Nitroguanidine Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440394 | Date : Jan, 2026 | Pages : 242 | Region : Global | Publisher : MRU

Nitroguanidine Market Size

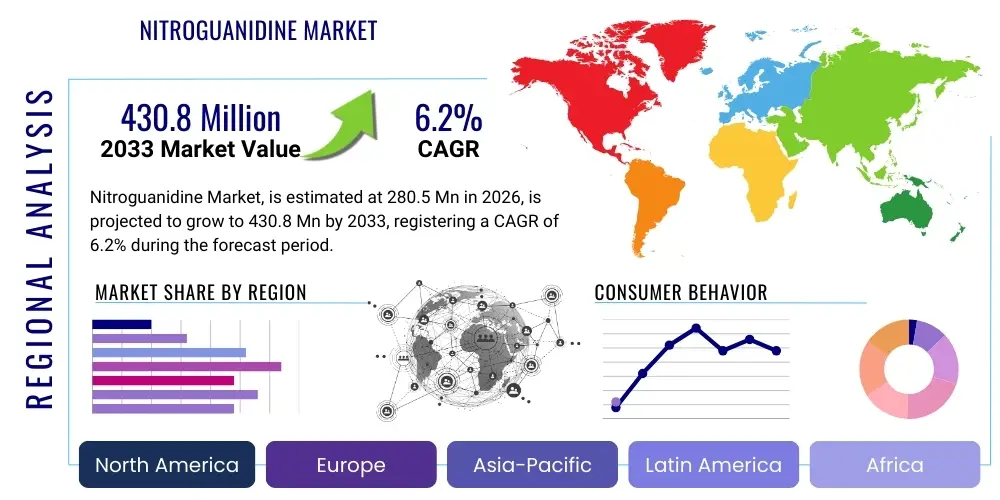

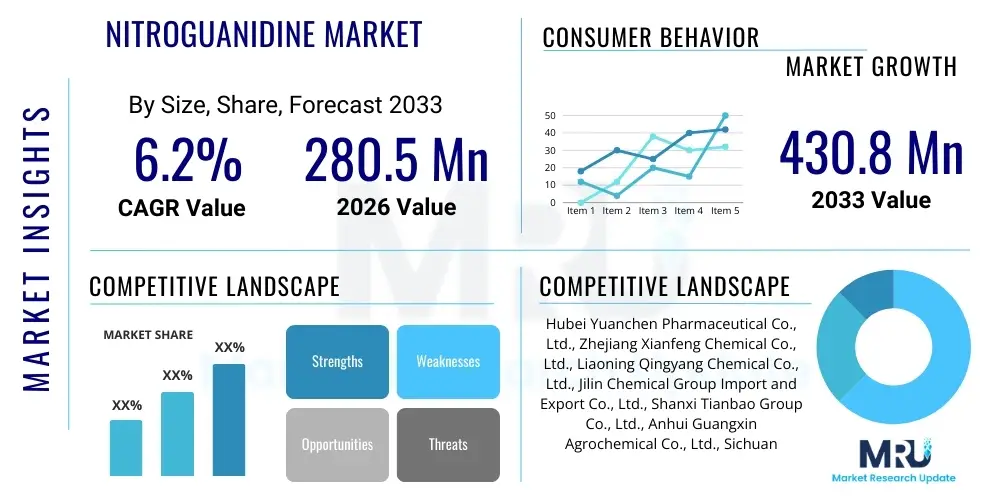

The Nitroguanidine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.2% between 2026 and 2033. The market is estimated at USD 280.5 Million in 2026 and is projected to reach USD 430.8 Million by the end of the forecast period in 2033.

Nitroguanidine Market introduction

Nitroguanidine is a highly energetic, nitrogen-rich organic compound primarily known for its pivotal role in the production of propellants and explosives. As a white crystalline solid, it possesses exceptional thermal stability and low sensitivity, making it a preferred component in various energetic formulations where safety and consistent performance are paramount. Its unique chemical structure allows for a high nitrogen content, contributing to its energetic properties without the high sensitivity often associated with other explosive materials. This stability is critical for both manufacturing and storage, enhancing the safety profile of products that incorporate it. Beyond its energetic applications, nitroguanidine serves as a versatile chemical intermediate, finding utility in the synthesis of a broad spectrum of specialty chemicals and pharmaceutical compounds.

The product's description highlights its physical and chemical properties that make it indispensable across diverse industries. It is typically supplied in technical or high-purity grades, tailored to specific application requirements. Technical grade nitroguanidine is widely utilized in bulk industrial applications like mining explosives and military propellants, where cost-effectiveness and energetic output are key considerations. High-purity grades, on the other hand, are essential for sensitive applications such as pharmaceutical synthesis or advanced material science, where impurities could compromise the final product's efficacy or safety. The manufacturing process involves controlled nitration of guanidine, with continuous advancements focusing on improving yield, purity, and environmental sustainability. Quality control measures throughout the production chain ensure that the nitroguanidine meets stringent industry standards, especially given its hazardous nature and critical applications.

Major applications for nitroguanidine span across several sectors. In the defense and aerospace industries, it is a core ingredient in smokeless propellants for artillery shells, rockets, and small arms ammunition due to its high specific impulse and low muzzle flash. Its inclusion helps in formulating propellants that burn efficiently and predictably, crucial for military operations. In the mining and construction sectors, it enhances the performance of industrial explosives used for blasting operations, rock excavation, and demolition, contributing to improved efficiency and safety. Furthermore, nitroguanidine is a key building block in the pharmaceutical industry for synthesizing various active pharmaceutical ingredients (APIs), including certain antihypertensive drugs and anthelmintics. It also serves as an intermediate in the production of agricultural chemicals, such as some pesticides and plant growth regulators, showcasing its broad chemical versatility. The continuous exploration of new applications in material science and energy storage further underscores its multifaceted utility.

The benefits associated with nitroguanidine are numerous and contribute significantly to its market demand. Its high energy content ensures potent performance in energetic applications, while its inherent thermal stability and reduced sensitivity compared to other energetic materials enhance safety during handling, storage, and application. This balance of energy and safety is a primary driver for its adoption in critical defense and industrial contexts. Additionally, its properties allow for the development of cleaner-burning propellants, reducing environmental impact and improving visibility in combat situations. As a chemical intermediate, its reactive functional groups enable diverse synthetic pathways, providing flexibility for manufacturers of specialty chemicals and pharmaceuticals. Its ability to contribute to formulations that offer both performance and safety makes it a highly valued compound across its various end-use industries.

Driving factors propelling the nitroguanidine market include escalating global defense spending, particularly by nations modernizing their arsenals and developing advanced weapon systems that require high-performance propellants. The robust growth in the global mining and construction industries, driven by urbanization and infrastructure development projects, fuels demand for industrial explosives. Moreover, the expanding pharmaceutical sector, with its continuous need for novel chemical intermediates for drug synthesis, significantly contributes to market growth. The increasing focus on material science and the development of new applications in niche areas also present growth opportunities. However, the market also faces restraints such such as stringent environmental regulations, safety concerns related to production and handling, and volatility in raw material prices. Despite these challenges, ongoing research into safer manufacturing processes and more sustainable applications continues to drive innovation and maintain market momentum.

Nitroguanidine Market Executive Summary

The Nitroguanidine Market is experiencing dynamic shifts, influenced by a confluence of global business trends, regional economic developments, and evolving segment-specific demands. Key business trends indicate a strong emphasis on research and development to create safer, more efficient, and environmentally friendly production processes, as manufacturers seek to mitigate regulatory pressures and enhance operational sustainability. There is an increasing trend towards vertical integration among key players, aiming to secure raw material supplies and optimize the entire value chain, from synthesis to end-product formulation. Strategic alliances and collaborations between chemical manufacturers and defense contractors are also becoming more prevalent, fostering innovation in energetic materials and ensuring a steady supply for critical applications. Furthermore, the market is witnessing an acceleration in the adoption of advanced manufacturing technologies, including automation and real-time process monitoring, to improve yield, reduce waste, and enhance safety standards.

Regional trends significantly shape the nitroguanidine market landscape. The Asia Pacific region stands out as a primary growth engine, propelled by rapidly increasing defense expenditures in countries like China, India, and South Korea, coupled with extensive infrastructure development and mining activities. This region's industrial expansion directly translates into higher demand for both military propellants and industrial explosives. North America and Europe, while mature markets, maintain a stable demand, driven by ongoing modernization of defense capabilities, stringent quality requirements, and innovation in specialty chemical sectors. These regions are also at the forefront of adopting advanced manufacturing techniques and focusing on sustainable production. Latin America and the Middle East & Africa are emerging as promising markets, characterized by growing investments in mining, construction, and defense, although their market shares are currently smaller, they present significant future growth potential as economic development continues.

Segmentation trends reveal distinct patterns across applications, grades, and end-user industries. The propellants and explosives segment continues to dominate, largely due to unwavering demand from the global defense sector and the sustained need for blasting agents in mining and construction. Within this segment, there's a growing preference for high-performance and low-signature propellants. The pharmaceutical intermediates segment is witnessing robust growth, driven by the expansion of the global pharmaceutical industry and the continuous development of new drug compounds that utilize nitroguanidine as a key building block. Demand for high purity grade nitroguanidine is particularly strong in this sector. The agricultural chemicals segment, specifically for pesticide intermediates, also contributes steadily to market revenue. Manufacturers are increasingly tailoring product grades and specifications to meet the precise requirements of these diverse end-user industries, focusing on custom solutions and specialized formulations to gain a competitive edge. The market's future trajectory is expected to be shaped by ongoing technological advancements, shifting geopolitical landscapes, and a persistent drive towards enhancing product safety and environmental performance across all segments.

AI Impact Analysis on Nitroguanidine Market

User inquiries concerning the impact of Artificial Intelligence (AI) on the Nitroguanidine market frequently revolve around its potential to revolutionize safety, optimize production processes, and accelerate research and development. Common questions highlight an interest in how AI can prevent accidents in hazardous manufacturing environments, enhance the efficiency of complex chemical synthesis, and facilitate the discovery of novel, safer nitroguanidine formulations. Users also express curiosity about AI's role in supply chain resilience, predictive maintenance of equipment, and ensuring stringent quality control for a compound critical to defense and industrial applications. The overarching theme is an expectation that AI will bring about significant improvements in operational efficiency, safety protocols, and product innovation within this specialized chemical sector.

- Process Optimization: AI-driven algorithms can monitor and adjust real-time parameters in nitroguanidine synthesis, optimizing reaction conditions, minimizing by-products, and maximizing yield.

- Predictive Maintenance: AI can analyze sensor data from manufacturing equipment to predict potential failures, enabling proactive maintenance and reducing costly downtime in production facilities.

- R&D Acceleration: Machine learning models can analyze vast chemical datasets to identify potential new synthesis pathways, predict material properties, and accelerate the development of safer and more stable nitroguanidine formulations.

- Supply Chain Optimization: AI can enhance supply chain visibility, forecast demand fluctuations, and optimize logistics for raw materials and finished products, leading to improved efficiency and resilience.

- Quality Control: AI-powered vision systems and analytical tools can conduct real-time quality inspections, detecting impurities or inconsistencies in nitroguanidine production with high accuracy, ensuring product specifications are met.

- Safety Enhancement: AI can develop intelligent safety systems, using data from sensors to monitor hazardous environments, predict potential risks, and alert operators, thereby significantly reducing the likelihood of accidents.

- Waste Reduction & Sustainability: AI can optimize resource utilization, identify opportunities for recycling by-products, and streamline waste treatment processes, contributing to more sustainable nitroguanidine manufacturing.

DRO & Impact Forces Of Nitroguanidine Market

The Nitroguanidine market's trajectory is profoundly influenced by a complex interplay of Drivers, Restraints, Opportunities, and broader Impact Forces that shape its demand and supply dynamics. A primary driver is the escalating global defense expenditure, as nations continue to invest heavily in modernizing their military capabilities, which invariably includes advanced propellants and energetic materials where nitroguanidine is a key component. Concurrently, the robust growth in the global mining and construction sectors, spurred by rapid urbanization, industrialization, and infrastructure development projects worldwide, fuels a consistent demand for industrial explosives that incorporate nitroguanidine. Furthermore, the burgeoning pharmaceutical industry, with its continuous need for versatile chemical intermediates for synthesizing a wide array of active pharmaceutical ingredients (APIs), presents another significant growth impetus. Lastly, advancements in material science and the exploration of novel applications in areas such as gas generators and specialized chemical reagents contribute to diversifying the market's demand base, moving beyond traditional energetic uses.

However, the market also contends with substantial restraints that temper its growth potential. Foremost among these are the stringent environmental regulations and safety protocols governing the production, handling, storage, and transportation of hazardous chemicals like nitroguanidine. Compliance with these regulations often entails significant capital investment in advanced safety infrastructure and waste treatment facilities, increasing operational costs. The volatility in raw material prices, particularly for precursors such as guanidine and nitric acid, poses another challenge, impacting manufacturing costs and profit margins. Moreover, the inherent safety hazards associated with nitroguanidine, including its explosive nature, necessitate highly specialized equipment and rigorously trained personnel, limiting the number of producers and adding to the complexity of manufacturing. Lastly, the availability of substitute materials in certain niche applications, though not widespread, could present a restraint if these alternatives offer competitive performance with reduced hazards or lower costs.

Despite these challenges, the Nitroguanidine market is replete with significant opportunities for growth and innovation. One major opportunity lies in the intensified research and development efforts aimed at discovering and commercializing safer and more environmentally friendly synthesis methods, such as continuous flow chemistry or enzymatic processes, which could reduce waste and enhance operational safety. The emergence of new, high-performance applications in specialized fields, including advanced propellants for space exploration or novel gas generator formulations, opens up untapped market segments. Moreover, the rapid industrialization and economic growth observed in developing economies, particularly in Asia Pacific and parts of Latin America, represent substantial growth avenues as these regions increase their investments in defense, infrastructure, and chemical manufacturing. Strategic collaborations between manufacturers, research institutions, and end-users can accelerate product innovation and facilitate market penetration. Additionally, the increasing focus on vertical integration by key players, from raw material sourcing to end-product formulation, offers opportunities for greater control over the supply chain and enhanced cost efficiency.

The market is further shaped by several overarching impact forces. Global economic conditions exert a direct influence on discretionary defense spending and investment in large-scale infrastructure projects, thus affecting demand for nitroguanidine. Geopolitical stability and conflicts can significantly impact the defense sector, leading to spikes or dips in demand for energetic materials. Regulatory shifts, especially concerning environmental protection and chemical safety, can impose new compliance burdens or open doors for innovative, greener production technologies. Technological advancements, particularly in chemistry and process engineering, continuously drive improvements in nitroguanidine's synthesis efficiency, purity, and safety profile. Lastly, public perception and environmental activism, though often indirect, can influence policy decisions and consumer preferences, potentially encouraging a shift towards more sustainable chemical alternatives or processes.

Segmentation Analysis

The Nitroguanidine market is systematically segmented to provide granular insights into its diverse components, allowing for a comprehensive understanding of market dynamics, opportunities, and competitive landscapes. This segmentation is typically performed based on various criteria, including product type, application, end-user industry, and manufacturing process. Analyzing these segments helps stakeholders identify key growth areas, understand demand patterns, and strategize effectively for market penetration and expansion. Each segment responds differently to market drivers and restraints, necessitating a tailored approach to marketing and product development. This detailed breakdown ensures that market players can target specific niches with precision, optimize their product portfolios, and allocate resources efficiently, thereby maximizing their potential for success in this specialized chemical market.

- By Type:

- Technical Grade Nitroguanidine: Primarily used in bulk industrial applications, such as large-scale explosives and propellants, where cost-effectiveness and performance are key.

- High Purity Nitroguanidine: Essential for sensitive applications like pharmaceutical synthesis, advanced material research, and specialized propellants, demanding stringent purity standards.

- By Application:

- Propellants and Explosives:

- Military Propellants: For artillery, rockets, and small arms ammunition, focusing on high energy and low sensitivity.

- Industrial Explosives: Used in mining, quarrying, and construction for blasting and demolition.

- Pharmaceutical Intermediates: As a key building block in the synthesis of various active pharmaceutical ingredients (APIs).

- Pesticide Intermediates: Used in the production of certain agricultural chemicals and plant protection products.

- Chemical Reagents: For laboratory research and synthesis of other specialty chemicals.

- Others: Includes applications in gas generators, foaming agents, and niche chemical processes.

- Propellants and Explosives:

- By End-User Industry:

- Defense and Aerospace: Major consumer for military propellants and energetic components.

- Mining and Construction: Utilizes industrial explosives for excavation and infrastructure development.

- Chemical Manufacturing: For various synthesis processes and production of downstream chemicals.

- Pharmaceuticals: As an intermediate for drug synthesis.

- Agriculture: For pesticide and agrochemical manufacturing.

- Research and Development: Academic and industrial research for new material and chemical synthesis.

- By Manufacturing Process:

- Conventional Synthesis: Traditional batch processes involving nitration of guanidine.

- Advanced (Green) Synthesis: Newer methods focusing on improved efficiency, reduced environmental impact, and enhanced safety, such as continuous flow or enzymatic approaches.

Value Chain Analysis For Nitroguanidine Market

The value chain for the Nitroguanidine market is a intricate network encompassing multiple stages, from the sourcing of raw materials to the final distribution of the product to end-users. Understanding this chain is crucial for identifying key cost drivers, potential areas for efficiency improvement, and strategic leverage points. The upstream segment of the value chain is focused on the acquisition and initial processing of fundamental chemical precursors. This stage primarily involves the sourcing of raw materials such as guanidine (often derived from dicyandiamide or urea), nitric acid, and ammonia. Key suppliers in this segment are large-scale chemical manufacturers specializing in basic and intermediate chemicals. The quality and purity of these raw materials directly impact the efficiency and final yield of nitroguanidine synthesis, making supplier relationships and quality control paramount. Upstream analysis also considers the geopolitical stability and logistical efficiency related to these raw materials, as any disruption can ripple throughout the entire value chain, affecting production schedules and costs. Manufacturers often engage in long-term contracts or even backward integration to secure a stable and cost-effective supply of these critical inputs, mitigating price volatility and supply risks. Research into alternative and more sustainable raw material sources also falls under upstream considerations.

Following the upstream activities, the core manufacturing process involves the chemical synthesis of nitroguanidine. This stage encompasses reaction engineering, purification, crystallization, and drying. Manufacturers invest significantly in advanced chemical processing technologies, safety infrastructure, and quality assurance systems to ensure the production of high-grade nitroguanidine that meets stringent industry specifications. Efficiency in this segment is driven by process optimization, energy management, and waste reduction strategies. Downstream analysis then focuses on the subsequent processing, formulation, packaging, and branding of nitroguanidine products. This can involve blending nitroguanidine with other energetic materials to create specific propellant or explosive formulations, or processing it further for pharmaceutical-grade applications. Packaging is critical for safety and stability, often involving specialized containers to prevent contamination or accidental detonation during transport and storage. The final stage involves the distribution channels through which nitroguanidine reaches its diverse end-users.

The distribution channel for nitroguanidine is characterized by its dual nature: direct sales for large-volume industrial clients and defense contractors, and indirect distribution through specialized chemical distributors for smaller orders or niche applications. Direct sales are prevalent for bulk orders where manufacturers engage directly with major defense organizations, mining companies, or large pharmaceutical producers. This approach allows for customized supply agreements, technical support, and direct communication regarding product specifications and logistics. These direct relationships are often long-term and built on trust and reliability, given the critical nature of the product. Specialized distributors, on the other hand, play a vital role in reaching a broader customer base, including smaller chemical firms, research institutions, and specific industrial end-users that require smaller quantities or specialized formulations. These distributors often have expertise in handling hazardous materials, extensive logistical networks, and the capability to provide local technical support, thereby extending the manufacturer's market reach without the need for extensive direct sales infrastructure.

The distinction between direct and indirect distribution is crucial for market strategy. Direct sales often involve complex contractual agreements, strict regulatory compliance, and a strong emphasis on security and safety protocols. Manufacturers directly involved in this channel often have dedicated sales teams with specialized knowledge of the defense and industrial explosives sectors. Indirect channels, while offering broader market access, require careful selection of reputable distributors who adhere to all safety and regulatory guidelines for hazardous chemicals. Manufacturers must ensure that their distributors maintain the integrity and quality of the product throughout the supply chain and provide adequate technical and logistical support to end-users. Online platforms are beginning to emerge for certain niche or research-grade chemicals, though bulk nitroguanidine typically requires more controlled and specialized distribution due to its inherent hazards. Both direct and indirect channels are critical for market penetration and ensuring efficient delivery to a global customer base, necessitating a robust and adaptable supply chain strategy that addresses diverse customer needs and regulatory environments.

Nitroguanidine Market Potential Customers

The Nitroguanidine market serves a diverse array of potential customers, primarily concentrated within industries that require high-energy, stable, and versatile chemical compounds for critical applications. The primary end-users or buyers of nitroguanidine are defense organizations and aerospace manufacturers. These entities rely heavily on nitroguanidine as a crucial component in military propellants, explosives, and pyrotechnics for various weapon systems, including artillery shells, rocket propellants, and small arms ammunition. Their demand is driven by ongoing defense modernization programs, geopolitical considerations, and the need for reliable, high-performance energetic materials. Given the sensitive nature of these applications, these customers prioritize product consistency, stringent quality control, and adherence to specific military specifications. Long-term supply contracts and direct relationships with manufacturers are common in this sector, emphasizing security of supply and technical partnership.

Another significant segment of potential customers includes companies operating in the global mining and construction industries. These firms utilize industrial explosives for large-scale blasting operations, such as ore extraction in mining, quarrying for aggregates, and demolition activities in construction and infrastructure development. Nitroguanidine's contribution to stable and powerful explosive formulations makes it an invaluable ingredient for these demanding applications. The demand from this sector is closely tied to global economic growth, infrastructure spending, and raw material extraction rates. These customers seek explosives that offer consistent performance, cost-effectiveness, and adherence to evolving safety and environmental regulations, driving innovation in explosive compositions and blasting techniques. Suppliers often work closely with these customers to provide customized solutions that meet specific geological and operational requirements.

Furthermore, the pharmaceutical industry represents a growing customer base for high-purity nitroguanidine. Pharmaceutical manufacturers use it as a key chemical intermediate in the synthesis of various active pharmaceutical ingredients (APIs) and specialty chemicals. Its unique chemical structure allows for its incorporation into complex organic molecules, making it valuable in drug discovery and development processes. Demand from this sector is driven by the expansion of the global healthcare industry, pharmaceutical research and development, and the continuous introduction of new therapeutic compounds. These customers require extremely high purity grades, robust analytical support, and compliance with pharmaceutical manufacturing standards (e.g., GMP - Good Manufacturing Practices). Chemical manufacturing companies, generally, also constitute a broad category of potential customers, utilizing nitroguanidine as a reagent or intermediate for the production of other specialized chemicals, including certain polymers, resins, and fine chemicals, showcasing its versatility beyond energetic applications.

Lastly, the agricultural sector, specifically manufacturers of pesticides and other agrochemicals, forms another segment of potential customers. Nitroguanidine is used as an intermediate in the synthesis of certain plant protection products and other agricultural compounds. The demand here is influenced by global food security concerns, agricultural practices, and regulatory frameworks surrounding pesticide use. Research institutions and laboratories globally also represent a consistent, albeit smaller, customer base, purchasing nitroguanidine for various scientific studies, chemical synthesis experiments, and the development of new materials. These customers typically require smaller quantities but often demand specialized grades and comprehensive technical data sheets. Understanding the specific needs, regulatory environment, and purchasing behaviors of each of these diverse customer groups is essential for nitroguanidine manufacturers to effectively target, serve, and expand their market presence.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 280.5 Million |

| Market Forecast in 2033 | USD 430.8 Million |

| Growth Rate | 6.2% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Hubei Yuanchen Pharmaceutical Co., Ltd., Zhejiang Xianfeng Chemical Co., Ltd., Liaoning Qingyang Chemical Co., Ltd., Jilin Chemical Group Import and Export Co., Ltd., Shanxi Tianbao Group Co., Ltd., Anhui Guangxin Agrochemical Co., Ltd., Sichuan Nitroguanidine Chemical Co., Ltd., Jiangsu Huaiyang Chemical Co., Ltd., Hebei Jianting Chemical Co., Ltd., Hunan Xinjing Chemical Co., Ltd., Jiangsu Runze Chemical Co., Ltd., Shandong Luxi Chemical Group Co., Ltd., DuPont de Nemours, Inc., BASF SE, Evonik Industries AG, China North Industries Group Corporation (NORINCO), Indian Ordnance Factories, Eurenco, Rheinmetall AG, Sichuan Meishan Tianhua Chemical Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Nitroguanidine Market Key Technology Landscape

The Nitroguanidine market's technological landscape is continuously evolving, driven by the imperative to enhance safety, improve efficiency, reduce environmental impact, and meet increasingly stringent purity requirements for its diverse applications. A foundational aspect of this landscape involves advanced synthesis methods. While conventional batch processes for the nitration of guanidine remain prevalent, there is a significant push towards developing and adopting more sophisticated techniques. Continuous flow chemistry, for instance, offers advantages in terms of enhanced safety by minimizing the inventory of hazardous intermediates, better reaction control, improved heat and mass transfer, and higher throughput. Microreactor technology is also gaining traction, enabling precise control over reaction conditions and allowing for safer handling of exothermic reactions, which is crucial for energetic material synthesis. These advanced methods not only boost production efficiency but also contribute significantly to inherent safety measures, reducing the risk of accidents during manufacturing.

Process optimization software and automation are critical components of the modern nitroguanidine production landscape. Sophisticated software packages integrate real-time sensor data, process modeling, and predictive analytics to optimize reaction parameters, monitor equipment performance, and identify potential bottlenecks or deviations. This leads to higher yields, reduced waste, and more consistent product quality. Automation across various stages, from raw material feeding to product packaging, minimizes human exposure to hazardous materials, thereby enhancing workplace safety. Furthermore, advanced crystallization techniques are vital for achieving the high purity grades of nitroguanidine demanded by the pharmaceutical and specialized chemical sectors. Innovations in crystallization processes, such as controlled cooling and solvent selection, help in obtaining uniform crystal sizes and high purity, which are critical for subsequent applications.

Safety monitoring systems are paramount in the production of nitroguanidine. These systems incorporate a suite of technologies, including gas detectors, thermal imaging cameras, pressure sensors, and specialized fire suppression systems, all integrated into a central control system. Real-time data acquisition and alarm systems provide immediate alerts in case of abnormal conditions, allowing for rapid response and mitigation of potential hazards. Furthermore, the development of robust waste treatment technologies is an integral part of sustainable nitroguanidine production. Manufacturers are investing in technologies for treating effluent streams to remove or neutralize hazardous by-products, ensuring compliance with environmental regulations and minimizing ecological footprints. This includes advanced oxidation processes, biological treatments, and solvent recovery systems, all designed to reduce the environmental impact of chemical manufacturing processes.

Finally, the field of advanced analytical techniques plays a crucial role in ensuring the quality and consistency of nitroguanidine. Techniques such as High-Performance Liquid Chromatography (HPLC), Gas Chromatography-Mass Spectrometry (GC-MS), X-ray Diffraction (XRD), and Nuclear Magnetic Resonance (NMR) spectroscopy are routinely employed for precise identification, quantification of impurities, and characterization of the compound's physical and chemical properties. These analytical methods are essential for meeting the stringent quality control standards required by end-user industries, particularly defense and pharmaceuticals, where product performance and safety are non-negotiable. The ongoing synergy between chemical engineering, process automation, and analytical science continues to drive innovation, making the production of nitroguanidine safer, more efficient, and environmentally responsible, further solidifying its position in critical industrial applications.

Regional Highlights

- North America: This region represents a mature and technologically advanced market for nitroguanidine. Demand is predominantly driven by a robust defense sector, consistent investment in military modernization, and a strong emphasis on R&D for high-performance energetic materials. The presence of leading chemical manufacturers and defense contractors, coupled with stringent environmental and safety regulations, fosters innovation in cleaner production methods and safer formulations. The United States is a key consumer, supporting both domestic defense needs and maintaining a significant global defense presence.

- Europe: Similar to North America, Europe is a well-established market characterized by strict regulatory frameworks and a focus on sustainability. Demand primarily stems from its sophisticated defense industries and significant contributions to specialty chemicals and pharmaceuticals. Countries like Germany, France, and the UK are prominent players in both production and consumption. Continuous research into advanced energetic materials and greener chemical processes is a defining feature of the European market, balancing industrial needs with environmental stewardship.

- Asia Pacific (APAC): The APAC region is the fastest-growing market for nitroguanidine, propelled by escalating defense budgets, rapid industrialization, and massive infrastructure development projects, especially in China, India, and South Korea. Increased mining and construction activities further amplify the demand for industrial explosives. The expanding pharmaceutical and agricultural sectors also contribute significantly to market growth. While production capacity is high, the region faces challenges related to environmental compliance and safety standards, driving investment in modern manufacturing technologies.

- Latin America: This region exhibits emerging demand for nitroguanidine, primarily driven by substantial mining operations in countries like Brazil, Chile, and Peru, which require industrial explosives for raw material extraction. Growing investments in infrastructure and, to a lesser extent, defense sector modernization also contribute to market expansion. While the market size is smaller compared to APAC or North America, its potential for growth is significant as industrial development continues. Supply chains often rely on imports from major producing regions.

- Middle East & Africa (MEA): The MEA region is characterized by increasing defense spending and ongoing infrastructure development projects, particularly in Gulf Cooperation Council (GCC) countries and parts of Africa. This fuels demand for both military propellants and industrial explosives. However, market growth is often influenced by geopolitical stability, economic diversification efforts, and the development of local manufacturing capabilities. Opportunities exist for international suppliers to cater to this growing demand, often through strategic partnerships and direct supply agreements with governmental and industrial entities.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Nitroguanidine Market.- Hubei Yuanchen Pharmaceutical Co., Ltd.

- Zhejiang Xianfeng Chemical Co., Ltd.

- Liaoning Qingyang Chemical Co., Ltd.

- Jilin Chemical Group Import and Export Co., Ltd.

- Shanxi Tianbao Group Co., Ltd.

- Anhui Guangxin Agrochemical Co., Ltd.

- Sichuan Nitroguanidine Chemical Co., Ltd.

- Jiangsu Huaiyang Chemical Co., Ltd.

- Hebei Jianting Chemical Co., Ltd.

- Hunan Xinjing Chemical Co., Ltd.

- Jiangsu Runze Chemical Co., Ltd.

- Shandong Luxi Chemical Group Co., Ltd.

- DuPont de Nemours, Inc.

- BASF SE

- Evonik Industries AG

- China North Industries Group Corporation (NORINCO)

- Indian Ordnance Factories

- Eurenco

- Rheinmetall AG

- Sichuan Meishan Tianhua Chemical Co., Ltd.

Frequently Asked Questions

What is nitroguanidine primarily used for?

Nitroguanidine is primarily used as a key component in propellants and explosives for the defense, mining, and construction industries, and as an intermediate in pharmaceuticals and specialty chemicals.

What are the main challenges in the nitroguanidine market?

Key challenges include stringent environmental regulations, high raw material price volatility, significant safety concerns during production and handling, and geopolitical instability affecting supply chains.

How is the nitroguanidine market segmented?

The market is segmented by type (Technical Grade, High Purity Grade), application (Propellants & Explosives, Pharmaceuticals, Pesticides, Chemical Reagents), end-user industry, and manufacturing process.

What factors drive the growth of the nitroguanidine market?

Market growth is driven by increasing global defense spending, expansion in mining and construction, growth in the pharmaceutical industry, and technological advancements in energetic materials.

What are the environmental concerns related to nitroguanidine?

Environmental concerns include the generation of hazardous by-products during synthesis and the potential ecological impact from its use in explosives, driving demand for greener production methods and waste treatment technologies.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Nitroguanidine (CAS 556-88-7) Market Statistics 2025 Analysis By Application (Pharmaceuticals, Pesticides, Automotive airbags), By Type (Industrial Grade, Medical Grade), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Medical Grade Nitroguanidine Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (High Concentration, Low Concentration), By Application (Pharmaceuticals, Pesticides, Automotive airbags, Other), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager