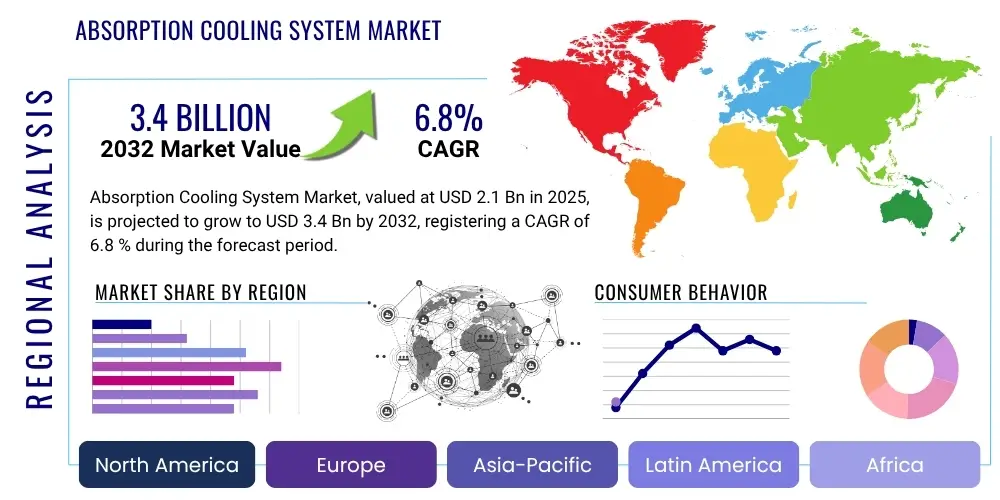

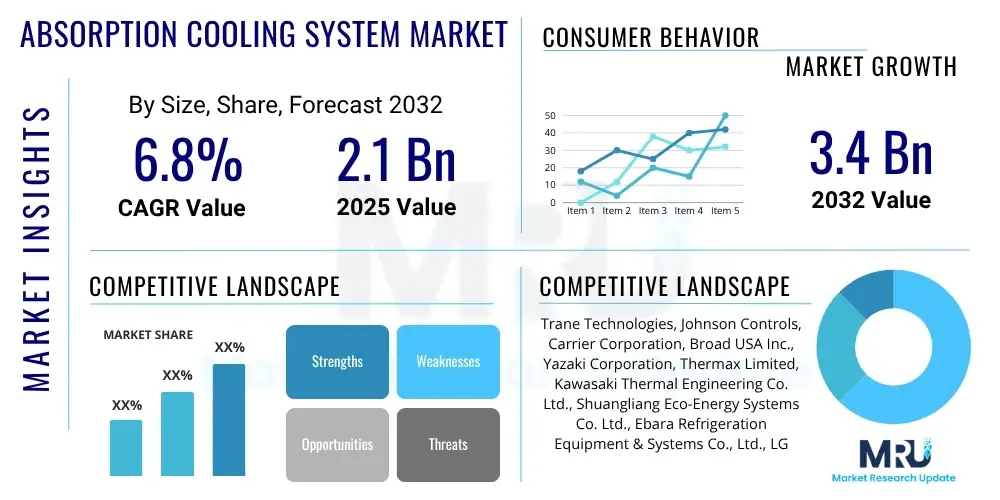

Absorption Cooling System Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427882 | Date : Oct, 2025 | Pages : 253 | Region : Global | Publisher : MRU

Absorption Cooling System Market Size

The Absorption Cooling System Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. This growth trajectory is fueled by increasing global emphasis on energy efficiency, the adoption of sustainable cooling solutions, and the rising demand for waste heat recovery across various industrial and commercial sectors. The market, estimated at USD 2.1 Billion in 2025, is poised for significant expansion, reflecting a broader shift towards environmentally conscious and cost-effective thermal management technologies. Projections indicate a substantial increase, with the market expected to reach USD 3.4 Billion by the end of the forecast period in 2032. This expansion is further underpinned by advancements in absorption technology, making these systems more competitive and versatile for a diverse range of applications. Governments and industries worldwide are increasingly investing in infrastructure that supports lower carbon footprints and optimized energy consumption, directly benefiting the absorption cooling sector. The inherent advantages of utilizing readily available waste heat or renewable thermal energy sources position absorption cooling systems as a critical component in achieving future energy sustainability goals.

Absorption Cooling System Market introduction

The Absorption Cooling System Market encompasses technologies that provide refrigeration and air conditioning by using a heat source, such as waste heat from industrial processes, natural gas, or solar thermal energy, rather than electrical energy to drive a vapor compression cycle. These systems operate on thermodynamic principles, typically involving a refrigerant (like water) and an absorbent (like lithium bromide) in a closed loop. The process leverages the physical phenomenon where a liquid absorbent draws in refrigerant vapor, and subsequent heating separates the two, allowing the refrigerant to condense and then evaporate, creating a cooling effect. This innovative approach significantly reduces electricity consumption, offering a compelling alternative to conventional compressor-based cooling systems. The primary benefit lies in their ability to convert low-grade heat, often a byproduct of other operations, into a useful cooling output, thereby improving overall energy efficiency and reducing operational costs. Such systems are widely utilized in scenarios where a reliable and abundant heat source is available, making them particularly attractive for industrial facilities, district cooling networks, and large commercial complexes seeking to minimize their environmental impact and capitalize on energy recovery strategies. The core product offering includes single-effect, double-effect, and triple-effect absorption chillers, differentiated by their energy efficiency and the temperature of the heat source required for operation. Major applications span across industrial sectors such as chemical processing, oil and gas, power generation, and food and beverage, where significant amounts of waste heat are generated. Furthermore, the commercial sector heavily employs these systems in hospitals, hotels, office buildings, and data centers for large-scale air conditioning. The increasing global focus on sustainability and energy conservation, coupled with rising energy prices and stringent environmental regulations pertaining to refrigerant emissions, acts as a primary driving factor for the market's robust growth. Benefits extend beyond energy savings to include lower maintenance requirements due to fewer moving parts, quieter operation, and the avoidance of ozone-depleting refrigerants, making them a preferred choice for ecologically responsible and economically savvy organizations looking for long-term cooling solutions.

Absorption Cooling System Market Executive Summary

The Absorption Cooling System Market is witnessing dynamic shifts driven by overarching business trends emphasizing sustainability, resource optimization, and cost efficiency. A prominent trend is the increasing integration of absorption chillers into hybrid cooling systems, combining them with conventional vapor compression units to maximize efficiency and reliability across varying load conditions. Furthermore, there is a growing demand for compact and modular absorption cooling solutions, particularly for commercial and decentralized applications, facilitating easier installation and scalability. The market is also experiencing a surge in smart technology integration, where advanced controls and IoT-enabled monitoring systems enhance operational performance, predictive maintenance, and energy management. Environmentally conscious procurement policies by corporations and public entities are fueling the adoption of absorption systems, especially those utilizing natural refrigerants. Regional trends highlight Asia-Pacific as the fastest-growing and largest market, propelled by rapid industrialization, urbanization, and significant investments in energy-efficient infrastructure in countries like China and India. European markets are characterized by stringent environmental regulations and a strong emphasis on district heating and cooling networks, driving the demand for high-efficiency absorption chillers that can integrate with renewable energy sources. North America is focused on upgrading aging cooling infrastructure and leveraging absorption systems for industrial waste heat recovery, alongside increasing interest in solar thermal-driven cooling for commercial buildings. In terms of segment trends, the industrial application segment continues to dominate due to the abundance of waste heat and the significant potential for energy cost savings in manufacturing, chemical, and power generation facilities. The commercial segment, encompassing large buildings, data centers, and hospitals, is also demonstrating robust growth as owners seek to lower operating expenses and achieve green building certifications. Heat source trends show a move towards diversifying energy inputs, with increasing interest in solar thermal and geothermal sources alongside traditional waste heat and natural gas. Overall, the market's executive summary points to a sustained growth trajectory, underpinned by technological innovation, favorable regulatory landscapes, and an undeniable economic and environmental value proposition across diverse geographies and end-use sectors.

AI Impact Analysis on Absorption Cooling System Market

Common user questions regarding the impact of Artificial Intelligence (AI) on the Absorption Cooling System Market frequently revolve around how AI can enhance efficiency, optimize performance, reduce operational costs, and facilitate predictive maintenance for these complex systems. Users are keen to understand the practical applications of AI in real-time energy management, fault detection, and the integration of absorption chillers with smart building management systems. Concerns often include the initial investment required for AI implementation, data security, the need for specialized skills, and the scalability of AI solutions across different system sizes and complexities. There is a clear expectation that AI will unlock new levels of performance and reliability, making absorption cooling systems even more competitive against conventional alternatives.

The integration of AI holds transformative potential for the absorption cooling system market, moving beyond traditional control mechanisms to achieve unprecedented levels of operational efficiency and reliability. AI algorithms can analyze vast datasets from sensor networks, including ambient temperature, humidity, heat source availability, cooling load demands, and system parameters such as generator temperature, condenser pressure, and absorber performance. This data-driven approach allows for dynamic optimization of operating conditions in real-time, predicting optimal set points to maximize coefficient of performance (COP) and minimize energy consumption. For instance, AI can anticipate fluctuations in waste heat availability or cooling demand based on weather forecasts and occupancy patterns, proactively adjusting system parameters to maintain stable and efficient operation. Such predictive capabilities significantly reduce reactive maintenance and unnecessary energy expenditure, translating directly into lower operational costs and enhanced system longevity. Moreover, AI can identify subtle correlations between various operational parameters that might indicate impending component failure or performance degradation, flagging issues long before they become critical. This shift from reactive to predictive maintenance is a game-changer for complex mechanical systems like absorption chillers, minimizing downtime and extending service life.

Beyond optimizing individual units, AI can play a pivotal role in orchestrating the performance of absorption cooling systems within larger, integrated energy ecosystems, such as district cooling networks or smart grids. By leveraging machine learning models, these systems can autonomously adapt to grid demands, prioritize renewable heat sources, and interact seamlessly with other building utilities to achieve holistic energy efficiency goals. The continuous learning nature of AI means that system performance will improve over time as more operational data is collected and analyzed, leading to self-optimizing cooling solutions. Challenges remain in standardizing data collection, ensuring interoperability between diverse hardware and software platforms, and developing robust AI models that can handle the specific complexities of absorption thermodynamics. However, the clear benefits in terms of energy savings, operational resilience, and reduced environmental impact are driving rapid innovation and adoption. The future of absorption cooling will undoubtedly be intertwined with advanced AI, transforming these systems into intelligent, self-managing thermal assets that contribute significantly to a sustainable energy future.

- AI-driven predictive maintenance: Algorithms analyze operational data to forecast equipment failures, allowing for proactive servicing and minimizing costly downtime.

- Real-time operational optimization: AI adjusts chiller parameters (e.g., solution concentration, flow rates) dynamically based on environmental conditions and cooling load for peak efficiency.

- Enhanced energy management: AI integrates absorption cooling with overall building energy systems, optimizing heat source utilization and reducing electricity consumption across the facility.

- Fault detection and diagnostics: Machine learning models quickly identify anomalies and potential malfunctions, providing early warnings and guiding troubleshooting efforts.

- Smart grid integration: AI enables absorption chillers to respond to grid signals, participating in demand response programs and leveraging off-peak energy for heat sources.

- Improved system control and automation: Advanced AI controllers learn optimal operating strategies, reducing the need for manual intervention and improving system responsiveness.

- Performance benchmarking and reporting: AI provides detailed analytics on system performance, efficiency metrics, and energy savings, aiding in continuous improvement and compliance reporting.

DRO & Impact Forces Of Absorption Cooling System Market

The Absorption Cooling System Market is significantly shaped by a confluence of Drivers, Restraints, Opportunities, and broader Impact Forces that dictate its growth trajectory and adoption rates. A primary driver is the escalating global demand for energy-efficient cooling solutions, propelled by rising energy costs and an intensified focus on reducing carbon emissions. Industries and commercial establishments are increasingly recognizing the economic and environmental advantages of utilizing waste heat or renewable thermal energy sources for cooling, which absorption systems are uniquely positioned to offer. Furthermore, stringent environmental regulations, particularly those aimed at phasing out ozone-depleting refrigerants (like HFCs) used in traditional vapor compression systems, create a favorable regulatory landscape for absorption chillers that typically use water as a refrigerant. This regulatory pressure, coupled with growing corporate sustainability mandates, strongly influences procurement decisions. However, the market faces notable restraints, primarily the higher initial capital investment required for absorption cooling systems compared to conventional electric chillers. The complexity of installation, especially for larger industrial applications, and the need for specialized technical expertise for maintenance can also pose challenges, potentially deterring some potential adopters. Limited awareness of absorption technology benefits in certain emerging markets further restricts its widespread penetration. Despite these hurdles, significant opportunities abound. The integration of absorption systems with renewable energy sources such as solar thermal and geothermal, offers a compelling path towards completely green cooling. The expansion of district cooling networks globally provides a scalable platform for large-capacity absorption chillers. Moreover, continuous advancements in materials science, heat exchanger design, and control technologies are enhancing the efficiency and cost-effectiveness of these systems, making them more attractive. The increasing industrialization and urbanization in developing regions, particularly in Asia-Pacific, present a vast untapped market for waste heat recovery and energy-efficient cooling. Broader impact forces, including fluctuating global energy prices, geopolitical shifts affecting energy policy, ongoing technological innovation in thermal management, and evolving environmental mandates, continuously shape the competitive landscape and strategic direction of the absorption cooling market. The collective interplay of these factors will determine the market's evolution, favoring solutions that offer a balance of economic viability, environmental sustainability, and operational reliability in an increasingly energy-conscious world.

Segmentation Analysis

The Absorption Cooling System Market is comprehensively segmented across several key dimensions, providing a granular view of its diverse landscape and enabling targeted strategic approaches. These segmentations are critical for understanding market dynamics, identifying growth pockets, and tailoring product development to specific end-user needs and applications. The primary categorizations typically include the type of absorption chiller, the heat source utilized, the various end-use applications, and the capacity of the systems. Each segment exhibits distinct characteristics, market drivers, and competitive forces, reflecting the varied requirements of industrial, commercial, and even nascent residential cooling demands. Analyzing these segments helps stakeholders understand where growth is most pronounced and where technological innovation is most impactful, guiding investment decisions and market entry strategies within this specialized cooling technology sector.

- By Type: This segment distinguishes between different configurations of absorption chillers based on their operational efficiency and complexity, driven by the number of absorber-generator stages.

- Single Effect: These systems operate with a single generator and typically achieve a Coefficient of Performance (COP) between 0.6 and 0.8. They are simpler in design and cost-effective, best suited for applications with readily available low-grade heat sources (around 70-100°C) and where energy efficiency is less critical than initial cost. Common in smaller commercial buildings or specific industrial waste heat recovery scenarios.

- Double Effect: Employing two generators and a higher operating temperature (typically 150-200°C), double-effect chillers offer a higher COP, ranging from 1.0 to 1.4, significantly improving energy efficiency. They are predominantly used in large commercial and industrial applications where high-pressure steam or direct-fired natural gas is available as a heat source, making them more economical in the long run for substantial cooling loads.

- Triple Effect: Representing the pinnacle of absorption cooling efficiency, triple-effect systems utilize three generators, requiring even higher heat source temperatures (above 200°C) and achieving COPs up to 1.7. While more complex and expensive, they are designed for very large-scale industrial processes and district cooling plants where ultra-high efficiency and maximum energy savings are paramount, often integrated with concentrated solar power or high-temperature industrial waste heat.

- By Heat Source: This segmentation classifies systems based on the primary energy input used to drive the absorption cycle, highlighting versatility and adaptability to different energy landscapes.

- Waste Heat: The most significant segment, leveraging exhaust gases, hot water, or steam from industrial processes, power generation, and cogeneration plants. This is a crucial driver for sustainability and cost reduction, converting otherwise discarded energy into useful cooling.

- Natural Gas: Direct-fired gas absorption chillers use natural gas combustion to generate the necessary heat. These are popular where natural gas is an economical and readily available fuel source, offering a lower carbon footprint than electricity from fossil fuels in many regions.

- Hot Water/Steam: Utilizing hot water or steam generated from boilers, district heating systems, or other thermal energy sources. This provides flexibility for integration into existing thermal infrastructure.

- Solar Energy: Systems powered by solar thermal collectors, converting sunlight into heat to drive the absorption cycle. An increasingly important segment for truly renewable and zero-emission cooling, especially in regions with high solar insolation.

- Others: Includes less common but emerging heat sources such as geothermal energy, biomass combustion, or hybrid combinations designed for optimal energy utilization.

- By Application: This segment categorizes absorption cooling systems based on their primary end-use sector, reflecting diverse requirements and market sizes.

- Industrial: The largest application segment, encompassing chemical processing, oil & gas refineries, power generation (combined heat and power plants), food & beverage processing, pharmaceuticals, and manufacturing. These sectors often have abundant waste heat and significant cooling demands.

- Commercial: Includes large-scale air conditioning for hospitals, hotels, office buildings, shopping malls, educational institutions, and data centers. Driven by the need for energy-efficient, reliable, and quiet cooling for human comfort and critical infrastructure.

- District Cooling: Centralized cooling plants that distribute chilled water to multiple buildings within a geographical area. Absorption chillers are ideal for these systems due to their large capacities and ability to utilize diversified heat sources.

- Residential: While less common, smaller absorption units are being explored for residential applications, particularly in conjunction with solar thermal systems or waste heat from domestic hot water production, though market penetration remains low compared to other segments.

- By Capacity: This segmentation groups systems based on their cooling output, addressing the varied scale of cooling requirements from small commercial to massive industrial installations.

- Small Capacity (Up to 350 kW): Typically single-effect chillers used for smaller commercial buildings, specific industrial processes, or niche applications where moderate cooling is needed.

- Medium Capacity (350 kW - 7000 kW): Primarily double-effect chillers, catering to large commercial complexes, mid-sized industrial facilities, and initial phases of district cooling projects. This segment represents a significant portion of the market due to its broad applicability.

- Large Capacity (Above 7000 kW): Dominated by double and triple-effect chillers, designed for very large industrial plants, extensive district cooling networks, and major infrastructure projects where massive cooling loads require highly efficient and robust solutions.

Value Chain Analysis For Absorption Cooling System Market

The Value Chain Analysis for the Absorption Cooling System Market provides a comprehensive overview of the sequential processes and activities involved in bringing these specialized cooling solutions from conception to end-use, encompassing everything from raw material sourcing to post-installation services. At the upstream end, the value chain begins with the procurement of critical raw materials and components, which include various metals like stainless steel, copper, and aluminum for heat exchangers, shells, and piping, as well as specialized chemicals such as lithium bromide or ammonia for the absorbent and refrigerant. Key component manufacturers supply essential parts like pumps, valves, burners (for direct-fired systems), vacuum pumps, and control systems. The quality and availability of these upstream materials significantly impact the overall cost, performance, and durability of the final absorption chiller. Research and development activities also sit firmly in the upstream, focusing on improving efficiency, reducing size, enhancing material compatibility, and developing advanced control algorithms. Moving downstream, the manufacturing phase involves the intricate assembly, welding, and testing of these components into complete absorption chiller units, requiring specialized engineering expertise and quality control processes to ensure reliability and adherence to performance specifications. Post-manufacturing, the distribution channel plays a crucial role in market penetration and customer reach. This channel can be broadly categorized into direct and indirect sales. Direct sales involve manufacturers selling directly to large industrial clients or major district cooling project developers, often supported by in-house engineering and project management teams. This approach allows for direct communication, custom solutions, and deeper client relationships, particularly for complex or large-scale installations. Indirect distribution, on the other hand, relies heavily on a network of authorized distributors, local sales agents, and Engineering, Procurement, and Construction (EPC) contractors. These partners provide regional market access, technical support, installation services, and sometimes maintenance, acting as crucial intermediaries for smaller commercial projects and geographically dispersed clients. EPC contractors are particularly vital as they integrate the absorption chillers into larger building management or industrial process systems. Finally, the value chain extends to post-sales services, including installation, commissioning, warranty support, routine maintenance, spare parts supply, and remote monitoring. The efficiency and reliability of these downstream services are paramount for customer satisfaction and long-term market reputation. The integration of digital tools for remote diagnostics and predictive maintenance is also becoming increasingly important in this phase. Understanding these interdependencies across the value chain is critical for identifying areas of cost optimization, enhancing operational efficiency, and leveraging strategic partnerships to strengthen market position and deliver superior customer value in the absorption cooling system industry.

Absorption Cooling System Market Potential Customers

The Absorption Cooling System Market caters to a diverse range of end-users and buyers, spanning various sectors that prioritize energy efficiency, waste heat utilization, and sustainable cooling solutions. Industrial facilities represent a significant segment of potential customers, particularly those involved in chemical processing, oil and gas, power generation, food and beverage, and pharmaceutical manufacturing. These industries often generate substantial amounts of waste heat (in the form of hot exhaust gases, steam, or hot water) as a byproduct of their primary operations, which can be efficiently converted into useful cooling using absorption chillers. For these industrial players, the ability to reduce energy costs, lower their carbon footprint, and comply with environmental regulations makes absorption cooling an attractive proposition. The economic benefit derived from converting a waste product into a valuable resource directly impacts their operational expenditure and enhances overall plant efficiency, positioning them as prime candidates for adoption.

Beyond heavy industry, the commercial sector constitutes another substantial segment of potential customers. This includes large commercial buildings such as hospitals, hotels, shopping malls, office complexes, and educational institutions. These establishments have significant and continuous cooling demands, and the adoption of absorption systems helps them achieve sustainability targets, gain green building certifications, and reduce long-term operating costs associated with electricity consumption for air conditioning. Data centers, which require continuous and reliable cooling to maintain optimal operating temperatures for servers, are increasingly turning to absorption chillers, especially when they can leverage waste heat from their own IT equipment or external sources. The quiet operation and fewer moving parts of absorption systems also contribute to their appeal in noise-sensitive environments like healthcare facilities.

Furthermore, district cooling operators and municipal bodies represent a growing customer base. District cooling systems, which centralize the production of chilled water and distribute it to multiple buildings through an underground pipeline network, often incorporate large-scale absorption chillers due to their capacity to integrate various heat sources, including cogeneration plants or renewable thermal energy. Governments and public sector organizations are also potential buyers, especially those implementing large-scale infrastructure projects, developing smart cities, or retrofitting public buildings with energy-efficient technologies to meet national climate goals. The long operational lifespan and low maintenance requirements of absorption systems align well with public sector investments that seek long-term value and reduced recurring costs. While currently a niche, even some high-end residential developments or communities with access to centralized thermal energy could be considered emerging potential customers, particularly as the integration of solar thermal and other localized heat sources becomes more prevalent, indicating a broad and evolving spectrum of buyers across the global economy.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 2.1 Billion |

| Market Forecast in 2032 | USD 3.4 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Trane Technologies, Johnson Controls, Carrier Corporation, Broad USA Inc., Yazaki Corporation, Thermax Limited, Kawasaki Thermal Engineering Co. Ltd., Shuangliang Eco-Energy Systems Co. Ltd., Ebara Refrigeration Equipment & Systems Co., Ltd., LG Chem, Power Partners, Cofely (Engie), Hitachi Ltd., Hyundai Climate Control, Century Corporation, pink, pink, pink, pink, pink |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Absorption Cooling System Market Key Technology Landscape

The technological landscape of the Absorption Cooling System Market is characterized by continuous innovation aimed at enhancing efficiency, expanding application versatility, and improving the overall economic and environmental viability of these systems. At its core, the technology relies on the fundamental thermodynamic principles of absorption, utilizing a refrigerant and an absorbent pair. The most common pairs are lithium bromide/water for chilling applications above freezing point and ammonia/water for refrigeration below freezing point. Recent technological advancements focus heavily on optimizing the internal components to achieve higher Coefficients of Performance (COP) and reduce physical footprints. This includes sophisticated designs of heat exchangers—such as advanced plate heat exchangers, shell-and-tube configurations, and microchannel designs—which maximize heat transfer efficiency within a compact volume. Materials science plays a crucial role in developing corrosion-resistant alloys and coatings, particularly for lithium bromide systems where corrosion can be a significant challenge, thereby extending the operational lifespan and reliability of the chillers. Furthermore, research into new, environmentally benign refrigerant-absorbent combinations seeks to broaden the temperature range of operation and address specific niche applications, while ensuring compliance with evolving environmental regulations concerning chemical usage and emissions.

A significant area of technological advancement involves the integration of absorption cooling systems into hybrid configurations. Hybrid absorption-compression chillers combine the energy-saving benefits of absorption with the rapid response and precise temperature control of vapor compression units. These systems leverage the absorption component during periods of high waste heat availability or low electricity prices, switching to or augmenting with the compression cycle as needed, thus optimizing performance and efficiency under varying load conditions. Another key trend is the development of desiccant cooling integration, where absorption chillers are combined with desiccant dehumidification systems. This synergistic approach effectively manages both sensible (temperature) and latent (humidity) loads, offering comprehensive climate control with enhanced energy efficiency, particularly in humid environments. The ongoing refinement of direct-fired absorption chillers, utilizing natural gas or other fuels, focuses on improving combustion efficiency and reducing emissions, making them more attractive for applications where a dedicated thermal source is required and waste heat is not available.

The advent of smart control systems, IoT (Internet of Things) integration, and advanced analytics is revolutionizing the operation and maintenance of absorption cooling systems. Modern chillers are equipped with sophisticated sensors and control algorithms that monitor performance parameters in real-time, allowing for dynamic optimization of operational settings based on environmental conditions, cooling demand, and heat source availability. These intelligent systems enable predictive maintenance, anticipating potential failures before they occur, thus minimizing downtime and extending equipment life. Remote monitoring capabilities provide operators with real-time insights and allow for troubleshooting from off-site locations, significantly reducing service costs and improving response times. Furthermore, the integration of absorption chillers with Building Management Systems (BMS) and smart grid technologies allows for seamless communication and coordinated operation with other building utilities, contributing to holistic energy management strategies. The emphasis on modular design also facilitates easier installation, scalability, and maintenance, especially for distributed cooling applications. These technological advancements collectively contribute to making absorption cooling systems more efficient, reliable, versatile, and competitive in the evolving landscape of thermal management solutions.

Regional Highlights

- North America: The North American market for absorption cooling systems is primarily driven by the increasing emphasis on energy efficiency, the need to upgrade aging infrastructure, and the growing adoption of waste heat recovery solutions in industrial sectors such as oil & gas, chemicals, and power generation. Strict environmental regulations and incentives for sustainable energy technologies in countries like the United States and Canada are encouraging businesses and institutions to invest in absorption chillers. There is also a notable trend towards implementing solar thermal cooling systems in commercial buildings and campuses, leveraging tax credits and utility rebates. The region benefits from a well-developed industrial base and a strong focus on advanced manufacturing, providing a conducive environment for technological adoption and innovation in energy-efficient thermal management solutions. Investments in data centers, which require continuous and reliable cooling, further bolster market growth, as absorption chillers offer a robust and often more resilient alternative to traditional electric cooling.

- Europe: Europe is a mature market for absorption cooling systems, characterized by stringent environmental regulations, high energy costs, and a robust framework for district heating and cooling networks. Countries like Germany, Italy, and Scandinavia are at the forefront of adopting high-efficiency absorption chillers, particularly those integrated with renewable energy sources and combined heat and power (CHP) plants. The European Union's ambitious decarbonization targets and directives promoting energy efficiency in buildings and industries provide a strong impetus for the market. Public sector investments in sustainable infrastructure and the widespread adoption of green building certifications further drive demand. The region's focus on circular economy principles and resource efficiency makes absorption cooling, with its ability to utilize waste heat, a highly attractive solution. Continued retrofitting of older commercial and industrial facilities with advanced absorption systems is a key trend, aiming to improve energy performance and reduce operational expenses across diverse sectors.

- Asia Pacific (APAC): The Asia Pacific region stands as the largest and fastest-growing market for absorption cooling systems globally, propelled by rapid industrialization, urbanization, and massive infrastructure development, particularly in emerging economies like China, India, and Southeast Asian nations. The burgeoning manufacturing sector, coupled with a growing demand for commercial and residential air conditioning, creates immense opportunities. Governments in the region are actively promoting energy-efficient technologies and sustainable development through various policies, subsidies, and incentives to address rising energy consumption and air pollution. The abundance of industrial waste heat in densely industrialized areas provides a natural fit for absorption cooling solutions, enabling significant energy savings and operational cost reductions for factories and power plants. Investments in large-scale commercial complexes, data centers, and the expansion of district cooling networks are further accelerating market penetration, making APAC a critical hub for both demand and production of absorption cooling technologies.

- Latin America: The Latin American absorption cooling system market is characterized by emerging growth, driven by increasing industrialization, particularly in sectors such as mining, food processing, and chemical manufacturing in countries like Brazil, Mexico, and Chile. The region's hot climate necessitates reliable and efficient cooling solutions, and absorption systems offer an attractive option for businesses looking to manage energy costs and improve sustainability. While the market is still developing compared to other regions, growing investments in commercial construction, tourism infrastructure, and renewable energy projects are creating new avenues for adoption. Awareness of waste heat recovery and energy efficiency benefits is gradually increasing, prompting industries to explore alternatives to conventional cooling. Strategic partnerships with international technology providers and local government initiatives to promote green technologies are expected to accelerate market expansion in the coming years.

- Middle East and Africa (MEA): The Middle East and Africa region presents significant potential for absorption cooling systems, primarily due to its extreme climatic conditions, which necessitate extensive cooling year-round. The booming construction sector, particularly in the UAE, Saudi Arabia, and Qatar, with massive investments in commercial buildings, hospitality, and mega-projects, is a major demand driver. The oil & gas industry in the Middle East, with its vast waste heat resources from refineries and processing plants, is a key adopter of absorption chillers for process cooling and air conditioning, seeking to enhance operational efficiency and reduce energy consumption. Furthermore, the expansion of district cooling networks is a prominent trend, with absorption systems being a core component due to their large capacities and ability to integrate with diverse heat sources, including solar thermal. African markets, while nascent, are showing growing interest as industrialization progresses and energy infrastructure develops, with a focus on sustainable solutions that can leverage local resources and reduce reliance on grid electricity.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Absorption Cooling System Market.- Trane Technologies

- Johnson Controls International plc

- Carrier Corporation

- Broad USA Inc.

- Yazaki Corporation

- Thermax Limited

- Kawasaki Thermal Engineering Co. Ltd.

- Shuangliang Eco-Energy Systems Co. Ltd.

- Ebara Refrigeration Equipment & Systems Co., Ltd.

- LG Chem

- Power Partners, LLC

- Cofely (Engie)

- Hitachi Ltd.

- Hyundai Climate Control Co., Ltd.

- Century Corporation

- Robur S.p.A.

- Bosch Thermotechnology Ltd.

- Energy Recovery Inc.

- DAIKIN INDUSTRIES, Ltd.

- Beijing Shuanglong Group Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Absorption Cooling System market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is an absorption cooling system and how does it differ from traditional cooling methods?

An absorption cooling system generates refrigeration or air conditioning using a heat source (like waste heat, natural gas, or solar thermal) instead of electricity to power a compressor. Unlike conventional vapor compression chillers that rely on mechanical compressors to circulate refrigerant, absorption systems use a thermodynamic process involving a refrigerant (e.g., water) and an absorbent (e.g., lithium bromide). This fundamental difference makes them ideal for applications with available waste heat, offering significant energy savings by reducing electricity consumption, lowering operational costs, and minimizing greenhouse gas emissions. They are also known for quieter operation and fewer moving parts.

What are the primary advantages of implementing absorption cooling systems?

The key advantages of absorption cooling systems are multi-faceted, making them a compelling choice for many industrial and commercial applications. Foremost is their exceptional energy efficiency, particularly when utilizing free or low-cost waste heat, leading to substantial reductions in electricity consumption and operational expenses. Environmentally, they use benign refrigerants like water, avoiding ozone-depleting substances and potent greenhouse gases found in many traditional refrigerants. They also contribute to a lower carbon footprint by reducing electricity demand. Furthermore, these systems offer high reliability due to fewer moving parts, resulting in lower maintenance requirements and extended operational lifespans. Their quiet operation and ability to integrate with various heat sources further enhance their appeal for sustainable and cost-effective cooling solutions.

What are the main applications and end-users of absorption cooling technology?

Absorption cooling technology finds widespread application across diverse sectors. Industrially, it is extensively used in chemical processing, oil & gas refineries, power generation (especially in combined heat and power plants), food & beverage processing, and pharmaceutical manufacturing, where abundant waste heat can be converted into useful cooling for processes or air conditioning. In the commercial sector, large buildings such as hospitals, hotels, office complexes, shopping malls, and data centers utilize absorption chillers for efficient and sustainable air conditioning. District cooling networks, which centralize cooling production for multiple buildings, are also significant end-users. While less common, some niche residential applications, particularly those integrated with solar thermal systems, are emerging.

What are the major challenges or restraints hindering the growth of the absorption cooling market?

Despite their numerous benefits, the absorption cooling market faces several significant challenges. The primary restraint is the higher initial capital investment required for these systems compared to conventional electric chillers. This higher upfront cost can be a barrier for potential adopters, especially in smaller commercial projects or in regions with less favorable financing options. Furthermore, the installation and maintenance of absorption chillers can be more complex, often requiring specialized technical expertise, which may not be readily available in all markets. Limited awareness about the long-term energy savings and environmental benefits of absorption technology in some regions also acts as a restraint, as businesses may not fully understand the return on investment. Competition from continuously improving conventional cooling technologies, which often have lower initial costs, also presents a competitive challenge.

How is technological innovation impacting the future of absorption cooling systems?

Technological innovation is profoundly shaping the future of absorption cooling systems, making them more efficient, versatile, and competitive. Key advancements include the development of hybrid absorption-compression chillers that optimize performance under varying loads and heat source availability. Progress in materials science and heat exchanger design is leading to more compact, durable, and highly efficient units. The integration of smart control systems, IoT, and AI-driven analytics is enabling real-time operational optimization, predictive maintenance, and seamless integration with building management systems and smart grids, enhancing reliability and reducing operational costs. Furthermore, ongoing research into new refrigerant-absorbent pairs and the expanded use of renewable heat sources like solar thermal and geothermal energy are pushing the boundaries of sustainable cooling, ensuring absorption technology remains a critical component of future energy landscapes.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager