Nitroparaffins Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 431433 | Date : Dec, 2025 | Pages : 257 | Region : Global | Publisher : MRU

Nitroparaffins Market Size

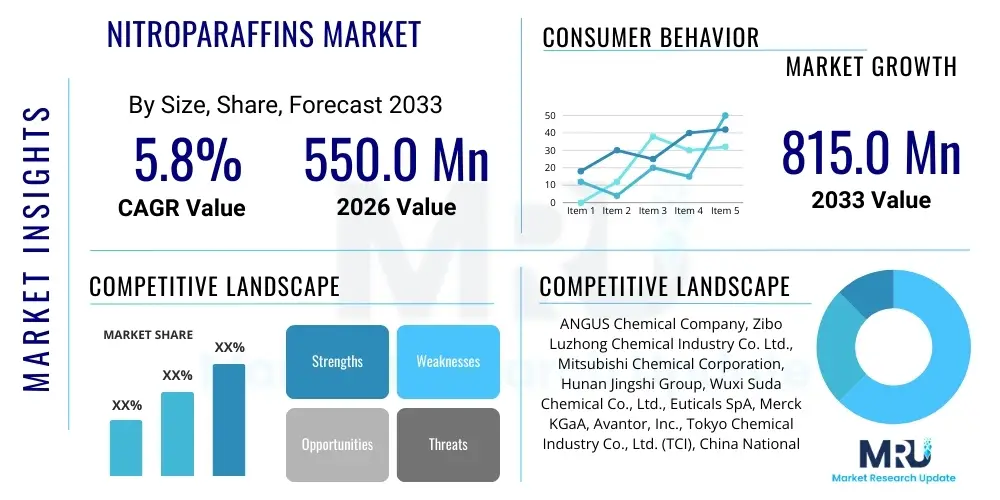

The Nitroparaffins Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at $550.0 million in 2026 and is projected to reach $815.0 million by the end of the forecast period in 2033.

Nitroparaffins Market introduction

The Nitroparaffins Market encompasses compounds derived from alkanes where one or more hydrogen atoms are replaced by a nitro group. These versatile organic intermediates, primarily including Nitromethane, Nitroethane, and Nitropropanes (1-NP and 2-NP), are crucial building blocks in organic synthesis and industrial applications. Their unique chemical properties—high solvency, strong oxidizing potential, and ability to undergo various chemical transformations—make them indispensable across diverse manufacturing sectors. The market growth is inherently linked to the performance of downstream industries such as pharmaceuticals, specialty chemicals, aerospace, and agriculture, which rely on nitroparaffins for specialized solvent characteristics and intermediate synthesis.

Nitroparaffins serve extensive functions, notably as highly efficient solvents for polymers, resins, and cellulose esters, making them vital in coatings, inks, and adhesive formulations. Furthermore, they are extensively utilized as chemical intermediates for the production of amino alcohols, hydroxylamines, oximes, and various nitro derivatives essential for pharmaceutical synthesis, particularly antibiotics and anti-tuberculosis drugs. Specific applications, such as the use of nitromethane as a high-performance fuel additive in racing and industrial engines, contribute significantly to market dynamics, although regulatory scrutiny concerning potential misuse and environmental impact often influences regional consumption patterns.

Key benefits driving the adoption of nitroparaffins include their exceptional thermal stability, low toxicity profiles compared to some alternative chlorinated solvents (for certain applications), and their efficacy in facilitating complex chemical reactions. Driving factors for market expansion include the increasing demand for high-purity pharmaceutical intermediates, technological advancements in polymerization processes requiring specific solvents, and rising industrialization in the Asia Pacific region. However, challenges related to volatile pricing of raw materials (paraffins) and stringent environmental regulations regarding volatile organic compound (VOC) emissions pose potential constraints on sustained market acceleration.

Nitroparaffins Market Executive Summary

The global Nitroparaffins Market is poised for stable expansion, primarily driven by robust demand from the pharmaceutical sector for specialty synthesis and the increasing need for high-performance solvents in advanced coatings and industrial cleaning applications. Business trends indicate a strategic focus on expanding production capacity, particularly in regions with lower operating costs and burgeoning industrial bases, such as China and India. Key manufacturers are also investing in research and development to create less volatile and more environmentally friendly derivatives to comply with evolving global chemical regulations. Consolidation and strategic partnerships among producers and major end-users are becoming prominent strategies to secure supply chains and optimize distribution efficiencies.

Regional trends highlight the Asia Pacific (APAC) as the fastest-growing market, propelled by rapid industrial expansion, significant investments in pharmaceutical manufacturing, and the burgeoning agricultural chemical industry. North America and Europe maintain substantial market shares due to high consumption in specialized applications like aerospace coatings and high-end automotive fuels, though growth rates are comparatively slower due to mature economies and stringent environmental protection agency mandates on chemical handling and emissions. The focus in developed regions remains on purity enhancements and specialized, niche applications, moving away from large-volume, general industrial solvent uses.

Segmentation trends reveal that the Nitromethane segment currently dominates the market, primarily due to its widespread use as an intermediate and its crucial role in high-energy applications. However, the Nitroethane and 2-Nitropropane segments are expected to exhibit higher growth CAGRs during the forecast period, fueled by their expanding utility as solvents in coatings and as intermediates in the production of specific agrochemicals and plasticizers. Application-wise, the Intermediates segment, particularly those utilized in synthesizing pharmaceutical compounds and specialty chemicals, holds the largest market share and is forecast to remain the primary revenue generator throughout 2033.

AI Impact Analysis on Nitroparaffins Market

Common user questions regarding AI's impact on the Nitroparaffins Market often revolve around optimizing synthesis efficiency, predicting raw material price fluctuations, and improving safety protocols in production. Users are particularly keen on understanding how AI-driven predictive modeling can mitigate the inherent risks associated with handling highly reactive or volatile nitroparaffins. Key themes emerging from these queries focus on implementing AI for real-time quality control, designing novel, sustainable nitroparaffin derivatives, and automating complex separation and purification processes to achieve higher grades required by the pharmaceutical industry. There is significant expectation that AI tools, particularly machine learning (ML) algorithms, will enable rapid identification of optimal reaction conditions (pressure, temperature, catalyst loading), thereby reducing energy consumption and waste generation during the manufacturing process, fundamentally altering cost structures and operational safety standards across the industry.

The primary concern users express is the initial investment and the complexity of integrating AI models into legacy chemical plant infrastructures. While the potential for optimizing yield and reducing batch failures is high, the proprietary nature of existing production data and the need for specialized data scientists within the chemical sector present adoption barriers. Furthermore, users question AI's ability to truly predict rare, high-impact events like runaway reactions or equipment failures specific to nitroparaffins handling, which require extremely high data fidelity and robust simulation capabilities. Addressing these concerns through standardized industrial AI platforms and cloud-based solutions is crucial for widespread market adoption of these transformative technologies.

Ultimately, AI is expected to catalyze innovation by accelerating the discovery of new, less hazardous synthetic pathways for nitroparaffins and their derivatives. By analyzing vast databases of chemical reactions and materials properties, AI can guide chemists toward greener synthesis methods that reduce the reliance on highly toxic or volatile precursors. This technological shift will not only improve operational safety and efficiency but also strengthen the industry's compliance profile, enhancing overall market competitiveness and responsiveness to stringent global regulatory environments regarding chemical process safety and environmental accountability.

- AI-driven optimization reduces energy usage and raw material consumption in synthesis processes.

- Machine learning algorithms enhance predictive maintenance, minimizing unplanned downtime in production facilities.

- AI enables rapid modeling and simulation of novel nitroparaffin derivatives for targeted applications (e.g., specific pharmaceutical intermediates).

- Real-time quality control using computer vision and sensor data ensures high-purity product yields, critical for pharmaceutical use.

- Predictive analytics helps manage supply chain volatility by forecasting feedstock price fluctuations and demand shifts.

DRO & Impact Forces Of Nitroparaffins Market

The Nitroparaffins Market is subject to a complex interplay of Drivers, Restraints, and Opportunities, collectively forming powerful Impact Forces that shape its trajectory. Key drivers include the escalating demand for Nitromethane as an essential intermediate in the pharmaceutical sector, especially for synthesizing critical drugs, coupled with the increasing adoption of nitroparaffin-based solvents in advanced industrial coatings that require superior resistance and drying characteristics. Opportunities arise from developing greener synthesis methods, focusing on catalytic conversions instead of traditional nitration processes, and exploring niche applications in new energy storage technologies where nitroparaffins or their derivatives might play a role as electrolytes or precursors.

However, significant restraints temper the market's potential. The highly flammable and explosive nature of some nitroparaffins necessitates stringent storage, transportation, and handling protocols, significantly increasing operational costs and limiting market access in regions with restrictive safety regulations. Furthermore, volatility in the prices of key feedstocks, particularly propane and natural gas, coupled with the high energy intensity of the manufacturing process, compress profit margins for producers. Environmental concerns related to VOC emissions from solvent applications and the need for rigorous waste treatment associated with nitration chemistry also present substantial regulatory hurdles that restrain broad industrial adoption.

The collective impact forces suggest a market moving towards specialization and high-value applications rather than commodity solvent use. The balance between regulatory pressure (a restraining force) and technological innovation (an enabling opportunity) will dictate future growth. The critical impact force is the regulatory environment: stricter environmental standards worldwide push companies to invest heavily in process improvements and transition to less toxic derivatives, thereby creating opportunities for specialized, high-ppurity products but simultaneously restricting growth in traditional, high-volume solvent markets. Success hinges on mastering high-yield, safe production techniques for specialized grades demanded by pharmaceutical and agrochemical industries.

Segmentation Analysis

The Nitroparaffins Market segmentation provides a granular view of market dynamics based on product type, application, and end-use industry, illustrating differential growth trajectories across various segments. Product segmentation is crucial, as the chemical properties and primary uses vary significantly among the major nitroparaffin compounds, leading to distinct market performance. The application analysis highlights the dominance of the intermediate chemical synthesis segment, reinforcing the compound's role as a fundamental building block rather than a final consumer product. End-use categorization reveals the reliance of the market on highly regulated sectors such as pharmaceuticals and specialty chemicals, which prioritize product quality and purity above all else.

By product type, the market is typically segmented into Nitromethane, Nitroethane, 1-Nitropropane (1-NP), and 2-Nitropropane (2-NP). Nitromethane accounts for the largest share due to its established use in synthesizing pharmaceuticals and its application as a high-performance fuel additive. However, 2-Nitropropane is gaining traction rapidly as a replacement for certain toxic solvents in the coatings industry, driven by its excellent solvency characteristics and lower volatility compared to alternatives, promising a higher growth rate during the forecast period. Monitoring these shifts in product preference is essential for market players planning capital expenditures and resource allocation.

The principal applications driving demand include usage as Solvents, Chemical Intermediates, Fuel Additives, and Others (e.g., specialized propellants or fumigants). The segment of Chemical Intermediates remains paramount, serving as the foundational element for producing numerous high-value chemicals, including Chloropicrin (an agricultural fumigant), various amino alcohols (used in pharmaceuticals and cosmetics), and specialty resins. The consistent requirement for highly pure starting materials in drug synthesis provides robust, non-cyclical demand, stabilizing the overall market against broader economic fluctuations.

- Product Type:

- Nitromethane

- Nitroethane

- 1-Nitropropane (1-NP)

- 2-Nitropropane (2-NP)

- Application:

- Solvents (Coatings, Inks, Adhesives)

- Chemical Intermediates (Pharmaceuticals, Agrochemicals)

- Fuel Additives (Racing, Industrial)

- Others (Fumigants, Specialty Chemicals)

- End-Use Industry:

- Pharmaceuticals

- Agrochemicals

- Coatings and Resins

- Automotive and Aerospace

- Plastics and Polymers

Value Chain Analysis For Nitroparaffins Market

The value chain for the Nitroparaffins Market begins with upstream activities focused on securing and processing essential raw materials, primarily propane and natural gas, which are subjected to high-temperature vapor phase nitration. This upstream segment is highly capital-intensive, requiring specialized facilities for handling corrosive reagents and managing the exothermic nature of the nitration reaction. The purity and cost of these paraffin feedstocks directly impact the overall production cost of nitroparaffins. Key players often integrate backward into feedstock supply or secure long-term contracts to stabilize raw material pricing and ensure consistent supply necessary for continuous manufacturing processes, which is a critical determinant of competitive advantage.

The midstream segment involves the core manufacturing process, followed by extensive purification and fractional distillation to separate the mixture of isomeric nitroparaffins (Nitromethane, Nitroethane, 1-NP, and 2-NP). Process efficiency and energy management are paramount in this stage due to the high energy consumption. Once separated and purified to the required grade (industrial, technical, or pharmaceutical), the products move to downstream channels. Downstream analysis reveals that distribution is often specialized, given the hazardous nature of these compounds, relying on chemical logistics experts who comply with strict Dangerous Goods regulations (e.g., DOT, ADR) for storage and transportation, including specialized tank cars and packaging designed to prevent accidents.

Distribution channels for nitroparaffins are predominantly direct for large-volume industrial end-users like major chemical producers and indirect through specialized chemical distributors for smaller orders and niche market participants, such as custom synthesis organizations. Direct distribution ensures quality control and security of supply for large pharmaceutical and agrochemical clients. Indirect distribution leverages the local knowledge and small-batch logistical capabilities of distributors, especially in fragmented regional markets like APAC. The highly technical nature of the product demands that distributors possess adequate technical sales support to assist customers in handling and application, further solidifying the necessity for specialized, rather than generalized, chemical distribution networks.

Nitroparaffins Market Potential Customers

Potential customers for nitroparaffins span a diverse range of high-value industrial sectors, primarily defined by their need for superior solvency, reactive intermediates, or high-energy characteristics. The largest segment of end-users comprises pharmaceutical and life sciences companies, who utilize highly pure nitroparaffins, particularly Nitromethane, as essential starting materials for complex organic synthesis pathways, including the creation of various amino alcohols and heterocyclic compounds vital for modern drug manufacturing, such as antibiotics, analgesics, and central nervous system therapeutics. Their purchasing decisions are critically dependent on product purity, batch consistency, and reliable supply chain security, necessitating stringent supplier qualification processes.

Another significant customer base exists within the coatings, resins, and adhesives industries. These manufacturers rely on nitroparaffins like 2-Nitropropane for their powerful solvent capabilities, which allow them to dissolve highly crystalline polymers and resins unsuitable for conventional solvents, resulting in superior high-solids, low-viscosity formulations. This customer group values the rapid evaporation rates and low-odor characteristics provided by certain nitroparaffins, particularly in specialized applications such as aerospace coatings, high-performance automotive finishes, and printing inks that require fast drying times and excellent film formation. Demand is often cyclical and tied to general construction and manufacturing activity.

The third major segment includes the agrochemical and specialty chemical producers. Agrochemical companies use nitroparaffins as precursors for insecticides, herbicides, and fungicides (e.g., Chloropicrin derived from nitromethane). Specialty chemical companies utilize these compounds for synthesizing plasticizers, stabilizers, and specialized textile finishing agents. Furthermore, a niche but high-impact group of customers includes the high-performance motorsports industry and specific industrial engine operators who purchase Nitromethane as a critical component in fuel mixtures due to its high oxygen content and powerful combustion characteristics, demanding specialized packaging and immediate availability.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $550.0 million |

| Market Forecast in 2033 | $815.0 million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | ANGUS Chemical Company, Zibo Luzhong Chemical Industry Co. Ltd., Mitsubishi Chemical Corporation, Hunan Jingshi Group, Wuxi Suda Chemical Co., Ltd., Euticals SpA, Merck KGaA, Avantor, Inc., Tokyo Chemical Industry Co., Ltd. (TCI), China National Chemical Corporation (ChemChina), Dow Inc., AkzoNobel N.V., Spectrum Chemical Manufacturing Corp., Haihang Industry Co., Ltd., Alfa Aesar (Thermo Fisher Scientific), BASF SE, Shandong Xinyu Chemical Co., Ltd., Jilin Chemical Industry Co., Ltd., Huntsman Corporation, Shell plc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Nitroparaffins Market Key Technology Landscape

The fundamental technology for producing nitroparaffins relies on the classical high-temperature vapor phase nitration of propane, a highly complex and energy-intensive process that yields a mixture of all four primary nitroparaffins. Recent technological advancements, however, are focused less on replacing this foundational reaction and more on improving downstream efficiency and selectivity. Key advancements include the optimization of fractional distillation columns using advanced process control (APC) systems to achieve higher purity separation of the isomeric mixture, which is critical for meeting pharmaceutical grade specifications. There is also ongoing research into heterogeneous catalysis to potentially lower the required reaction temperatures and pressures, thereby improving safety and reducing operational energy costs, while also enhancing the selectivity toward desired isomers like 2-Nitropropane.

A second crucial area of technological focus involves the development of cleaner synthesis routes to mitigate environmental concerns associated with traditional nitration chemistry. This includes exploring catalytic oxidative nitration using non-fuming nitric acid or nitrogen dioxide, aiming for less corrosive conditions and lower levels of hazardous byproducts. While still largely in the research phase, success in these areas could drastically reduce capital expenditure on specialized corrosion-resistant equipment and improve the environmental profile of the manufacturing process, making it more attractive in heavily regulated jurisdictions like Western Europe. The implementation of flow chemistry techniques is also being investigated to handle the highly exothermic reactions more safely and continuously, moving away from large batch reactors.

Furthermore, technology is playing a vital role in ensuring safe handling and storage, particularly through the use of advanced sensing technologies and predictive maintenance frameworks. In terms of downstream applications, the technological landscape is characterized by the use of nitroparaffins in specialized polymerization techniques and as co-solvents in advanced lithography and semiconductor manufacturing processes, where ultra-high purity is non-negotiable. Manufacturers are investing in specialized analytical technologies, such as advanced gas chromatography and mass spectrometry, to ensure minimal impurity profiles (parts per billion), securing their position as preferred suppliers for sensitive end-use industries like electronics and advanced materials.

Regional Highlights

- Asia Pacific (APAC): APAC represents the most dynamic and rapidly expanding market for nitroparaffins globally. This growth is predominantly fueled by the exponential expansion of the manufacturing base, particularly in China and India, which are rapidly becoming global hubs for pharmaceutical ingredient synthesis, bulk chemical production, and agrochemical formulation. High domestic and export demand for generic drugs and crop protection chemicals drives significant consumption of nitroparaffin intermediates. Regulatory enforcement is generally less restrictive compared to Western counterparts, allowing for faster industrial adoption, though local governments are steadily tightening safety standards.

- North America: North America is a mature market characterized by high consumption of specialized, high-purity grades. The demand here is concentrated in niche applications, including aerospace coatings (for specific solvent properties), high-performance fuels (Nitromethane), and specialized pharmaceutical intermediates. The market is defined by stringent environmental regulations, particularly concerning VOC emissions and chemical process safety (OSHA and EPA). This regulatory framework pushes manufacturers towards innovation in low-VOC solvent alternatives derived from nitroparaffins and efficient production technologies.

- Europe: The European market exhibits moderate growth, driven primarily by the established chemical and pharmaceutical industries, especially in Germany, Switzerland, and the UK. Strict REACH regulations heavily influence market dynamics, requiring thorough substance evaluation and risk management. European manufacturers often focus on producing nitroparaffins for captive consumption or for use in high-end, specialized products requiring the highest purity standards, placing a premium on sustainability and circular economy practices within the chemical sector.

- Latin America (LATAM): The LATAM market is smaller but demonstrates steady growth, mainly linked to the burgeoning agricultural sector, particularly in Brazil and Argentina, driving demand for agrochemical intermediates derived from nitroparaffins. Economic instability and fluctuating currency exchange rates can impact import costs, making local production or robust distribution networks crucial for market penetration.

- Middle East and Africa (MEA): MEA remains the smallest regional market, with demand primarily concentrated in the Middle Eastern petrochemical hub for use in oilfield chemicals and specialized industrial solvents. Growth is sporadic and highly dependent on regional investment in infrastructure and diversification away from primary oil production.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Nitroparaffins Market.- ANGUS Chemical Company

- Zibo Luzhong Chemical Industry Co. Ltd.

- Mitsubishi Chemical Corporation

- Hunan Jingshi Group

- Wuxi Suda Chemical Co., Ltd.

- Euticals SpA

- Merck KGaA

- Avantor, Inc.

- Tokyo Chemical Industry Co., Ltd. (TCI)

- China National Chemical Corporation (ChemChina)

- Dow Inc.

- AkzoNobel N.V.

- Spectrum Chemical Manufacturing Corp.

- Haihang Industry Co., Ltd.

- Alfa Aesar (Thermo Fisher Scientific)

- BASF SE

- Shandong Xinyu Chemical Co., Ltd.

- Jilin Chemical Industry Co., Ltd.

- Huntsman Corporation

- Shell plc.

Frequently Asked Questions

Analyze common user questions about the Nitroparaffins market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary drivers of growth in the Nitroparaffins Market?

The primary drivers include the escalating global demand for high-purity chemical intermediates, particularly Nitromethane, used extensively in the synthesis of specialized pharmaceuticals and antibiotics. Additionally, the need for high-performance, selective solvents in advanced industrial coatings and agrochemical formulations contributes significantly to market expansion.

Which nitroparaffin segment is expected to exhibit the fastest growth rate?

The 2-Nitropropane (2-NP) segment is projected to experience the fastest growth rate. This acceleration is driven by its increasing adoption as a favorable solvent replacement in the coatings and adhesives industry, offering superior solvency and better regulatory compliance compared to many traditional volatile organic compound (VOC) solvents.

What regulatory challenges face the manufacturing and application of nitroparaffins?

Nitroparaffins, due to their flammable and sometimes explosive nature, face stringent regulatory challenges worldwide, including strict transportation regulations (Dangerous Goods classification) and environmental mandates such as the EU's REACH regulation and global VOC emission limits. Compliance necessitates high investments in safety protocols and advanced waste treatment technologies.

How does the pharmaceutical industry utilize nitroparaffins?

The pharmaceutical industry uses ultra-high purity nitroparaffins almost exclusively as versatile chemical building blocks or intermediates. They are crucial for the synthesis of amino alcohols, which are precursors for various life-saving drugs, including cardiovascular medications and certain antibiotics, ensuring a non-cyclical, stable demand stream.

Which geographic region dominates the global consumption of nitroparaffins?

The Asia Pacific (APAC) region currently dominates the market in terms of both consumption volume and growth rate. This dominance is primarily attributed to the rapid industrialization, massive scale expansion of pharmaceutical and agrochemical manufacturing facilities, and comparatively lower production costs in major economies like China and India.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager