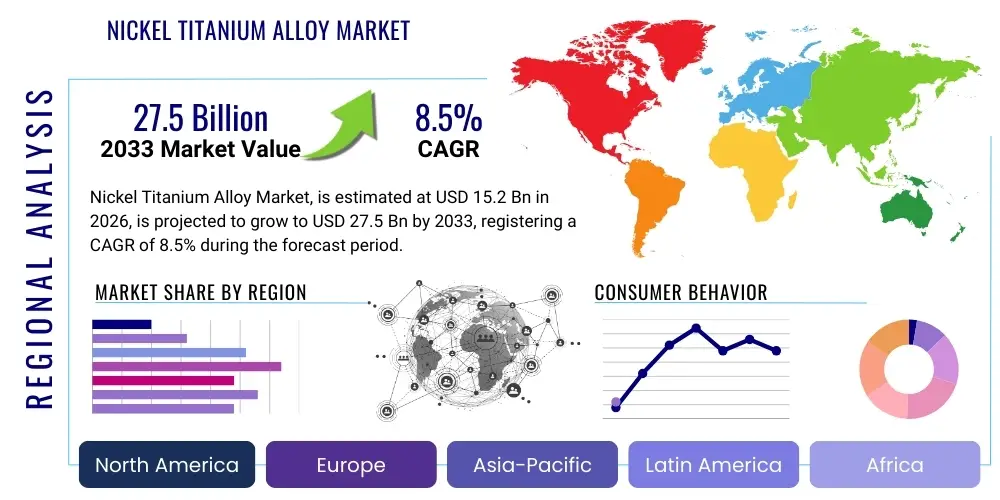

Nickel Titanium Alloy Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 435255 | Date : Dec, 2025 | Pages : 257 | Region : Global | Publisher : MRU

Nickel Titanium Alloy Market Size

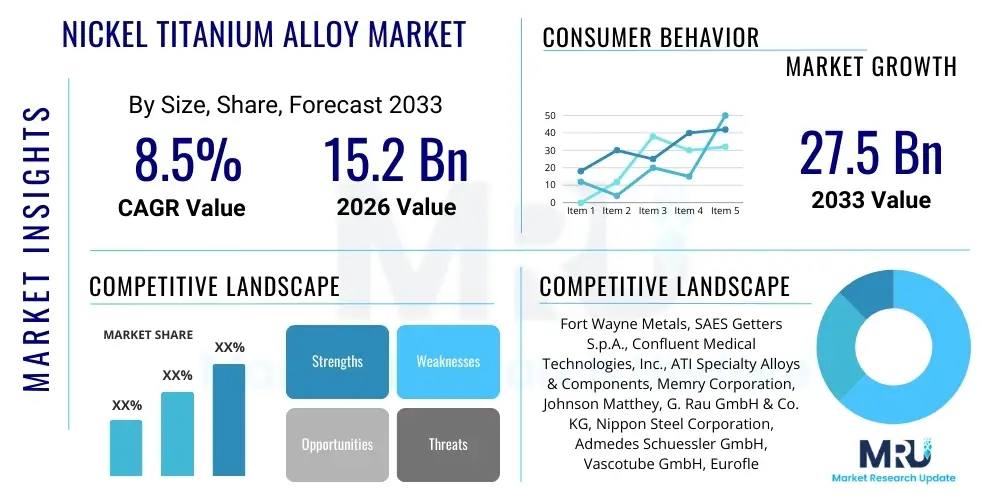

The Nickel Titanium Alloy Market, commonly recognized by its commercial designation Nitinol, is a highly specialized sector driven by the unique superelastic and shape memory characteristics of the material. This alloy is projected to grow at a robust Compound Annual Growth Rate (CAGR) of 8.5% between 2026 and 2033, significantly outpacing traditional materials due to its increasing adoption in critical medical and aerospace applications. The resilience and biocompatibility of Nitinol are key factors supporting this sustained expansion across various high-value industries globally, particularly those focusing on miniaturization and high-performance components.

The market is estimated at USD 15.2 Billion in 2026, reflecting the substantial foundational demand from established stent and orthodontic markets, alongside initial penetration into next-generation consumer electronics and specialized industrial components. By the end of the forecast period in 2033, the market is projected to reach USD 27.5 Billion. This significant valuation increase is attributed to technological advancements in alloy processing, reduction in manufacturing costs associated with large-scale production, and the exponential rise in minimally invasive surgical procedures worldwide that rely heavily on Nitinol’s flexibility and thermal responsiveness.

Nickel Titanium Alloy Market introduction

Nickel Titanium Alloy, predominantly known as Nitinol (a contraction of Nickel Titanium Naval Ordnance Laboratory), represents a class of smart materials exhibiting extraordinary properties: the shape memory effect (SME) and superelasticity (SE). The shape memory effect allows the alloy to be deformed at one temperature and subsequently return to its predetermined original shape upon heating. Superelasticity, conversely, allows the material to undergo large, reversible strains without permanent deformation, offering unparalleled flexibility and fatigue resistance compared to conventional metals. These intrinsic characteristics make Nitinol indispensable in complex engineering scenarios where high performance, structural integrity, and compact design are critical necessities.

The product is primarily manufactured into complex forms such as fine wires, tubes, strips, and rods, catering to high-precision demands across diverse sectors. Major applications are concentrated within the biomedical industry, particularly in cardiovascular stents, orthopedic implants, and orthodontic devices, where biocompatibility and exceptional strain recovery are non-negotiable requirements. Beyond healthcare, Nitinol is vital in the aerospace sector for actuators and damping components, in consumer electronics for miniature moving parts, and in industrial automation for highly responsive sensors and connectors. The inherent ability of Nitinol components to sustain millions of cycles without material failure solidifies its position as a high-performance material.

Driving factors for the market include the global aging population necessitating increased medical device usage, continuous innovation in minimally invasive surgical techniques, and significant R&D investments aimed at expanding Nitinol’s application range into new areas such as smart textiles and micro-robotics. The benefits derived from using Nickel Titanium Alloys—including reduced patient recovery times due to less invasive procedures, improved device lifespan, and enhanced overall structural reliability—are central to its accelerated market adoption and sustained commercial viability.

Nickel Titanium Alloy Market Executive Summary

The Nickel Titanium Alloy Market is defined by robust growth driven fundamentally by persistent innovation in the medical and dental sectors. Current business trends indicate a strong shift towards the use of higher-grade Nitinol alloys and the adoption of advanced manufacturing techniques, such notably additive manufacturing, to create highly customized and intricate medical devices, thereby improving patient outcomes and expanding the scope of treatable conditions. Key industry players are focusing on vertical integration and strategic partnerships to secure raw material supplies and optimize complex processing techniques essential for maintaining the alloy's specialized characteristics, leading to heightened competitive rivalry based on product quality and compliance with stringent regulatory standards (e.g., FDA, CE Marking).

Regional trends reveal that North America holds the largest market share, predominantly due to the presence of major medical device manufacturers, high healthcare expenditure, and substantial government support for R&D activities in smart materials and advanced implants. However, the Asia Pacific (APAC) region is projected to experience the fastest growth, fueled by burgeoning healthcare infrastructure, rising medical tourism, increasing prevalence of cardiovascular diseases, and the rapid expansion of dental care services, particularly in countries like China, India, and Japan. Europe maintains a significant market presence, backed by stringent material quality standards and strong participation in aerospace and defense applications that utilize Nitinol actuators.

Segmentation trends indicate that the medical segment, specifically cardiovascular stents and guidewires, remains the dominant application area due to the critical nature of these devices and Nitinol's superior performance in the human body. By product type, wire and strips/ribbon formats account for the largest revenue shares, reflecting their ubiquity in orthodontic braces, staple manufacturing, and guidewire fabrication. Future growth is anticipated to be heavily reliant on the adoption of specialized Nitinol tubes for endovascular repair and drug delivery systems, alongside expansion into non-traditional segments such as advanced thermal actuators in the automotive and energy industries, diversifying the overall market landscape beyond its traditional medical reliance.

AI Impact Analysis on Nickel Titanium Alloy Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Nickel Titanium Alloy Market frequently center on three main themes: how AI can optimize the notoriously complex and sensitive melting and thermomechanical processing of Nitinol; whether AI can accelerate the discovery and testing of new Nitinol compositions with enhanced properties (e.g., higher transformation temperatures or improved fatigue life); and the role of machine learning in improving quality control and minimizing defects in high-volume Nitinol manufacturing, particularly concerning surface finish and phase transformation consistency. The consensus expectation is that AI systems will significantly enhance material efficiency, reduce the high scrap rates currently associated with Nitinol production, and facilitate the customization of alloy properties for specialized biomedical applications, ultimately driving down costs and speeding up time-to-market for innovative devices.

AI’s influence is manifesting through sophisticated computational materials science and predictive modeling. Traditional Nitinol processing involves extensive trial-and-error, especially concerning aging and heat treatment protocols which determine the final transformation temperatures and mechanical properties. AI and machine learning algorithms are now being deployed to analyze vast datasets of microstructure, chemical composition variances, and processing parameters to accurately predict the resulting material behavior, allowing manufacturers to fine-tune production settings in real-time. This predictive capability is crucial for alloys like Nitinol where minute variations in processing temperature can drastically alter performance, ensuring higher batch consistency and regulatory compliance across different manufacturing lots.

Furthermore, AI-driven digital twins of manufacturing processes allow researchers to simulate the effects of alloying element additions or new forming techniques before expensive physical trials are initiated. This not only accelerates R&D but also opens pathways for synthesizing novel Nickel-Titanium-based alloys with ternary or quaternary additions designed specifically for extreme conditions, such as high-temperature environments in jet engines or specific fatigue profiles needed for long-term orthopedics. The integration of AI in sensor-laden manufacturing lines provides continuous, high-fidelity monitoring, enabling instant detection of microstructural defects and automating corrective actions, thereby realizing true precision manufacturing for these critical components.

- AI optimizes complex thermal processing parameters (e.g., aging and annealing) to achieve precise transformation temperatures (Af).

- Machine learning models predict fatigue life and superelastic performance based on raw material inputs and microstructural variations.

- Computational materials science, powered by AI, accelerates the discovery of new multi-component shape memory alloys derived from Nitinol.

- AI-enhanced quality control systems perform automated, high-speed inspection of surface defects and geometric tolerances in fine wires and tubes.

- Predictive maintenance schedules for high-vacuum melting furnaces are improved using AI to reduce downtime and ensure process stability.

- AI aids in simulating the performance of Nitinol devices in vivo, optimizing design parameters for customized medical implants.

DRO & Impact Forces Of Nickel Titanium Alloy Market

The Nickel Titanium Alloy Market is significantly shaped by a powerful interplay of drivers, restraints, and opportunities. The primary driver is the accelerating global demand for minimally invasive medical devices, where Nitinol’s flexibility, biocompatibility, and ability to self-expand upon reaching body temperature offer unparalleled advantages over stainless steel or cobalt-chromium alloys. This driver is counterbalanced by major restraints, primarily the exceedingly high manufacturing cost associated with producing Nitinol, which involves specialized high-vacuum melting techniques, complex thermomechanical processing, and extremely demanding quality assurance protocols. Despite these costs, the opportunity for market expansion lies in the development of new, high-volume, non-medical applications, such as responsive actuators for the automotive sector and advanced cooling/heating systems utilizing the material's latent heat transformation properties.

Impact forces within the market are predominantly driven by technological advances and regulatory stringency. The regulatory requirements, particularly in North America and Europe, necessitate extremely detailed documentation and verification of material consistency, which acts as a barrier to entry for new players but reinforces the dominance of established manufacturers capable of meeting these high standards. Furthermore, the inherent price volatility of key raw materials, Nickel and Titanium, exerts financial pressure on the entire supply chain, influencing final product pricing. However, continuous research into improved surface treatment techniques (e.g., oxide layer passivation) is an important force, addressing historical concerns regarding potential nickel ion release, thereby enhancing patient safety and widening the scope of long-term implant applications.

Overall market dynamics suggest that while initial investment and processing complexity present significant headwinds, the critical performance advantage of Nitinol in life-saving and high-reliability devices continues to push adoption. The convergence of 3D printing techniques tailored for Nitinol and the integration of smart sensors into Nitinol structures (smart implants) represent strategic opportunities that promise to revolutionize product design, allowing for patient-specific devices and opening lucrative niche markets, ensuring that the market’s trajectory remains steep despite the inherent material challenges. The long-term performance benefits often justify the high initial material expense, particularly in high-stakes fields like cardiology and neurosurgery.

Segmentation Analysis

The Nickel Titanium Alloy Market is fundamentally segmented based on its structural form (Product Type), the specific industry utilizing the material (Application), and the key functional mechanism leveraged (Mechanism). This comprehensive segmentation allows for a granular analysis of demand patterns, pricing strategies, and technological shifts within specific end-user categories. The product type segmentation reveals a mature market for fine wires and tubing, which are the foundational components for stents and guidewires, contrasted with emerging demand for complex components manufactured via sophisticated shaping processes like laser micromachining or additive techniques.

Application analysis highlights the overwhelming dominance of the Medical and Dental sectors, where stringent regulatory approval and specialized knowledge create high entry barriers but assure premium pricing and stable demand. Within the medical field, cardiovascular intervention remains the largest sub-segment due to the global burden of heart disease, followed closely by orthopedic and neurological applications. The growing influence of the non-medical sectors, including aerospace, defense, and robotics, driven by the need for high-actuation-density components and vibration dampening capabilities, is expected to provide significant diversification opportunities outside of traditional healthcare revenue streams throughout the forecast period.

The segmentation by mechanism is critical for understanding technological innovation, distinguishing between devices that utilize the superelasticity property for constant force delivery (e.g., orthodontic wires, guidewires) and those that exploit the shape memory effect for actuation or deployment (e.g., deployable filters, self-tightening fasteners, thermal actuators). Understanding which mechanism drives a particular product category helps manufacturers tailor processing parameters precisely, as the required transformation temperatures and mechanical response profiles are vastly different for each functional requirement, dictating specific heat treatment protocols and alloy chemistries.

- By Product Type:

- Wire & Filaments

- Tubes

- Strips & Ribbons

- Rods & Bars

- Customized Components (Sheets, Foils, etc.)

- By Application:

- Medical & Dental Devices

- Cardiovascular Stents & Guidewires

- Orthopedic Implants (Surgical Staples, Bone Plates)

- Orthodontic Archwires & Brackets

- Neurological Devices (Clot Retrieval, Filters)

- Endoscopic Tools

- Aerospace & Defense

- Automotive Industry (Actuators, Thermal Bypass Valves)

- Consumer Electronics & Robotics

- Industrial & Energy Applications (Couplings, Fasteners)

- By Mechanism:

- Superelasticity

- Shape Memory Effect (Thermal Actuation)

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East & Africa (MEA)

Value Chain Analysis For Nickel Titanium Alloy Market

The value chain for the Nickel Titanium Alloy Market is inherently complex, starting with the highly specialized procurement and processing of raw materials—high-purity Nickel and Titanium—followed by the rigorous melting and homogenization processes. Upstream activities involve sourcing and refining these materials, demanding strict control over impurities, which can severely compromise the alloy’s unique properties. Melting processes, typically performed under high vacuum using techniques like Vacuum Induction Melting (VIM) followed by Vacuum Arc Remelting (VAR) or Electron Beam Melting (EBM), are critical for achieving the precise chemical composition and homogeneity necessary for the shape memory effect and superelasticity. This initial processing stage represents a significant cost driver and major technical barrier in the market.

Midstream activities involve sophisticated primary and secondary forming processes, including hot rolling, cold drawing, swaging, and extrusion, to convert ingots into semi-finished products such as rods, wires, and tubes. This stage requires meticulous control of thermomechanical deformation to establish the correct crystalline microstructure. Further specialized processing, such as surface treatments (e.g., electropolishing, mechanical polishing, and passivation) and final heat treatments (aging), are mandatory to set the final transformation temperatures (Af) and ensure biocompatibility and fatigue resistance, especially for medical-grade Nitinol components. Quality control at this stage is extremely intense, focusing on dimensional accuracy, phase transformation testing (using Differential Scanning Calorimetry, DSC), and fatigue testing.

Downstream distribution channels are characterized by direct sales to Original Equipment Manufacturers (OEMs) in the medical device, aerospace, and automotive industries. Due to the highly technical nature of the material, indirect distribution through general industrial distributors is rare; instead, specialized material suppliers work directly with design engineers at the end-user companies to specify the exact alloy composition, transformation temperature, and mechanical profile required. Regulatory compliance and traceability are paramount in the downstream segment, especially for Class II and Class III medical devices. The direct channel ensures that technical expertise and post-sales support, crucial for implementing Nitinol effectively, are readily available to end-users.

Nickel Titanium Alloy Market Potential Customers

Potential customers for Nickel Titanium Alloy are concentrated in highly regulated, high-value-add industries where material failure is unacceptable and superior mechanical performance justifies the premium cost. The largest segment of end-users consists of major medical device manufacturers (OEMs) specializing in interventional cardiology and structural heart devices, such as providers of peripheral vascular stents, transcatheter aortic valve replacement (TAVR) systems, and guidewires. These companies require Nitinol tubing and wire forms with exceptional fatigue life, precise phase transformation characteristics, and guaranteed biocompatibility to ensure the safety and efficacy of long-term implants within the human body.

Another significant group of potential customers includes specialized orthopedic and dental device manufacturers. Orthopedic buyers utilize Nitinol primarily for surgical staples that self-tighten upon heating, fracture fixation devices, and specialized instruments that require flexibility and resilience. Dental customers, including major orthodontic suppliers, rely on Nitinol archwires and springs due to their superelastic properties, which allow them to deliver constant, low-level forces necessary for effective tooth movement over extended periods, minimizing patient discomfort and accelerating treatment timelines. These applications demand high material consistency and adherence to global standards like ISO 15841.

Furthermore, emerging potential customers reside in the high-reliability engineering sectors, particularly aerospace and advanced robotics. Aerospace companies use Nitinol for lightweight, thermally activated actuators, vibration damping elements in airframes, and coupling systems that need to maintain integrity across extreme temperature gradients. Robotics and micro-electromechanical systems (MEMS) developers are exploring Nitinol for compact, high-force actuators and grippers, capitalizing on the material's high work output per unit volume, which is crucial for miniaturization. These end-users prioritize high cyclic stability and precise thermal response control over traditional mechanical components.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 15.2 Billion |

| Market Forecast in 2033 | USD 27.5 Billion |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Fort Wayne Metals, SAES Getters S.p.A., Confluent Medical Technologies, Inc., ATI Specialty Alloys & Components, Memry Corporation, Johnson Matthey, G. Rau GmbH & Co. KG, Nippon Steel Corporation, Admedes Schuessler GmbH, Vascotube GmbH, Euroflex GmbH, Dynalloy, Inc., Ultimate NiTi Technologies Inc., Nitinol Devices & Components (NDC) - Medtronic, Sanicro, Zimmer Biomet Holdings, Inc., Boston Scientific Corporation, Stryker Corporation, B. Braun Melsungen AG, Teleflex Incorporated. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Nickel Titanium Alloy Market Key Technology Landscape

The Nickel Titanium Alloy market is highly dependent on specialized metallurgical and fabrication technologies due to the material's sensitivity to processing parameters. Core technology revolves around the advanced melting techniques required to produce homogeneous ingots, free of detrimental inclusions and segregation. Vacuum Induction Melting (VIM) followed by Vacuum Arc Remelting (VAR) or plasma melting processes are essential for achieving the high purity and precise stoichiometry required for consistent performance. These technologies minimize interstitial contaminants like oxygen and nitrogen, which otherwise severely degrade the mechanical properties and fatigue life of the final product, a critical consideration for medical implants designed to withstand billions of cycles over decades.

Following the melting phase, the thermomechanical processing landscape is dominated by sophisticated forming technologies. Cold drawing and tube drawing techniques are crucial for producing the high-precision fine wires and thin-walled tubes necessary for stents and guidewires, often involving multiple stages of reduction and intermediate annealing under controlled atmospheric conditions. Specialized surface modification techniques are also paramount; these include electropolishing, chemical etching, and micro-blasting, which not only enhance the surface finish but also optimize the stable passive oxide layer, minimizing the potential for nickel ion leaching and ensuring maximal biocompatibility, a requirement mandated by regulatory bodies like the FDA for long-term implantation.

Most recently, the technological frontier has been pushed by additive manufacturing (AM), specifically Laser Powder Bed Fusion (LPBF) and Electron Beam Melting (EBM) of Nitinol powder. While challenging due to the material's reactive nature and high-temperature requirements, AM enables the production of highly complex, patient-specific geometries that are impossible to achieve through traditional subtractive manufacturing or forming methods. Ongoing research focuses on mitigating porosity and controlling the post-build phase transformation characteristics, often requiring subsequent Hot Isostatic Pressing (HIP) and specialized heat treatments. Furthermore, the use of advanced testing technologies, such as Differential Scanning Calorimetry (DSC) for phase transformation temperature verification and proprietary fatigue testing rigs, remains central to maintaining the high reliability demanded by end-user applications.

Regional Highlights

- North America: North America, led by the United States, represents the largest and most mature market for Nickel Titanium Alloys, accounting for the highest revenue share. This dominance is attributed to the concentrated presence of global medical device giants, robust R&D infrastructure supported by government and private funding, high adoption rates of advanced surgical procedures (especially in cardiology and orthopedics), and significantly high healthcare spending per capita. The region serves as a primary hub for technological innovation in Nitinol processing and device design, driving early adoption of customized and 3D-printed Nitinol components, and maintains stringent, high standards for material quality and regulatory approval.

- Europe: Europe holds a strong position, driven by mature aerospace and defense industries in countries like Germany, France, and the UK, alongside a leading medical device manufacturing sector. European nations emphasize high-quality material standards and compliance with demanding regulations (e.g., MDR/IVDR), ensuring that only premium-grade Nitinol is used. The market is characterized by specialized, highly technical suppliers focused on precision tube and wire production, catering heavily to both cardiovascular intervention and industrial actuation systems across the continent.

- Asia Pacific (APAC): The APAC region is poised for the fastest Compound Annual Growth Rate (CAGR) due to rapid development in healthcare infrastructure, increasing prevalence of lifestyle diseases such as diabetes and cardiovascular conditions, and expanding access to modern medical treatments in populous countries like China and India. The region is seeing a significant expansion in both manufacturing capabilities for lower-cost Nitinol devices and substantial growth in demand for high-quality imported implants, particularly driven by medical tourism and improving economic conditions increasing patient affordability for advanced treatments.

- Latin America (LATAM): LATAM is an emerging market characterized by increasing investment in healthcare modernization, particularly in Brazil and Mexico. The demand for Nitinol is primarily focused on essential medical devices, although growth is constrained by uneven regulatory environments and reliance on imported high-end products. However, growing regional manufacturing bases are starting to explore opportunities for lower-cost Nitinol component fabrication to serve local and neighboring markets.

- Middle East & Africa (MEA): The MEA market for Nitinol is nascent but growing, largely concentrated in the Gulf Cooperation Council (GCC) states due to high healthcare spending power and ambitious infrastructure projects. Demand is almost entirely focused on high-quality medical devices imported from North America and Europe. Future growth depends heavily on the successful implementation of regional healthcare expansion strategies and the establishment of local manufacturing capabilities for basic medical supplies.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Nickel Titanium Alloy Market, covering their business overview, product offerings, key financial data (where available), strategic developments (e.g., mergers, acquisitions, partnerships), and competitive landscape analysis, demonstrating their roles in shaping the global market dynamics.- Fort Wayne Metals

- SAES Getters S.p.A.

- Confluent Medical Technologies, Inc.

- ATI Specialty Alloys & Components

- Memry Corporation

- Johnson Matthey

- G. Rau GmbH & Co. KG

- Nippon Steel Corporation

- Admedes Schuessler GmbH

- Vascotube GmbH

- Euroflex GmbH

- Dynalloy, Inc.

- Ultimate NiTi Technologies Inc.

- Nitinol Devices & Components (NDC) - Medtronic

- Sanicro

- Zimmer Biomet Holdings, Inc.

- Boston Scientific Corporation

- Stryker Corporation

- B. Braun Melsungen AG

- Teleflex Incorporated

Frequently Asked Questions

Analyze common user questions about the Nickel Titanium Alloy market and generate a concise list of summarized FAQs reflecting key topics and concerns.What makes Nickel Titanium Alloy (Nitinol) essential for modern medical devices?

Nitinol is essential due to its unique properties: superelasticity (allowing large reversible deformation without permanent damage) and the shape memory effect (allowing deployment in a constrained space and self-expansion at body temperature). These features are critical for minimally invasive procedures, especially in cardiovascular stents and orthopedic staples, ensuring optimal device function and patient safety.

What are the primary challenges associated with manufacturing high-quality Nitinol components?

The primary challenges include high processing costs, the necessity for specialized high-vacuum melting techniques to maintain precise stoichiometry and purity, and the difficulty in controlling the thermomechanical processing and heat treatments required to achieve specific, reproducible phase transformation temperatures (Af) and fatigue life characteristics demanded by regulatory bodies.

How does the superelasticity of Nitinol differ from conventional metal flexibility?

Nitinol's superelasticity is achieved through a stress-induced phase transformation (martensitic transformation), allowing it to recover up to 8% strain compared to 0.5% for conventional metals like stainless steel. This unique mechanism enables devices to navigate complex anatomical structures and maintain structure under extreme deformation without plastic deformation.

Is there a risk of nickel toxicity or allergy from Nitinol implants?

Nitinol devices are generally considered highly biocompatible. While they contain nickel, the formation of a stable, dense titanium oxide passive layer on the surface significantly prevents nickel ion leaching into the body. Manufacturers employ rigorous surface treatments and passivation techniques to ensure this protective layer is robust and minimize any potential for allergic or toxic reactions in sensitive patients.

Which non-medical industries are driving new growth opportunities for Nickel Titanium Alloys?

The aerospace, automotive, and robotics sectors are driving new opportunities. Aerospace utilizes Nitinol for lightweight, thermally activated actuators and vibration control. The automotive industry is applying it in thermal bypass valves and responsive components, leveraging the shape memory effect for energy-efficient actuation and control systems in increasingly complex mechanical assemblies.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager