3D Printed Drones Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429959 | Date : Nov, 2025 | Pages : 255 | Region : Global | Publisher : MRU

3D Printed Drones Market Size

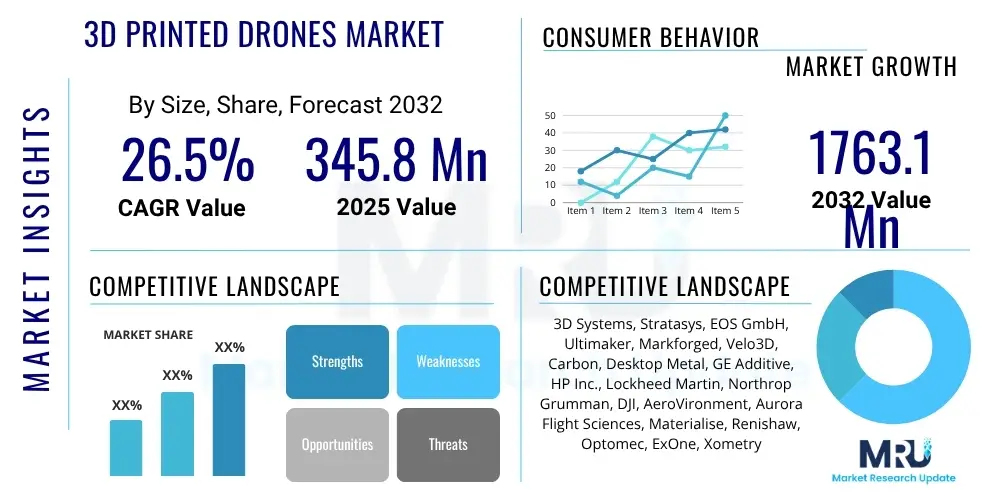

The 3D Printed Drones Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 26.5% between 2025 and 2032. The market is estimated at USD 345.8 million in 2025 and is projected to reach USD 1763.1 million by the end of the forecast period in 2032.

3D Printed Drones Market introduction

The 3D Printed Drones Market represents a rapidly evolving segment within the broader unmanned aerial vehicle (UAV) industry, leveraging additive manufacturing technologies to produce highly customized, lightweight, and efficient drone components and full airframes. This innovative approach significantly reduces traditional manufacturing lead times and costs, while enabling unparalleled design flexibility. Products range from specialized components like propellers and structural frames to complete operational drones, designed for specific mission profiles and environmental conditions. The ability to rapidly iterate designs, integrate complex geometries, and optimize material usage makes 3D printing an ideal solution for the dynamic requirements of drone development.

Major applications for 3D printed drones span across various sectors, including defense and military operations for surveillance and reconnaissance, agricultural monitoring, infrastructure inspection (pipelines, bridges, power lines), package delivery, and specialized scientific research. These drones offer significant benefits such as enhanced payload capacity due to lighter structures, improved aerodynamic performance through intricate designs, and rapid prototyping capabilities that accelerate development cycles. The intrinsic ability to produce complex internal structures also allows for better cable management, sensor integration, and overall system optimization, which are critical for advanced drone functionalities.

Several driving factors are propelling the growth of this market. Foremost among these is the continuous advancement in 3D printing technologies, including improvements in print speed, material properties, and machine reliability, making the production of high-performance drone parts more feasible and economical. The increasing demand for customizable drones tailored to specific tasks, often requiring unique shapes or specialized sensor mounts, further fuels market expansion. Additionally, the drive for localized manufacturing and supply chain resilience, coupled with a growing emphasis on reducing waste and improving resource efficiency in production, positions 3D printing as a strategic advantage for drone manufacturers and operators globally.

3D Printed Drones Market Executive Summary

The 3D Printed Drones Market is experiencing robust expansion, driven by significant business trends focused on innovation, strategic partnerships, and increased investment in research and development. Manufacturers are increasingly adopting additive manufacturing to streamline their production processes, moving towards on-demand production and reducing reliance on traditional tooling. This shift allows for greater agility in product development, enabling companies to quickly respond to market demands for specialized drone applications. Furthermore, the market is characterized by a growing ecosystem of material suppliers, software developers, and printing service providers collaborating to enhance the performance and accessibility of 3D printed drone solutions, fostering a competitive and technologically advanced landscape.

Regional trends indicate strong growth across North America, Europe, and the Asia Pacific, each contributing uniquely to the market's trajectory. North America, with its robust defense spending and advanced aerospace industry, leads in military and commercial drone innovations, particularly in the integration of high-performance materials and complex systems. Europe is a hub for R&D in additive manufacturing and sustainable production methods, driving advancements in eco-friendly drone designs and diverse commercial applications. The Asia Pacific region is rapidly emerging due to its strong manufacturing base, increasing adoption of industrial automation, and growing demand for drones in agriculture, logistics, and surveillance, leveraging cost-effective production capabilities to scale market penetration.

Segmentation trends highlight particular areas of accelerated growth. The defense and military sector continues to be a primary driver, valuing the customization capabilities for specialized missions and rapid replacement of parts in the field. Simultaneously, the logistics and delivery segment is witnessing substantial interest, as 3D printing allows for the rapid creation of prototypes and components optimized for payload and aerodynamic efficiency, crucial for last-mile delivery solutions. The agricultural sector is also adopting 3D printed drones for precise spraying and monitoring, benefiting from the ability to quickly integrate custom sensor arrays. Material advancements, particularly in high-strength composites and lightweight metals, are enabling the creation of more durable and capable drones, further diversifying their potential applications across commercial and industrial end-users.

AI Impact Analysis on 3D Printed Drones Market

User inquiries concerning AI's influence on the 3D Printed Drones Market frequently revolve around how artificial intelligence enhances drone autonomy, operational efficiency, and data processing capabilities. Key themes include questions regarding AI's role in advanced navigation, real-time decision-making, predictive maintenance of 3D printed components, and the ethical implications of autonomous drone deployment. There is a clear expectation that AI will unlock new levels of sophistication in drone functionality, enabling them to perform complex tasks with minimal human intervention, while also raising concerns about data security, system reliability, and regulatory frameworks for intelligent systems. Users are keenly interested in the synergy between advanced manufacturing and intelligent control systems to create truly next-generation aerial platforms.

- AI-driven design optimization: Utilizing generative design algorithms to create lightweight, structurally efficient 3D printable drone parts.

- Enhanced flight autonomy: AI enables drones to navigate complex environments, avoid obstacles, and execute missions without human control.

- Real-time data analysis: AI processes sensor data onboard, allowing for immediate insights and adaptive mission planning in applications like inspection or agriculture.

- Predictive maintenance: AI algorithms analyze flight data and component stress to predict potential failures in 3D printed parts, scheduling proactive repairs.

- Improved sensor fusion and perception: AI integrates data from multiple sensors (visual, thermal, LiDAR) for superior environmental understanding and target identification.

- Advanced payload management: AI optimizes the distribution and deployment of payloads, enhancing drone stability and mission effectiveness.

- Swarm intelligence: AI facilitates coordinated operation of multiple drones for complex tasks such as large-area mapping or synchronized delivery.

- Cybersecurity enhancements: AI-powered intrusion detection systems protect drone communication and control systems from cyber threats.

DRO & Impact Forces Of 3D Printed Drones Market

The 3D Printed Drones Market is significantly influenced by a dynamic interplay of drivers, restraints, and opportunities, underpinned by various impact forces that shape its growth trajectory. Key drivers include the inherent design flexibility and rapid prototyping capabilities of additive manufacturing, which allow for bespoke drone solutions tailored to niche applications across defense, logistics, and infrastructure inspection. The ability to produce lightweight components with optimized strength-to-weight ratios enhances drone performance and flight endurance. However, the market faces restraints such as the relatively high cost of advanced 3D printing materials, limitations in material availability for specific aerospace-grade requirements, and stringent regulatory hurdles governing drone operations, which can slow adoption. Furthermore, the initial investment in 3D printing equipment and the need for specialized design expertise also pose challenges to broader market entry for smaller entities.

Opportunities for growth are abundant, particularly in the development of new high-performance and multi-functional materials that can withstand harsh operating conditions and offer superior structural integrity for drone applications. The expansion into emerging markets, coupled with the increasing integration of Internet of Things (IoT) technologies and artificial intelligence (AI) for enhanced drone autonomy and data processing, presents significant avenues for market diversification. Niche applications, such as emergency response, remote habitat monitoring, and specialized scientific data collection in hazardous environments, are also burgeoning areas where the customization offered by 3D printing provides a distinct advantage. Strategic collaborations between 3D printing technology providers, drone manufacturers, and end-users are expected to accelerate innovation and market penetration.

Impact forces on the market are diverse, with technological advancements in additive manufacturing processes continually pushing the boundaries of what is possible, including faster print speeds, larger build volumes, and finer resolution. Regulatory changes, particularly concerning drone airspace integration and autonomous operation, will profoundly influence market growth and structure. Economic conditions, including global supply chain stability and investment in advanced manufacturing, dictate the pace of adoption. Environmental considerations are also playing an increasingly important role, as 3D printing enables localized production, potentially reducing transportation emissions, and facilitates the use of recycled or more sustainable materials, aligning with broader sustainability goals in the aerospace and defense sectors.

Segmentation Analysis

The 3D Printed Drones Market is comprehensively segmented by various parameters including component, material, application, end-user, and type, each offering distinct insights into market dynamics and growth opportunities. This detailed segmentation allows for a granular understanding of where demand is strongest, what technological advancements are most impactful, and which end-user industries are driving adoption. The diversity across these segments highlights the versatility of 3D printing in addressing specific needs within the rapidly expanding drone industry, from custom airframe designs to specialized propulsion systems and advanced sensor housings, all tailored to optimize performance and operational efficiency for a broad spectrum of missions.

- By Component

- Frame

- Propellers

- Motors

- Batteries

- Flight Controllers

- Cameras and Sensors

- Landing Gear

- Electronic Speed Controllers (ESCs)

- Payload Mounts

- By Material

- Plastics (PLA, ABS, Nylon, Polycarbonate, PEEK, PEI)

- Composites (Carbon Fiber Reinforced Polymers, Glass Fiber Reinforced Polymers)

- Metals (Aluminum, Titanium, Stainless Steel, Nickel Alloys)

- Ceramics

- By Application

- Surveillance and Reconnaissance

- Inspection and Monitoring (Infrastructure, Energy, Oil & Gas)

- Logistics and Delivery

- Agriculture and Forestry

- Defense and Military

- Mapping and Surveying

- Media and Entertainment

- Search and Rescue

- Research and Development

- By End-User

- Commercial (Logistics, Agriculture, Construction, Media, Inspection Services)

- Military and Defense

- Government and Public Safety (Law Enforcement, Emergency Services)

- Consumer and Hobbyist

- Academic and Research Institutions

- By Type

- Fixed-Wing Drones

- Rotary-Wing Drones (Multirotor, Single Rotor)

- Hybrid Drones (VTOL)

- Flapping-Wing Drones

Value Chain Analysis For 3D Printed Drones Market

The value chain for the 3D Printed Drones Market encompasses a sophisticated network of activities, beginning with upstream raw material suppliers and extending through to downstream end-users and service providers. Upstream activities involve the procurement and processing of specialized materials crucial for additive manufacturing, such as high-performance polymer filaments, resin formulations, and metal powders. These suppliers play a critical role in dictating the mechanical properties, weight, and overall durability of 3D printed drone components. Additionally, this stage includes manufacturers of 3D printing hardware (e.g., FDM, SLA, SLS, SLM machines) and developers of sophisticated design software, including CAD/CAM tools and simulation platforms that enable complex part geometries and structural optimization. Innovation at this upstream level directly impacts the capabilities and cost-effectiveness of 3D printed drones.

Midstream activities primarily focus on the design, manufacturing, and assembly of the drones. This involves drone designers and engineers utilizing 3D printing technologies to produce customized airframes, structural components, and intricate internal structures. Following component fabrication, the process moves to the integration of various off-the-shelf and custom-printed parts, including motors, batteries, flight controllers, sensors, and communication modules. Drone assemblers and integrators play a crucial role in bringing these diverse components together, ensuring seamless functionality and adherence to performance specifications. Quality control and testing are paramount at this stage to ensure the reliability and safety of the final product before it reaches the market.

Downstream activities involve the distribution, sales, and post-sales support for 3D printed drones. Distribution channels can be direct, with large manufacturers selling directly to government agencies or large commercial enterprises, or indirect, through specialized drone retailers, value-added resellers (VARs), and online marketplaces catering to a broader range of businesses and consumers. Direct sales often involve customized solutions and direct technical support, while indirect channels provide wider market access and localized support. Post-sales services, including maintenance, repairs, upgrades, and operational training, are vital for ensuring customer satisfaction and the longevity of the drone systems. This comprehensive value chain ensures that the specialized benefits of 3D printing are effectively translated into functional and market-ready drone solutions for various applications.

3D Printed Drones Market Potential Customers

The potential customers for the 3D Printed Drones Market span a wide array of industries and governmental entities, driven by the unique advantages of customization, rapid prototyping, and lightweight construction that additive manufacturing offers. Defense and military organizations represent a significant end-user segment, utilizing these drones for advanced surveillance, reconnaissance missions, target acquisition, and even logistics in contested environments, where the ability to quickly produce or replace specialized parts in the field is invaluable. Their demand often centers on high-performance, durable, and mission-specific designs that can adapt to evolving operational requirements, making 3D printing an ideal manufacturing method for tactical flexibility.

Beyond defense, the commercial sector offers extensive opportunities. Logistics and package delivery companies are increasingly exploring 3D printed drones to optimize payload capacity, reduce operational costs, and accelerate the development of specialized delivery vehicles for urban and rural environments. Agriculture firms are leveraging these drones for precision farming, crop monitoring, and localized spraying, benefiting from customizable designs that can carry specific sensor packages or spray nozzles. Infrastructure inspection companies, particularly in energy, oil and gas, and construction, find value in drones that can be rapidly customized with specialized cameras and sensors for detailed structural analysis, enhancing safety and efficiency in monitoring large assets like pipelines, bridges, and power lines.

Government agencies and public safety organizations, including law enforcement and emergency services, are also key buyers. They utilize 3D printed drones for search and rescue operations, disaster assessment, border patrol, and crowd monitoring, where bespoke designs for specific environments or payloads are often required. Academic and research institutions represent another crucial customer base, driving innovation through the development and testing of new drone concepts, materials, and applications. The ability to rapidly iterate designs and perform cost-effective experimental prototyping with 3D printing makes it indispensable for their R&D efforts. Furthermore, hobbyists and prosumers interested in advanced custom builds also form a niche but growing segment, seeking unique aesthetic and functional designs that cannot be achieved with traditional manufacturing methods, underscoring the broad appeal and diverse utility of 3D printed drones across multiple sophisticated end-user applications.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 345.8 Million |

| Market Forecast in 2032 | USD 1763.1 Million |

| Growth Rate | 26.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | 3D Systems, Stratasys, EOS GmbH, Ultimaker, Markforged, Velo3D, Carbon, Desktop Metal, GE Additive, HP Inc., Lockheed Martin, Northrop Grumman, DJI, AeroVironment, Aurora Flight Sciences, Materialise, Renishaw, Optomec, ExOne, Xometry |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

3D Printed Drones Market Key Technology Landscape

The 3D Printed Drones Market is underpinned by a dynamic key technology landscape that integrates advanced additive manufacturing processes with sophisticated design and operational technologies. At its core are various 3D printing techniques, each offering distinct advantages for drone component fabrication. Fused Deposition Modeling (FDM) is widely used for prototyping and non-structural components due to its affordability and material versatility, utilizing thermoplastic filaments. Stereolithography (SLA) and Digital Light Processing (DLP) are employed for parts requiring high detail and smooth surfaces, often for aerodynamic components or intricate sensor housings. More advanced methods like Selective Laser Sintering (SLS) and Selective Laser Melting (SLM) are crucial for producing high-strength, lightweight parts from polymer powders and metal alloys respectively, enabling the creation of robust structural elements and critical functional components with superior mechanical properties.

Beyond the printing hardware, the technology landscape includes the rapid evolution of advanced materials specifically engineered for additive manufacturing and aerospace applications. This encompasses high-performance polymers such as PEEK and PEI, which offer excellent strength-to-weight ratios and thermal resistance, as well as carbon fiber and glass fiber reinforced composites that provide exceptional stiffness and durability. The increasing availability of aerospace-grade metal powders, like titanium and aluminum alloys, for SLM processes allows for the fabrication of critical load-bearing parts with intricate internal structures, significantly reducing overall drone weight while maintaining structural integrity. These material advancements are pivotal in overcoming the historical limitations of 3D printing regarding part strength and reliability, expanding the range of feasible drone applications.

Furthermore, the market's technological prowess extends to sophisticated design software and integrated intelligence systems. Generative design tools, often powered by artificial intelligence, enable engineers to automatically create optimized part geometries that are impossible to achieve with traditional manufacturing, leading to ultra-lightweight and high-performing structures. Simulation and topology optimization software play a vital role in validating these designs for structural integrity, aerodynamic efficiency, and thermal management before physical printing. The integration of AI and machine learning for enhanced flight control, autonomous navigation, real-time data processing from advanced sensors, and predictive maintenance capabilities is transforming drone operational efficiency and expanding their mission profiles. This holistic technological approach, from material science to intelligent systems, collectively drives the innovation and capabilities of 3D printed drones.

Regional Highlights

- North America: This region is a leading market for 3D printed drones, primarily driven by substantial defense spending, rapid technological innovation, and a robust aerospace industry. The presence of major drone manufacturers, advanced 3D printing technology providers, and a strong ecosystem for R&D fuels market growth. Applications in military, commercial inspection, and logistics are particularly strong.

- Europe: Europe represents a significant market, characterized by stringent regulatory environments that encourage advanced design and safety features, often enabled by 3D printing. Strong investment in additive manufacturing research, coupled with a focus on sustainable production and diverse commercial applications in agriculture, infrastructure, and environmental monitoring, contributes to its expansion. Germany, France, and the UK are key contributors.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing region, owing to its rapidly expanding manufacturing capabilities, increasing adoption of automation, and rising demand for drones in sectors like agriculture, surveillance, and industrial inspection. Countries like China, Japan, South Korea, and India are investing heavily in drone technology and leveraging 3D printing for cost-effective and rapid production.

- Latin America: This region is an emerging market, driven by increasing awareness and adoption of drone technology for agricultural applications, mining, and infrastructure development. While still in nascent stages, the demand for customizable and affordable drone solutions, facilitated by 3D printing, is expected to grow as economic conditions improve and technological access expands.

- Middle East and Africa (MEA): The MEA region is experiencing growth, particularly in defense and security applications, along with significant investments in smart city projects and oil & gas infrastructure, which create demand for advanced inspection and surveillance drones. The ability to rapidly customize and deploy drones for specific regional needs, often in harsh environments, positions 3D printing as a key enabler.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the 3D Printed Drones Market.- 3D Systems

- Stratasys

- EOS GmbH

- Ultimaker (UltiMaker)

- Markforged

- Velo3D

- Carbon

- Desktop Metal

- GE Additive

- HP Inc.

- Lockheed Martin

- Northrop Grumman

- DJI

- AeroVironment

- Aurora Flight Sciences

- Materialise

- Renishaw

- Optomec

- ExOne

- Xometry

Frequently Asked Questions

What are the primary benefits of using 3D printing in drone manufacturing?

The primary benefits of using 3D printing in drone manufacturing include unparalleled design flexibility, enabling the creation of complex geometries and internal structures impossible with traditional methods, leading to highly optimized aerodynamics and component integration. It allows for rapid prototyping and iteration, significantly reducing development cycles and time-to-market. Furthermore, 3D printing facilitates the production of lightweight parts with optimized strength-to-weight ratios, enhancing drone performance, flight duration, and payload capacity, while also enabling cost-effective customization for specific mission requirements and on-demand manufacturing for spare parts.

What types of materials are commonly used for 3D printing drones?

Commonly used materials for 3D printing drones include various plastics such as Nylon, ABS, PLA, Polycarbonate, PEEK, and PEI, selected for their balance of strength, flexibility, and heat resistance. Advanced composites like carbon fiber reinforced polymers and glass fiber reinforced polymers are increasingly popular for high-performance structural components due offering superior stiffness and durability while maintaining low weight. For critical load-bearing parts and intricate metal components, metals such as aluminum alloys, titanium, and stainless steel are employed through processes like Selective Laser Melting (SLM), providing exceptional strength and precision for demanding aerospace applications.

How does 3D printing enhance the design flexibility of drones?

3D printing fundamentally enhances drone design flexibility by removing the constraints of traditional manufacturing, allowing engineers to create highly complex, organic, and intricate geometries. This includes intricate internal lattice structures for weight reduction, optimized aerodynamic shapes, and integrated functional features like internal wiring channels or specialized sensor mounts within a single print. Designers can easily iterate on designs, test various configurations, and quickly adapt to changing mission requirements or performance goals without incurring significant retooling costs or delays, leading to highly customized and optimized drone solutions.

What are the key applications for 3D printed drones across various industries?

Key applications for 3D printed drones span numerous industries. In defense and military, they are used for advanced surveillance, reconnaissance, and rapid deployment of customized tactical assets. Commercial applications include infrastructure inspection for critical assets like pipelines and bridges, precision agriculture for crop monitoring and spraying, and efficient logistics for last-mile package delivery. Furthermore, they are employed in search and rescue operations, scientific research in hazardous environments, aerial mapping and surveying, and media and entertainment for specialized aerial cinematography, leveraging their customizable nature for diverse operational needs.

What challenges does the 3D Printed Drones Market currently face?

The 3D Printed Drones Market currently faces several challenges that impact its widespread adoption and growth. These include the relatively high cost of advanced, aerospace-grade 3D printing materials, which can be more expensive than conventional materials, and limitations in the availability of certain specialized materials. Regulatory hurdles for drone operations, particularly concerning autonomous flight, beyond visual line of sight (BVLOS), and airspace integration, impose significant constraints. Additionally, there is a need for a highly skilled workforce proficient in both additive manufacturing and drone technology, alongside the substantial initial investment required for advanced 3D printing equipment, which can deter smaller enterprises from entering the market.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager