AAC (Autoclaved Aerated Concrete) Blocks Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430429 | Date : Nov, 2025 | Pages : 257 | Region : Global | Publisher : MRU

AAC (Autoclaved Aerated Concrete) Blocks Market Size

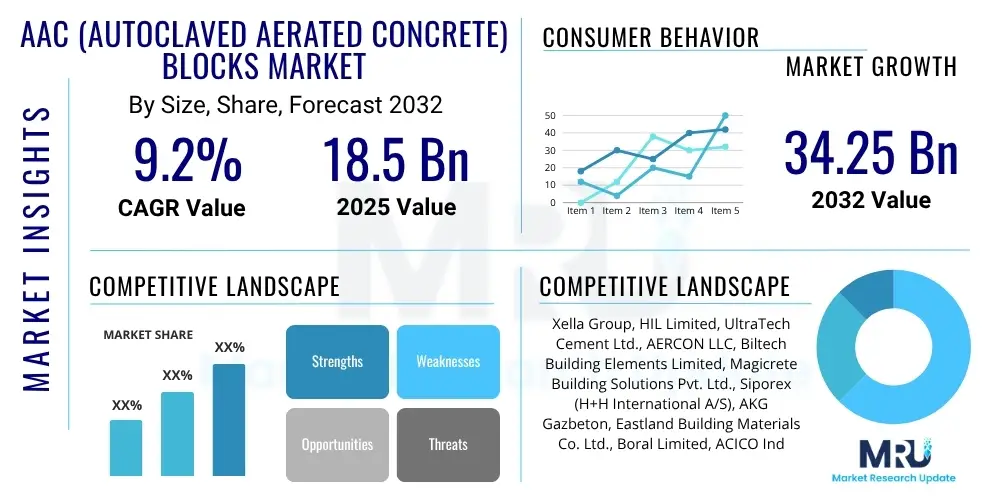

The AAC (Autoclaved Aerated Concrete) Blocks Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 9.2% between 2025 and 2032. The market is estimated at USD 18.5 Billion in 2025 and is projected to reach USD 34.25 Billion by the end of the forecast period in 2032.

AAC (Autoclaved Aerated Concrete) Blocks Market introduction

The AAC (Autoclaved Aerated Concrete) Blocks Market encompasses the production, distribution, and application of lightweight, precast, foam concrete building materials. These innovative blocks are manufactured from a blend of quartz sand, cement, lime, gypsum, water, and an aeration agent like aluminum powder, which creates a cellular structure through a chemical reaction. The mixture is then cut into desired shapes and cured in an autoclave under high pressure and temperature, imparting exceptional strength and stability to the material.

Major applications of AAC blocks span across diverse construction sectors, including residential buildings, commercial complexes, industrial facilities, and infrastructure projects, primarily for both load-bearing and non-load-bearing walls, partitions, and facade systems. The significant benefits of AAC blocks include superior thermal insulation properties that lead to reduced energy consumption for heating and cooling, excellent fire resistance, effective sound absorption, and their lightweight nature which facilitates faster construction and reduced structural load. These attributes, coupled with their eco-friendly manufacturing process and composition from abundant raw materials, position AAC blocks as a preferred choice in modern sustainable construction practices.

Key driving factors propelling the AAC blocks market include the accelerating pace of urbanization and industrialization globally, particularly in emerging economies, which fuels massive construction demand. Furthermore, stringent government regulations and increasing consumer awareness regarding energy efficiency and sustainable building materials are significantly boosting the adoption of AAC blocks. The rising emphasis on green building certifications and the need for cost-effective, durable, and environmentally responsible construction solutions further contribute to the market's robust growth trajectory, making them a cornerstone of future-oriented building development.

AAC (Autoclaved Aerated Concrete) Blocks Market Executive Summary

The AAC (Autoclaved Aerated Concrete) Blocks Market is experiencing dynamic shifts driven by evolving business trends, pronounced regional growth, and distinct segment transformations. A key business trend shaping the market is the intensified focus on sustainable construction practices and green building certifications, compelling manufacturers to invest in advanced production technologies that minimize environmental impact. There is also a growing emphasis on modular and prefabrication construction techniques, where AAC blocks offer inherent advantages due to their standardized dimensions and ease of handling, leading to faster project completion times and reduced labor costs. Furthermore, consolidation within the industry through mergers and acquisitions is observed, aimed at expanding geographic reach and enhancing production capabilities, while technological advancements are improving block strength, durability, and customization options.

Regionally, the Asia Pacific continues to dominate the AAC blocks market, primarily due to rapid urbanization, extensive infrastructure development, and burgeoning residential construction in countries like China and India. This region benefits from favorable government policies promoting affordable housing and eco-friendly building materials. Europe and North America also exhibit significant growth, driven by stringent energy efficiency regulations, a strong inclination towards sustainable building materials, and the renovation of existing structures. Latin America and the Middle East & Africa regions are emerging as high-potential markets, spurred by increasing investment in construction and a growing awareness of AAC's benefits, though often encountering challenges related to nascent manufacturing capabilities and established traditional construction methods. Localized supply chains and regional market dynamics, including raw material availability and logistics, play a critical role in shaping market competition and growth across these diverse geographical landscapes.

In terms of segment trends, the residential sector remains the largest end-use segment for AAC blocks, propelled by the global demand for housing and the push for sustainable residential developments that offer enhanced energy efficiency and comfort. The commercial segment is witnessing substantial growth as businesses and institutions increasingly adopt AAC blocks for office buildings, retail spaces, and educational facilities, appreciating their aesthetic flexibility, fire safety, and sound insulation properties. Within product categories, standard AAC blocks account for the majority share, but there is an increasing demand for specialized AAC panels, lintels, and floor systems that offer integrated solutions and quicker installation. The market is also seeing innovation in block formulations, including those designed for specific climatic conditions or enhanced structural performance, catering to a broader range of construction requirements and driving diversification across application areas.

AI Impact Analysis on AAC (Autoclaved Aerated Concrete) Blocks Market

Common user questions regarding AI's influence on the AAC (Autoclaved Aerated Concrete) Blocks market frequently revolve around its potential to optimize manufacturing processes, enhance product quality, streamline supply chain logistics, and contribute to sustainable construction goals. Users are keen to understand how AI can reduce production costs, improve energy efficiency in factories, predict material demand more accurately, and even assist in the design and engineering phases of projects utilizing AAC blocks. There is also interest in AI's role in quality control, maintenance prediction for machinery, and the overall digitization of the construction value chain, leading to concerns about job displacement versus creation of new roles requiring specialized skills.

- AI driven predictive maintenance of manufacturing machinery, reducing downtime and operational costs.

- Optimization of raw material mixing and curing processes through AI algorithms, ensuring consistent product quality and reducing waste.

- Enhanced supply chain management and logistics, including demand forecasting and optimized transportation routes for AAC blocks.

- Integration of AI with Building Information Modeling (BIM) for smarter design, material estimation, and clash detection in AAC block construction.

- Automation of quality control systems using computer vision and AI for defect detection in finished blocks.

- AI powered energy management systems in production facilities, leading to lower energy consumption and reduced carbon footprint.

- Development of smart inventory management solutions for AAC blocks, minimizing storage costs and ensuring timely delivery.

- Personalized product development and customization for architects and builders through AI driven design tools.

DRO & Impact Forces Of AAC (Autoclaved Aerated Concrete) Blocks Market

The AAC (Autoclaved Aerated Concrete) Blocks Market is profoundly influenced by a complex interplay of drivers, restraints, and opportunities, alongside significant impact forces. Key drivers include the global imperative for sustainable and green building materials, driven by increasing environmental awareness and stringent governmental regulations promoting energy efficiency in construction. The lightweight nature of AAC blocks, offering ease of handling and faster construction times, addresses the growing demand for rapid urbanization and industrialization, particularly in developing economies. Furthermore, superior thermal insulation, fire resistance, and soundproofing properties of AAC blocks make them highly attractive for modern building codes and consumer preferences for comfort and safety, contributing significantly to their market adoption. The rising costs of traditional construction materials and labor also push builders towards more efficient and cost-effective alternatives like AAC blocks.

However, the market faces several notable restraints. The initial capital investment required for establishing AAC block manufacturing units is substantial, posing a barrier to entry for new players and limiting expansion for smaller enterprises. Compared to traditional bricks, the initial per unit cost of AAC blocks can sometimes be higher, which might deter budget-conscious projects, particularly in regions where traditional methods are deeply entrenched and cheaper. Additionally, the relatively fragile nature of AAC blocks during transportation and handling can lead to breakages if not properly managed, increasing waste and logistics complexities. A lack of widespread awareness and skilled labor for proper installation in some regions also acts as a restraint, requiring significant market education and training efforts by manufacturers and industry associations.

Despite these challenges, significant opportunities abound for the AAC blocks market. The burgeoning demand for affordable housing in developing nations presents a vast untapped market, with governments increasingly supporting innovative construction techniques. Advances in manufacturing technology, including automation and energy-efficient processes, offer opportunities for cost reduction and quality improvement, enhancing the competitiveness of AAC blocks. Moreover, diversification into new applications beyond standard walls, such as prefabrication components like floor and roof panels, and the development of specialized AAC products for specific construction needs (e.g., higher strength, improved moisture resistance), open new revenue streams. Collaborations with architects, urban planners, and construction firms to promote integrated AAC solutions can further unlock market potential, especially in projects aiming for green building certifications and long-term operational efficiency.

Segmentation Analysis

The AAC (Autoclaved Aerated Concrete) Blocks market is segmented based on several key parameters, allowing for a detailed understanding of market dynamics and consumer preferences across various applications and product types. This segmentation helps to analyze market trends, identify lucrative opportunities, and strategize effectively within the diverse construction industry landscape. The primary segmentation criteria typically include end-use sectors, product types, and major applications, reflecting the versatile utility of AAC blocks in modern construction.

- By End-Use:

- Residential

- Commercial

- Industrial

- Infrastructure

- Others (e.g., institutional, agricultural)

- By Product Type:

- Blocks (Standard and customized sizes)

- Panels (Wall panels, floor panels, roof panels)

- Lintels

- Others (e.g., U-shaped blocks, decorative elements)

- By Application:

- Internal Walls

- External Walls

- Partition Walls

- Roofing

- Flooring

- Cladding

- Foundation Walls

- By Compressive Strength:

- Standard Strength

- High Strength

- By Density:

- Low Density

- Medium Density

- High Density

- By Region:

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East & Africa

Value Chain Analysis For AAC (Autoclaved Aerated Concrete) Blocks Market

The value chain for the AAC (Autoclaved Aerated Concrete) Blocks market begins with the upstream activities involving the sourcing and preparation of essential raw materials. These include quartz sand, cement (typically Portland cement), lime, gypsum, water, and aluminum powder, each requiring specific quality standards and consistent supply. The efficiency of raw material procurement, including transportation and storage, directly impacts the cost and quality of the final product. Manufacturers often establish long-term relationships with suppliers to ensure a steady and cost-effective supply, with some larger players even integrating backward to control critical raw material production.

Midstream activities primarily encompass the manufacturing process itself, which involves precise mixing of raw materials, pouring into molds, pre-curing, cutting into desired block or panel sizes, and finally, autoclaving under high pressure and temperature. This phase is highly capital-intensive, requiring specialized machinery and energy-efficient autoclaves. Downstream activities focus on the distribution, sales, and end-use application of AAC blocks. This involves a network of distributors, dealers, and direct sales channels to reach a diverse customer base ranging from large-scale construction companies and developers to individual homeowners and contractors. Effective warehousing and transportation logistics are crucial here, given the volume and specific handling requirements of AAC blocks to prevent damage.

Distribution channels for AAC blocks typically involve both direct and indirect approaches. Direct sales involve manufacturers selling directly to large project developers, government contracts, or major construction firms, often for bulk orders and specific project requirements. Indirect channels leverage a network of authorized distributors, retailers, and building material suppliers who then cater to smaller contractors, individual builders, and a broader market. The choice of channel often depends on the manufacturer's scale, market reach, and the specific target customer segment, with a growing emphasis on online platforms and digital engagement to streamline order processing and improve customer access. After-sales support, technical assistance, and installation guidance also form a crucial part of the downstream value proposition, ensuring customer satisfaction and promoting repeat business within the competitive construction materials market.

AAC (Autoclaved Aerated Concrete) Blocks Market Potential Customers

The primary potential customers for AAC (Autoclaved Aerated Concrete) Blocks are diverse and span across various segments of the construction industry, reflecting the material's broad applicability. These end-users or buyers are typically driven by a need for sustainable, energy-efficient, fire-resistant, and cost-effective building solutions that also offer speed of construction. The largest segment of potential customers includes residential developers and housing boards, who utilize AAC blocks extensively for constructing individual homes, multi-story apartment complexes, and large-scale affordable housing projects. Their focus is on delivering durable, comfortable, and energy-efficient living spaces while managing project timelines and budgets efficiently. The superior thermal insulation of AAC blocks appeals directly to these developers as it enhances the marketability of their properties through lower utility bills for future residents.

Another significant customer base comprises commercial construction companies and developers responsible for building offices, retail establishments, hotels, educational institutions, and healthcare facilities. For these customers, AAC blocks offer advantages such as excellent sound insulation, which is critical in commercial spaces, and enhanced fire safety, a crucial requirement for public buildings. The material's lightweight nature also reduces the dead load on structures, potentially leading to savings in foundation costs and enabling taller, more efficient designs. Industrial sector clients, including manufacturers constructing factories, warehouses, and cold storage facilities, also represent potential buyers, valuing AAC's insulation properties for temperature control and its durability in demanding environments.

Furthermore, government agencies involved in public infrastructure projects and urban development, as well as individual homeowners undertaking self-build projects or renovations, constitute important customer segments. Government initiatives focusing on green building standards and affordable housing often prioritize materials like AAC blocks due to their environmental benefits and construction efficiency. Individual homeowners are increasingly opting for AAC blocks for their homes due to growing awareness of energy savings, comfort, and long-term durability. Architects and structural engineers also act as indirect but highly influential customers, as their specifications and recommendations often guide the material choices made by project owners and contractors, making them crucial stakeholders in market expansion.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 18.5 Billion |

| Market Forecast in 2032 | USD 34.25 Billion |

| Growth Rate | CAGR 9.2% |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Xella Group, HIL Limited, UltraTech Cement Ltd., AERCON LLC, Biltech Building Elements Limited, Magicrete Building Solutions Pvt. Ltd., Siporex (H+H International A/S), AKG Gazbeton, Eastland Building Materials Co. Ltd., Boral Limited, ACICO Industries Co., Domat Control System, Brickwell, JK Lakshmi Cement Ltd., Eastern Concrete, J.K. Cement Ltd., Big Bloc Construction Ltd., Cindrigo, NCL Industries Ltd., Saint-Gobain Construction Products. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

AAC (Autoclaved Aerated Concrete) Blocks Market Key Technology Landscape

The AAC (Autoclaved Aerated Concrete) Blocks market's technology landscape is characterized by a continuous drive towards greater efficiency, automation, and enhanced product performance, underpinning modern manufacturing practices. Central to this is the sophisticated process of raw material preparation, which involves precise batching and mixing of finely ground quartz sand, cement, lime, gypsum, water, and aluminum powder. Advanced grinding mills and mixing equipment are employed to achieve the desired particle size distribution and homogenous slurry, which is critical for the chemical reactions that create the cellular structure of AAC. Innovations in this area focus on optimizing mix designs for different block properties and reducing energy consumption during the grinding process.

The subsequent stages, including casting, pre-curing, cutting, and autoclaving, utilize specialized machinery that has seen significant technological advancements. Automated cutting machines, often employing steel wires, are capable of precise and high-speed cutting of the green cake into various block and panel sizes, minimizing material waste and ensuring dimensional accuracy. The autoclaving process, which provides the final strength and stability, relies on robust pressure vessels and sophisticated control systems to maintain optimal temperature and pressure cycles. Recent technological developments focus on larger autoclaves for increased production capacity, as well as energy recovery systems and more efficient steam generation to reduce the overall energy footprint of the autoclaving plant.

Beyond core manufacturing, the technology landscape extends to plant automation and integration. Modern AAC block manufacturing facilities increasingly incorporate fully automated production lines, from raw material handling to packaging, reducing manual labor and enhancing operational consistency and safety. This includes robotic stacking and packaging systems, as well as integrated quality control mechanisms leveraging sensors and data analytics for real-time process monitoring and defect detection. Furthermore, the adoption of Building Information Modeling (BIM) by architects and engineers is influencing product development, as manufacturers are creating BIM-ready AAC block libraries to facilitate easier integration into digital construction workflows, further streamlining design and construction processes and enhancing the overall value proposition of AAC materials in the digital age of construction.

Regional Highlights

- Asia Pacific: This region stands as the largest and fastest-growing market for AAC blocks, primarily driven by rapid urbanization, significant investments in infrastructure development, and an accelerating demand for affordable and sustainable housing. Countries like China, India, and Southeast Asian nations are at the forefront, benefiting from government initiatives promoting green building materials and energy-efficient construction practices. The abundant availability of raw materials and lower labor costs also contribute to the region's dominance, making it a pivotal hub for AAC block production and consumption.

- Europe: Europe represents a mature yet steadily growing market, heavily influenced by stringent energy efficiency regulations and a strong emphasis on sustainable construction. Countries such as Germany, the UK, and Poland are leading in the adoption of AAC blocks for both new constructions and renovation projects. The market here is characterized by a high demand for high-performance building materials that contribute to achieving nearly zero-energy building (NZEB) standards and reduce carbon footprints, aligning perfectly with AAC block properties.

- North America: The North American market, including the United States and Canada, is experiencing consistent growth, fueled by increasing awareness about green building, rising construction costs, and a growing preference for lightweight and energy-efficient materials. Adoption is driven by the desire to meet strict building codes and reduce long-term operational costs for heating and cooling. Investments in residential and commercial sectors, alongside innovative construction techniques, are key growth drivers in this region.

- Latin America: This region is an emerging market for AAC blocks, propelled by economic development, urbanization, and government initiatives aimed at addressing housing shortages. Countries like Brazil and Mexico are witnessing increasing adoption as construction companies seek cost-effective, durable, and thermally efficient building solutions. While still smaller than established markets, the growth potential is substantial as awareness and distribution networks expand.

- Middle East & Africa (MEA): The MEA region presents significant growth opportunities, particularly in the Middle East, driven by extensive construction projects in residential, commercial, and hospitality sectors. The demand for thermally insulated materials is high due to the region's hot climate, making AAC blocks an attractive choice for energy efficiency. In Africa, growing construction activity and the need for affordable, quick-to-build structures are slowly increasing AAC block penetration, though logistical challenges and competition from traditional materials remain factors.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the AAC (Autoclaved Aerated Concrete) Blocks Market.- Xella Group

- HIL Limited

- UltraTech Cement Ltd.

- AERCON LLC

- Biltech Building Elements Limited

- Magicrete Building Solutions Pvt. Ltd.

- Siporex (H+H International A/S)

- AKG Gazbeton

- Eastland Building Materials Co. Ltd.

- Boral Limited

- ACICO Industries Co.

- Domat Control System

- Brickwell

- JK Lakshmi Cement Ltd.

- Eastern Concrete

- J.K. Cement Ltd.

- Big Bloc Construction Ltd.

- Cindrigo

- NCL Industries Ltd.

- Saint-Gobain Construction Products

Frequently Asked Questions

What are the primary benefits of using AAC (Autoclaved Aerated Concrete) Blocks in construction?

AAC blocks offer superior thermal insulation, leading to significant energy savings, excellent fire resistance for enhanced safety, and effective sound absorption. They are lightweight, facilitating faster construction, reducing structural load, and are also environmentally friendly due to their sustainable composition and production process.

How do AAC blocks contribute to sustainable building practices?

AAC blocks are produced using eco-friendly materials such as sand, cement, lime, and water, with minimal waste generated during manufacturing. Their excellent thermal insulation properties reduce heating and cooling energy consumption in buildings, thereby lowering greenhouse gas emissions and supporting green building certifications like LEED.

Are AAC blocks more expensive than traditional building materials?

While the initial unit cost of AAC blocks might sometimes be slightly higher than traditional bricks, their overall project cost can be lower due to faster construction times, reduced labor requirements, decreased need for additional insulation, and savings on structural components because of their lightweight nature. Long-term energy savings also contribute to a lower total cost of ownership.

What are the main applications of AAC blocks in modern construction?

AAC blocks are extensively used for internal and external walls, partition walls, roofing, and flooring in residential, commercial, and industrial buildings. They are also suitable for high-rise structures, cold storage facilities, and as infill panels for framed structures due to their excellent insulation and structural properties.

What is the expected growth rate for the AAC Blocks Market in the coming years?

The AAC Blocks Market is projected to experience robust growth, with a Compound Annual Growth Rate (CAGR) of 9.2% between 2025 and 2032. This growth is driven by increasing urbanization, demand for sustainable construction, and favorable government regulations promoting energy-efficient building materials worldwide.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager