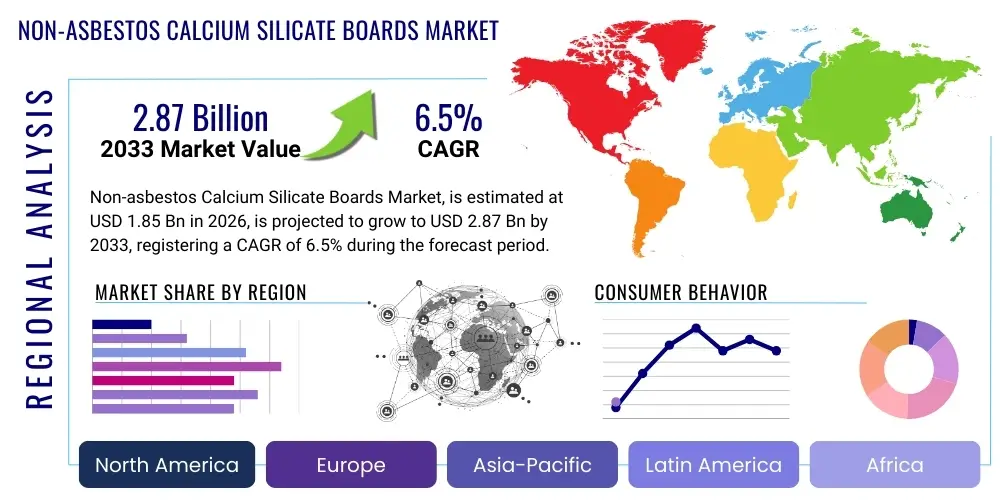

Non-asbestos Calcium Silicate Boards Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436033 | Date : Dec, 2025 | Pages : 255 | Region : Global | Publisher : MRU

Non-asbestos Calcium Silicate Boards Market Size

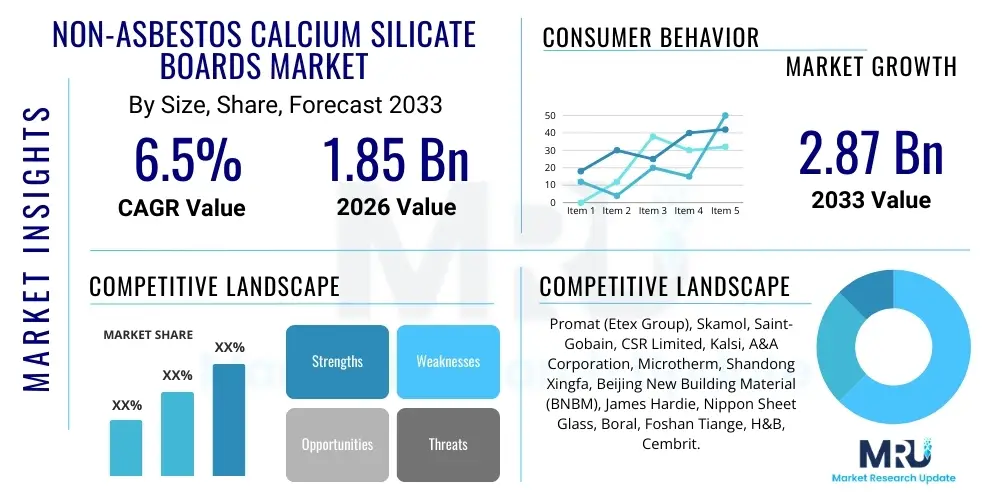

The Non-asbestos Calcium Silicate Boards Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 1.85 Billion in 2026 and is projected to reach USD 2.87 Billion by the end of the forecast period in 2033.

Non-asbestos Calcium Silicate Boards Market introduction

Non-asbestos Calcium Silicate (C-S) boards represent a crucial segment of the modern building materials industry, offering high-performance solutions primarily for fire protection and thermal insulation. These boards are fabricated through a process involving raw materials such as quicklime, silica, cement, and often reinforced with cellulose fibers or other mineral fillers, specifically excluding harmful asbestos fibers. The resultant product is lightweight, durable, and highly resistant to fire and moisture, making it a preferred choice in construction environments where stringent safety standards are mandated. This transition away from asbestos-containing materials has been a primary global driver, positioning C-S boards as essential components in both renovation projects and new construction.

The core utility of non-asbestos C-S boards spans across diverse applications, including internal and external wall linings, ceilings, partitions, and specialized fire-rated ducting and enclosures. Their inherent ability to withstand high temperatures and prevent flame spread for extended periods is a fundamental benefit that underpins their market demand, particularly in commercial, institutional, and high-density residential buildings. Furthermore, these boards offer excellent dimensional stability and workability, allowing for ease of installation and reduced construction timelines, contributing significantly to overall project efficiency and cost-effectiveness over the product lifecycle.

Market expansion is significantly fueled by global regulatory enforcement pertaining to fire safety codes and environmental sustainability mandates. Key driving factors include the rapid urbanization across Asia Pacific, leading to increased construction volume; rising governmental focus on replacing older, asbestos-contaminated infrastructure; and continuous product innovation leading to enhanced strength-to-weight ratios and superior insulating properties. The combination of mandatory safety compliance and performance benefits ensures a robust growth trajectory for the Non-asbestos Calcium Silicate Boards market throughout the forecast period.

Non-asbestos Calcium Silicate Boards Market Executive Summary

The Non-asbestos Calcium Silicate Boards market is characterized by robust business trends centered on sustainability, stringent regulatory compliance, and technological advancements aimed at optimizing material performance. Key business trends include increased consolidation among large manufacturers seeking economies of scale, and strategic partnerships focused on developing specialized, application-specific products, such as those tailored for extreme moisture resistance or ultra-high thermal insulation for industrial furnace linings. The shift towards prefabricated and modular construction methods further boosts demand for C-S boards due to their standardized dimensions and ease of assembly. Manufacturers are also focusing on optimizing supply chains to manage the volatility in raw material costs, particularly silica and cement, maintaining competitive pricing while adhering to high quality standards.

Regionally, Asia Pacific dominates the market, driven by massive infrastructure development and the mandatory adoption of international fire safety standards in rapidly expanding urban centers like China and India. North America and Europe demonstrate mature market characteristics, focusing primarily on renovation, retrofitting, and high-value industrial applications, particularly driven by energy efficiency goals and the complete eradication of legacy asbestos materials. Emerging regions in Latin America and MEA are witnessing accelerated adoption, stimulated by foreign investment in commercial real estate and regulatory updates aligning local building codes with global best practices for passive fire protection.

Segmentation analysis reveals that the fire protection application segment holds the largest market share due to critical safety mandates across commercial and industrial sectors. The high-density board segment, utilized heavily in structural elements and external claddings requiring superior mechanical strength and impact resistance, is projected to exhibit the fastest growth. Customer preferences are increasingly shifting towards multifunctional boards that offer a combination of fire resistance, soundproofing, and thermal management, influencing product development pipelines significantly. This diversified demand structure necessitates manufacturers to maintain flexible production capabilities and a broad product portfolio to capture growth across various end-use sectors.

AI Impact Analysis on Non-asbestos Calcium Silicate Boards Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Non-asbestos Calcium Silicate Boards market typically revolve around optimizing manufacturing efficiency, predictive maintenance for production lines, and enhancing material quality control. Users frequently ask how AI can reduce waste, forecast demand accurately given seasonal construction cycles, and integrate C-S boards into smart building systems. A major theme is the potential for AI-driven material science to discover novel composite formulations that improve both fire resistance and environmental performance. These concerns highlight expectations for AI to drive down operational costs, ensure consistent product specifications, and facilitate smarter inventory management, ultimately improving profitability and market responsiveness for board manufacturers.

The deployment of AI and machine learning models in manufacturing plants allows for the real-time monitoring of kiln temperatures, mixing ratios, and curing processes, which are critical steps in producing high-quality calcium silicate boards. By analyzing vast datasets, AI systems can immediately detect deviations, predict potential equipment failures before they occur, and adjust parameters automatically, leading to a significant reduction in defective batches and unnecessary energy consumption. This level of precision is vital for maintaining the structural integrity and certified fire ratings of the final product, addressing a key constraint related to batch-to-batch variability in traditional production.

Furthermore, AI is instrumental in streamlining the supply chain and logistics. Predictive analytics allows manufacturers to forecast material needs based on global construction forecasts and specific regional demand spikes, optimizing raw material procurement and minimizing storage costs. In the application phase, AI-powered tools can assist architects and engineers in selecting the optimal C-S board specification (density, thickness) for specific passive fire protection needs, integrating regulatory requirements directly into the design process through Building Information Modeling (BIM) software, thus enhancing the overall efficiency and compliance of construction projects.

- AI optimizes manufacturing processes, leading to reduced energy consumption and lower waste generation.

- Predictive maintenance driven by machine learning minimizes downtime on high-volume production lines.

- AI-enhanced quality control ensures consistent density, strength, and certified fire resistance of every board.

- Demand forecasting using AI improves raw material sourcing and inventory management efficiency.

- Integration into BIM platforms facilitates intelligent material selection and fire safety compliance during design.

DRO & Impact Forces Of Non-asbestos Calcium Silicate Boards Market

The Non-asbestos Calcium Silicate Boards market is fundamentally shaped by powerful regulatory drivers mandating the phase-out of asbestos and increasing global focus on passive fire protection in densely populated and high-risk structures. The primary driver is the superior fire resistance properties of C-S boards, often achieving several hours of integrity and insulation ratings, which is crucial for compliance with modern building safety codes across North America and Europe. However, market growth faces restraints, notably the relatively higher cost of C-S boards compared to traditional gypsum drywall or plywood, which can deter adoption in price-sensitive developing markets. Opportunities are abundant, specifically in the green building movement, where C-S boards contribute to energy efficiency and low-toxicity material requirements. The collective impact forces related to regulatory pressures and consumer safety demands are extremely high, ensuring sustained market penetration.

Specific market drivers include the rapid expansion of commercial infrastructure, such as airports, hospitals, and data centers, all requiring specialized fire-rated enclosures and partitions. Moreover, the inherent thermal stability and resistance to biological attack (mold, mildew) make C-S boards highly desirable for applications in harsh environments, including industrial facilities and wet areas like swimming pools and laundries. The global momentum to renovate and upgrade aging public and residential buildings, replacing outdated fire separation systems with modern, non-combustible alternatives, further underpins steady demand growth across established economies.

Conversely, the supply chain for raw materials, particularly synthetic silica and specialized cellulosic fibers, can introduce price volatility and logistical challenges, acting as a moderate restraint. Furthermore, despite excellent moisture resistance when properly sealed, extreme or prolonged water exposure can compromise the board's structural integrity if not manufactured to specific standards, necessitating careful product selection and installation. The core opportunity lies in technological breakthroughs, such as developing lighter C-S boards with equivalent or better mechanical properties, and expanding applications into non-traditional uses like sound attenuation panels or specialized external thermal insulation composite systems (ETICS), capitalizing on the material's versatile performance profile.

Segmentation Analysis

The Non-asbestos Calcium Silicate Boards market is extensively segmented based on key parameters including density, thickness, application, and end-use, allowing manufacturers to target specific performance requirements across the construction and industrial sectors. Density segmentation (Low, Medium, and High) is crucial as it dictates the primary function: low density for insulation and non-load-bearing applications, and high density for structural use requiring robust mechanical strength and impact resistance. Thickness segmentation addresses varied requirements for fire rating periods and thermal performance. Application segmentation clearly defines market utility, separating the high-volume building board market from specialized industrial insulation needs. End-use segmentation tracks demand from key sectors, with commercial and industrial construction often dictating volume and specification rigor.

- By Density:

- Low Density (Primarily for thermal insulation)

- Medium Density (General building applications, internal partitions)

- High Density (Heavy duty, exterior facades, structural fire protection)

- By Thickness:

- 6 mm to 12 mm (Ceilings, light partitions)

- Above 12 mm (External walls, structural fire rated enclosures)

- By Application:

- Building Boards (General purpose, partitions, ceilings)

- Insulation Boards (Thermal and sound insulation)

- Fire Protection Boards (Ducting, encapsulation, fire barriers)

- By End-Use Sector:

- Residential Construction

- Commercial Construction (Hospitals, Offices, Retail)

- Industrial Facilities (Petrochemicals, Power Plants, Foundries)

- Infrastructure (Tunnels, Transportation Hubs)

Value Chain Analysis For Non-asbestos Calcium Silicate Boards Market

The value chain for Non-asbestos Calcium Silicate Boards begins with the upstream sourcing of critical raw materials, primarily high-purity silica, lime (calcium oxide), and various cellulosic or mineral reinforcement fibers, often requiring significant energy input for processing and calcination. Material suppliers, therefore, hold moderate bargaining power influenced by global commodity pricing and energy costs. Manufacturers then engage in specialized hydrothermal synthesis processes (autoclaving) to create the stable crystalline structure of calcium silicate. Efficiency at this stage is crucial, as production technology determines the board's final properties, such as porosity, strength, and fire rating. Leading manufacturers invest heavily in proprietary formulation and production technology to achieve differentiated, high-performance products, creating barriers to entry for smaller players.

The midstream of the value chain involves fabrication, cutting, and finishing processes, including surface treatments for moisture resistance, painting, or decorative finishes, preparing the boards for distribution. Distribution channels are varied, incorporating both direct sales to large construction firms, infrastructure projects, and industrial end-users, and indirect sales through extensive networks of construction material wholesalers, specialized distributors, and retailers. The effectiveness of the distribution network, particularly the ability to handle bulky, heavy materials efficiently and ensure immediate availability, is a critical factor influencing market penetration and regional success.

Downstream analysis focuses on the end-users: architects and engineers specify the product, general contractors purchase and install the boards, and specialized fire protection contractors often handle high-risk installations. The ultimate value delivery is realized in the application—passive fire protection, thermal insulation, or general construction—where the board's performance directly impacts safety and building longevity. Key downstream activities also include customer education on proper handling and installation techniques, ensuring the certified performance standards are met in situ. Direct sales channels are favored for large industrial projects requiring customized specifications, while indirect channels serve the fragmented residential and smaller commercial construction markets efficiently.

Non-asbestos Calcium Silicate Boards Market Potential Customers

The primary potential customers and buyers of Non-asbestos Calcium Silicate Boards are segmented across the construction ecosystem, ranging from large public works agencies to individual homeowners undertaking renovation. Key institutional buyers include governmental bodies responsible for building public infrastructure (e.g., mass transit systems, tunnels) where fire safety is paramount, and large commercial developers constructing high-rise office buildings, hotels, and hospitals, requiring certified, multi-hour fire separation systems. These customers demand high volumes, strict adherence to international safety certifications (e.g., ASTM, EN standards), and detailed technical support.

The industrial sector represents another critical customer base, particularly companies operating in energy, petrochemicals, and manufacturing. These buyers use C-S boards for specialized high-temperature applications, such as lining furnaces, ovens, and steam piping, where thermal insulation and resistance to chemical attack are essential. These industrial clients often prioritize performance metrics like maximum operating temperature and durability over initial cost. Furthermore, specialized fire protection contractors act as influential intermediaries, recommending and purchasing specific C-S board types for complex installations like fire-rated ventilation ducts and cable enclosures.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.85 Billion |

| Market Forecast in 2033 | USD 2.87 Billion |

| Growth Rate | CAGR 6.5% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Promat (Etex Group), Skamol, Saint-Gobain, CSR Limited, Kalsi, A&A Corporation, Microtherm, Shandong Xingfa, Beijing New Building Material (BNBM), James Hardie, Nippon Sheet Glass, Boral, Foshan Tiange, H&B, Cembrit. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Non-asbestos Calcium Silicate Boards Market Key Technology Landscape

The technology landscape in the Non-asbestos Calcium Silicate Boards market is primarily centered on manufacturing process optimization and material formulation to enhance specific board properties, such as reduced weight, improved mechanical strength, and superior moisture performance. The core manufacturing technology involves hydrothermal synthesis under high pressure and temperature (autoclaving), which yields the stable tobermorite structure characteristic of C-S boards. Recent technological advancements focus on optimizing the ratio of raw materials (lime and silica) and the use of advanced reinforcing agents, such as specialized glass fibers or synthetic polymer additives, to replace traditional wood pulp fibers entirely in certain high-performance products, ensuring better long-term durability and dimensional stability.

A significant trend involves the development of proprietary formulations that achieve ultra-low thermal conductivity, expanding the use of these boards into high-efficiency thermal insulation applications within industrial furnaces, kilns, and specialized refrigeration units. This requires micro-engineering the material structure to maximize porosity without compromising structural integrity. Furthermore, advancements in surface treatment technologies, including specialized water-repellent coatings and hydrophobic additives integrated during mixing, are crucial for increasing the board’s resilience in exterior and high-humidity environments, addressing a historical vulnerability of calcium silicate materials.

Automation and digitalization are also key technological factors. Modern plants utilize sophisticated sensors and control systems to maintain precise conditions during the mixing, pressing, and autoclaving stages, which is essential for consistent quality across large production runs. The adoption of continuous production lines, rather than traditional batch processing, is becoming prevalent among market leaders to improve throughput and reduce production costs, leveraging techniques borrowed from advanced materials manufacturing to maintain competitive advantage and meet rapidly escalating global demand for high-specification fire-rated materials.

Regional Highlights

Regional dynamics play a crucial role in shaping the Non-asbestos Calcium Silicate Boards market, driven by varying construction spending, regulatory frameworks, and climate-specific requirements across major economic zones.

- Asia Pacific (APAC): APAC is the dominant and fastest-growing region, fueled by unprecedented urbanization, massive government investment in infrastructure (e.g., public transport, high-speed rail), and mandatory adherence to modern fire safety codes, particularly in commercial and high-rise residential construction in China, India, and Southeast Asian nations. The region acts as both a major producer and consumer.

- North America (NA): Characterized by stringent, frequently updated building codes, especially concerning passive fire protection and natural disaster resilience (earthquakes, wildfires). Demand is stable, driven primarily by continuous retrofitting of older commercial buildings, industrial applications (petrochemicals, power generation), and the requirement for highly durable, certified materials.

- Europe: The market is mature, highly regulated, and heavily focused on energy efficiency and sustainability. Demand is strong for high-performance insulation boards and materials that contribute to achieving net-zero energy targets. The mandatory replacement of residual asbestos materials in Eastern and Western Europe continues to provide foundational market demand.

- Middle East and Africa (MEA): Growth is accelerating due to large-scale, high-profile construction projects (mega-cities, commercial hubs) in the GCC states (UAE, Saudi Arabia). These projects prioritize premium fire safety specifications, given the high investment and density, leading to strong uptake of high-density C-S boards for external cladding and fire barriers.

- Latin America (LATAM): Market adoption is steady, driven by increasing foreign investment in commercial and industrial real estate. Regulatory environments are gradually standardizing towards international safety benchmarks, creating opportunity, though price sensitivity remains a key determinant for broad residential adoption.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Non-asbestos Calcium Silicate Boards Market.- Promat (Etex Group)

- Skamol A/S

- Saint-Gobain

- CSR Limited

- Kalsi

- A&A Corporation

- Microtherm NV

- Shandong Xingfa Group

- Beijing New Building Material (BNBM)

- James Hardie Industries PLC

- Nippon Sheet Glass (NSG)

- Boral Limited

- Foshan Tiange Building Materials Co., Ltd.

- H&B Group

- Cembrit Holding A/S

- China National Building Material (CNBM)

- Taisheng New Building Materials Co., Ltd.

- Vicat S.A.

- Siniat (Etex Group)

Frequently Asked Questions

Analyze common user questions about the Non-asbestos Calcium Silicate Boards market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the demand for Non-asbestos Calcium Silicate Boards?

The primary driver is stringent global regulatory mandates requiring superior passive fire protection in commercial and public buildings, coupled with the absolute necessity of replacing legacy asbestos-containing building materials worldwide.

How do Calcium Silicate Boards compare to Gypsum Boards in terms of fire rating and durability?

Calcium Silicate Boards typically offer significantly higher fire resistance (often multi-hour rated) and superior moisture and impact resistance compared to standard gypsum boards, making them suitable for heavy-duty, high-risk, or industrial applications.

Which regional market holds the largest share and why is it experiencing high growth?

Asia Pacific holds the largest market share, driven by rapid urbanization, massive infrastructure development, and increasing adoption of international building safety standards across major developing economies like China and India.

What are the key technological advancements expected in Calcium Silicate Board manufacturing?

Key advancements include the development of lighter-weight formulations, improved hydrophobic treatments for moisture protection, and the integration of AI-driven quality control and process optimization in the hydrothermal synthesis (autoclaving) process.

What is the main restraint impacting the widespread adoption of these boards?

The primary restraint is the relatively higher initial cost of Non-asbestos Calcium Silicate Boards compared to conventional, lower-performance alternatives, which can limit their use in budget-constrained residential or developing market projects.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager