Acoustic Diaphragm Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430611 | Date : Nov, 2025 | Pages : 257 | Region : Global | Publisher : MRU

Acoustic Diaphragm Market Size

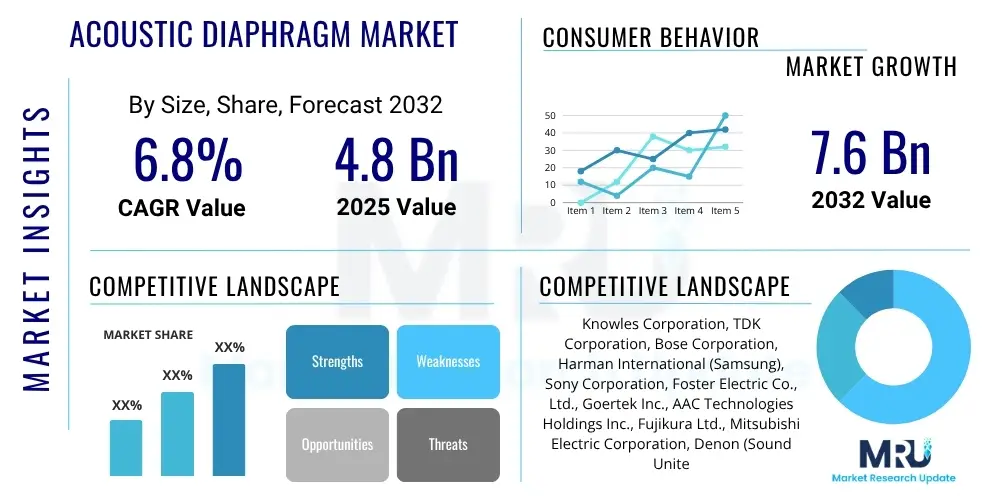

The Acoustic Diaphragm Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at USD 4.8 Billion in 2025 and is projected to reach USD 7.6 Billion by the end of the forecast period in 2032.

Acoustic Diaphragm Market introduction

Acoustic diaphragms represent critical engineering components indispensable in the functionality of sound reproduction and detection systems, serving as sophisticated transducers that meticulously convert electrical signals into palpable mechanical vibrations to generate audible sound, or conversely, to transduce ambient sound waves into electrical impulses. These exquisitely crafted, thin, and remarkably flexible membranes are fabricated with stringent precision, incorporating an array of advanced materials such as high-performance polymers, specialized papers, various metals, and cutting-edge composite substances. The selection of each material is meticulously orchestrated based on its unique acoustic characteristics, including but not limited to inherent stiffness, effective damping capabilities, and optimized mass, all of which are paramount in dictating the diaphragm's ultimate acoustic performance. The fundamental role of an acoustic diaphragm is to efficiently displace air, thereby initiating and propagating sound waves, or to responsively vibrate in direct reaction to incoming sound waves, subsequently producing discernible electrical signals. The intrinsic quality and characteristics of an acoustic diaphragm fundamentally determine the fidelity, expansive frequency response, and overall sound clarity delivered by the audio device in which it is integrated. This versatility renders these components indispensable across an extensive spectrum of applications, ranging from sophisticated high-fidelity consumer electronics to highly specialized industrial instrumentation and advanced medical diagnostic apparatus.

The range of major applications for acoustic diaphragms is remarkably broad, spanning the rapidly evolving domain of consumer electronics, where they are integral to premium headphones, high-definition loudspeakers, sensitive microphones, and advanced smart home devices, playing a pivotal role in delivering crystal-clear, immersive, and dynamically rich audio experiences. Within the burgeoning automotive sector, acoustic diaphragms are seamlessly integrated into sophisticated in-car audio systems, ensuring the reproduction of superior sound quality and an unparalleled acoustic environment throughout the vehicle cabins, significantly enhancing the driving experience. The highly demanding medical field extensively utilizes these specialized diaphragms in precision instruments such as electronic stethoscopes, discreet hearing aids, and cutting-edge ultrasonic diagnostic equipment, applications that necessitate unparalleled sensitivity, absolute accuracy, and unwavering reliability for critical diagnostic purposes. From an industrial perspective, these diaphragms find utility in a variety of advanced sensors, high-decibel alarms, and non-destructive testing devices, where their precise acoustic response and robust construction are vital for operational integrity and safety. The inherent advantages and numerous benefits derived from high-performance acoustic diaphragms are manifold, encompassing superior sound clarity, an expansive and true-to-life frequency response, enhanced structural durability against wear and tear, and significantly improved power handling capabilities, all of which collectively contribute to the delivery of a richer, more reliable, and consistently high-quality audio output across all usage scenarios. These compelling advantages are absolutely pivotal in addressing and meeting the increasingly sophisticated and escalating consumer demand for state-of-the-art audio technologies, as well as fulfilling the stringent requirements of highly specialized and mission-critical applications.

The sustained growth and dynamic evolution of the market for acoustic diaphragms are substantially propelled by a confluence of several pivotal driving factors that continually reshape the industry landscape. Foremost among these is the relentless pace of innovation and the expansive growth observed within the consumer electronics sector, particularly evidenced by the pervasive proliferation of smartphones, the widespread adoption of wireless headphones, and the increasing integration of smart speakers into daily life, which collectively generate a robust and unwavering demand for superior quality audio components. The automotive industry's steadfast and accelerating commitment to developing and integrating highly advanced infotainment systems and delivering premium audio experiences in its new vehicle models acts as a powerful catalyst, further propelling significant market expansion and demanding more sophisticated diaphragm solutions. Moreover, the continuous and groundbreaking advancements in material science are profoundly influencing the market, facilitating the conceptualization and development of next-generation diaphragms endowed with remarkably improved acoustic properties, significantly lighter weight profiles, and unparalleled long-term durability. These material innovations are instrumental in enabling the creation of even more sophisticated, compact, and energy-efficient audio devices that push the boundaries of performance. Furthermore, the burgeoning adoption of advanced voice-activated assistants, coupled with the widespread integration of active noise-cancelling technologies across various devices, emphatically underscores the indispensable and critical role played by advanced acoustic diaphragms, compelling manufacturers to continually innovate, refine, and diversify their product offerings to meet these escalating technological demands and consumer expectations.

Acoustic Diaphragm Market Executive Summary

The Acoustic Diaphragm Market is currently experiencing robust business trends characterized by a strong emphasis on material innovation, precision manufacturing, and strategic market diversification. Manufacturers are increasingly exploring and adopting advanced composite materials like graphene, beryllium, specialized polymers such as PEEK and PEN, and hybrid formulations to significantly enhance acoustic performance, achieve substantial weight reduction, and improve overall durability. This focus on material science directly addresses the escalating demand for high-fidelity audio in increasingly compact and portable form factors across a multitude of end-use applications. Strategic collaborations and partnerships between pioneering material suppliers, specialized diaphragm manufacturers, and leading audio device OEMs are becoming more prevalent. These alliances foster a synergistic approach to co-development, enabling the creation of next-generation diaphragms that are meticulously tailored for specific acoustic requirements and operational environments, ensuring optimal integration and performance. Furthermore, customization and superior integration capabilities are emerging as pivotal business trends, as Original Equipment Manufacturers actively seek unique and proprietary acoustic solutions that provide a tangible competitive edge and differentiate their products within an intensely competitive market landscape. This pursuit often leads to the development of highly specialized diaphragm designs, bespoke manufacturing processes, and rigorous quality control methodologies. Concurrently, a growing commitment to sustainability is influencing product development, with an increasing number of companies exploring eco-friendly materials and energy-efficient manufacturing processes to align with global environmental objectives and consumer preferences for sustainable products.

Regionally, the market exhibits dynamic and varied growth patterns, with the Asia Pacific (APAC) region solidifying its position as the dominant force and simultaneously experiencing the most rapid growth rate. This unparalleled ascendancy is primarily attributable to the colossal and continuously expanding manufacturing base for consumer electronics located in economic powerhouses such as China, South Korea, Japan, and India. This robust production ecosystem is complemented by a rapidly expanding middle class across these nations, coupled with increasing disposable incomes, which collectively lead to higher adoption rates of a wide array of audio devices, from entry-level headphones to advanced smart home audio systems. In contrast, North America and Europe represent mature markets within the acoustic diaphragm industry. These regions are characterized by stable and consistent demand for premium audio products, coupled with relentless innovation within the professional audio, automotive, and specialized industrial sectors. Here, the emphasis remains firmly on technological advancements, precision engineering, and the development of niche market acoustic solutions. Consequently, there is a strong focus on extensive research and development initiatives aimed at producing cutting-edge diaphragm technologies. Emerging markets in Latin America and the Middle East & Africa regions are also demonstrating promising growth trajectories, driven by increasing urbanization, accelerating digitalization, and the rising penetration of consumer electronics, which collectively present significant future opportunities for sustained market expansion and investment.

Segment trends within the acoustic diaphragm market underscore distinct areas of technological advancement and concentrated growth. From a material perspective, the market is witnessing a notable shift and a surge in demand for lightweight, yet highly rigid materials that offer superior sound reproduction capabilities. This trend signifies a significant evolution beyond traditional paper cones towards innovative advanced polymers, sophisticated metals, and revolutionary composite materials. The application segment continues to be predominantly driven by consumer electronics, which remains a primary catalyst for innovation, particularly in the ever-evolving categories of headphones, earphones, and smart speakers. However, the automotive audio systems and specialized medical devices sectors are concurrently demonstrating substantial growth, propelled by increasingly stringent performance requirements, the demand for enhanced durability, and complex technological integration within their respective products. The escalating consumer demand for advanced noise-cancellation technologies and highly immersive audio experiences is profoundly influencing contemporary diaphragm design. This has led to the exploration and implementation of multi-layered diaphragm structures, optimized geometric configurations, and advanced material combinations to achieve superior acoustic isolation and sound clarity. Furthermore, the burgeoning adoption of voice recognition systems and smart assistant technologies is significantly bolstering the imperative need for highly sensitive, extraordinarily accurate, and incredibly responsive microphone diaphragms. This trend unequivocally points towards a diversified and robust growth trajectory across a multitude of end-use applications for advanced acoustic diaphragm solutions.

AI Impact Analysis on Acoustic Diaphragm Market

User questions related to the impact of AI on the Acoustic Diaphragm Market frequently revolve around how artificial intelligence can fundamentally optimize and revolutionize design and manufacturing processes, substantially enhance product performance, and enable entirely new functionalities within audio devices. Key thematic concerns and areas of interest consistently emerge, focusing on the transformative potential for AI-driven material discovery and subsequent optimization of composite structures, the strategic deployment of machine learning algorithms for predictive maintenance within complex manufacturing lines, and AI's overarching role in conceptualizing and creating adaptive acoustic systems. Such adaptive systems would possess the inherent capability to intelligently adjust sound profiles in real-time, based on dynamically changing environmental factors or highly nuanced individual user preferences and biometric data. Concerns often touch upon the initial significant capital investment required for comprehensive AI integration across the value chain, coupled with the critical need for specialized expertise and skilled personnel to effectively implement and manage these advanced AI solutions. Despite these considerations, expectations are demonstrably high for AI to usher in a new era for acoustic diaphragm development, promising more efficient production cycles, the realization of unprecedented levels of superior sound quality, and the creation of highly personalized, context-aware audio experiences that redefine user interaction with sound.

- AI-driven material discovery and synthesis: Accelerates the identification, simulation, and development of novel materials with optimized acoustic properties for diaphragms, significantly reducing traditional research and development timelines and costs.

- Generative design optimization for diaphragm geometries: Utilizes AI algorithms to rapidly explore and generate millions of potential design iterations, leading to innovative diaphragm shapes and structures that inherently improve sound fidelity, enhance acoustic efficiency, and reduce distortion.

- Predictive maintenance in manufacturing lines: Machine learning models analyze vast datasets from production equipment to anticipate potential mechanical failures or process deviations, minimizing unscheduled downtime, reducing material waste, and ensuring consistent product quality.

- Automated quality control and defect detection: AI-powered vision systems, coupled with advanced sensor arrays, are deployed to detect microscopic imperfections, material inconsistencies, and structural defects in manufactured diaphragms with higher accuracy and significantly greater speed than conventional human inspection methods.

- Personalized and adaptive acoustic experiences: AI algorithms enable the development of intelligent acoustic systems that can dynamically tune diaphragm performance and sound output in real-time, adjusting to ambient noise levels, individual user biometrics, auditory preferences, or the specific type of audio content being consumed.

- Enhanced active noise cancellation capabilities: AI algorithms work in sophisticated conjunction with advanced diaphragm designs to dynamically identify, analyze, and counter unwanted sound frequencies, thereby significantly improving the performance and effectiveness of active noise-cancelling devices.

- Supply chain optimization and demand forecasting: AI models assist in the meticulous management of raw material procurement, optimizing inventory levels, streamlining logistics, and accurately predicting market demand fluctuations, leading to more efficient production scheduling and reduced operational costs.

- Advanced acoustic simulation and modeling: AI significantly enhances the accuracy, speed, and computational efficiency of complex acoustic simulations, allowing engineers to conduct more precise predictions of diaphragm behavior under various operational conditions, thereby refining design and prototyping processes.

DRO & Impact Forces Of Acoustic Diaphragm Market

The Acoustic Diaphragm Market is influenced by a highly intricate and dynamic interplay of drivers, restraints, opportunities, and broader impact forces that collectively shape its strategic trajectory and growth potential. Key market drivers encompass the ever-escalating and insatiable demand for high-fidelity audio across the vast landscape of consumer electronics, ranging from premium headphones to immersive home theater systems. This demand is further amplified by the rapid and continuous expansion of the global automotive sector, with a pronounced emphasis on integrating highly advanced infotainment systems and offering sophisticated audio experiences within new vehicle models. Concurrently, ongoing and groundbreaking innovation in material science is a pivotal driver, consistently leading to the development of superior performance diaphragms that push the boundaries of acoustic engineering. These combined factors exert substantial pressure on manufacturers, compelling them towards the continuous development of more sophisticated, durable, and acoustically precise diaphragms. However, the market concurrently navigates significant restraints, including the inherent volatility in pricing of critical raw materials, such as rare earth elements, specialized polymers, and high-performance metals, which can directly impact production costs and profit margins. Furthermore, the complex and highly precise manufacturing processes involved in diaphragm production demand significant capital investment, specialized machinery, and highly skilled labor, creating substantial barriers to entry. Adding to this complexity is the intense competitive landscape, characterized by numerous global and regional players vying for market share, which often leads to price pressures and heightened innovation cycles.

Despite these challenges, abundant opportunities for strategic growth are readily identifiable within the Acoustic Diaphragm Market, particularly in burgeoning emerging markets across Asia Pacific, Latin America, and the Middle East & Africa, where accelerating digitalization and increasing consumer electronics adoption rates are creating new demand vectors. The seamless integration of acoustic diaphragms into the rapidly expanding Internet of Things (IoT) ecosystem, enabling the creation of advanced smart audio devices, interconnected home automation systems, and intelligent industrial sensors, presents a particularly significant and lucrative avenue for market expansion. Moreover, the relentless pursuit of highly personalized audio experiences, fueled by consumer preferences for customized sound profiles and adaptive technologies, coupled with the continuous advancements in medical diagnostics utilizing sophisticated ultrasonic technology, further broadens the application scope for innovative and specialized diaphragm designs. These opportunities encourage manufacturers to diversify their product portfolios and invest in research and development to address specific niche market needs. Effectively overcoming existing restraints by strategically leveraging technological advancements and capitalizing on these emerging opportunities will be absolutely crucial for market participants to achieve sustained growth, secure a strong competitive advantage, and solidify their position within the rapidly evolving global market landscape.

Beyond internal dynamics, the market is profoundly shaped by several overarching impact forces that define its competitive environment and influence strategic decision-making. The bargaining power of buyers, primarily comprising large Original Equipment Manufacturers (OEMs) within the consumer electronics and automotive industries, remains notably substantial. This is primarily due to their significant volume purchases, sophisticated procurement processes, and inherent ability to readily switch between suppliers, which collectively compel diaphragm manufacturers to offer highly competitive pricing, flexible terms, and extensively customized acoustic solutions. Conversely, the bargaining power of suppliers of specialized raw materials, especially for proprietary compounds, scarce elements, or highly specialized manufacturing equipment, can range from moderate to high. This can significantly influence production costs, impact lead times, and potentially disrupt supply chains for diaphragm manufacturers. The threat of new entrants into the Acoustic Diaphragm Market is generally perceived as moderate, as establishing a competitive presence necessitates substantial capital investment in R&D, sophisticated manufacturing infrastructure, and the accumulation of specialized acoustic engineering expertise, thereby creating formidable barriers to market entry. While the threat of substitutes from alternative sound technologies exists, it is relatively low for core acoustic diaphragm applications due to their proven efficiency, unparalleled performance, and cost-effectiveness in sound transduction. Lastly, intense industry rivalry among established players drives a continuous cycle of innovation, necessitates distinct product differentiation strategies, and maintains competitive pricing pressures, ensuring a dynamic and ever-evolving market environment where strategic agility is paramount.

Segmentation Analysis

The Acoustic Diaphragm Market is meticulously segmented to provide a granular and comprehensive understanding of its diverse components, intricate dynamics, and varied growth avenues across different product specifications and end-use sectors. This detailed segmentation facilitates a precise and nuanced analysis of market trends, allowing for the identification of distinct market niches and their unique demands, which are critical for strategic planning. The primary categories within this segmentation meticulously reflect the fundamental choices in diaphragm construction materials, the various types of diaphragm geometries, the broad spectrum of end-use applications, and the specific industries they serve, ranging from everyday consumer gadgets to highly specialized industrial and medical equipment. Such a granular understanding of the market structure is absolutely crucial for stakeholders to effectively tailor their product development roadmaps, refine their marketing strategies, optimize investment decisions, and ultimately identify specific areas of high growth potential and address previously unmet customer needs within the complex and interconnected global market landscape. This structured approach empowers businesses to target specific customer segments with precision, offering solutions that are perfectly aligned with their technical requirements and market expectations.

- By Material: This segment analyzes the market based on the fundamental substances used in diaphragm construction, each offering unique acoustic and mechanical properties.

- Polymer Diaphragms: Widely adopted for their flexibility, cost-effectiveness, and ease of molding. Examples include Mylar (Polyethylene Terephthalate PET), Polyimide, PEEK (Polyetheretherketone), and PEN (Polyethylene Naphthalate), offering varying degrees of stiffness, damping, and temperature resistance.

- Paper Diaphragms: Traditional and still prevalent, valued for their natural damping and warm sound characteristics. Includes cellulose pulp, often treated with special coatings or combined with other fibers for enhanced rigidity and moisture resistance.

- Metal Diaphragms: Chosen for their high stiffness-to-mass ratio and excellent transient response, often used in high-frequency drivers. Materials include Aluminum, Titanium, Beryllium (known for exceptional rigidity and speed), and Magnesium.

- Ceramic Diaphragms: Offer extreme stiffness and high internal damping, providing very low distortion. Examples include Alumina and Zirconia, typically used in ultra-high-end audio applications.

- Composite Diaphragms: Advanced materials combining multiple elements to leverage their synergistic properties, creating diaphragms with optimized stiffness, damping, and low mass. Includes Carbon Fiber, Graphene (renowned for strength and lightness), and Glass Fiber, often layered for specific acoustic profiles.

- Fabric Diaphragms: Utilized for their natural damping properties and smooth frequency response, commonly found in soft dome tweeters. Examples include silk and various synthetic aramid fibers.

- By Type: This segmentation categorizes diaphragms based on their structural shape, which dictates their vibrational characteristics and suitability for different frequency ranges.

- Dome Diaphragms: Typically used in tweeters and mid-range drivers due to their ability to provide wide dispersion and handle higher frequencies. Examples include soft domes (silk, fabric) and hard domes (metal, ceramic).

- Cone Diaphragms: Predominantly used in woofers and subwoofers for their ability to displace large volumes of air and reproduce lower frequencies effectively. Vary in size and material from paper to advanced composites.

- Flat Diaphragms: Found in specialized speaker designs like planar magnetic, electrostatic, and ribbon speakers, offering unique sound dispersion and reduced phase distortion.

- Membrane Diaphragms: Very thin and highly sensitive, primarily used in microphones, industrial sensors, and medical devices for precise sound capture or pressure sensing.

- By Application: This segment analyzes demand based on the end-use devices and systems where acoustic diaphragms are integrated.

- Headphones and Earphones: A major driver, requiring miniaturized, high-performance diaphragms for superior personal audio experiences.

- Loudspeakers: Encompasses home audio systems, professional studio monitors, concert sound systems, and car audio, demanding a wide range of diaphragm types and sizes.

- Microphones: From consumer-grade devices to professional studio microphones and specialized industrial sensors, requiring highly sensitive and accurate diaphragms.

- Hearing Aids: Demands extremely small, efficient, and precise diaphragms for clear sound amplification and processing.

- Smart Speakers and Voice Assistants: Growing segment requiring robust diaphragms for voice recognition and clear audio output in connected home devices.

- Automotive Infotainment Systems: Requires durable, high-fidelity diaphragms capable of performing reliably in challenging automotive environments.

- Medical Devices: Includes advanced stethoscopes, ultrasonic probes for imaging, and other diagnostic tools where precision and sensitivity are critical.

- Industrial Sensors and Alarms: Diaphragms used in pressure sensors, flow meters, and audible alarms within industrial settings.

- Defense and Aerospace: Specialized applications in communication systems, sonar, and acoustic detection, requiring diaphragms with extreme resilience and performance under harsh conditions.

- By End-User: This segmentation focuses on the primary industries that utilize acoustic diaphragms in their products.

- Consumer Electronics: Largest end-user segment, including manufacturers of audio devices, smartphones, tablets, and smart home gadgets.

- Automotive: Manufacturers of vehicles and automotive audio components.

- Healthcare: Medical device manufacturers specializing in diagnostics, therapeutics, and hearing solutions.

- Industrial: Companies producing sensors, machinery, and various industrial equipment.

- Telecommunications: Manufacturers of communication devices and infrastructure components.

- Aerospace and Defense: Companies involved in specialized communication, surveillance, and acoustic detection systems for military and aviation applications.

Value Chain Analysis For Acoustic Diaphragm Market

The value chain for the Acoustic Diaphragm Market is a multifaceted and interconnected network of stages, commencing with the rigorous sourcing and processing of raw materials and culminating in the meticulous delivery of integrated audio products to the discerning end-user. This intricate chain vividly illustrates the sequential flow of value creation and highlights the pivotal entities involved at each successive stage, unveiling a complex network comprising material suppliers, specialized diaphragm manufacturers, original equipment manufacturers (OEMs), various distributors, and ultimately, the final consumers. Upstream activities in this value chain involve the precise extraction, refinement, and initial processing of fundamental materials. These include highly specialized polymers, various grades of metals, and innovative advanced composites that form the foundational constituents of diaphragm construction. Suppliers of these raw materials occupy a critically important position, as they are responsible for providing high-quality, consistent, and meticulously specified inputs that must adhere to stringent acoustic performance requirements. Their offerings profoundly contribute to the overall cost structure, specific acoustic characteristics, and long-term durability of the final diaphragm product. The strategic selection and qualification of upstream suppliers are therefore paramount, ensuring the desired acoustic properties are achieved and manufacturing feasibility is maintained throughout the production cycle.

Midstream operations are primarily dominated by the highly specialized and precision-intensive manufacturing of acoustic diaphragms themselves. This stage often incorporates a suite of highly technical processes such as advanced injection molding, precise thermoforming, intricate etching, and sophisticated coating applications. These processes are essential for mass production, ensuring exceptional consistency and adherence to extremely tight dimensional and material tolerances. Specialized diaphragm manufacturers employ state-of-the-art design tools, including computational fluid dynamics and finite element analysis, coupled with rigorous in-process quality control measures, to meticulously produce diaphragms that meet exact specifications for stiffness, weight, damping characteristics, and resonant frequencies. Following the meticulous production and stringent quality assurance of these diaphragms, they are subsequently supplied to Original Equipment Manufacturers (OEMs). These OEMs then integrate the acoustic diaphragms as critical components into their complete audio devices, which include a wide array of products such as premium headphones, high-definition loudspeakers, sensitive microphones, and advanced smart speakers. This integration phase is crucial, as the diaphragm's performance must be seamlessly harmonized with other audio components to achieve the desired overall sound signature and device functionality.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 4.8 Billion |

| Market Forecast in 2032 | USD 7.6 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Knowles Corporation, TDK Corporation, Bose Corporation, Harman International (Samsung), Sony Corporation, Foster Electric Co., Ltd., Goertek Inc., AAC Technologies Holdings Inc., Fujikura Ltd., Mitsubishi Electric Corporation, Denon (Sound United LLC), Dynaudio A/S, Pioneer Corporation, Audio-Technica Corporation, AKG Acoustics (Harman International), Sennheiser Electronic GmbH & Co. KG, Yamaha Corporation, Fostex Company, Celestion International Ltd., Scan-Speak A/S |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Acoustic Diaphragm Market Key Technology Landscape

The acoustic diaphragm market is characterized by a remarkably dynamic and continuously evolving technology landscape, profoundly driven by relentless innovation across materials science, sophisticated manufacturing processes, and advanced design methodologies. Advancements in materials science are at the very forefront of this technological evolution, with researchers and leading manufacturers actively exploring, developing, and adopting novel substances to significantly enhance diaphragm performance across all critical parameters. Materials such as graphene, celebrated for its exceptional stiffness-to-weight ratio, extraordinary strength, and unparalleled acoustic transparency, and beryllium, highly prized for its inherent rigidity and incredibly high sound velocity, are rapidly gaining substantial traction in high-end audio applications where uncompromised fidelity is paramount. Additionally, specialized high-performance polymers, including Polyetheretherketone (PEEK) and Polyethylene Naphthalate (PEN), offer excellent internal damping characteristics, superior fatigue resistance, and enhanced durability, rendering them eminently suitable for a vast and diverse range of consumer and industrial products. The continuous development of innovative composite materials, which strategically combine the inherent strengths of multiple distinct substances, further enables the creation of diaphragms with precisely tailored acoustic properties. This allows for the engineering of components that are simultaneously lightweight, exceptionally rigid, and optimally damped, thereby effectively addressing highly specific frequency response requirements and significantly improving power handling capabilities for diverse audio demands.

Manufacturing technologies within the acoustic diaphragm sector have also witnessed profound strides, enabling the exceptionally precise, highly consistent, and cost-effective production of increasingly complex diaphragm geometries. Advanced injection molding techniques, precise thermoforming, intricate chemical etching, and sophisticated high-precision stamping processes are absolutely crucial for efficient mass production, ensuring remarkable consistency, adherence to extremely tight dimensional tolerances, and optimal material utilization. The transformative emergence of additive manufacturing, commonly known as 3D printing, is opening entirely new and exciting possibilities for creating highly customized, geometrically complex, and intricate diaphragm structures with unparalleled design flexibility. This groundbreaking capability facilitates rapid prototyping cycles and enables specialized small-batch production, catering to niche applications and bespoke audio solutions. Furthermore, state-of-the-art coating technologies are being extensively employed to apply ultra-thin, highly controlled layers of specific materials, such as diamond-like carbon (DLC) or microscopic ceramic particles, directly onto diaphragm surfaces. These advanced coatings significantly enhance diaphragm stiffness, augment internal damping, improve surface hardness, and ultimately elevate overall acoustic performance, while simultaneously providing robust protection against environmental degradation and markedly extending product longevity and reliability.

In the realm of design and simulation, the acoustic diaphragm market heavily relies on cutting-edge computational tools and sophisticated analytical techniques. Finite Element Analysis (FEA) and advanced acoustic simulation software are indispensable for meticulously modeling complex diaphragm behavior, accurately predicting frequency response characteristics, and precisely optimizing mechanical properties even before any physical prototyping commences. These powerful computational tools empower engineers to iterate through countless design variations rapidly and efficiently, thereby minimizing extensive development cycles and significantly reducing associated costs. The nascent yet rapidly growing integration of Artificial Intelligence (AI) and Machine Learning (ML) is beginning to profoundly impact this technological landscape by enabling generative design processes. In this paradigm, sophisticated AI algorithms intelligently explore vast design spaces, proposing and suggesting optimal diaphragm structures and material compositions based on a set of predefined desired performance parameters and constraints. This technological evolution ensures that acoustic diaphragms continue to not only meet but consistently exceed the escalating demands for higher fidelity, smaller form factors, greater energy efficiency, and enhanced durability across an increasingly diverse array of applications, ranging from ubiquitous consumer electronics to highly sensitive and mission-critical medical devices and robust industrial equipment.

Regional Highlights

The global Acoustic Diaphragm Market demonstrates substantial regional variations in terms of growth dynamics, adoption rates of advanced technologies, and the overall landscape of technological development. Asia Pacific has firmly established itself as the predominant and most influential force within this market, driven by its unparalleled extensive manufacturing capabilities in consumer electronics and a rapidly expanding consumer base endowed with increasing purchasing power. North America and Europe, while representing more mature market landscapes, continue to serve as crucial epicenters for innovation, high-end audio product development, and specialized applications, with significant contributions emanating from the professional audio, automotive, and industrial sectors. Emerging markets in Latin America and the Middle East & Africa are currently experiencing robust growth, characterized by accelerated urbanization, increasing digitalization, and the rising penetration of smart devices, which collectively offer substantial future growth opportunities and avenues for market expansion for acoustic diaphragm manufacturers.

- North America: This region represents a mature yet highly innovative market, characterized by strong and consistent demand for premium audio products, sophisticated professional sound equipment, and advanced automotive infotainment systems. The market here benefits from high levels of research and development investment, with a pronounced focus on pioneering innovative materials, advanced manufacturing processes, and cutting-edge acoustic technologies that prioritize superior performance and durability.

- Europe: The European market is distinguished by a robust presence of established high-fidelity audio brands, a significant and expanding luxury segment within the automotive industry, and a growing emphasis on adopting sustainable manufacturing practices and eco-friendly material solutions. There is substantial adoption of acoustic diaphragms in specialized telecommunications infrastructure, high-precision industrial applications, and professional recording equipment, reflecting a demand for precision and reliability.

- Asia Pacific (APAC): As the largest and most rapidly growing market, APAC is primarily propelled by the colossal production volumes of consumer electronics, including smartphones, wireless headphones, smart speakers, and other portable audio devices, emanating from manufacturing hubs in countries like China, Japan, South Korea, and India. Rapid urbanization, increasing disposable incomes, and a large youth demographic are key demographic drivers fueling the demand for advanced audio components in this region.

- Latin America: This emerging market is experiencing consistent and notable growth, primarily attributed to increasing disposable incomes, accelerated digitalization across various sectors, and the rising adoption rates of consumer electronics. The market in Latin America often focuses on accessible yet quality audio solutions, presenting opportunities for manufacturers to provide cost-effective and high-performance acoustic diaphragm components.

- Middle East & Africa (MEA): The MEA region is exhibiting steady growth, largely influenced by significant infrastructural development projects, the increasing penetration of smart devices and internet connectivity, and a growing youth population that actively drives demand for consumer electronics. Investment in telecommunications and automotive sectors further contributes to the expanding market for acoustic diaphragms in this region.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Acoustic Diaphragm Market.- Knowles Corporation

- TDK Corporation

- Bose Corporation

- Harman International (Samsung)

- Sony Corporation

- Foster Electric Co., Ltd.

- Goertek Inc.

- AAC Technologies Holdings Inc.

- Fujikura Ltd.

- Mitsubishi Electric Corporation

- Denon (Sound United LLC)

- Dynaudio A/S

- Pioneer Corporation

- Audio-Technica Corporation

- AKG Acoustics (Harman International)

- Sennheiser Electronic GmbH & Co. KG

- Yamaha Corporation

- Fostex Company

- Celestion International Ltd.

- Scan-Speak A/S

Frequently Asked Questions

Analyze common user questions about the Acoustic Diaphragm market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is an acoustic diaphragm and why is it important in audio technology?

An acoustic diaphragm is a thin, flexible membrane that converts electrical signals into mechanical vibrations to produce sound, or vice versa, to capture sound. Its material and design are critical as they directly influence the sound quality, frequency response, distortion levels, and overall fidelity of audio devices like speakers, headphones, and microphones, making it a foundational component in sound reproduction.

What are the primary materials utilized in the manufacture of acoustic diaphragms?

The primary materials commonly employed for acoustic diaphragms include various polymers such as Mylar, Polyimide, PEEK, and PEN; traditional paper compositions like cellulose pulp; metals such as Aluminum, Titanium, Beryllium, and Magnesium; ceramics like Alumina; and advanced composites including carbon fiber, graphene, and glass fiber. The selection is based on desired acoustic properties like stiffness, damping, weight, and durability for specific applications.

How is artificial intelligence (AI) influencing the future of the Acoustic Diaphragm Market?

AI is profoundly impacting the Acoustic Diaphragm Market by enabling generative design for optimal geometries, accelerating the discovery and development of novel materials, enhancing predictive maintenance in manufacturing processes, and improving the accuracy and speed of automated quality control. This leads to more efficient production, superior sound quality, and the potential for highly personalized adaptive audio experiences in end products.

Which specific applications are the key drivers of demand for acoustic diaphragms?

The key applications primarily driving demand for acoustic diaphragms include a broad range of consumer electronics (such as headphones, earphones, loudspeakers, soundbars, and smart speakers), sophisticated automotive infotainment systems, precision medical devices (like hearing aids and ultrasonic probes), and various industrial sensors, alarms, and specialized communication equipment. The continuous innovation in these sectors fuels ongoing market growth.

What are the significant growth opportunities available within the Acoustic Diaphragm Market?

Significant growth opportunities exist in emerging economies, driven by increasing disposable incomes and digitalization trends. Further opportunities stem from the integration of acoustic diaphragms into the expanding Internet of Things (IoT) ecosystem, the rising consumer demand for personalized and immersive audio experiences, continuous advancements in active noise-cancellation technologies, and the expansion of high-precision applications in the medical and automotive industries.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager