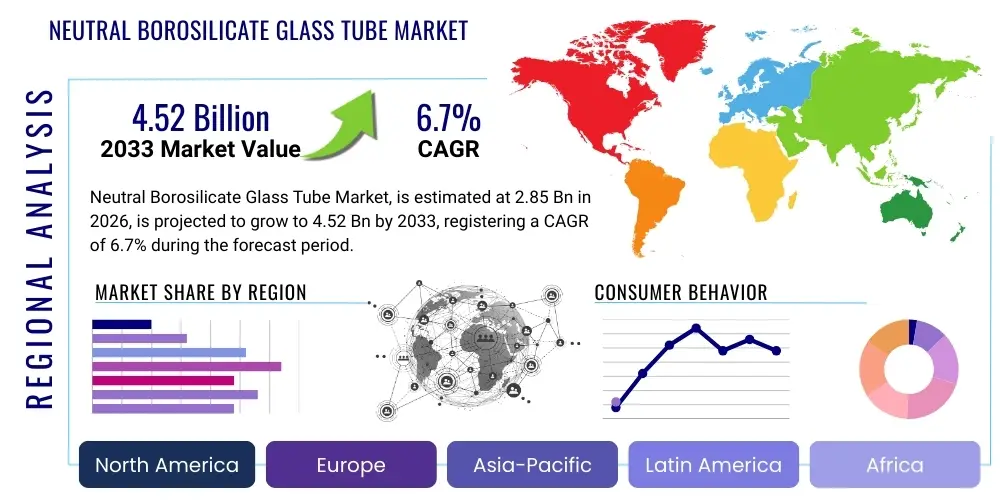

Neutral Borosilicate Glass Tube Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440282 | Date : Jan, 2026 | Pages : 257 | Region : Global | Publisher : MRU

Neutral Borosilicate Glass Tube Market Size

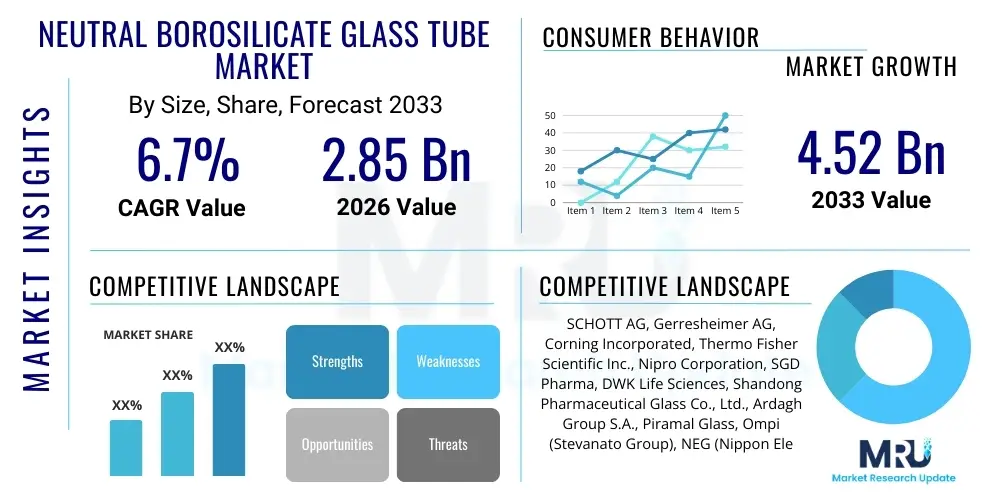

The Neutral Borosilicate Glass Tube Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.7% between 2026 and 2033. The market is estimated at USD 2.85 Billion in 2026 and is projected to reach USD 4.52 Billion by the end of the forecast period in 2033.

Neutral Borosilicate Glass Tube Market introduction

The neutral borosilicate glass tube market encompasses the manufacturing and distribution of specialized glass tubes characterized by their high resistance to thermal shock, chemical attack, and minimal interaction with stored substances. These tubes are primarily composed of silica and boron trioxide, which impart superior hydrolytic resistance, making them ideal for sensitive applications where product integrity is paramount. Their neutral pH further ensures that they do not leach alkalis into pharmaceutical formulations or other sensitive materials, thereby maintaining the stability and efficacy of contents.

Major applications of neutral borosilicate glass tubes include primary pharmaceutical packaging (such as vials, ampoules, cartridges, and syringes), laboratory glassware, medical devices, and high-performance lighting. The benefits derived from using these tubes stem from their exceptional durability, optical clarity, and inertness. These properties are critical for ensuring the safety, purity, and shelf-life of pharmaceutical drugs, vaccines, and diagnostic reagents. Key driving factors for market expansion include the burgeoning global pharmaceutical and biotechnology industries, increasing demand for safe and contamination-free drug delivery systems, and stringent regulatory requirements for pharmaceutical packaging materials. The robust growth in vaccine production and the expansion of chronic disease management therapies further bolster the demand for these specialized glass tubes.

Neutral Borosilicate Glass Tube Market Executive Summary

The neutral borosilicate glass tube market is witnessing substantial growth driven by advancements in pharmaceutical manufacturing and a heightened focus on patient safety and product integrity. Business trends indicate a strategic shift towards automated production processes and the development of customized glass solutions to meet diverse client needs, particularly within the biopharmaceutical sector. There is an increasing emphasis on sustainable manufacturing practices and the use of recycled content, aligning with broader industry environmental, social, and governance (ESG) goals. Strategic collaborations between glass manufacturers and pharmaceutical companies are also becoming more prevalent to ensure a stable supply chain and foster innovation in packaging solutions.

Regional trends highlight Asia Pacific as a rapidly expanding market, propelled by its growing pharmaceutical manufacturing base, increasing healthcare expenditure, and expanding generics market. North America and Europe maintain significant market shares due to well-established pharmaceutical industries, robust research and development activities, and stringent regulatory frameworks. Segmentation trends reveal that pharmaceutical packaging remains the dominant application segment, with pre-filled syringes and cartridges showing particularly strong growth due to their convenience and reduced risk of contamination. Type I borosilicate glass, known for its superior hydrolytic resistance, continues to be the preferred choice across critical applications, signaling a strong market preference for premium-grade materials.

AI Impact Analysis on Neutral Borosilicate Glass Tube Market

Common user questions regarding AI's impact on the neutral borosilicate glass tube market frequently revolve around its potential to enhance manufacturing efficiency, improve quality control, optimize supply chains, and reduce production costs. Users are keen to understand how AI can address challenges like defect detection, material waste, and demand forecasting in a highly specialized manufacturing environment. There are expectations that AI will enable more precise process control, leading to higher product consistency and fewer human errors, ultimately bolstering product safety and regulatory compliance within the pharmaceutical packaging sector. The interest extends to AI's role in accelerating research and development for new glass formulations and packaging innovations.

The integration of Artificial intelligence (AI) is poised to revolutionize various facets of the neutral borosilicate glass tube market by introducing unprecedented levels of automation, precision, and data-driven decision-making. AI-powered vision systems are already enhancing quality control processes, enabling real-time detection of minute defects that might be missed by human inspection, thereby significantly reducing rejection rates and improving overall product quality. Predictive maintenance algorithms, leveraging machine learning, can forecast equipment failures before they occur, minimizing downtime and optimizing production schedules. Furthermore, AI can optimize complex supply chain logistics, from raw material sourcing to finished product delivery, ensuring efficient inventory management and reducing lead times, which is critical for the just-in-time demands of the pharmaceutical industry. This comprehensive integration promises to foster greater efficiency, consistency, and innovation across the entire value chain.

- Enhanced quality control through AI-powered visual inspection systems, detecting micro-cracks and imperfections with high accuracy.

- Optimized manufacturing processes via machine learning algorithms for real-time adjustments, reducing material waste and energy consumption.

- Predictive maintenance of machinery, minimizing downtime and increasing operational efficiency.

- Improved supply chain management and demand forecasting, leading to better inventory control and reduced logistics costs.

- Accelerated research and development for novel glass formulations and coatings using AI-driven material discovery platforms.

- Robotic automation guided by AI for precise handling and packaging, reducing contamination risks and labor costs.

- Data analytics for market trend prediction, guiding strategic investment and product development decisions.

DRO & Impact Forces Of Neutral Borosilicate Glass Tube Market

The neutral borosilicate glass tube market is significantly shaped by a combination of key drivers, inherent restraints, and emerging opportunities, all contributing to various impact forces. The primary drivers include the continuous expansion of the global pharmaceutical and biotechnology sectors, especially the increasing production of biologics, vaccines, and injectables, which necessitate high-quality, inert primary packaging. Additionally, stringent regulatory standards imposed by health authorities worldwide, demanding superior packaging materials to ensure drug safety and efficacy, further propel the adoption of neutral borosilicate glass. The rising prevalence of chronic diseases and the subsequent growth in drug consumption also act as significant market catalysts.

However, the market faces several restraints, such as the high manufacturing cost associated with neutral borosilicate glass tubes due to complex production processes and the need for specialized equipment and raw materials. Price volatility of energy and raw materials, particularly silica and boron, can also impact profit margins. Furthermore, the emergence of alternative packaging materials like advanced plastics and polymer-based solutions, which offer lightweight and sometimes shatter-resistant properties, poses a competitive challenge. Opportunities within this market are substantial, particularly in developing personalized medicine, advanced drug delivery systems, and the growth of sterile injectable formulations. Expansion into emerging markets with rapidly developing healthcare infrastructure and a focus on sustainable manufacturing practices, including recycling initiatives and energy-efficient production, also presents avenues for growth. The combined influence of these factors dictates market dynamics, pushing for continuous innovation in product quality, manufacturing efficiency, and supply chain resilience.

Segmentation Analysis

The neutral borosilicate glass tube market is extensively segmented to provide a comprehensive view of its intricate dynamics, categorized primarily by type, application, and end-user. This granular segmentation allows for a detailed understanding of demand patterns, technological preferences, and market penetration across various sectors. Each segment represents distinct requirements and growth drivers, reflecting the diverse utility of neutral borosilicate glass in critical industries. Understanding these segments is crucial for strategic planning, product development, and identifying key growth areas within the global market landscape.

- By Type

- Type I Borosilicate Glass

- Type II Borosilicate Glass

- Type III Borosilicate Glass

- By Application

- Pharmaceutical Packaging

- Vials

- Ampoules

- Cartridges

- Syringes (Pre-fillable)

- Bottles

- Laboratory Glassware

- Test Tubes

- Beakers

- Flasks

- Condensers

- Medical Devices

- Solar Energy

- Lighting

- Chemical Industry

- Others

- Pharmaceutical Packaging

- By End-User

- Pharmaceutical and Biotechnology Companies

- Contract Research Organizations (CROs)

- Academic and Research Institutions

- Hospitals and Clinics

- Chemical and Petrochemical Companies

- Solar Panel Manufacturers

- Lighting Manufacturers

- Others

- By Region

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East & Africa

Value Chain Analysis For Neutral Borosilicate Glass Tube Market

The value chain for the neutral borosilicate glass tube market begins with the upstream analysis, focusing on the sourcing and processing of essential raw materials. Key raw materials include high-purity silica sand, boron oxide, aluminum oxide, and other alkali earth oxides, which are carefully selected to ensure the desired chemical resistance and thermal properties of the final glass product. Suppliers of these raw materials play a critical role, as the quality and consistency of their offerings directly impact the integrity of the glass tubes. The manufacturing process involves melting these raw materials at extremely high temperatures, followed by precision drawing and forming into tubes, which requires specialized machinery and highly skilled labor. This stage is capital-intensive and technologically demanding, characterized by continuous process optimization to reduce defects and improve yield.

Further along the value chain, downstream analysis involves the intricate processes of converting these glass tubes into finished primary packaging components or laboratory ware. This includes cutting, annealing, surface treatment, printing, and sterile packaging. Manufacturers often collaborate with pharmaceutical companies to develop customized solutions, adhering to stringent quality standards and regulatory requirements such as USP, EP, and JP. The distribution channel for neutral borosilicate glass tubes can be bifurcated into direct and indirect methods. Direct channels involve manufacturers selling directly to large pharmaceutical companies, biotechnology firms, or major laboratory equipment suppliers, often through long-term contracts and dedicated sales teams. This approach allows for direct communication, customization, and strong client relationships.

Conversely, indirect distribution channels involve sales through a network of distributors, wholesalers, and specialized packaging solution providers who cater to smaller pharmaceutical companies, research institutions, hospitals, and other end-users. These intermediaries provide market reach, logistics support, and local technical assistance, making the products accessible to a broader client base. Both direct and indirect channels are crucial for market penetration and ensuring the efficient delivery of these critical components to a diverse range of end-users across the globe. The choice of channel often depends on the scale of the customer, the volume of the order, and the geographical reach required, with a trend towards integrated supply chain solutions that combine aspects of both.

Neutral Borosilicate Glass Tube Market Potential Customers

The primary potential customers for neutral borosilicate glass tubes are deeply embedded within industries that demand high levels of chemical inertness, thermal resistance, and product stability, predominantly the pharmaceutical and biotechnology sectors. Pharmaceutical companies represent the largest segment of end-users, requiring these tubes for primary packaging of injectable drugs, vaccines, biologics, and other sensitive formulations where any interaction with the packaging material could compromise efficacy or safety. This includes major multinational pharmaceutical corporations as well as numerous generic drug manufacturers globally. The stringent regulatory environment for drug packaging makes neutral borosilicate glass an indispensable choice for these entities.

Beyond pharmaceuticals, the biotechnology industry is a rapidly growing customer base, utilizing neutral borosilicate glass tubes for cell culture, reagent storage, and various diagnostic applications where purity and non-reactivity are paramount. Contract Research Organizations (CROs) and academic and government research institutions also constitute significant end-users, requiring laboratory glassware such as test tubes, beakers, and flasks that can withstand harsh chemical environments and high temperatures during experiments. Additionally, medical device manufacturers use these tubes for specialized components, and segments within the solar energy industry and high-performance lighting also contribute to the customer base, albeit to a lesser extent than the core healthcare-related industries. The consistent demand from these sectors underscores the critical importance of neutral borosilicate glass tubes in maintaining product integrity and safety across diverse, high-stakes applications.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 2.85 Billion |

| Market Forecast in 2033 | USD 4.52 Billion |

| Growth Rate | 6.7% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | SCHOTT AG, Gerresheimer AG, Corning Incorporated, Thermo Fisher Scientific Inc., Nipro Corporation, SGD Pharma, DWK Life Sciences, Shandong Pharmaceutical Glass Co., Ltd., Ardagh Group S.A., Piramal Glass, Ompi (Stevanato Group), NEG (Nippon Electric Glass Co., Ltd.), Bormioli Pharma S.p.A., Hindustan National Glass & Industries Ltd., Zibo RW Pharmaceutical Glass Co., Ltd., Tredegar Corporation (for film applications), Acme Glass Company, J.P. Scientific Glass Works, Kaiser Glass GmbH, Fiolax (Schott Group Brand) |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Neutral Borosilicate Glass Tube Market Key Technology Landscape

The neutral borosilicate glass tube market is underpinned by a sophisticated technological landscape that ensures the precise manufacturing, stringent quality control, and functional integrity of these critical products. At the core are advanced glass melting and drawing technologies, which involve highly controlled processes to produce tubes with exceptional dimensional accuracy, uniform wall thickness, and defect-free surfaces. These processes often utilize electric melting furnaces or oxy-fuel combustion to achieve the high temperatures required, coupled with precision drawing machines that can produce tubes with very tight tolerances. Continuous innovation in furnace design and energy recovery systems also contributes to more sustainable and cost-effective production, aligning with industry goals for environmental responsibility.

Furthermore, the technological landscape includes specialized post-processing techniques such as annealing, which relieves internal stresses to enhance the mechanical strength and thermal shock resistance of the glass. Surface treatment technologies, including siliconization or specialized coatings, are also employed to improve the glass tubes' barrier properties, reduce protein adsorption, and enhance drug compatibility, particularly for sensitive biologic formulations. Automated inspection systems, often incorporating high-resolution cameras and artificial intelligence algorithms, are crucial for detecting minute flaws and ensuring that every tube meets the exacting quality standards required for pharmaceutical applications. Cleanroom manufacturing environments, complying with ISO and GMP standards, are indispensable for preventing contamination during the production and packaging stages, guaranteeing product sterility. The integration of robotics for handling and packaging further minimizes human intervention and contamination risks, boosting overall manufacturing efficiency and product safety.

Material science advancements continuously drive the development of new glass formulations with even higher hydrolytic resistance and tailored thermal expansion coefficients. Research efforts focus on optimizing the chemical composition of borosilicate glass to enhance its performance characteristics for emerging drug delivery systems and medical applications. The development of advanced analytical techniques for characterizing glass surfaces and detecting subtle interactions with drug formulations is also vital, allowing manufacturers to refine their products and meet future industry demands. Traceability technologies, such as laser marking and digital serialization, are increasingly implemented to ensure product authenticity and facilitate supply chain transparency, crucial for regulatory compliance and combating counterfeiting. This comprehensive suite of technologies forms the backbone of the neutral borosilicate glass tube market, enabling the production of high-performance, reliable packaging solutions.

Regional Highlights

- North America: A mature market characterized by a robust pharmaceutical and biotechnology industry, extensive R&D investments, and stringent regulatory frameworks. Significant demand for pre-filled syringes and vials for biologics and vaccines.

- Europe: A key hub for pharmaceutical manufacturing and innovation, with Germany, France, and Switzerland leading in demand for high-quality glass packaging. Focus on advanced drug delivery systems and sustainable production.

- Asia Pacific (APAC): The fastest-growing market, driven by expanding pharmaceutical industries in China, India, and Japan, increasing healthcare access, and rising disposable incomes. Growing generic drug production and vaccine manufacturing contribute significantly to market expansion.

- Latin America: Emerging market with increasing healthcare expenditure and growing pharmaceutical production, particularly in Brazil and Mexico. Demand for basic pharmaceutical packaging and laboratory glassware is on the rise.

- Middle East & Africa (MEA): A developing market with investments in healthcare infrastructure and local pharmaceutical manufacturing capacities. Opportunities for growth are tied to expanding access to essential medicines and vaccines.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Neutral Borosilicate Glass Tube Market.- SCHOTT AG

- Gerresheimer AG

- Corning Incorporated

- Thermo Fisher Scientific Inc.

- Nipro Corporation

- SGD Pharma

- DWK Life Sciences

- Shandong Pharmaceutical Glass Co., Ltd.

- Ardagh Group S.A.

- Piramal Glass

- Ompi (Stevanato Group)

- NEG (Nippon Electric Glass Co., Ltd.)

- Bormioli Pharma S.p.A.

- Hindustan National Glass & Industries Ltd.

- Zibo RW Pharmaceutical Glass Co., Ltd.

- Acme Glass Company

- J.P. Scientific Glass Works

- Kaiser Glass GmbH

- Verallia S.A.

- APEX Medical Corporation

Frequently Asked Questions

What are the primary applications of neutral borosilicate glass tubes?

Neutral borosilicate glass tubes are primarily utilized in pharmaceutical packaging, including vials, ampoules, cartridges, and pre-fillable syringes, due to their chemical inertness and high hydrolytic resistance. They are also extensively used for laboratory glassware, medical devices, and specialized lighting applications where thermal stability is crucial.

Why is Type I borosilicate glass preferred for pharmaceutical packaging?

Type I borosilicate glass is preferred for pharmaceutical packaging because it offers the highest level of hydrolytic resistance among all glass types, meaning it releases minimal alkaline substances into stored solutions. This ensures the stability, purity, and efficacy of sensitive injectable drugs, biologics, and vaccines, complying with stringent regulatory standards.

What key factors are driving the growth of the neutral borosilicate glass tube market?

The market's growth is primarily driven by the expanding global pharmaceutical and biotechnology industries, particularly the increasing demand for injectable drugs and vaccines. Stringent regulatory requirements for drug packaging safety and the growing prevalence of chronic diseases also contribute significantly to market expansion.

How does AI impact the manufacturing of neutral borosilicate glass tubes?

AI significantly impacts manufacturing by enhancing quality control through automated visual inspection systems, optimizing production processes for reduced waste, and enabling predictive maintenance of machinery. This leads to higher efficiency, consistent product quality, and improved overall operational performance.

Which regions are key contributors to the neutral borosilicate glass tube market?

North America and Europe are significant contributors due to their established pharmaceutical sectors and robust R&D. Asia Pacific, particularly China and India, is the fastest-growing region, driven by expanding manufacturing capabilities and increasing healthcare investments. Latin America and MEA are emerging markets.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager