Nonwoven Fabrics for HVAC Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440274 | Date : Jan, 2026 | Pages : 255 | Region : Global | Publisher : MRU

Nonwoven Fabrics for HVAC Market Size

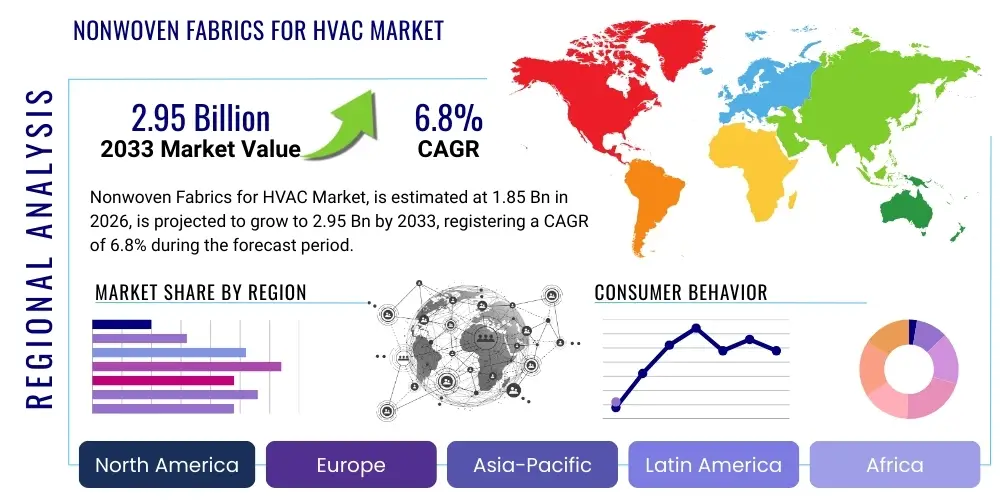

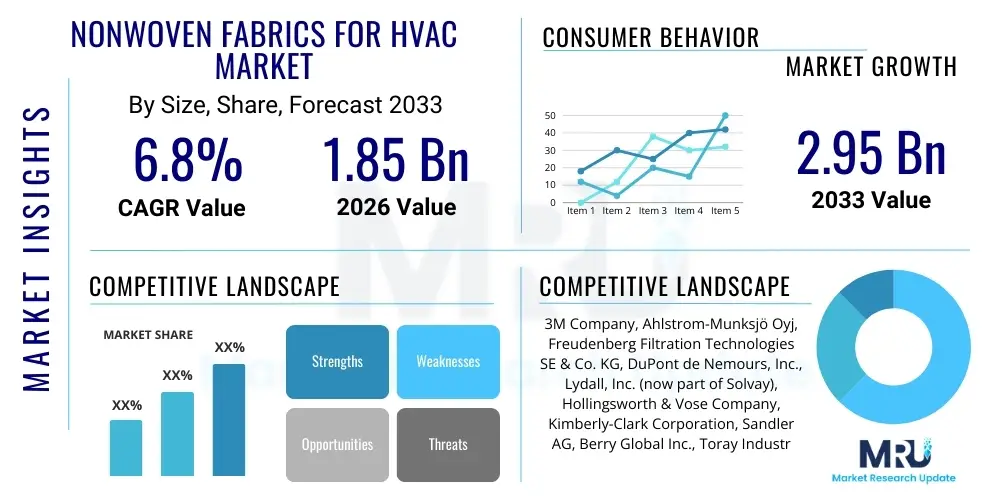

The Nonwoven Fabrics for HVAC Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 1.85 Billion in 2026 and is projected to reach USD 2.95 Billion by the end of the forecast period in 2033.

Nonwoven Fabrics for HVAC Market introduction

The nonwoven fabrics for HVAC market encompasses a critical segment within air filtration technology, providing essential media for heating, ventilation, and air conditioning systems across diverse applications. Nonwoven fabrics are engineered textile materials, typically produced by entangling fibers mechanically, thermally, or chemically, rather than weaving or knitting. In HVAC systems, these fabrics serve as the primary filtration medium, efficiently capturing particulate matter, allergens, dust, and other airborne contaminants to improve indoor air quality and protect HVAC equipment. The market's significance is growing due to increasing global awareness of public health, stringent air quality regulations, and the need for energy-efficient filtration solutions.

Products within this market range from basic dust filters to high-efficiency particulate air (HEPA) filters and ultra-low penetration air (ULPA) filters, utilizing various nonwoven technologies such as melt-blown, spunbond, needle-punched, and electrospun nanofibers. These fabrics are predominantly made from synthetic polymers like polypropylene, polyester, and fiberglass, chosen for their superior filtration capabilities, durability, and cost-effectiveness. Major applications span residential, commercial, industrial, and institutional sectors, including offices, hospitals, cleanrooms, data centers, and manufacturing plants. The inherent benefits of nonwoven fabrics, such as their high dust holding capacity, low pressure drop, lightweight nature, and customizable pore sizes, make them indispensable for modern HVAC systems.

Key driving factors for the market include the escalating levels of indoor and outdoor air pollution, which necessitate advanced filtration solutions to safeguard human health. Furthermore, the rising incidence of respiratory diseases and allergies, coupled with increasing disposable incomes and urbanization, fuels demand for improved air quality in living and working environments. Government regulations mandating minimum efficiency reporting values (MERV) and promoting energy-efficient building standards also significantly contribute to market expansion. The continuous development of smart building technologies and the integration of IoT for predictive maintenance and optimized filter performance further accelerate market growth by enhancing the value proposition of nonwoven filtration media.

Nonwoven Fabrics for HVAC Market Executive Summary

The Nonwoven Fabrics for HVAC market is poised for robust expansion, driven by evolving business trends centered on sustainability, advanced material science, and digitalization. A significant trend involves the development of eco-friendly nonwoven materials and filter designs that offer enhanced biodegradability or recyclability, aligning with global environmental objectives and consumer preferences for greener products. Moreover, the industry is witnessing increased innovation in nanofiber technology and composite filter media, leading to filters with higher efficiency, lower pressure drop, and extended service life. Strategic partnerships and mergers among nonwoven manufacturers and filter system providers are also shaping the competitive landscape, aiming to create integrated solutions and optimize supply chains. The adoption of smart filtration systems, incorporating sensors and IoT for real-time monitoring and predictive maintenance, represents a transformative business trend, moving towards performance-based filtration solutions.

Regionally, the Asia Pacific (APAC) market is expected to exhibit the highest growth rate, primarily due to rapid industrialization, urbanization, and increasing construction activities, particularly in emerging economies like China and India. The escalating concerns regarding air pollution and the implementation of stringent environmental regulations in these countries are significant drivers. North America and Europe, while more mature markets, are characterized by high demand for premium, high-efficiency filters driven by strict indoor air quality standards and a strong focus on energy efficiency in commercial and residential buildings. Latin America and the Middle East & Africa regions are also showing nascent growth, stimulated by infrastructure development projects and growing awareness of public health, albeit at a slower pace compared to developed regions.

Segmentation trends within the market highlight the dominance of HVAC filters as the primary application, accounting for the largest share due to their ubiquitous use across all end-user segments. Within filter types, pleated filters and panel filters remain widely adopted, but there is a growing shift towards bag filters and HEPA filters for higher efficiency applications in healthcare and industrial cleanrooms. Material-wise, polypropylene and polyester continue to be the workhorses, though research into advanced materials like bio-based polymers and specialized fibers for specific contaminant removal is gaining traction. The commercial and industrial end-user segments are expected to maintain their leading positions, driven by the sheer volume of air filtration required in large buildings and manufacturing processes, while the residential segment is growing rapidly due to increasing consumer demand for healthy indoor environments.

AI Impact Analysis on Nonwoven Fabrics for HVAC Market

The integration of Artificial Intelligence (AI) is set to revolutionize various facets of the Nonwoven Fabrics for HVAC Market, addressing common user questions related to efficiency, predictive capabilities, and material innovation. Users frequently inquire about how AI can enhance the performance and longevity of HVAC filters, optimize maintenance schedules, and improve the overall air quality management experience. There is keen interest in AI's role in making filters smarter, more responsive to environmental changes, and capable of providing real-time insights into air quality and filter status. Expectations center around AI's ability to move beyond static filtration to dynamic, adaptive systems that maximize both air purity and energy savings, while also streamlining manufacturing processes for nonwoven media.

The key themes emerging from user inquiries revolve around AI-driven solutions for predictive maintenance, intelligent filter replacement, energy optimization, and advanced material development. Users anticipate AI algorithms processing data from smart sensors embedded in HVAC systems to accurately predict filter saturation, thereby enabling timely replacement and preventing energy wastage due to clogged filters. This proactive approach not only extends the operational life of HVAC units but also ensures consistent indoor air quality. Furthermore, there is a strong expectation that AI will facilitate the design and development of next-generation nonwoven materials with tailored filtration properties, optimizing fiber structures and compositions for specific pollutant types and environmental conditions.

Concerns often include the initial investment required for AI integration, data privacy, cybersecurity, and the need for skilled personnel to manage and interpret AI-generated insights. However, the overarching expectation is that the long-term benefits in terms of operational efficiency, reduced maintenance costs, superior air quality, and enhanced sustainability will outweigh these challenges. AI is viewed as a critical enabler for transforming the HVAC filtration market from a reactive, scheduled maintenance model to a proactive, performance-optimized ecosystem, leading to more personalized and adaptive indoor environments.

- AI-powered sensors and IoT devices enable real-time monitoring of filter performance, pressure drop, and air quality, providing data for predictive maintenance.

- Predictive analytics driven by AI algorithms forecasts optimal filter replacement times, minimizing energy consumption from clogged filters and reducing unnecessary changes.

- AI assists in optimizing the manufacturing processes of nonwoven fabrics, leading to more consistent quality, reduced waste, and enhanced material properties for filtration media.

- Machine learning models analyze vast datasets to identify optimal fiber compositions and structural designs for nonwoven filters, tailoring them for specific pollutant removal efficiencies.

- Smart HVAC systems integrated with AI can dynamically adjust fan speeds and airflow based on real-time air quality data, extending filter life and improving energy efficiency.

- AI supports the development of adaptive filtration, where filter media can change properties (e.g., pore size) in response to varying pollutant levels or environmental conditions.

- Enhanced quality control during nonwoven fabric production through AI-driven image recognition and anomaly detection, ensuring high-performance filtration media.

- AI can optimize supply chain logistics for nonwoven fabric raw materials and finished filters, improving efficiency and reducing lead times.

DRO & Impact Forces Of Nonwoven Fabrics for HVAC Market

The Nonwoven Fabrics for HVAC Market is significantly shaped by a dynamic interplay of drivers, restraints, opportunities, and various impact forces. Key drivers include the escalating global concern over indoor and outdoor air pollution, which is fueling demand for advanced filtration solutions to protect public health. The increasing prevalence of respiratory diseases and allergies also compels consumers and organizations to invest in high-efficiency air filtration. Furthermore, stringent government regulations and building codes mandating specific indoor air quality standards and energy efficiency targets worldwide are pivotal in driving the adoption of nonwoven HVAC filters. Urbanization, industrial expansion, and the growing construction sector, particularly in emerging economies, contribute to a larger installed base of HVAC systems requiring filtration. The continuous push for energy savings in commercial and residential buildings, recognizing that efficient filters reduce fan energy consumption, further strengthens market growth. These drivers collectively underscore the essential role of nonwoven fabrics in creating healthier and more sustainable indoor environments.

Conversely, the market faces several notable restraints. Fluctuations in the prices of raw materials, primarily petrochemical-derived polymers like polypropylene and polyester, can impact manufacturing costs and profit margins, leading to price volatility for finished filter media. The relatively high initial cost of advanced, high-efficiency nonwoven filters, such as HEPA or ULPA types, can be a barrier to adoption in price-sensitive markets or for smaller enterprises. Moreover, a lack of awareness or education regarding the long-term benefits of superior air filtration and the specific advantages of nonwoven media among certain end-users, particularly in developing regions, can hinder market penetration. The issue of counterfeiting and the proliferation of low-quality, inefficient filters also pose a challenge, eroding consumer trust and potentially undermining the market for genuine, high-performance products. These restraints necessitate strategic responses from market players, including innovation in cost-effective materials and robust marketing efforts.

Despite these challenges, substantial opportunities exist for market players to capitalize on. The development of sustainable and eco-friendly nonwoven materials, including bio-based polymers and recyclable filter designs, presents a significant growth avenue, aligning with global environmental objectives and consumer demand for green products. The ongoing trend towards smart filtration systems, incorporating IoT sensors and AI for predictive maintenance and real-time air quality monitoring, opens up new product categories and service offerings. Emerging markets, especially in Asia Pacific and parts of Latin America and Africa, represent untapped potential due to their rapid infrastructure development and increasing environmental consciousness. Furthermore, opportunities arise from the retrofitting of existing HVAC systems with more efficient nonwoven filters to meet updated regulations and energy efficiency goals. Specialized applications in healthcare (e.g., infectious disease control), pharmaceuticals, and cleanroom environments continue to demand advanced, customized nonwoven filtration solutions, offering premium market segments for specialized manufacturers. These opportunities suggest a vibrant future for innovation and expansion within the nonwoven fabrics for HVAC sector.

Segmentation Analysis

The Nonwoven Fabrics for HVAC Market is meticulously segmented to provide a granular understanding of its diverse components and drivers. This segmentation allows for targeted market strategies, product development, and investment decisions by identifying distinct customer groups, application areas, and material preferences. The market can be broadly categorized based on material type, technology used in fabric production, the specific application of the nonwoven media, and the end-user industry. Each segment exhibits unique growth dynamics, influenced by technological advancements, regulatory frameworks, and evolving consumer and industrial demands for air quality and energy efficiency. Analyzing these segments provides critical insights into the market's structure and future growth trajectories.

- By Material Type:

- Polypropylene (PP)

- Polyester (PET)

- Fiberglass

- Polyethylene (PE)

- Polyphenylene Sulfide (PPS)

- Activated Carbon

- Blended Fibers

- Natural Fibers (e.g., Cellulose, Cotton)

- By Technology:

- Melt-Blown

- Spunbond

- Needle-Punched

- Wetlaid

- Airlaid

- Electrospinning (Nanofiber)

- Thermal Bonded

- Chemical Bonded

- By Application:

- HVAC Filters

- Panel Filters

- Pleated Filters

- Bag Filters

- Cartridge Filters

- HEPA/ULPA Filters

- Air Purifiers

- Cleanroom Filters

- Automotive Cabin Air Filters

- Industrial Dust Collection

- Gas Turbine Inlet Air Filtration

- HVAC Filters

- By End-User Industry:

- Residential

- Commercial

- Offices

- Retail

- Hospitality

- Educational Institutions

- Public Buildings

- Industrial

- Manufacturing

- Food & Beverage

- Pharmaceuticals

- Chemical Processing

- Power Generation

- Healthcare

- Hospitals

- Clinics

- Laboratories

- Automotive

- Aerospace

- By Efficiency Rating:

- MERV 1-8 (Low Efficiency)

- MERV 9-12 (Medium Efficiency)

- MERV 13-16 (High Efficiency)

- MERV 17-20 (HEPA/ULPA equivalent)

Value Chain Analysis For Nonwoven Fabrics for HVAC Market

The value chain for the Nonwoven Fabrics for HVAC Market is a complex network spanning raw material sourcing to end-use application, involving multiple stages of transformation and distribution. It begins with upstream activities, primarily the production of various polymer resins such as polypropylene, polyester, and polyethylene by petrochemical companies, or the sourcing of specialty fibers like fiberglass, activated carbon, and natural fibers. This stage also includes the manufacturing of specialized machinery required for nonwoven fabric production, such as melt-blown and spunbond lines. Suppliers in this segment dictate the quality, cost, and availability of fundamental inputs, which directly influence the subsequent stages of the value chain. Innovation in sustainable raw materials, such as bio-based polymers or recycled content, is a significant trend at this upstream level.

The midstream segment involves the core manufacturing of nonwoven fabrics. Nonwoven manufacturers process raw fibers into filtration media using various technologies like melt-blown, spunbond, needle-punching, or electrospinning. These specialized manufacturers produce fabrics with specific characteristics, such as fiber diameter, density, pore size distribution, and surface treatments, tailored for air filtration applications. These nonwoven media are then often supplied to filter assemblers or HVAC system manufacturers, who integrate these fabrics into finished filter cartridges, panels, or bags. This stage is crucial for ensuring the technical performance and efficiency of the filter product, requiring stringent quality control and adherence to filtration standards. The focus here is on achieving optimal filtration efficiency while maintaining low pressure drop and high dust holding capacity.

Downstream activities encompass the distribution and end-user application of the finished nonwoven HVAC filters. Products are distributed through various channels, including direct sales to large original equipment manufacturers (OEMs) of HVAC systems, wholesalers, specialized distributors catering to commercial and industrial facilities, and retailers for the residential market. Online platforms are also gaining prominence, providing direct access to a broader customer base. Installers and maintenance service providers play a critical role in the final implementation and ongoing upkeep of these filtration systems. The direct distribution channel often involves large, strategic partnerships with major HVAC system providers, ensuring a steady demand, while indirect channels leverage extensive networks to reach diverse end-users. After-sales support, technical assistance, and recycling services further extend the value chain, ensuring customer satisfaction and promoting circular economy principles within the industry.

Nonwoven Fabrics for HVAC Market Potential Customers

The Nonwoven Fabrics for HVAC Market serves a diverse range of potential customers, broadly categorized by their need for improved air quality, equipment protection, and energy efficiency across various sectors. At the forefront are original equipment manufacturers (OEMs) of heating, ventilation, and air conditioning systems, who integrate nonwoven filter media directly into their products. These OEMs span residential, commercial, and industrial HVAC unit producers, seeking reliable, high-performance, and cost-effective filtration solutions that meet stringent industry standards and regulatory requirements. Their purchasing decisions are often driven by factors such as material innovation, supply chain stability, and the ability to offer differentiated products to their end-consumers, making them a cornerstone of the market's demand. The long-term relationships and technical collaboration with these OEMs are vital for nonwoven fabric suppliers.

Another significant customer segment comprises building owners and facility managers across commercial, industrial, and institutional sectors. These include administrators of office buildings, retail complexes, hotels, educational institutions, manufacturing plants, data centers, and public infrastructure. Their primary concerns are maintaining healthy indoor air quality for occupants, protecting expensive HVAC machinery from particulate damage, and optimizing energy consumption. For these customers, the choice of nonwoven HVAC filters is critical for compliance with health and safety regulations, enhancing employee productivity and comfort, and reducing operational costs associated with HVAC system maintenance and energy bills. They often rely on specialized distributors and service providers for filter procurement, installation, and scheduled replacement, emphasizing product reliability and efficiency.

Specialized sectors, such as healthcare facilities and cleanroom operators, represent a high-value customer segment with unique and rigorous demands for air purity. Hospitals, clinics, pharmaceutical manufacturing plants, biotechnology labs, and semiconductor fabrication facilities require HEPA and ULPA grade nonwoven filters to control airborne pathogens, allergens, and microscopic contaminants, ensuring sterile or controlled environments. These customers prioritize filtration efficiency, validation, and compliance with industry-specific standards (e.g., ISO, FDA). Additionally, the automotive industry represents a growing customer base for nonwoven fabrics used in cabin air filters, where improving in-car air quality is a key differentiating factor for vehicle manufacturers. The residential sector, driven by increasing awareness of indoor air quality and personal health, also constitutes a significant and expanding customer segment, purchasing filters for home HVAC systems and standalone air purifiers through retail channels and home improvement services.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.85 Billion |

| Market Forecast in 2033 | USD 2.95 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | 3M Company, Ahlstrom-Munksjö Oyj, Freudenberg Filtration Technologies SE & Co. KG, DuPont de Nemours, Inc., Lydall, Inc. (now part of Solvay), Hollingsworth & Vose Company, Kimberly-Clark Corporation, Sandler AG, Berry Global Inc., Toray Industries, Inc., Johns Manville (Berkshire Hathaway Company), Andrew Industries Ltd., Fiberweb (part of Polymer Group, Inc.), Srilan, Glatfelter Corporation, P. H. Glatfelter Company, Toyobo Co., Ltd., Georgia-Pacific LLC, Mitsubishi Chemical Corporation, Ultrapore (A division of Hollingsworth & Vose) |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Nonwoven Fabrics for HVAC Market Key Technology Landscape

The technological landscape of the Nonwoven Fabrics for HVAC Market is characterized by continuous innovation aimed at enhancing filtration efficiency, reducing pressure drop, extending filter life, and improving sustainability. One of the most critical technologies is melt-blown fabrication, which produces extremely fine fibers, often in the sub-micron range, creating highly effective filtration media with excellent particle capture capabilities. Spunbond technology, on the other hand, yields stronger, more durable fabrics typically used as support layers or pre-filters. The combination of these technologies, often in multi-layered composite structures, allows for tailored filtration performance, balancing efficiency with airflow resistance. Further advancements include the development of electret treatments, which impart an electrostatic charge to nonwoven fibers, significantly boosting their ability to attract and retain airborne particles without increasing air resistance, thereby improving MERV ratings.

Nanofiber technology, particularly through electrospinning, represents a cutting-edge area within the market. Electrospun nanofibers, with diameters often below 100 nanometers, create extremely high surface area and very small pore sizes, leading to superior HEPA/ULPA level filtration efficiency while maintaining a relatively low pressure drop compared to traditional media. This technology is crucial for applications requiring ultra-clean air, such as in cleanrooms, healthcare facilities, and specialized industrial processes. Beyond physical filtration, the integration of activated carbon into nonwoven structures is a well-established technology for chemical filtration, enabling the adsorption of volatile organic compounds (VOCs), odors, and harmful gases. Antimicrobial and antiviral treatments are also increasingly being applied to nonwoven filters, enhancing their functionality by inhibiting the growth of microorganisms within the filter media and providing an additional layer of protection against airborne pathogens.

Looking ahead, smart filter technology is gaining traction, integrating sensors and Internet of Things (IoT) capabilities directly into nonwoven filtration media or HVAC systems. These smart filters can monitor real-time air quality, filter saturation levels, and pressure drop, transmitting data for predictive maintenance and optimized filter replacement schedules. This shifts maintenance from a time-based model to a condition-based model, reducing operational costs and ensuring consistent performance. Advances in sustainable manufacturing processes, such as the use of recycled content, bio-based polymers, and energy-efficient production methods, are also crucial technological trends. The development of self-cleaning or regenerative filter media, although still in nascent stages, represents a long-term goal to further reduce waste and extend the lifespan of filtration products. These technological developments collectively drive the evolution of the nonwoven fabrics for HVAC market towards more intelligent, efficient, and environmentally responsible solutions.

Regional Highlights

- North America: A mature market characterized by stringent indoor air quality regulations, high adoption rates of advanced HVAC systems, and a strong emphasis on energy efficiency. The United States and Canada are leading contributors, driven by commercial and industrial infrastructure and a robust residential renovation market. Demand for high-efficiency MERV 13+ filters is particularly strong.

- Europe: Similar to North America, Europe exhibits high demand for premium filtration solutions, particularly in countries like Germany, the UK, France, and Italy. Strict environmental protection laws, a focus on health and well-being, and a significant installed base of HVAC systems in commercial and healthcare sectors fuel market growth. The region is also at the forefront of sustainable nonwoven material development.

- Asia Pacific (APAC): Projected to be the fastest-growing market due to rapid urbanization, industrialization, and infrastructure development, especially in China, India, Japan, and South Korea. Escalating air pollution levels and increasing awareness of associated health risks are significant drivers. Government initiatives to improve air quality and increasing disposable incomes contribute to the expanding adoption of HVAC systems and advanced filters.

- Latin America: An emerging market with growing construction activities and increasing environmental awareness in countries like Brazil and Mexico. The market is developing, with rising demand for commercial and industrial HVAC filtration solutions, although residential adoption is still gaining momentum. Economic stability and foreign investments play a crucial role in market expansion.

- Middle East and Africa (MEA): This region is experiencing growth driven by significant infrastructure projects, particularly in the GCC countries (UAE, Saudi Arabia) and parts of Africa. Extreme climatic conditions necessitate robust HVAC systems, leading to increased demand for high-performance nonwoven filters. Awareness of air quality and health concerns is gradually increasing, contributing to market development.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Nonwoven Fabrics for HVAC Market.- 3M Company

- Ahlstrom-Munksjö Oyj

- Freudenberg Filtration Technologies SE & Co. KG

- DuPont de Nemours, Inc.

- Lydall, Inc. (now part of Solvay)

- Hollingsworth & Vose Company

- Kimberly-Clark Corporation

- Sandler AG

- Berry Global Inc.

- Toray Industries, Inc.

- Johns Manville (Berkshire Hathaway Company)

- Andrew Industries Ltd.

- Fiberweb (part of Polymer Group, Inc.)

- Srilan

- Glatfelter Corporation

- P. H. Glatfelter Company

- Toyobo Co., Ltd.

- Georgia-Pacific LLC

- Mitsubishi Chemical Corporation

- Ultrapore (A division of Hollingsworth & Vose)

Frequently Asked Questions

What are nonwoven fabrics and why are they used in HVAC systems?

Nonwoven fabrics are engineered materials made from fibers bonded together without weaving or knitting. They are critical in HVAC systems because their unique structure allows for efficient capture of airborne particles while maintaining good airflow. This improves indoor air quality, protects HVAC equipment, and contributes to energy efficiency.

What are the primary benefits of using nonwoven fabrics for HVAC filtration?

The primary benefits include high filtration efficiency across various particle sizes, low pressure drop for reduced energy consumption, high dust holding capacity, lightweight and durable construction, and cost-effectiveness. They contribute significantly to healthier indoor environments and extend the lifespan of HVAC units.

What types of nonwoven technologies are prevalent in HVAC filters?

Key technologies include melt-blown for fine fiber production and high efficiency, spunbond for strength and support, needle-punched for depth filtration, and electrospinning for advanced nanofiber media. These technologies are often combined to create multi-layered composite filters optimized for specific applications and efficiency ratings.

How is the Nonwoven Fabrics for HVAC Market expected to grow?

The market is projected for substantial growth, driven by increasing global air pollution, rising health awareness, and stringent regulations for indoor air quality and energy efficiency. Innovations in sustainable materials and smart filtration technologies are also significant growth accelerators, particularly in the Asia Pacific region.

What impact is AI expected to have on the Nonwoven Fabrics for HVAC Market?

AI is set to revolutionize the market by enabling smart filtration systems with real-time monitoring and predictive maintenance, optimizing filter replacement schedules, and enhancing energy efficiency. AI also facilitates the development of advanced nonwoven materials with tailored properties and improves manufacturing quality control, leading to more intelligent and adaptive filtration solutions.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager