AC Servo Motors and Drives Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428282 | Date : Oct, 2025 | Pages : 258 | Region : Global | Publisher : MRU

AC Servo Motors and Drives Market Size

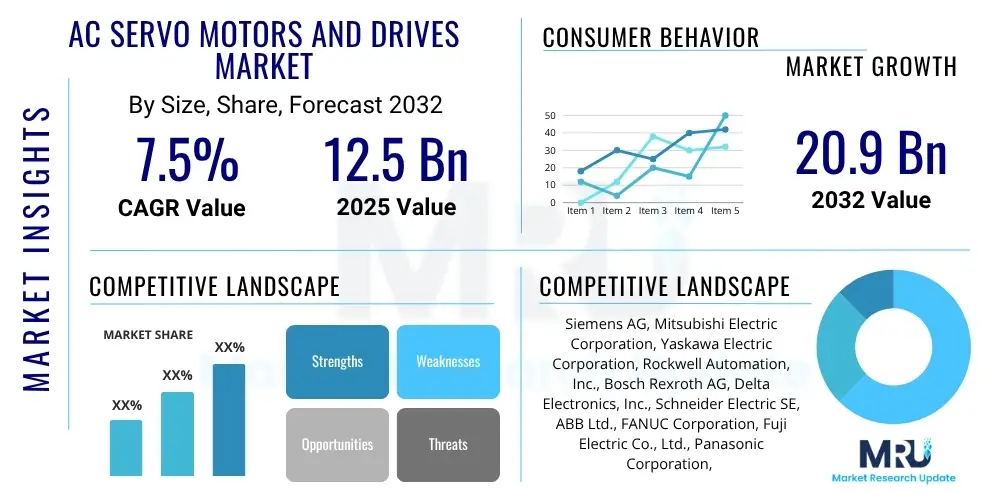

The AC Servo Motors and Drives Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.5% between 2025 and 2032. The market is estimated at USD 12.5 Billion in 2025 and is projected to reach USD 20.9 Billion by the end of the forecast period in 2032.

AC Servo Motors and Drives Market introduction

The AC Servo Motors and Drives Market is a pivotal segment within the global industrial automation landscape, providing high-precision, dynamic, and reliable motion control solutions critical for advanced manufacturing processes. These sophisticated systems integrate an AC servo motor, typically a synchronous permanent magnet motor, with an electronic drive that precisely controls the motor's position, velocity, and torque, based on continuous feedback from an encoder or resolver. This closed-loop control mechanism allows for exceptional accuracy and repeatability, which are indispensable in modern industrial applications. The technology enables machines to perform intricate tasks with unparalleled precision and speed, significantly contributing to enhanced productivity and operational efficiency across diverse sectors.

Major applications for AC servo motors and drives span a wide array of industries, including but not limited to robotics, Computer Numerical Control (CNC) machinery, packaging equipment, material handling systems, printing presses, and textile manufacturing. These systems are instrumental in facilitating the automation of complex tasks, reducing human intervention, and ensuring consistent product quality. The primary benefits derived from the adoption of AC servo systems include superior energy efficiency, high dynamic response, low maintenance requirements, and robust reliability, leading to substantial reductions in operational costs and improvements in overall system performance. The market's growth is predominantly driven by the accelerating demand for industrial automation, the proliferation of Industry 4.0 initiatives, and the increasing global emphasis on precision manufacturing to meet stringent quality standards and competitive market demands.

AC Servo Motors and Drives Market Executive Summary

The AC Servo Motors and Drives Market is experiencing robust growth, propelled by significant advancements in industrial automation and the pervasive adoption of smart manufacturing technologies worldwide. Current business trends indicate a strong emphasis on integrating these systems with advanced communication protocols and IoT platforms to enable real-time data exchange, predictive maintenance, and remote diagnostics, thus enhancing operational intelligence. Companies are increasingly investing in research and development to offer more compact, energy-efficient, and intelligent servo solutions, capable of seamless integration into complex production environments. Furthermore, the market is characterized by strategic collaborations, mergers, and acquisitions aimed at expanding product portfolios, enhancing technological capabilities, and strengthening market presence across key geographical regions. Sustainability considerations are also gaining prominence, driving demand for more energy-efficient and environmentally conscious servo drive technologies.

From a regional perspective, Asia Pacific continues to dominate the market, primarily due to the rapid industrialization, burgeoning manufacturing sector, and significant investments in automation infrastructure in countries such as China, Japan, South Korea, and India. Europe also represents a mature but innovation-driven market, with Germany and Italy at the forefront of adopting advanced manufacturing technologies and stringent quality control standards. North America is experiencing steady growth, fueled by technological advancements, the reshoring of manufacturing activities, and strong demand from the aerospace, automotive, and semiconductor industries for high-precision motion control solutions. Segment-wise, the robotics and machine tools sectors remain the largest consumers of AC servo motors and drives, driven by continuous innovation and the increasing sophistication of automated production lines. However, emerging applications in logistics automation, medical devices, and food and beverage processing are also contributing significantly to market expansion, indicating a diversified growth trajectory across various industrial verticals.

AI Impact Analysis on AC Servo Motors and Drives Market

Common user inquiries regarding the influence of Artificial Intelligence (AI) on the AC Servo Motors and Drives Market frequently revolve around how AI can enhance the intelligence, efficiency, and reliability of these critical components. Users are particularly interested in AI's potential to revolutionize predictive maintenance, enabling proactive interventions to minimize downtime and extend equipment lifespan. There is also significant curiosity about AI-driven adaptive control algorithms that can optimize servo performance in real-time, responding dynamically to changing load conditions and environmental factors. Furthermore, users explore how AI facilitates the development of more autonomous manufacturing systems, human-robot collaboration, and advanced fault detection capabilities within servo-driven machinery, ultimately seeking insights into new levels of operational excellence and expanded application possibilities for these sophisticated motion control systems.

- Predictive Maintenance: AI algorithms analyze real-time operational data from servo motors and drives to predict potential failures, allowing for scheduled maintenance and significantly reducing unexpected downtime and costly repairs.

- Adaptive Control Systems: AI enables servo drives to learn and adapt to varying load conditions and environmental changes, dynamically optimizing parameters for enhanced precision, speed, and energy efficiency in real-time operation.

- Autonomous Operations: Integration of AI with servo systems facilitates the development of more autonomous robotic and manufacturing processes, minimizing human intervention and enabling complex tasks to be performed with higher consistency.

- Energy Optimization: AI-driven analytics can identify patterns in energy consumption, leading to optimized motor operation and drive settings that reduce overall power usage, aligning with sustainability goals and lowering operating costs.

- Human-Robot Collaboration (Cobots): AI enhances the safety and responsiveness of collaborative robots utilizing servo technology, allowing them to work alongside humans more intuitively and efficiently, opening new avenues for flexible automation.

- Advanced Fault Detection and Diagnostics: AI models can detect subtle anomalies in servo system performance, identifying incipient faults long before they manifest as critical failures, improving system reliability and diagnostic speed.

- Enhanced Process Optimization: AI analyzes data from servo-controlled processes to identify bottlenecks and inefficiencies, recommending adjustments that can improve throughput, quality, and overall production line performance.

- Machine Learning for Tuning: AI algorithms can automate and optimize the complex tuning process of servo drives, achieving superior performance parameters faster and more reliably than manual tuning, even for non-expert users.

DRO & Impact Forces Of AC Servo Motors and Drives Market

The AC Servo Motors and Drives Market is shaped by a complex interplay of various driving factors, inherent restraints, and emerging opportunities, all of which contribute to its dynamic growth trajectory and influence its future direction. A primary driver is the escalating global demand for industrial automation, fueled by the need for increased productivity, efficiency, and precision in manufacturing across virtually all sectors. The widespread adoption of Industry 4.0 principles, emphasizing smart factories, interconnected systems, and data-driven decision-making, further propels the integration of advanced servo technologies. Furthermore, the rising cost of manual labor, coupled with a persistent shortage of skilled workers in many economies, incentivizes businesses to invest in automated solutions that rely heavily on precise motion control, directly boosting the demand for AC servo motors and drives. Technological advancements leading to more compact, powerful, and energy-efficient servo systems also act as a significant market driver, expanding the applicability of these solutions.

Despite the strong growth drivers, the market faces several notable restraints. The relatively high initial investment required for AC servo systems compared to conventional motor solutions can be a barrier for small and medium-sized enterprises (SMEs) or industries with limited capital budgets. The technical complexity involved in designing, integrating, and maintaining sophisticated servo systems necessitates a highly skilled workforce, and the shortage of such specialized personnel can impede widespread adoption and efficient operation. Additionally, the intensive research and development costs associated with developing next-generation servo technologies, coupled with intense market competition, can put pressure on profit margins for manufacturers. The global supply chain volatility, especially concerning critical electronic components and rare earth magnets, also poses a recurrent challenge affecting production and delivery timelines.

Conversely, numerous opportunities are emerging that promise to unlock new growth avenues for the AC Servo Motors and Drives Market. The seamless integration of AC servo systems with cutting-edge technologies like Artificial Intelligence (AI), Machine Learning (ML), and the Internet of Things (IoT) offers significant potential for creating smarter, more autonomous, and predictive motion control solutions. This integration enables features such as predictive maintenance, real-time diagnostics, and adaptive control, enhancing overall system intelligence and efficiency. Furthermore, the expansion into emerging economies, particularly in Asia Pacific and Latin America, where industrial infrastructure is rapidly developing, presents vast untapped markets for automation technologies. The growing trend towards customized and application-specific servo solutions, tailored to unique industrial requirements, also offers manufacturers an opportunity to differentiate their offerings and capture niche market segments. The increasing focus on energy efficiency and sustainability globally further creates opportunities for advanced servo technologies that can significantly reduce power consumption in industrial processes.

Segmentation Analysis

The AC Servo Motors and Drives Market is comprehensively segmented to provide a granular understanding of its diverse components and dynamics. This segmentation, typically categorized by type, voltage, application, and end-user industry, allows for a detailed analysis of market trends, identifying key growth areas and strategic opportunities within various industrial contexts. Each segment represents distinct technological requirements, operational preferences, and market demand patterns, offering valuable insights for stakeholders, manufacturers, and investors aiming to navigate the complexities of this sophisticated market. Understanding these segments is crucial for effective product development, market positioning, and strategic planning in the industrial automation sector.

- By Type: The market for AC Servo Motors and Drives is predominantly categorized based on the specific type of motor and drive unit, each offering distinct performance characteristics and suitability for various industrial demands.

- AC Servo Motors: These motors are designed for high precision and dynamic control, crucial for modern automation processes requiring exact and repeatable motion.

- Synchronous AC Servo Motors: Characterized by permanent magnets in the rotor, offering high power density, excellent dynamic response, and precise speed and position control, widely used in demanding applications like robotics, CNC machinery, and high-speed packaging.

- Asynchronous AC Servo Motors (Induction Motors): Utilized in applications requiring robust performance and reliability, though generally less dynamic than synchronous motors, they are suitable for tasks needing stable speed over a broad range and high-torque applications where extreme precision is not the primary requirement.

- AC Servo Drives: These electronic controllers manage the motor's operation based on feedback signals, crucial for system performance, efficiency, and integration within the automation framework.

- Analog Servo Drives: Older technology, offering continuous signal control, often used in simpler, cost-sensitive applications where extreme precision and advanced communication features are not the primary requirements, providing basic yet reliable motion control.

- Digital Servo Drives: Employ microprocessors for precise control, offering advanced functionalities like auto-tuning, diagnostic capabilities, multi-axis synchronization, and robust communication protocols (e.g., EtherCAT, PROFINET), making them suitable for complex, high-performance systems and Industry 4.0 environments.

- Hybrid Servo Drives: Combining aspects of both stepper and servo systems, these drives offer an intermediate solution, often used in applications where a balance between cost-effectiveness, high torque at low speeds, and performance is desired, bridging the gap for various industrial needs.

- AC Servo Motors: These motors are designed for high precision and dynamic control, crucial for modern automation processes requiring exact and repeatable motion.

- By Voltage: Segmentation by voltage highlights the diverse power requirements and application scales, from compact, low-power devices to heavy-duty industrial machinery.

- Low Voltage (<48V): Primarily used in smaller, compact automation systems, battery-powered devices, and applications where safety standards for low voltage are critical, such as certain medical equipment or mobile robotics.

- Medium Voltage (48V-400V): The most common range for industrial automation, catering to a vast majority of applications including general manufacturing machinery, packaging lines, and CNC machines, balancing power and efficiency.

- High Voltage (>400V): Employed in large-scale industrial machinery, heavy material handling equipment, and high-power applications where greater torque and speed are required, often in specialized heavy industry environments.

- By Application: This segmentation focuses on the specific industrial processes or machines where AC servo motors and drives are functionally integrated, showcasing their versatility.

- Robotics: Crucial for enabling precise, repeatable, and dynamic movements in industrial robots, including articulated robots, SCARA robots, and collaborative robots (cobots) for tasks like assembly, welding, and material handling.

- Machine Tools: Essential for the accurate control of axes in CNC milling machines, lathes, grinding machines, and other precision cutting and shaping equipment, ensuring high quality and surface finish.

- Packaging: Drives high-speed and accurate operations in packaging machinery, including filling, sealing, labeling, and palletizing, optimizing throughput and reducing waste in production lines.

- Material Handling: Used in conveyor systems, automated guided vehicles (AGVs), automated storage and retrieval systems (AS/RS), and gantry systems for efficient and precise movement of goods within factories and warehouses.

- Printing: Critical for precise web tension control, registration, and color alignment in printing presses, ensuring high-quality output and minimizing errors in commercial and industrial printing.

- Textile: Enables synchronized movements in weaving, knitting, spinning, and cutting machines, improving efficiency and product quality in the textile manufacturing process.

- Medical: Found in precision medical devices, diagnostic equipment, laboratory automation, and rehabilitation robotics, where accuracy, reliability, and smooth motion are paramount for patient safety and efficacy.

- Food & Beverage: Utilized in processing, packaging, and bottling lines, requiring hygienic designs and precise control for handling products and ensuring compliance with strict food safety standards.

- Semiconductor: Crucial for ultra-high precision positioning in semiconductor manufacturing equipment, such as wafer handling, inspection, and lithography machines, where micron-level accuracy is essential.

- Other Applications: Includes specialized applications in aerospace and defense, woodworking, glass processing, and various custom automation solutions requiring precise and dynamic motion control.

- By End-User Industry: This segment categorizes the market based on the primary industry that procures and utilizes these servo systems, reflecting broad economic trends.

- Manufacturing: A broad category encompassing general manufacturing processes that rely on automation for assembly, machining, and quality control across various product types.

- Automotive: Utilizes servo systems extensively in car manufacturing for robotics, welding, painting, assembly lines, and engine production, ensuring precision and high throughput.

- Electronics & Semiconductor: Critical for manufacturing electronic components, circuit boards, and semiconductors, where extreme precision, speed, and cleanroom compatibility are mandatory.

- Healthcare: Includes medical device manufacturers, pharmaceutical production, and laboratory automation, where sterile environments and precise dosage or movement are essential.

- Aerospace & Defense: Applications range from precision component manufacturing and assembly to simulation and testing equipment, demanding robust and highly reliable motion control.

- Packaging: Encompasses industries that package products, from food and beverage to consumer goods, utilizing servo systems for efficient and accurate packaging operations.

- Other End-User Industries: Includes energy, agriculture, construction, and logistics sectors, which are increasingly adopting automation for enhanced operational efficiency and resource management.

Value Chain Analysis For AC Servo Motors and Drives Market

The value chain for the AC Servo Motors and Drives Market is a complex and interconnected network, beginning with the sourcing of raw materials and extending through various stages of manufacturing, assembly, distribution, and ultimate deployment by end-users. At the upstream end, the process involves the procurement of essential raw materials and specialized components critical for the fabrication of both motors and drives. This includes high-grade steel, copper, and aluminum for motor windings and casings, as well as rare earth metals for permanent magnets in synchronous motors, which are often subject to geopolitical and supply chain fluctuations. Furthermore, the upstream segment encompasses the manufacturing of advanced electronic components such as semiconductors, microcontrollers, digital signal processors (DSPs), and power modules, which form the core intelligence and power electronics of servo drives, requiring sophisticated fabrication processes and often relying on a specialized global supply base.

Moving downstream, the value chain encompasses the sophisticated processes of component integration and system assembly, where motors and drives are meticulously put together, tested, and often paired with feedback devices like encoders to form complete servo systems. This stage also includes the development of proprietary software and firmware that govern the precise control algorithms and communication protocols essential for the system's performance. The distribution channel plays a crucial role in connecting manufacturers with end-users, involving both direct and indirect sales approaches. Direct sales often cater to large original equipment manufacturers (OEMs) and strategic industrial clients who require customized solutions, direct technical support, and long-term partnerships. This direct engagement allows manufacturers to provide bespoke engineering and integration services, fostering strong relationships and ensuring optimal system performance tailored to specific application requirements.

Indirect distribution typically involves a network of authorized distributors, system integrators, and value-added resellers (VARs) who provide broader market coverage, local support, and often integrate servo systems into larger automation solutions for a diverse customer base, including small and medium-sized enterprises (SMEs). These intermediaries play a vital role in providing local stock, technical assistance, and pre-sales and post-sales support, bridging the gap between sophisticated manufacturers and varied end-user needs. The final stage involves the installation, commissioning, and ongoing maintenance of AC servo systems at the end-user's facility, where system integrators and field service engineers ensure optimal operation and provide necessary technical support and troubleshooting. This entire value chain emphasizes precision manufacturing, advanced technological capabilities, and a robust support infrastructure to deliver high-performance motion control solutions to the global industrial automation sector.

AC Servo Motors and Drives Market Potential Customers

The potential customers for AC Servo Motors and Drives represent a broad spectrum of industries and organizations that prioritize precision, efficiency, and reliability in their automated processes. At the forefront are manufacturers across diverse sectors, including automotive, electronics and semiconductor, packaging, material handling, and general industrial manufacturing. These entities constantly seek to enhance their production capabilities, reduce operational costs, and improve product quality by implementing advanced automation solutions that rely heavily on the dynamic and accurate motion control provided by servo systems. Within the automotive industry, for instance, servo motors are indispensable for robotic welding, painting, assembly lines, and component manufacturing, where exacting standards for repeatability and speed are paramount.

Beyond traditional manufacturing, the customer base extends to specialized applications and emerging markets. Companies involved in the development and deployment of robotics, from industrial articulated arms to collaborative robots (cobots), are significant buyers, as servo drives are the core components enabling fluid and precise movements. Furthermore, original equipment manufacturers (OEMs) that build machine tools, textile machinery, printing presses, and medical diagnostic equipment constitute a substantial segment of potential customers, as they integrate servo systems directly into their advanced products. The food and beverage sector, with its stringent hygiene requirements and demand for high-speed processing and packaging, also represents a growing customer segment for specialized, often stainless-steel, servo solutions. Moreover, the increasing adoption of automated guided vehicles (AGVs) and automated storage and retrieval systems (AS/RS) in logistics and warehousing further expands the customer landscape, showcasing the pervasive need for precise and controlled motion in modern industrial and commercial environments.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 12.5 Billion |

| Market Forecast in 2032 | USD 20.9 Billion |

| Growth Rate | 7.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Siemens AG, Mitsubishi Electric Corporation, Yaskawa Electric Corporation, Rockwell Automation, Inc., Bosch Rexroth AG, Delta Electronics, Inc., Schneider Electric SE, ABB Ltd., FANUC Corporation, Fuji Electric Co., Ltd., Panasonic Corporation, Beckhoff Automation GmbH & Co. KG, Omron Corporation, KEBA AG, Estun Automation Co., Ltd., Lenze SE, Parker Hannifin Corporation, Nidec Corporation, Oriental Motor Co., Ltd., Kollmorgen (Regal Rexnord) |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

AC Servo Motors and Drives Market Key Technology Landscape

The AC Servo Motors and Drives Market is continuously evolving, driven by significant advancements in underlying technologies that enhance performance, efficiency, connectivity, and intelligence. A cornerstone of this technological landscape is the sophisticated control algorithms, particularly Field-Oriented Control (FOC) or vector control, which enable highly precise manipulation of motor torque and speed by independently controlling the motor's flux and torque-producing components. This allows for superior dynamic response and efficiency compared to traditional control methods. Furthermore, the integration of powerful Digital Signal Processors (DSPs) and high-speed microcontrollers in servo drives is pivotal, facilitating complex computations for real-time control, auto-tuning functions that simplify setup, and advanced diagnostic capabilities that enhance system reliability and ease of maintenance.

Connectivity and communication technologies are also transforming the market, with industrial Ethernet protocols such as EtherCAT, PROFINET, and SERCOS III becoming standard for high-speed, synchronized multi-axis control. These protocols enable seamless integration of servo systems into broader automation architectures, supporting Industry 4.0 initiatives by facilitating real-time data exchange and remote management. The use of high-resolution absolute encoders provides precise position feedback, crucial for applications demanding micron-level accuracy and ensuring that the system retains its position information even after power cycling. Moreover, the emergence of sensorless control techniques, although not universally applicable, offers potential cost reductions and simplifies wiring in certain scenarios. The ongoing trend towards modular and compact designs also plays a crucial role, allowing for greater flexibility in machine design and easier integration into space-constrained applications, while integrated safety functions within drives simplify compliance with machine safety standards and enhance operational security.

Regional Highlights

- Asia Pacific (APAC): Dominates the global market due to rapid industrialization, extensive manufacturing base in countries like China, Japan, South Korea, and India, and significant government investments in automation and smart factory initiatives. The region is a key producer and consumer of AC servo systems, driven by strong demand from automotive, electronics, and machine tools industries.

- Europe: A mature market characterized by high adoption of advanced manufacturing technologies, stringent quality standards, and strong focus on R&D. Countries such as Germany, Italy, and Switzerland are leaders in developing and deploying high-precision servo systems, especially in machine tools, robotics, and specialized industrial machinery sectors.

- North America: Exhibits steady growth fueled by technological innovation, increasing demand for automation in aerospace, automotive, and semiconductor industries, and growing emphasis on revitalizing domestic manufacturing. Investments in smart factories and advanced robotics are key drivers for the AC servo market in this region.

- Latin America: An emerging market experiencing increasing industrialization and investments in manufacturing infrastructure, particularly in countries like Brazil and Mexico. The adoption of AC servo motors and drives is on the rise as industries seek to improve efficiency and competitiveness, though growth can be influenced by economic stability and foreign investment.

- Middle East and Africa (MEA): Shows potential for growth, driven by economic diversification efforts, infrastructure development projects, and rising adoption of automation in sectors such as oil and gas, manufacturing, and logistics. Countries like UAE and Saudi Arabia are investing in advanced technologies to modernize their industrial bases.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the AC Servo Motors and Drives Market.- Siemens AG: A global powerhouse in industrial automation, offering a comprehensive portfolio of SIMOTICS servo motors and SINAMICS drives known for their precision, integration, and intelligence across various industrial applications.

- Mitsubishi Electric Corporation: A leading Japanese manufacturer providing a wide range of MELSERVO series servo amplifiers and motors, highly regarded for their high speed, high accuracy, and energy-saving capabilities.

- Yaskawa Electric Corporation: Renowned for its MOTION CONTROL technology, Yaskawa offers a broad selection of SERVOPACK servo drives and SERVOMOTORs, particularly dominant in the robotics and machine tool sectors globally.

- Rockwell Automation, Inc.: A major American provider of industrial automation and information solutions, offering Allen-Bradley Kinetix servo drives and motors integrated with their comprehensive automation platforms for seamless control.

- Bosch Rexroth AG: A subsidiary of Robert Bosch GmbH, specializing in drive and control technology, providing highly dynamic and precise IndraDrive and IndraDyn servo systems for machinery and plant engineering.

- Delta Electronics, Inc.: A Taiwan-based company known for its industrial automation products, including a robust lineup of AC servo motors and drives that deliver high responsiveness and stable performance for diverse applications.

- Schneider Electric SE: A global specialist in energy management and automation, offering Lexium servo drives and motors that provide flexible and scalable motion control solutions for industrial machinery.

- ABB Ltd.: A Swedish-Swiss multinational corporation providing advanced industrial automation solutions, including high-performance servo motors and drives that ensure reliable and efficient motion control in various industries.

- FANUC Corporation: A Japanese company primarily known for its robotics and CNC systems, also a significant provider of high-reliability servo motors and drives that are deeply integrated into its automation offerings.

- Fuji Electric Co., Ltd.: A Japanese manufacturer offering a wide range of industrial equipment, including advanced AC servo systems designed for high precision and efficiency in demanding automation tasks.

- Panasonic Corporation: Provides MINAS series AC servo motors and drives, known for their compact size, high speed, and excellent control performance, suitable for a broad spectrum of industrial applications.

- Beckhoff Automation GmbH & Co. KG: A German company recognized for its PC-based control technology, offering high-performance EtherCAT-based servo drives and motors for highly dynamic and precise motion control.

- Omron Corporation: A Japanese leader in industrial automation, providing AC servo motors and drives that are designed for ease of integration, high speed, and precision in various manufacturing environments.

- KEBA AG: An Austrian automation company delivering flexible and powerful KEBA Kemotion servo drives and motors, particularly strong in robotics and plastics processing machinery.

- Estun Automation Co., Ltd.: A Chinese company specializing in industrial automation, offering a competitive range of AC servo systems known for their reliability and cost-effectiveness in the global market.

- Lenze SE: A German specialist in motion centric automation, providing a comprehensive portfolio of servo motors and drives optimized for energy efficiency and dynamic machine control.

- Parker Hannifin Corporation: A global leader in motion and control technologies, offering a wide array of AC servo motors and drives tailored for precision applications in various industrial sectors.

- Nidec Corporation: A Japanese manufacturer of motors and drives, providing a broad range of servo solutions known for their compact design and high performance, catering to diverse industrial needs.

- Oriental Motor Co., Ltd.: A Japanese company providing a wide range of fractional horsepower motors, including AC servo motors and drives, focused on precision and energy efficiency for smaller to medium-sized applications.

- Kollmorgen (Regal Rexnord): A leading provider of high-performance motion control systems, offering a vast array of AC servo motors and drives renowned for their precision, reliability, and customizability for demanding industrial applications.

Frequently Asked Questions

What are AC servo motors and drives?

AC servo motors and drives are sophisticated industrial components forming a closed-loop motion control system. An AC servo motor is an electric motor (typically synchronous permanent magnet) designed for precise speed, position, and torque control. An AC servo drive is an electronic amplifier that powers and controls the servo motor based on feedback from an encoder, ensuring highly accurate and dynamic movements essential for automation.

What are the primary applications of AC servo motors and drives?

Primary applications for AC servo motors and drives are found in industries requiring high precision, speed, and repeatability. These include industrial robotics, Computer Numerical Control (CNC) machinery, high-speed packaging equipment, advanced material handling systems, printing presses, textile manufacturing, medical devices, and semiconductor production, where exact motion control is paramount for operational efficiency and product quality.

How does Industry 4.0 influence the AC servo motors and drives market?

Industry 4.0 significantly influences the AC servo motors and drives market by driving demand for smart, connected, and highly efficient motion control solutions. It fosters the integration of servo systems with IoT platforms and industrial Ethernet for real-time data exchange, predictive maintenance, and remote diagnostics. This enables more intelligent, autonomous, and flexible manufacturing processes, enhancing productivity and supporting the vision of smart factories globally.

What are the key benefits of using AC servo systems?

Key benefits of using AC servo systems include exceptional precision and accuracy in position, velocity, and torque control, leading to high-quality output and minimal waste. They offer superior dynamic response, allowing for rapid acceleration and deceleration. Furthermore, AC servo systems provide high energy efficiency, robust reliability, and require less maintenance compared to traditional motor systems, contributing to lower operational costs and increased productivity in automated environments.

What technological trends are shaping the AC servo motors and drives market?

Technological trends shaping the AC servo motors and drives market include the increased integration of AI and Machine Learning for adaptive control and predictive maintenance, advancements in industrial Ethernet protocols (e.g., EtherCAT) for high-speed communication, and the development of more compact and energy-efficient designs. There is also a growing emphasis on integrated safety functions, higher resolution feedback systems, and modular solutions to meet the evolving demands of sophisticated industrial automation.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager