

However, the market faces significant restraints, primarily stemming from the volatility of raw material prices, specifically petrochemical-derived monomers used in Neoprene production, which directly impacts manufacturing costs and profit margins. Environmental concerns regarding the disposal and non-biodegradability of synthetic rubber products pose a long-term challenge, pushing regulatory bodies and environmental advocacy groups to seek sustainable alternatives. Furthermore, intense competition from substitute materials, such as silicone and EPDM (Ethylene Propylene Diene Monomer) rubber, particularly in applications where extreme temperature resistance is the primary concern, necessitates continuous product innovation to maintain market dominance. These constraints require strategic management of the supply chain and ongoing investment in process efficiency improvements.

Despite these restraints, substantial growth opportunities exist through the strategic penetration of niche high-value markets, such as aerospace, medical devices, and specialized industrial filtration systems, where high certification standards and bespoke material requirements command premium pricing. Technological opportunities lie in developing advanced formulations of flame-retardant and low-smoke Neoprene compounds to meet strict safety regulations in mass transit (rail, marine). The strategic shift towards adopting closed-cell Neoprene sponge cords with ultra-low compression set properties for demanding gasketing applications presents a lucrative avenue for market expansion. Leveraging digital transformation tools, including AI for quality assurance and optimizing production yield, will be critical for capturing these emerging opportunities and strengthening market positioning against competing materials.

The immediate impact forces are characterized by strong positive momentum from the electrification of the automotive fleet, balanced by short-term pressures arising from geopolitical instability affecting global shipping and raw material supply chains. The market is currently experiencing high differentiation pressures as end-users demand cords with increasingly specific dimensional tolerances and enhanced resistance profiles. Medium-to-long term success will be dictated by manufacturers’ ability to standardize quality across global operations while simultaneously offering hyper-customized solutions for specialized engineering requirements. The overarching force is the drive towards 'resilience and reliability' in industrial components, favoring proven, durable materials like Neoprene sponge cord, thereby sustaining high-value market entry points.

Segmentation Analysis

The Neoprene Sponge Cord Market is meticulously segmented based on key criteria including Cell Structure, Density, Diameter, and End-User Industry, enabling a granular understanding of market dynamics and targeted strategic planning. The segmentation by Cell Structure, primarily closed-cell versus semi-closed cell, is crucial as it dictates the material's sealing properties; closed-cell structures dominate due to their superior impermeability to liquids and gases, which is vital in automotive and construction sealing applications. Density segmentation, ranging from soft (low density) to firm (high density), directly influences the cord’s compression set and cushioning capabilities, catering to specific requirements for vibration damping or heavy-duty gasketing.

The segmentation based on Diameter (e.g., small, medium, large) reflects the dimensional precision required by various assemblies, with smaller diameters often utilized in intricate electronic enclosures and larger ones common in substantial industrial equipment or structural applications. Furthermore, the End-User Industry segmentation is perhaps the most defining, encompassing major consumption sectors such as Automotive, Construction, Electrical & Electronics, and Industrial Manufacturing. This division highlights the application diversity and allows market players to specialize their product offerings, focusing R&D efforts on meeting the sector-specific regulations and performance benchmarks inherent to each major consuming industry.

Understanding these segments provides a clear roadmap for market penetration and product development. For instance, the demand for high-density, closed-cell cords is soaring in the EV battery manufacturing segment (under Automotive), whereas construction often seeks medium-density cords for weatherstripping and expansion joints. Geographic segmentation overlays these product and application divisions, showing that while APAC leads in volume driven by automotive production, North America and Europe lead in value due to high demand for premium, regulated products in aerospace and high-speed rail, illustrating the varied strategic importance of each segment and region.

- By Cell Structure:

- Closed-Cell Neoprene Sponge Cord

- Semi-Closed Cell Neoprene Sponge Cord

- By Density:

- Low Density (Soft)

- Medium Density (Medium Firmness)

- High Density (Firm)

- By Diameter:

- Less than 5 mm

- 5 mm to 15 mm

- Above 15 mm

- By End-User Industry:

- Automotive (Including Electric Vehicles)

- Construction and HVAC

- Aerospace and Defense

- Electrical and Electronics

- Marine and Shipbuilding

- General Industrial Manufacturing

Value Chain Analysis For Neoprene Sponge Cord Market

The value chain for the Neoprene Sponge Cord Market initiates with upstream activities involving the sourcing and polymerization of raw materials, primarily chloroprene rubber (Neoprene polymer), foaming agents, vulcanizing chemicals, and various performance additives. This stage is dominated by major petrochemical companies and specialized chemical manufacturers, where raw material cost volatility and supply stability significantly influence the entire chain's profitability. Manufacturing, the central stage, involves specialized extrusion, compounding, continuous curing (vulcanization), and precision cutting processes. Efficiency in this stage relies heavily on advanced machinery and expertise in formulating the exact material blend to achieve specific cell structures, densities, and dimensional tolerances required by end-users, differentiating high-quality producers from mass-market suppliers.

Downstream activities focus on distribution, sales, and end-use application. The distribution network involves specialized industrial distributors, wholesale suppliers, and direct sales channels to large Original Equipment Manufacturers (OEMs), particularly in the automotive and aerospace sectors. Direct sales often cater to customized, high-volume orders, ensuring tight quality control and integrated supply chain management. Indirect channels, typically through regional distributors, serve smaller industrial end-users and the general MRO (Maintenance, Repair, and Operations) market, offering a broader array of standard sizes and specifications. The effectiveness of the downstream channel is critical for ensuring just-in-time delivery and technical support to diverse industrial clients who require precise sealing solutions for their respective manufacturing or assembly processes.

The interplay between upstream constraints and downstream demands highlights the importance of strategic partnerships. Upstream analysis reveals that securing favorable long-term contracts for chloroprene monomer is a competitive advantage, mitigating risks associated with commodity price fluctuations. Downstream success is often measured by the ability to offer value-added services, such as technical consultations on material selection, customized profile shapes, and quick turnaround times for specialized orders. The trend towards direct relationships with key OEMs strengthens the value chain, allowing manufacturers to participate earlier in the design phase, thus optimizing the sponge cord specifications for maximum performance in critical sealing and vibration-damping applications.

Neoprene Sponge Cord Market Potential Customers

The potential customer base for the Neoprene Sponge Cord Market is extremely diversified, primarily comprising major industrial manufacturers and specialized component suppliers who integrate these cords into their final products as essential sealing, gasketing, or cushioning elements. The largest end-users include Tier 1 and Tier 2 suppliers within the automotive industry, specifically those producing window and door seals, trunk seals, and protective elements for sensitive electronic components in both conventional and electric vehicles. These buyers prioritize materials with superior resistance to weather, oil, and continuous flexing, demanding high volume and consistent quality from their sponge cord suppliers.

Another significant segment consists of construction material suppliers and HVAC system manufacturers, who utilize Neoprene cords extensively for weather stripping, thermal insulation, and sound dampening in commercial and residential buildings. These customers value compliance with fire safety standards and long-term durability in external environments. Furthermore, industrial equipment manufacturers, covering sectors like heavy machinery, fluid power systems, and specialized processing equipment, represent critical buyers, needing precise dimensional control and chemical resistance for critical sealing interfaces, often requiring specialized, high-density variants of the cord for reliable operation under stress.

Niche but high-value customer groups include aerospace and defense contractors, who require materials meeting strict regulatory approvals for low smoke, flame spread, and operation at extreme temperatures. Buyers in the electrical and electronics sector purchase Neoprene sponge cords for shock absorption, dust sealing, and electromagnetic interference (EMI) shielding in enclosures and instrumentation panels. The diversity of these end-user/buyer groups underscores the market's resilience, as demand is distributed across multiple industrial cycles, ensuring continuous reliance on the material for its reliable sealing and environmental protection properties.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450.5 Million |

| Market Forecast in 2033 | USD 668.2 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Lauren Manufacturing, 3M Company, Trelleborg AB, Saint-Gobain Performance Plastics, Rubber-Cal Inc., Gasket Supply, Specialty Tapes Manufacturing, Atlantic Gasket Corporation, Custom Rubber Corp, Fairprene Inc., Martin's Rubber Company, Polymax Elastomers, Allied Metrics Seals & Packing, Monarch Rubber, D.R. Smith & Sons Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Neoprene Sponge Cord Market Key Technology Landscape

The manufacturing of Neoprene Sponge Cord is heavily reliant on precise chemical compounding and advanced continuous manufacturing technologies to achieve the required physical properties and dimensional accuracy. A core technological aspect is the continuous extrusion process, which uses specialized dies and screw mechanisms to shape the uncured Neoprene compound into a cord profile. Modern extrusion lines incorporate sophisticated feedback loops and control systems to maintain consistent pressure and temperature, crucial for preventing premature foaming and ensuring a smooth, uniform surface finish. Furthermore, advancements in tooling materials and die design are enabling the production of increasingly complex and customized cross-sectional profiles, expanding the application scope beyond traditional round cords into intricate P, D, and E shapes used for specialized sealing applications.

Following extrusion, the technology landscape is defined by the vulcanization (curing) process. The industry has increasingly adopted continuous curing systems, such as microwave curing and fluid bed curing, which offer rapid and highly uniform heat distribution compared to traditional hot air ovens. Microwave technology, in particular, allows for curing the Neoprene rapidly from the inside out, resulting in a consistent cell structure and superior compression set characteristics throughout the cord's cross-section. The efficiency and consistency provided by these advanced curing methods are pivotal for achieving the high-performance standards demanded by automotive and aerospace clients, driving process efficiency and reducing energy consumption.

Material science innovation represents the third critical technology domain. Research is focused on developing proprietary Neoprene blends using advanced additives to enhance specific properties, such as improved flame retardancy (low-smoke, low-toxicity formulations for rail and marine), higher temperature resistance, and optimized resistance to aggressive industrial lubricants and coolants. The use of specialized compounding equipment, including high-shear internal mixers, ensures the homogeneous dispersion of foaming agents and reinforcing fillers, directly influencing the density and closed-cell percentage of the final sponge cord. These technological enhancements are essential for maintaining the market competitiveness of Neoprene against alternative elastomers like silicone in high-specification sealing tasks.

Regional Highlights

The global Neoprene Sponge Cord market exhibits significant regional variation in terms of consumption volume, value growth, and industrial application focus.

- Asia Pacific (APAC): APAC represents the largest and fastest-growing market globally, driven by massive manufacturing capacities in China, India, and South Korea, particularly within the automotive (including EV) and construction sectors. Rapid urbanization and infrastructure expansion necessitate high volumes of basic and medium-density cords for weatherstripping and general sealing, though the adoption of high-performance cords for electronics and specialized machinery is rapidly increasing, establishing the region as the powerhouse of volume consumption.

- North America: Characterized by high-value consumption and stringent quality standards, North America is a mature market focused on replacement and high-specification OEM applications. Demand is strong from the aerospace, military, and energy sectors, requiring specialized, certified, flame-retardant cords. The market here emphasizes technological differentiation, favoring suppliers who can provide bespoke dimensions and guaranteed material traceability.

- Europe: Europe showcases steady, quality-driven growth, heavily influenced by EU regulations regarding material safety, fire resistance (especially in rail and public transport), and environmental compliance. Germany, the UK, and France are key consumers, with a high demand for premium closed-cell cords utilized in sophisticated engineering applications, machinery manufacturing, and the luxury automotive segment, prioritizing long-term durability and low-emission characteristics.

- Latin America (LATAM): The LATAM market is gradually expanding, fueled by growing domestic automotive production (especially in Brazil and Mexico) and increasing investment in construction and infrastructure. The market is sensitive to price, leading to a focus on cost-effective, standard-grade cords, but demand for higher-specification products is rising in specialized industrial segments.

- Middle East and Africa (MEA): Growth in MEA is episodic, tied primarily to large-scale construction projects, oil and gas infrastructure maintenance, and shipbuilding. The region requires cords with excellent resistance to extreme heat, sand, and harsh atmospheric conditions prevalent in the Gulf countries, creating niche opportunities for suppliers of high-performance, weather-resistant Neoprene materials.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Neoprene Sponge Cord Market.- Lauren Manufacturing

- 3M Company

- Trelleborg AB

- Saint-Gobain Performance Plastics

- Rubber-Cal Inc.

- Gasket Supply

- Specialty Tapes Manufacturing

- Atlantic Gasket Corporation

- Custom Rubber Corp

- Fairprene Inc.

- Martin's Rubber Company

- Polymax Elastomers

- Allied Metrics Seals & Packing

- Monarch Rubber

- D.R. Smith & Sons Ltd.

- Stockwell Elastomerics Inc.

- Extruded Rubber Products Inc.

- Precision Engineering Products Ltd.

- Advanced Gasket & Supply

Frequently Asked Questions

Analyze common user questions about the Neoprene Sponge Cord market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is Neoprene Sponge Cord and what are its primary industrial uses?

Neoprene Sponge Cord is a flexible, extruded sealing material made from closed-cell polychloroprene rubber. Its primary uses involve gasketing, sealing against dust and moisture, weatherstripping, and vibration damping in critical industries such as automotive, construction, and electronics due to its excellent resilience and resistance to oil, ozone, and weathering.

How do closed-cell and semi-closed cell Neoprene cords differ in performance?

Closed-cell Neoprene sponge cord features internal cells that are fully sealed, offering superior impermeability to water and gases, making it ideal for environmental sealing. Semi-closed cell cords have some interconnected cells, offering better compression characteristics and flexibility but reduced water resistance, often used for cushioning or light gasketing applications.

Which end-user segment drives the highest demand for Neoprene Sponge Cord?

The Automotive sector, particularly the rapidly expanding Electric Vehicle (EV) segment, drives the highest demand. EVs require specialized, highly durable, and fire-resistant Neoprene seals for battery enclosures, thermal management systems, and interior gasketing, ensuring safety and longevity.

What are the main challenges facing the Neoprene Sponge Cord Market?

The primary challenges include the high volatility and fluctuating cost of petrochemical-derived raw materials (chloroprene monomer), posing significant pricing pressure. Additionally, increasing competition from substitute materials like silicone and EPDM in certain extreme-temperature applications presents a constant challenge for market share maintenance.

Is the market trending towards customized or standard Neoprene Sponge Cord products?

The market is experiencing a strong dual trend: high-volume standard cords remain essential for general industrial and MRO needs, but there is an accelerating strategic shift toward customized, highly specialized products with specific density, diameter, and chemical resistance properties tailored for niche high-value applications like aerospace sealing and specialized machinery components.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager