3D Printed Prosthetics Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429897 | Date : Nov, 2025 | Pages : 257 | Region : Global | Publisher : MRU

3D Printed Prosthetics Market Size

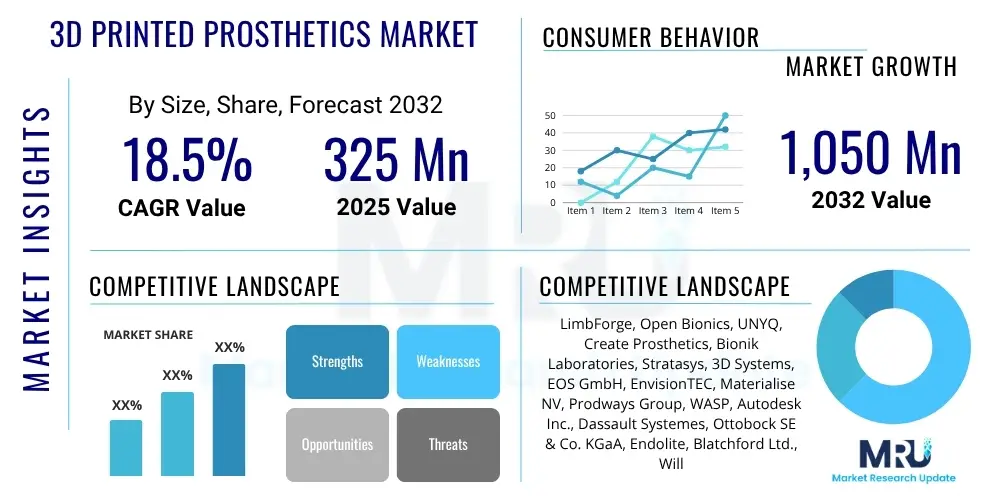

The 3D Printed Prosthetics Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 18.5% between 2025 and 2032. The market is estimated at $325 million in 2025 and is projected to reach $1,050 million by the end of the forecast period in 2032.

3D Printed Prosthetics Market introduction

The 3D Printed Prosthetics Market is witnessing significant expansion driven by advancements in additive manufacturing technology, offering unparalleled customization and accessibility in prosthetic solutions. These devices, ranging from advanced bionic limbs to simple cosmetic covers, are manufactured using various 3D printing techniques, allowing for a precise fit and often at a fraction of the cost of traditional prosthetics. The core product involves the digital design and layer-by-layer fabrication of prosthetic components using biocompatible materials.

Major applications of 3D printed prosthetics span upper limb, lower limb, and cosmetic restoration, catering to a diverse patient population suffering from congenital deformities, traumatic injuries, or disease-related amputations. The primary benefits include a highly personalized fit that enhances patient comfort and function, accelerated production timelines, and substantial cost reductions, making advanced prosthetic technology more accessible globally. These advantages are pivotal driving factors, alongside the rising global incidence of limb loss and continuous innovation in materials science and printing methodologies, propelling the market forward with robust growth prospects.

3D Printed Prosthetics Market Executive Summary

The 3D Printed Prosthetics Market is characterized by a strong trend toward patient-centric solutions, emphasizing custom fit, aesthetic appeal, and functional utility. Business trends indicate increasing collaboration between technology firms and healthcare providers to streamline design and manufacturing processes, alongside a growing focus on research and development to enhance material properties and integrate smart technologies. The market is also seeing a rise in direct-to-consumer models and open-source designs, which further democratize access to prosthetic limbs.

Regionally, North America and Europe are currently dominant due to advanced healthcare infrastructure, significant R&D investments, and higher awareness, while the Asia Pacific region is emerging as a high-growth market, driven by a large population base, increasing healthcare expenditure, and improving technological adoption. Segment trends highlight a robust demand for upper limb prosthetics, especially those incorporating advanced bionic functionalities, and a steady increase in the adoption of polymer-based prosthetics due to their lightweight properties and cost-effectiveness. The market is also experiencing shifts towards more localized manufacturing, reducing supply chain complexities and improving responsiveness to patient needs.

AI Impact Analysis on 3D Printed Prosthetics Market

Users frequently inquire about how Artificial Intelligence (AI) will revolutionize the design, manufacturing, and functionality of 3D printed prosthetics. Common themes include AI's role in optimizing prosthetic fit and comfort through predictive modeling, enhancing material selection based on patient activity and biomechanics, and enabling truly personalized adaptive prosthetics. Concerns often revolve around the cost implications of integrating AI, data privacy for patient-specific designs, and the need for specialized skills to leverage these advanced tools. Expectations are high for AI to deliver prosthetics that are more intuitive, responsive, and seamlessly integrated with the user's body and lifestyle, ultimately improving quality of life for amputees significantly.

- Enhanced prosthetic design and optimization through generative AI algorithms.

- Predictive analytics for precise fit and comfort, minimizing trial-and-error.

- Automated material selection based on usage patterns and patient needs.

- Integration of AI-powered sensors for real-time feedback and adaptive functionality.

- Streamlined manufacturing workflows, from scan to print, reducing lead times.

- Personalized rehabilitation plans supported by AI-driven gait analysis.

- Improved diagnostic capabilities for identifying optimal prosthetic solutions.

- Development of smart prosthetics with machine learning capabilities for user adaptation.

DRO & Impact Forces Of 3D Printed Prosthetics Market

The 3D Printed Prosthetics Market is significantly influenced by a confluence of drivers, restraints, and opportunities, all shaped by various impact forces. Key drivers include the escalating global incidence of limb loss due to factors like diabetes, vascular diseases, and trauma, alongside the inherent benefits of 3D printing such as customization, cost efficiency, and rapid prototyping. Technological advancements in additive manufacturing, materials science, and digital design software further fuel market expansion, enabling the creation of lighter, stronger, and more functional prosthetics tailored to individual patient needs, thereby driving demand and adoption across diverse demographics.

However, market growth faces restraints such as stringent regulatory approval processes for medical devices, particularly for novel 3D printed solutions, which can prolong time-to-market. The limited availability of highly specialized biomedical engineers and additive manufacturing experts capable of designing and fabricating complex prosthetics also poses a challenge. Furthermore, the perception regarding the durability and long-term performance of certain 3D printed materials compared to traditional counterparts can create hesitancy among some healthcare providers and patients, impacting wider acceptance and adoption rates in clinical settings, particularly for load-bearing applications.

Opportunities for market growth are abundant, notably in emerging economies where access to traditional, expensive prosthetics is limited, making cost-effective 3D printed options highly attractive. Continuous innovation in biocompatible materials, including advanced polymers and composites, promises to enhance functionality and expand application areas. The integration of artificial intelligence and machine learning for design optimization, predictive analytics, and personalized fitting represents a transformative opportunity. Moreover, increasing investments in research and development by both public and private entities, coupled with a growing awareness of the benefits of 3D printing among the medical community and patient groups, are poised to unlock new avenues for market penetration and product diversification, especially in pediatric prosthetics and bionic limbs.

Segmentation Analysis

The 3D Printed Prosthetics Market is comprehensively segmented to address the diverse needs of patients and applications, providing a granular view of market dynamics. This segmentation typically includes categories based on product type, end-user, and material, allowing for a detailed analysis of demand patterns and technological preferences across different applications. Understanding these segments is crucial for stakeholders to tailor their offerings, develop targeted marketing strategies, and identify niche growth opportunities within the broader market landscape.

The product type segmentation differentiates between various components that comprise a prosthetic limb, ranging from sockets to specialized terminal devices, each requiring distinct design and manufacturing considerations. End-user segmentation identifies the primary recipients or facilities where these prosthetics are provided, reflecting the varied channels of distribution and care. Material segmentation focuses on the types of raw materials utilized in the 3D printing process, which significantly impacts the weight, durability, flexibility, and cost of the final prosthetic, catering to specific functional and aesthetic requirements of the amputee population.

- Product Type:

- Prosthetic Feet

- Prosthetic Hands

- Prosthetic Arms

- Prosthetic Legs

- Prosthetic Sockets

- Cosmetic Covers

- Custom Orthotics

- End User:

- Hospitals

- Rehabilitation Centers

- Prosthetic Clinics

- Ambulatory Surgical Centers

- Research Institutions

- Material:

- Polymers (e.g., PLA, ABS, Nylon, Polycarbonate, Thermoplastic Polyurethane)

- Metals (e.g., Titanium, Stainless Steel, Aluminum Alloys)

- Composites

- Biocompatible Resins

- Technology:

- Fused Deposition Modeling (FDM)

- Stereolithography (SLA)

- Selective Laser Sintering (SLS)

- Material Jetting

- Digital Light Processing (DLP)

Value Chain Analysis For 3D Printed Prosthetics Market

The value chain for the 3D Printed Prosthetics Market begins with upstream activities focused on the supply of raw materials and foundational technologies. This includes manufacturers of biocompatible polymers, metals, and composite filaments or resins, along with providers of specialized 3D printing hardware and software. Companies specializing in CAD/CAM software for prosthetic design, 3D scanning technologies for patient limb measurements, and simulation tools are crucial at this stage, laying the groundwork for customized product development. Strong relationships with these upstream suppliers are essential for ensuring material quality, technological innovation, and cost-effectiveness in the subsequent stages of the value chain.

Midstream activities encompass the core manufacturing and customization processes. This involves prosthetic design specialists who translate patient scan data into digital models, 3D printing service bureaus or in-house facilities that fabricate the prosthetic components, and assembly and finishing operations where printed parts are combined with traditional components like liners, harnesses, and articulating joints. Quality control and testing are integrated throughout this stage to ensure the safety, functionality, and durability of the finished prosthetic device. Efficiency and precision in these steps are paramount to delivering patient-specific solutions effectively.

Downstream activities focus on the distribution, fitting, and ongoing patient care. This segment primarily involves prosthetic clinics, hospitals, and rehabilitation centers that directly interact with patients for fitting, adjustments, and rehabilitation therapy. Distribution channels can be direct, where manufacturers sell directly to clinics or even end-users, or indirect, involving distributors and third-party logistics providers. The emergence of direct-to-consumer models, facilitated by open-source designs and online platforms, also represents a growing indirect channel. Post-sales support, maintenance, and replacement services form an integral part of this downstream segment, ensuring long-term patient satisfaction and product efficacy.

3D Printed Prosthetics Market Potential Customers

The primary potential customers for 3D printed prosthetics are individuals who have experienced limb loss due to various etiologies. This diverse group includes patients with congenital limb deficiencies who require custom-fitted devices from an early age, trauma survivors who have undergone amputation due to accidents or injuries, and individuals suffering from disease-related amputations, most commonly due to diabetes, peripheral vascular disease, or cancer. The demand extends across all age groups, from pediatric patients requiring frequent prosthetic replacements as they grow, to adults seeking functional or cosmetic restoration.

Beyond individual patients, key organizational buyers include hospitals, rehabilitation centers, and specialized prosthetic clinics that serve as crucial points of care and fitting. These institutions procure 3D printed prosthetic components or complete systems to integrate into their patient treatment pathways, driven by the desire to offer advanced, customized, and often more affordable solutions. Government healthcare programs, veterans' affairs departments, and charitable organizations also represent significant customer segments, often funding or facilitating access to prosthetics for eligible beneficiaries, particularly in underserved populations or regions with limited access to traditional prosthetic care.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $325 million |

| Market Forecast in 2032 | $1,050 million |

| Growth Rate | 18.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | LimbForge, Open Bionics, UNYQ, Create Prosthetics, Bionik Laboratories, Stratasys, 3D Systems, EOS GmbH, EnvisionTEC, Materialise NV, Prodways Group, WASP, Autodesk Inc., Dassault Systemes, Ottobock SE & Co. KGaA, Endolite, Blatchford Ltd., WillowWood Global LLC, Hanger Clinic, Coapt LLC |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

3D Printed Prosthetics Market Key Technology Landscape

The 3D Printed Prosthetics Market is underpinned by a diverse and evolving technological landscape, with several additive manufacturing processes forming its core. Fused Deposition Modeling (FDM) is widely used for its affordability and accessibility, extruding thermoplastic filaments layer by layer to build prosthetic components, particularly for sockets and cosmetic covers. Stereolithography (SLA) and Digital Light Processing (DLP) offer higher resolution and smoother surface finishes, ideal for intricate parts and precise fits using photopolymer resins. Selective Laser Sintering (SLS) is another crucial technology, employing a laser to sinter powdered materials, enabling the production of strong, complex geometries from nylon and other polymers without support structures, suitable for highly functional components.

Beyond the printing hardware, advanced software solutions are integral to the market's technological backbone. Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software are essential for creating highly customized prosthetic models from 3D scan data, allowing for intricate adjustments and optimizations before printing. Simulation software helps analyze stress distribution and biomechanical performance, ensuring the printed prosthetics are robust and functional. Furthermore, 3D scanning technologies, often utilizing structured light or laser scanning, are critical for accurately capturing the residual limb's geometry, which directly informs the custom design process and ensures a comfortable, precise fit for the end-user.

Material science also plays a pivotal role, with ongoing research and development in biocompatible and high-performance materials. The range of materials includes various polymers like PLA, ABS, Nylon, and TPU, selected for their specific properties such as flexibility, strength, and lightweight characteristics. Advances in metallic printing, utilizing titanium and stainless steel powders, are enabling the production of stronger, more durable, and lighter internal components and highly stressed parts. The emergence of composite materials further expands the possibilities, offering enhanced mechanical properties and improved integration with traditional prosthetic components, pushing the boundaries of what is achievable in personalized prosthetic design and functionality.

Regional Highlights

- North America: This region is a dominant market for 3D printed prosthetics, driven by high healthcare expenditure, significant research and development investments, and early adoption of advanced medical technologies. The presence of key market players, robust insurance coverage, and a high incidence of chronic diseases leading to amputations contribute to its leadership.

- Europe: Europe represents another substantial market, characterized by advanced healthcare infrastructure, strong government support for R&D, and increasing awareness of 3D printing benefits in medical applications. Countries like Germany, the UK, and France are at the forefront, with favorable regulatory frameworks and a focus on personalized healthcare solutions.

- Asia Pacific (APAC): The APAC region is projected to exhibit the fastest growth, primarily due to its large population base, improving healthcare access, rising disposable incomes, and increasing awareness of advanced prosthetic options. Emerging economies such as China, India, and Japan are investing heavily in healthcare infrastructure and technology, driving market expansion.

- Latin America: This region is witnessing steady growth, fueled by increasing healthcare spending, growing awareness, and the rising prevalence of conditions leading to limb loss. Initiatives to improve access to affordable medical solutions are also contributing to the adoption of 3D printed prosthetics.

- Middle East and Africa (MEA): The MEA market is developing, with growth attributed to improving healthcare facilities, increasing government initiatives to modernize healthcare, and a growing patient pool. However, adoption rates are slower compared to developed regions, primarily due to economic constraints and less mature technological infrastructure.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the 3D Printed Prosthetics Market.- LimbForge

- Open Bionics

- UNYQ

- Create Prosthetics

- Bionik Laboratories

- Stratasys

- 3D Systems

- EOS GmbH

- EnvisionTEC

- Materialise NV

- Prodways Group

- WASP

- Autodesk Inc.

- Dassault Systemes

- Ottobock SE & Co. KGaA

- Endolite

- Blatchford Ltd.

- WillowWood Global LLC

- Hanger Clinic

- Coapt LLC

Frequently Asked Questions

What are the primary benefits of 3D printed prosthetics?

The main benefits include highly personalized fit for enhanced comfort and function, significant cost reduction compared to traditional methods, and faster production times, making advanced prosthetic technology more accessible and tailored to individual patient needs.

How durable are 3D printed prosthetics compared to traditional ones?

The durability of 3D printed prosthetics varies greatly depending on the material and printing technology used. While some polymer-based 3D printed prosthetics may have different long-term wear characteristics, advancements in materials like advanced polymers and metals are significantly improving their strength and longevity, often making them comparable or superior for specific applications.

What role does AI play in the development of 3D printed prosthetics?

AI is increasingly vital in optimizing prosthetic design, enabling predictive analytics for precise fitting, and assisting in material selection. It also facilitates the development of smart prosthetics with adaptive functionalities and streamlines the entire design-to-manufacture workflow, leading to more intelligent and user-friendly devices.

Are 3D printed prosthetics covered by insurance?

Insurance coverage for 3D printed prosthetics varies by region, provider, and specific policy. As the technology gains wider acceptance and clinical validation, more insurance companies are beginning to offer partial or full coverage, especially for essential functional prosthetics. It is recommended to check with individual insurance providers for specific coverage details.

What materials are commonly used for 3D printed prosthetics?

Common materials include various polymers such as PLA, ABS, Nylon, and Thermoplastic Polyurethane (TPU), chosen for their specific properties like flexibility, strength, and lightweight nature. Additionally, metals like titanium and stainless steel are used for high-stress components, and biocompatible resins are utilized for finer details and specific applications.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager