Aerospace Bearings Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 431218 | Date : Nov, 2025 | Pages : 241 | Region : Global | Publisher : MRU

Aerospace Bearings Market Size

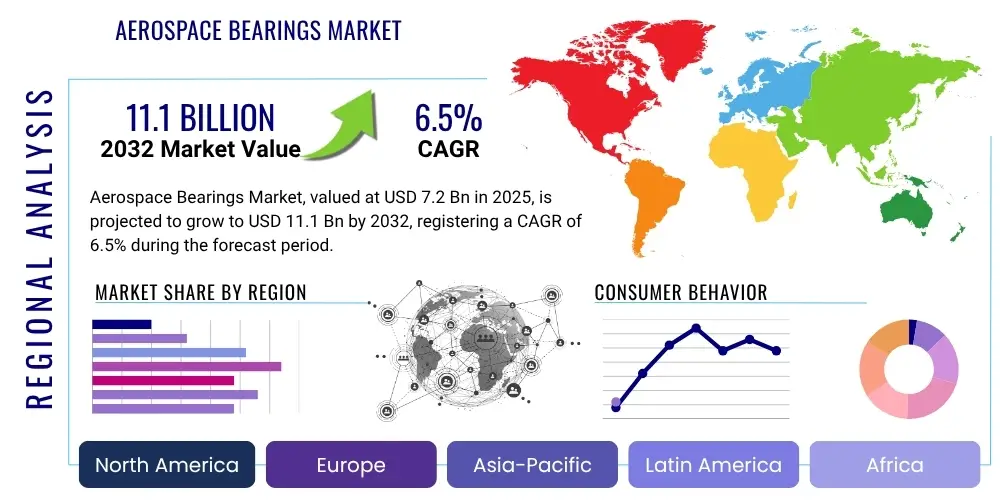

The Aerospace Bearings Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2025 and 2032. The market is estimated at $7.2 billion in 2025 and is projected to reach $11.1 billion by the end of the forecast period in 2032.

Aerospace Bearings Market introduction

The aerospace bearings market is a critical segment within the broader aerospace industry, providing specialized components essential for the reliable and safe operation of various aircraft systems. These precision-engineered products are designed to withstand extreme conditions, including high speeds, heavy loads, varying temperatures, and corrosive environments, ensuring optimal performance across a wide array of applications. The market encompasses a diverse range of bearing types, each tailored to specific requirements, from sophisticated engine components to robust landing gear assemblies.

Aerospace bearings are fundamental to numerous aircraft applications, including engines, airframes, landing gear systems, flight control surfaces, and auxiliary power units. Their primary function is to facilitate smooth motion, reduce friction, and support rotational parts, thereby enhancing efficiency, extending component lifespan, and significantly contributing to overall flight safety. The benefits derived from high-quality aerospace bearings are extensive, ranging from improved fuel efficiency due to reduced friction, enhanced operational reliability, and lower maintenance costs over the aircraft's lifecycle.

Key driving factors propelling the growth of this market include the increasing global demand for air travel, leading to a surge in new aircraft deliveries and a robust aftermarket for maintenance, repair, and overhaul (MRO) services. Furthermore, advancements in aircraft technology, such as the development of more fuel-efficient engines and lightweight airframes, necessitate continuous innovation in bearing design and materials. The global defense sector's consistent spending on military aircraft and drone programs also contributes significantly to market expansion, ensuring sustained demand for high-performance aerospace bearings.

Aerospace Bearings Market Executive Summary

The aerospace bearings market is characterized by a confluence of evolving business trends, distinct regional dynamics, and specialized segment developments that collectively shape its growth trajectory. Key business trends include a persistent focus on lightweighting and durability, driven by the aerospace industry's demand for enhanced fuel efficiency and reduced operational costs. Manufacturers are increasingly investing in research and development to introduce advanced materials like ceramics and composites, alongside innovative surface treatments and lubrication technologies, to meet stringent performance requirements. Consolidation among key players and strategic partnerships aimed at expanding technological capabilities and market reach are also notable business strategies observed across the competitive landscape.

Regionally, the market exhibits varied growth patterns. North America continues to dominate due to the strong presence of major aircraft OEMs, engine manufacturers, and a robust defense sector, which drives significant demand for both new installations and MRO services. Europe also holds a substantial market share, supported by leading aircraft manufacturers and a sophisticated aerospace supply chain. However, the Asia Pacific region is emerging as the fastest-growing market, propelled by rapid expansion in commercial aviation, increasing air passenger traffic, and significant investments in developing domestic aerospace manufacturing capabilities. Latin America, the Middle East, and Africa are experiencing steady growth, driven by fleet modernization efforts and rising air travel demands.

From a segmentation perspective, the commercial aircraft segment remains the largest contributor to market revenue, benefiting from substantial orders for new generation narrow-body and wide-body aircraft. The military aircraft segment provides a stable demand base, particularly for specialized, high-performance bearings required in defense applications. Within product types, roller bearings and ball bearings continue to be dominant, while plain bearings find niche applications. The aftermarket (MRO) segment plays a crucial role, providing a consistent revenue stream as aircraft fleets age and require routine maintenance and component replacements, highlighting the long lifecycle of aerospace assets.

AI Impact Analysis on Aerospace Bearings Market

User inquiries concerning AI's influence on the aerospace bearings market predominantly revolve around questions of efficiency, reliability, and cost reduction. Common themes include the potential for AI-driven predictive maintenance to extend bearing life, optimize MRO schedules, and prevent unscheduled downtime. Users also frequently question how AI might contribute to the design and manufacturing processes, specifically in terms of material optimization, fault detection, and quality control. There is significant interest in understanding AI's role in enhancing supply chain resilience and improving inventory management for these critical components. The overarching expectation is that AI will introduce unprecedented levels of precision and automation, leading to safer, more efficient, and more economically viable aerospace operations.

The primary concern for users often centers on the accuracy and reliability of AI algorithms in mission-critical aerospace applications, where failure is not an option. Data privacy and security, especially when integrating sensor data from aircraft for AI analysis, are also frequently raised. There is a desire to understand the investment required for AI implementation, including data infrastructure, algorithm development, and personnel training, and how these costs will translate into tangible benefits. Users are keen to explore how AI can provide a competitive edge in a highly regulated and performance-driven industry, seeking clarity on specific use cases and quantifiable improvements.

Ultimately, users anticipate that AI will revolutionize the lifecycle management of aerospace bearings, from initial design and material selection to in-service monitoring and end-of-life considerations. The expectation is for AI to move beyond mere data analysis to truly intelligent systems that can learn, adapt, and make autonomous decisions, thereby elevating the performance and safety standards of the entire aerospace sector. This transformation is expected to foster innovation in bearing technology, reducing both operational costs and environmental impact through optimized resource utilization and extended component durability, while also enabling proactive issue resolution before critical failures occur.

- Predictive maintenance: AI algorithms analyze sensor data (vibration, temperature) to forecast bearing wear, enabling proactive replacement and reducing unscheduled downtime.

- Optimized design: AI assists in simulating complex stress conditions and material behaviors, leading to more robust and efficient bearing designs.

- Enhanced manufacturing: AI-powered vision systems improve quality control, detecting microscopic defects and ensuring higher precision in production.

- Supply chain optimization: AI predicts demand fluctuations, streamlines inventory management, and improves logistics for bearing components, reducing lead times.

- Performance monitoring: Real-time AI analysis of in-flight bearing data provides immediate insights into operational health, supporting safer flight operations.

- Material innovation: AI accelerates the discovery and testing of novel materials and coatings, leading to bearings with superior strength and durability.

- Automated inspection: AI-driven robots can perform highly precise and repeatable inspections of bearings, minimizing human error and increasing throughput.

DRO & Impact Forces Of Aerospace Bearings Market

The aerospace bearings market is significantly influenced by a dynamic interplay of drivers, restraints, opportunities, and various impact forces that shape its current state and future trajectory. Key drivers include the robust growth in commercial aviation, characterized by increasing air passenger traffic and substantial backlogs of new aircraft orders globally. This surge necessitates a continuous supply of high-performance bearings for both initial equipment manufacturing (OEM) and subsequent maintenance, repair, and overhaul (MRO) activities. Additionally, sustained defense spending by various nations worldwide, particularly for upgrading existing military aircraft fleets and developing advanced combat platforms, provides a stable demand for specialized aerospace bearings capable of enduring extreme conditions. The ongoing pursuit of fuel efficiency and lightweighting in aircraft design further propels innovation and demand for advanced bearing solutions.

However, the market also faces considerable restraints that temper its growth. The aerospace industry is subject to extremely stringent regulatory and certification requirements, leading to lengthy and costly development cycles for new bearing technologies. High research and development expenditures, coupled with the capital-intensive nature of manufacturing precision aerospace components, pose significant barriers to entry for new players. Furthermore, the market is vulnerable to supply chain disruptions, particularly regarding the availability and pricing of specialized raw materials such as high-grade steels, ceramics, and advanced composites. Geopolitical instability and economic downturns can also directly impact defense budgets and commercial aviation investment, creating demand volatility.

Despite these challenges, numerous opportunities exist for market expansion and innovation. The emergence of new aircraft types, including electric and hybrid-electric aircraft, urban air mobility (UAM) vehicles, and unmanned aerial vehicles (UAVs), presents fresh avenues for bearing manufacturers to develop customized solutions. Advancements in materials science, such as additive manufacturing (3D printing) for complex bearing components and the development of self-lubricating materials, offer potential for improved performance and reduced weight. The integration of smart bearing technologies, incorporating sensors for real-time condition monitoring and predictive maintenance, represents a significant growth area, promising enhanced reliability and lower operational costs for airlines and defense operators. The emphasis on sustainable aviation also drives demand for more durable and efficient bearing systems.

Segmentation Analysis

The aerospace bearings market is intricately segmented to reflect the diverse applications, materials, and operational requirements within the aviation sector. This segmentation provides a granular view of market dynamics, allowing for a precise understanding of demand patterns and technological trends across various aircraft types, bearing designs, and end-use applications. The ability to differentiate between segments such as commercial and military aircraft, or between engine and airframe applications, is crucial for manufacturers to tailor their product offerings and strategic investments effectively. Furthermore, distinctions based on material composition, like specialty steels versus ceramics, highlight the ongoing innovation in lightweight and high-performance solutions.

The segmentation extends to the type of bearings, distinguishing between those designed for specific load capabilities and rotational speeds, and also by the sales channel, delineating between original equipment manufacturers (OEMs) and the aftermarket (MRO). Understanding these segments helps in forecasting market growth, identifying niche opportunities, and assessing competitive landscapes. For instance, the MRO segment typically exhibits more stable, long-term demand, driven by fleet longevity and maintenance cycles, whereas the OEM segment is more susceptible to fluctuations in new aircraft delivery schedules and defense procurement programs. This multi-dimensional approach to market segmentation is essential for comprehensive analysis and strategic planning within the aerospace bearings industry, ensuring that all critical aspects of supply and demand are considered.

The constant evolution of aircraft technology, including the rise of new propulsion systems and unmanned aerial vehicles, necessitates a flexible and adaptive segmentation approach. Manufacturers must continuously monitor these shifts to identify emerging opportunities, such as the demand for specialized bearings in electric motors or for extreme environments in hypersonic vehicles. This detailed market breakdown aids stakeholders in developing targeted marketing strategies, optimizing production processes, and fostering collaborations that align with specific industry needs, thereby maximizing their potential for growth and profitability in a highly specialized and demanding market. It allows for a more nuanced understanding of the forces driving different parts of the market.

- By Type

- Ball Bearings

- Roller Bearings (e.g., Cylindrical, Tapered, Spherical)

- Plain Bearings

- Others (e.g., Fluid Film Bearings, Air Bearings)

- By Aircraft Type

- Commercial Aircraft (e.g., Narrow-body, Wide-body, Regional Jets)

- Military Aircraft (e.g., Fighter Jets, Transport Aircraft, Helicopters)

- Helicopters (Commercial and Military)

- Business & General Aviation

- Unmanned Aerial Vehicles (UAVs)/Drones

- By Application

- Engine (e.g., Main Shaft, Accessory Gearbox)

- Airframe (e.g., Flaps, Slats, Control Surfaces)

- Landing Gear

- Flight Control Systems

- Interiors & Auxiliary Systems

- By Material

- Specialty Steel (e.g., Stainless Steel, High-Temperature Alloys)

- Ceramics (e.g., Silicon Nitride)

- Composites

- Others (e.g., Bronze, Aluminum Alloys)

- By Sales Channel

- Original Equipment Manufacturer (OEM)

- Aftermarket (Maintenance, Repair, and Overhaul MRO)

Value Chain Analysis For Aerospace Bearings Market

The value chain for the aerospace bearings market is a complex ecosystem involving multiple stages, from raw material extraction to the final end-user application, highlighting the collaborative and interdependent nature of the industry. At the upstream end, the chain begins with the mining and processing of specialized raw materials such as high-grade steels, titanium, ceramics (like silicon nitride), and advanced lubricants. These materials undergo rigorous quality checks and are supplied to component manufacturers who produce specialized rings, balls, rollers, and cages. Precision engineering and advanced material science are critical at this stage, as the quality of raw materials directly impacts the performance and reliability of the final bearing product, dictating its ability to withstand extreme aerospace operating conditions.

Midstream, the value chain encompasses the core manufacturing processes where these components are assembled into finished aerospace bearings. This involves highly specialized manufacturing techniques, including precision grinding, heat treatment, surface finishing, and advanced lubrication application. Bearing manufacturers, who are often large, globally established entities, leverage extensive R&D capabilities to innovate in design, materials, and manufacturing processes to meet increasingly stringent aerospace standards. Quality assurance and rigorous testing are paramount during this phase to ensure compliance with aviation safety regulations and OEM specifications. The distribution channel plays a vital role here, with both direct and indirect sales models influencing market reach.

Downstream, the finished aerospace bearings are supplied to original equipment manufacturers (OEMs) of aircraft (e.g., Boeing, Airbus), aircraft engines (e.g., GE Aviation, Rolls-Royce), and other aerospace systems (e.g., landing gear suppliers). A significant portion of the market also flows into the aftermarket, serving Maintenance, Repair, and Overhaul (MRO) service providers and airlines for routine servicing, repairs, and component replacements. Direct distribution channels involve direct contracts between bearing manufacturers and large OEMs, fostering long-term relationships and integrated supply chains. Indirect channels often involve specialized aerospace distributors who manage inventory and logistics for smaller OEMs, MRO facilities, and individual aviation operators, ensuring broader market access and efficient delivery of replacement parts. The aftermarket segment is particularly critical due to the extended operational life of aircraft, ensuring a steady demand for replacement bearings.

Aerospace Bearings Market Potential Customers

Potential customers for the aerospace bearings market primarily comprise entities involved in the design, manufacturing, operation, and maintenance of aircraft and related aerospace systems. The largest segment of end-users includes major aircraft manufacturers, such as Boeing, Airbus, Lockheed Martin, Embraer, and Bombardier. These OEMs integrate thousands of bearings into their new aircraft builds, covering applications in engines, airframes, landing gear, and control systems. Their demand is driven by new aircraft orders, evolving design requirements, and a continuous focus on performance, reliability, and weight reduction. Establishing long-term relationships and achieving certification with these prime contractors is paramount for bearing suppliers, as their purchasing cycles are typically extensive and highly integrated.

Another significant group of buyers includes aircraft engine manufacturers like GE Aviation, Rolls-Royce, and Pratt & Whitney. These companies require highly specialized, high-temperature, and high-speed bearings for critical engine components, where precision and durability are non-negotiable. Their demand is directly tied to engine production volumes and advancements in propulsion technology, including new turbofan designs and emerging electric propulsion systems. Additionally, system integrators and component manufacturers specializing in landing gear, flight control systems, and auxiliary power units also represent substantial potential customers, as they source bearings for their specific sub-assemblies before delivery to aircraft OEMs. Their focus is often on performance optimization within their specific subsystem.

Beyond the initial manufacturing phase, the aftermarket constitutes a robust and essential customer base, primarily consisting of Maintenance, Repair, and Overhaul (MRO) service providers, commercial airlines, and military maintenance depots. These customers purchase bearings for the routine servicing, repair, and replacement of parts in existing aircraft fleets. The demand from the MRO sector is driven by the operational life of aircraft, which can span decades, ensuring a consistent need for replacement bearings as components wear out or reach their service limits. Additionally, defense organizations, both national armed forces and government contractors, procure aerospace bearings for their vast military aircraft and unmanned aerial vehicle (UAV) fleets, prioritizing performance, reliability, and robust supply chain support. The growth of the global commercial fleet and increasing defense expenditure underpin the sustained demand from these diverse end-users, ensuring a broad and resilient customer base for aerospace bearing manufacturers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $7.2 billion |

| Market Forecast in 2032 | $11.1 billion |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | SKF, The Timken Company, Schaeffler AG, NTN Corporation, JTEKT Corporation, RBC Bearings Incorporated, Myonic GmbH (MinebeaMitsumi Group), Kaman Corporation (Kaman Specialty Bearings), Aurora Bearing Company, AST Bearings LLC, Daido Metal Co., Ltd., Nadella Group, NHBB (New Hampshire Ball Bearings), NMB (MinebeaMitsumi Inc.), Regal Rexnord Corporation, CCTY Bearing, Barden Corporation (Schaeffler Group), Kaydon Bearings (SKF Group), Silverthin Bearing Group, Altra Industrial Motion (Regal Rexnord). |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Aerospace Bearings Market Key Technology Landscape

The aerospace bearings market is continuously evolving, driven by advancements in materials science, manufacturing processes, and integration capabilities to meet the demanding performance and safety standards of the aviation industry. A pivotal area of technological focus is the development and adoption of advanced materials. While traditional specialty steels (like M50, M50Nil, and various stainless steels) remain foundational, there is a growing emphasis on high-performance ceramics, particularly silicon nitride (Si3N4), for applications requiring lighter weight, higher rigidity, improved wear resistance, and the ability to operate at extremely high temperatures and speeds. Hybrid bearings, which combine steel rings with ceramic balls, are becoming increasingly common, offering a synergistic blend of material properties that enhance overall bearing life and reduce maintenance requirements, especially in engine applications. The pursuit of even lighter and stronger components is also driving research into advanced composites and metal matrix composites, aiming to reduce fuel consumption and extend operational ranges for aircraft.

Another significant technological trend is the innovation in surface engineering and lubrication systems. Advanced coatings, such as Diamond-Like Carbon (DLC), Physical Vapor Deposition (PVD), and various solid lubricants, are being applied to bearing surfaces to reduce friction, enhance wear resistance, and enable operation in challenging environments where conventional liquid lubrication might be insufficient or impractical. These coatings are crucial for extending the lifespan of bearings, particularly in critical applications where extreme temperatures or vacuum conditions are present. Furthermore, the development of self-lubricating bearings and advanced lubrication delivery systems, including minimal lubrication and smart lubrication techniques, aims to further minimize maintenance intervals and improve reliability. These innovations are critical in reducing operational costs and ensuring the extended service life of aircraft components.

The aerospace bearings market is also witnessing a transformative shift with the integration of smart technologies and advanced manufacturing techniques. The advent of smart bearings, incorporating embedded sensors, allows for real-time condition monitoring, providing critical data on temperature, vibration, and load. This data is then utilized for predictive maintenance, allowing operators to anticipate potential failures and schedule maintenance proactively, thereby preventing costly unscheduled downtime and enhancing flight safety. Additive manufacturing, or 3D printing, is gaining traction for producing complex bearing components with optimized geometries that are difficult or impossible to achieve with traditional methods. This technology offers benefits such as reduced material waste, faster prototyping, and the ability to create customized, high-performance parts with tailored properties. These technological advancements collectively contribute to bearings that are lighter, more durable, more efficient, and smarter, directly supporting the broader aerospace industry's goals of enhanced performance, safety, and operational efficiency across all aircraft platforms.

Regional Highlights

- North America: This region consistently holds the largest share of the aerospace bearings market, driven by the strong presence of major aircraft OEMs like Boeing and Lockheed Martin, along with leading engine manufacturers. Significant defense spending and a mature MRO infrastructure further bolster demand. The United States, in particular, leads in military aircraft production and innovation in aerospace technology, ensuring sustained market growth for high-performance bearings.

- Europe: Europe represents a substantial market, primarily due to the operations of Airbus, a global leader in commercial aircraft manufacturing, and major engine manufacturers such as Rolls-Royce and Safran. Countries like France, Germany, and the UK have robust aerospace ecosystems, characterized by advanced research and development in materials and manufacturing processes. Demand is driven by new aircraft programs, fleet modernization, and a strong MRO sector.

- Asia Pacific (APAC): The APAC region is projected to be the fastest-growing market for aerospace bearings. This growth is fueled by an unprecedented increase in air passenger traffic, leading to substantial new aircraft orders from major airlines and the expansion of domestic aerospace manufacturing capabilities in countries like China and India. Investments in military aviation and the development of regional MRO hubs further contribute to its rapid expansion.

- Latin America: This region is experiencing steady growth in the aerospace bearings market, driven by fleet expansion and modernization efforts by local airlines. Brazil, with Embraer being a significant aircraft manufacturer, plays a key role. The market is also influenced by increasing air travel and the development of MRO facilities to support the growing regional fleet.

- Middle East and Africa (MEA): The MEA region is demonstrating consistent growth, primarily attributed to the substantial investments by Middle Eastern airlines in expanding and modernizing their fleets, acquiring numerous wide-body aircraft. Growing tourism and business travel contribute to increasing air traffic. African nations are also gradually investing in fleet upgrades and developing their aviation infrastructure, leading to a rising demand for aerospace bearings in both OEM and MRO segments.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Aerospace Bearings Market.- SKF

- The Timken Company

- Schaeffler AG

- NTN Corporation

- JTEKT Corporation

- RBC Bearings Incorporated

- Myonic GmbH (MinebeaMitsumi Group)

- Kaman Corporation (Kaman Specialty Bearings)

- Aurora Bearing Company

- AST Bearings LLC

- Daido Metal Co., Ltd.

- Nadella Group

- NHBB (New Hampshire Ball Bearings)

- NMB (MinebeaMitsumi Inc.)

- Regal Rexnord Corporation

- CCTY Bearing

- Barden Corporation (Schaeffler Group)

- Kaydon Bearings (SKF Group)

- Silverthin Bearing Group

- Altra Industrial Motion (Regal Rexnord)

Frequently Asked Questions

What types of bearings are commonly used in aerospace applications?

Aerospace applications primarily utilize ball bearings, roller bearings (e.g., cylindrical, tapered, spherical), and plain bearings, each selected for specific operational requirements such as load capacity, speed, and temperature resistance in components like engines, airframes, and landing gear.

How do aerospace bearings differ from industrial bearings?

Aerospace bearings are engineered to much stricter standards for reliability, precision, weight, and material properties, often incorporating advanced materials like ceramics and specialized coatings to withstand extreme conditions (high temperatures, speeds, vibrations) unique to aviation, unlike general industrial bearings.

What materials are critical for high-performance aerospace bearings?

Key materials include specialty steels (e.g., M50, stainless steels), high-performance ceramics (especially silicon nitride), advanced composites, and various high-temperature alloys, chosen for their superior strength, wear resistance, and thermal stability in demanding aerospace environments.

What is the impact of predictive maintenance on the aerospace bearings market?

Predictive maintenance, often enabled by AI and embedded sensors, allows for real-time monitoring of bearing health, forecasting potential failures. This extends bearing lifespan, optimizes MRO schedules, reduces unscheduled downtime, and significantly enhances flight safety and operational efficiency.

What are the key trends shaping the future of aerospace bearings?

Future trends include continued innovation in lightweight and advanced materials, integration of smart sensor technologies for condition monitoring, adoption of additive manufacturing for complex geometries, and the development of specialized bearings for electric/hybrid aircraft and urban air mobility (UAM) vehicles, all aimed at improving performance, efficiency, and safety.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager