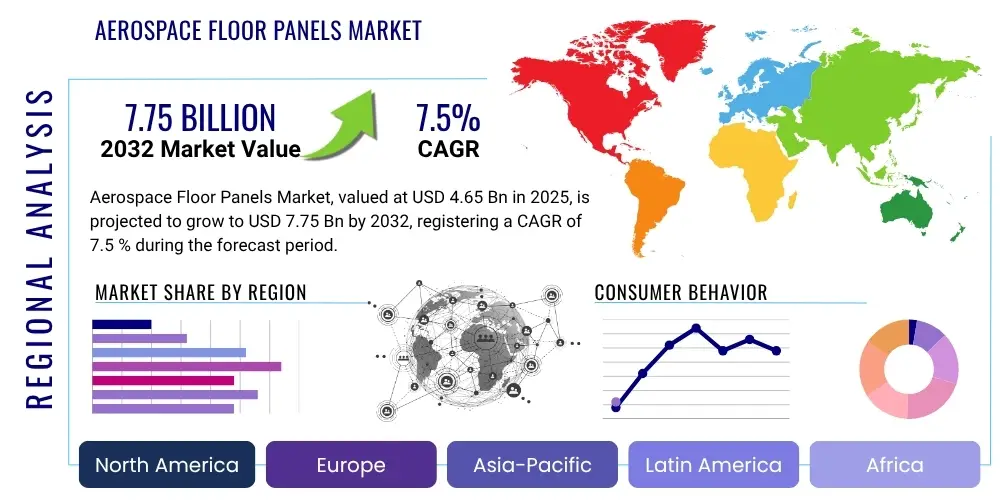

Aerospace Floor Panels Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427914 | Date : Oct, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Aerospace Floor Panels Market Size

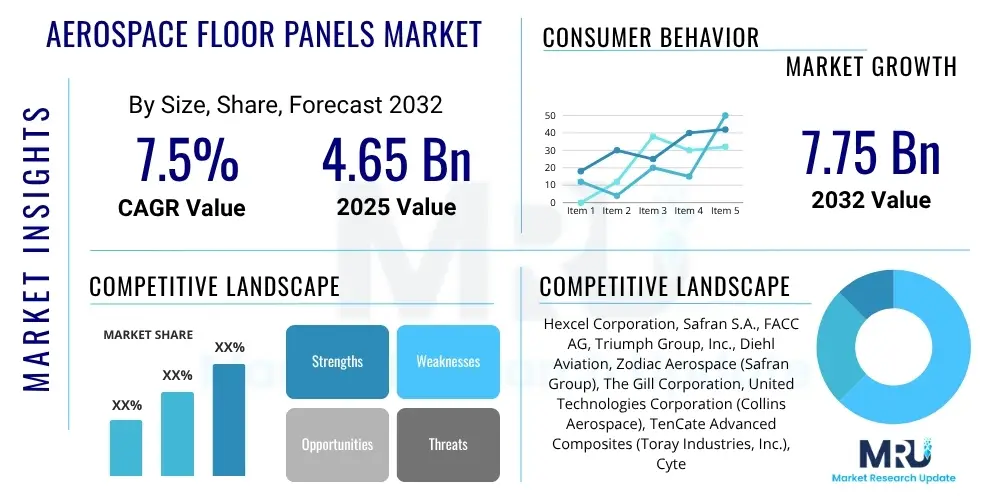

The Aerospace Floor Panels Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.5% between 2025 and 2032. The market is estimated at USD 4.65 Billion in 2025 and is projected to reach USD 7.75 Billion by the end of the forecast period in 2032.

Aerospace Floor Panels Market introduction

The aerospace floor panels market encompasses the design, manufacturing, and supply of structural flooring components crucial for all types of aircraft, including commercial, military, business jets, and helicopters. These panels serve as the foundation for interior cabins, cargo compartments, and cockpits, providing essential support for passengers, crew, and equipment while maintaining the aircraft's structural integrity and contributing to overall safety. The primary function of these panels extends beyond mere support; they are engineered to offer a myriad of benefits, including superior strength-to-weight ratio, exceptional durability, resistance to fire and moisture, effective sound dampening properties, and thermal insulation. Their sophisticated design and material composition are critical for enhancing fuel efficiency, reducing operational costs, and improving passenger comfort. The market's expansion is significantly driven by robust global air passenger traffic growth, leading to an increased demand for new aircraft deliveries and extensive maintenance, repair, and overhaul (MRO) activities. Furthermore, continuous technological advancements in material science and manufacturing processes are pivotal in shaping the market, introducing innovative solutions that meet the evolving performance and regulatory requirements of the aerospace industry.

Aerospace Floor Panels Market Executive Summary

The Aerospace Floor Panels Market is experiencing dynamic shifts, influenced by several key business, regional, and segment trends. Business trends highlight a pronounced industry focus on lightweighting initiatives, driven by the imperative for enhanced fuel efficiency and reduced carbon emissions across the aviation sector. This has spurred significant investments in advanced composite materials and innovative manufacturing techniques, pushing manufacturers towards strategic collaborations and mergers & acquisitions to consolidate expertise and market share. Supply chain resilience has also become a critical concern, leading to a re-evaluation of sourcing strategies and increased vertical integration efforts. Regionally, the market exhibits varied growth trajectories; Asia Pacific is emerging as a dominant force, propelled by rapid fleet expansion and infrastructure development in countries like China and India, while North America and Europe remain mature but significant markets due characterized by established aircraft manufacturing hubs and robust MRO networks. Latin America, the Middle East, and Africa also show promising growth due to increasing air travel and fleet modernization programs. Segment-wise, composite materials are steadily gaining prominence over traditional aluminum, owing to their superior performance attributes, particularly in new generation aircraft. The commercial aircraft sector continues to be the largest application segment, with ongoing demand for new narrow-body and wide-body aircraft driving market growth, complemented by a stable demand from military and business jet sectors. The MRO segment is also witnessing consistent growth, fueled by the aging global fleet and the need for regular maintenance and panel replacements.

AI Impact Analysis on Aerospace Floor Panels Market

Common user questions regarding AI's impact on the aerospace floor panels market frequently center on how artificial intelligence can revolutionize design processes, enhance manufacturing efficiency, enable predictive maintenance, and optimize supply chain operations. Users are keen to understand if AI can significantly reduce development timelines, improve material selection, predict panel failures before they occur, and make supply chains more resilient. There is also considerable interest in AI's role in ensuring stringent quality control and compliance with regulatory standards. Based on this analysis, AI is poised to act as a transformative force, fundamentally reshaping the entire lifecycle of aerospace floor panels from conceptualization to end-of-life. It promises to unlock unprecedented levels of efficiency, precision, and intelligence within the industry, addressing long-standing challenges related to cost, performance, and operational uptime. However, concerns persist around the complexities of data integration, the potential for algorithmic bias, the high initial investment required, and the pressing need for a skilled workforce capable of developing and managing AI-driven systems in such a highly regulated and safety-critical environment. The industry anticipates that successful AI adoption will lead to substantial advancements in product innovation and operational excellence, thereby ensuring competitive advantage and sustained market leadership.

- Generative Design and Material Optimization: AI algorithms can rapidly explore vast design possibilities for floor panels, optimizing complex geometries for maximum strength-to-weight ratios, acoustic properties, and thermal performance, leading to innovative lightweight structures with superior characteristics.

- Predictive Maintenance and Structural Health Monitoring: AI-powered analytics can process data from embedded sensors in floor panels, predicting potential failures or wear and tear long before they become critical, enabling proactive maintenance scheduling and extending panel lifespan while enhancing aircraft safety.

- Manufacturing Process Optimization: AI can optimize manufacturing parameters, such as curing cycles for composites or bonding processes, reducing waste, improving production efficiency, and ensuring consistent product quality through real-time monitoring and adaptive control.

- Enhanced Quality Control and Inspection: AI-driven vision systems and machine learning models can automatically detect defects in floor panels during production and inspection more accurately and rapidly than manual methods, ensuring adherence to stringent aerospace quality standards.

- Supply Chain Transparency and Resilience: AI tools can provide predictive insights into supply chain disruptions, optimize inventory management for raw materials and finished panels, and enhance logistical efficiency, leading to a more robust and responsive supply network.

- Data-Driven Material Selection and Performance Simulation: AI can analyze extensive material databases to recommend optimal composites or alloys for specific panel applications, simulating performance under various conditions to accelerate research and development cycles.

DRO & Impact Forces Of Aerospace Floor Panels Market

The aerospace floor panels market is shaped by a complex interplay of drivers, restraints, opportunities, and inherent impact forces. Key market drivers include the burgeoning global demand for new commercial aircraft, propelled by expanding air travel and fleet modernization initiatives across airlines worldwide. The increasing emphasis on lightweighting aircraft to enhance fuel efficiency and reduce carbon emissions further stimulates the adoption of advanced, lighter floor panel materials. Additionally, robust growth in Maintenance, Repair, and Overhaul (MRO) activities, necessitated by an aging global fleet and stringent safety regulations, provides a steady demand for replacement panels. However, the market faces significant restraints such as the high cost of advanced composite materials and specialized manufacturing processes, which can hinder broader adoption. Stringent regulatory frameworks and lengthy certification cycles, particularly for new materials and designs, impose considerable time and cost burdens on manufacturers. Furthermore, the inherent volatility and cyclical nature of the aerospace industry, coupled with potential supply chain disruptions, can impact production schedules and market stability. Amidst these challenges, substantial opportunities exist in the development of sustainable and recyclable materials, catering to the growing environmental consciousness within the industry. Advancements in additive manufacturing techniques for customized and complex panel components also present a promising avenue for innovation. The market's competitive landscape is defined by impact forces such as the significant bargaining power of major aircraft OEMs (buyers) who demand high-performance, cost-effective solutions. The bargaining power of suppliers, particularly those providing specialized composite raw materials, is also notable. The threat of new entrants remains relatively low due to high capital investment and regulatory barriers, while the threat of substitutes is moderate, primarily stemming from alternative lightweighting strategies or evolving interior design concepts. Intense competitive rivalry among existing players drives continuous innovation and product differentiation.

Segmentation Analysis

The Aerospace Floor Panels Market is comprehensively segmented to provide granular insights into its diverse components, offering a clearer understanding of market dynamics across various categories. This segmentation helps identify specific growth areas, competitive landscapes, and evolving consumer preferences, allowing stakeholders to tailor strategies effectively. The market is primarily analyzed based on critical factors such as material type, which dictates performance characteristics and cost, and aircraft type, reflecting the varying demand and specifications across different aviation sectors. Further segmentation by application highlights where these panels are predominantly utilized within an aircraft, while end-use segmentation differentiates between new aircraft manufacturing and aftermarket services. This structured approach ensures a thorough and actionable market assessment.

- By Material Type

- Composites

- Carbon Fiber Composites

- Glass Fiber Composites

- Hybrid Composites

- Aluminum Alloys

- Hybrid Materials

- Composites

- By Aircraft Type

- Commercial Aircraft

- Narrow-Body Aircraft

- Wide-Body Aircraft

- Regional Jets

- Military Aircraft

- Fighter Aircraft

- Transport Aircraft

- Special Mission Aircraft

- Business Jets

- Helicopters

- Commercial Aircraft

- By Application

- Passenger Compartment

- Cargo Compartment

- Cockpit

- Galley & Lavatory

- By End-Use

- Original Equipment Manufacturer (OEM)

- Aftermarket (MRO)

Value Chain Analysis For Aerospace Floor Panels Market

The value chain for aerospace floor panels is intricate, beginning with the upstream supply of highly specialized raw materials and extending through complex manufacturing processes to the downstream distribution channels that reach end-users. The upstream segment primarily involves suppliers of advanced composite materials such as carbon fibers, glass fibers, specialized resins, and honeycomb core materials (e.g., Nomex, aluminum honeycomb). These suppliers are critical as the quality and performance of the final panel heavily depend on the properties of these raw inputs, often requiring stringent certifications and long-term contracts. The midstream involves the core manufacturing processes where these raw materials are transformed into finished floor panels, typically through highly automated processes like resin infusion, prepreg lay-up, and sandwich panel assembly. This stage demands significant technical expertise and adherence to rigorous aerospace standards. Downstream activities focus on the distribution and sale of these panels. Direct channels involve manufacturers selling directly to major aircraft Original Equipment Manufacturers (OEMs) like Boeing, Airbus, and Embraer, facilitating integration into new aircraft assembly lines. Indirect channels primarily cater to the aftermarket segment, where panels are supplied to Maintenance, Repair, and Overhaul (MRO) facilities through specialized distributors or directly from panel manufacturers for replacement and repair purposes. The interplay between these stages ensures the continuous flow of products, optimizing for both direct new aircraft production and the ongoing support of existing fleets, with strict quality control maintained at every juncture to ensure flight safety and compliance.

Aerospace Floor Panels Market Potential Customers

The potential customers for aerospace floor panels represent a diverse yet highly specialized group, primarily consisting of entities involved in aircraft manufacturing, operation, and maintenance. At the forefront are major global aircraft Original Equipment Manufacturers (OEMs), including industry giants such as Boeing, Airbus, Embraer, Bombardier, and COMAC, who integrate these panels into their new aircraft assembly lines. These OEMs require panels that meet precise specifications for weight, strength, durability, and fire resistance, aligning with their aircraft models' design and performance parameters. Beyond commercial aviation, military aircraft manufacturers and defense contractors constitute a significant customer segment, demanding floor panels tailored for tactical, transport, and fighter aircraft, often with enhanced ballistic protection or specific operational requirements. Manufacturers of business jets, such as Gulfstream, Dassault, and Textron Aviation, also represent a niche but high-value customer base, prioritizing aesthetic appeal, acoustic insulation, and lightweight performance for executive travel. Furthermore, the expansive aftermarket segment comprises airlines globally, independent Maintenance, Repair, and Overhaul (MRO) facilities, and aircraft leasing companies. These customers require replacement and repair panels for existing aircraft fleets, driven by routine maintenance cycles, damage repair, or interior refurbishment projects. The decision-making process for these customers is heavily influenced by factors such as product certification, supplier reputation, panel performance, lifecycle costs, and the ability to provide customized solutions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 4.65 Billion |

| Market Forecast in 2032 | USD 7.75 Billion |

| Growth Rate | 7.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Hexcel Corporation, Safran S.A., FACC AG, Triumph Group, Inc., Diehl Aviation, Zodiac Aerospace (Safran Group), The Gill Corporation, United Technologies Corporation (Collins Aerospace), TenCate Advanced Composites (Toray Industries, Inc.), Cytec Solvay Group (Solvay S.A.), Airbus S.E., Boeing Company, Fokker Technologies (GKN Aerospace), Mitsubishi Heavy Industries, Ltd., Spirit AeroSystems, Inc., NORDAM, Daher, Elbe Flugzeugwerke GmbH (EFW), Premium Aerotec, GKN Aerospace. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Aerospace Floor Panels Market Key Technology Landscape

The aerospace floor panels market is characterized by a continuously evolving technology landscape, driven by the relentless pursuit of enhanced performance, reduced weight, and improved cost-efficiency. A cornerstone of this landscape is the advanced composites technology, predominantly involving carbon fiber reinforced polymers (CFRP) and glass fiber reinforced polymers (GFRP). These materials are often integrated with lightweight core structures, such as honeycomb (Nomex, aluminum) or foam cores, to create sandwich panels that offer exceptional stiffness-to-weight ratios, superior fatigue resistance, and excellent acoustic and thermal insulation properties. Innovations in resin systems, including thermosets and thermoplastics, further enable improved processability and enhanced mechanical performance. Manufacturing techniques are also advancing rapidly, with automated fiber placement (AFP) and automated tape laying (ATL) gaining prominence for their ability to precisely lay composite plies, reduce manual labor, and ensure highly consistent panel quality. Furthermore, the increasing adoption of additive manufacturing (3D printing) is being explored for producing complex internal structures, customized fittings, and prototypes, offering design freedom and potential weight savings for specific components within the floor panel assembly. The integration of smart panel technologies, embedding sensors within the panels for real-time structural health monitoring (SHM), is another emerging trend, promising predictive maintenance capabilities and enhanced safety by detecting damage or degradation early. Surface treatment technologies, aimed at improving abrasion resistance, fire retardancy, and moisture protection, also remain crucial, ensuring the longevity and compliance of these critical aircraft components. These technological advancements collectively contribute to meeting the stringent demands of the aerospace industry, driving innovation for future aircraft generations.

Regional Highlights

- North America: As a mature market, North America maintains a substantial share due to the strong presence of major aircraft OEMs (e.g., Boeing) and a robust defense sector. The region benefits from significant investments in aerospace R&D and a highly developed MRO infrastructure, ensuring sustained demand for both new and replacement panels.

- Europe: Driven by Airbus and a well-established network of aerospace component manufacturers, Europe represents a key market. The region emphasizes innovation in composite materials and sustainable manufacturing practices, with stringent environmental regulations influencing product development.

- Asia Pacific (APAC): Expected to be the fastest-growing market, APAC's expansion is fueled by increasing air passenger traffic, substantial investments in new airport infrastructure, and the rapid growth of airline fleets, particularly in China and India. Emerging domestic aircraft programs also contribute significantly to regional demand.

- Latin America: This region shows steady growth, primarily due to fleet modernization efforts by local airlines and an expanding tourism sector. Increased aircraft deliveries from global OEMs further stimulate the demand for aerospace floor panels.

- Middle East & Africa (MEA): MEA is witnessing growth driven by strategic geographical location, serving as a global aviation hub, and significant investments in developing new airlines and expanding existing fleets. The demand for both commercial and business jet panels is on the rise.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Aerospace Floor Panels Market.- Hexcel Corporation

- Safran S.A.

- FACC AG

- Triumph Group, Inc.

- Diehl Aviation

- The Gill Corporation

- Collins Aerospace (Raytheon Technologies)

- Toray Industries, Inc. (TenCate Advanced Composites)

- Solvay S.A. (Cytec Solvay Group)

- Airbus S.E.

- Boeing Company

- GKN Aerospace (Fokker Technologies)

- Mitsubishi Heavy Industries, Ltd.

- Spirit AeroSystems, Inc.

- NORDAM

- Daher

- Elbe Flugzeugwerke GmbH (EFW)

- Premium Aerotec

- Aerolam Co. Ltd.

- C. D. G. E. Composite Panel, Inc.

Frequently Asked Questions

Analyze common user questions about the Aerospace Floor Panels market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary drivers of the Aerospace Floor Panels Market growth?

The market's growth is predominantly driven by increasing global air passenger traffic, leading to a surge in demand for new aircraft deliveries. Additionally, the continuous industry focus on lightweighting aircraft to enhance fuel efficiency and reduce emissions, along with robust MRO activities for aging fleets, significantly propel market expansion.

Which material type is currently dominating the aerospace floor panels market?

Composite materials, particularly carbon fiber reinforced polymers combined with lightweight honeycomb cores, are currently dominating the aerospace floor panels market. Their superior strength-to-weight ratio, durability, and resistance to environmental factors make them ideal for modern aircraft designs that prioritize fuel efficiency and performance.

What are the main challenges faced by manufacturers in the Aerospace Floor Panels Market?

Key challenges include the high cost associated with advanced composite materials and complex manufacturing processes, alongside stringent regulatory requirements and lengthy certification cycles for new products. Additionally, the aerospace industry's cyclical nature and potential supply chain disruptions pose ongoing hurdles for manufacturers.

How does sustainability influence the development of aerospace floor panels?

Sustainability is a growing influence, driving innovations in the use of eco-friendly materials, recyclable composites, and manufacturing processes that minimize waste and energy consumption. There's a push towards developing panels with extended lifespans and easier end-of-life recycling options to reduce the environmental footprint of aviation.

What is the forecast for regional growth in the aerospace floor panels market?

The Asia Pacific (APAC) region is projected to exhibit the highest growth rate, fueled by expanding air travel, significant fleet modernization, and increasing investments in aviation infrastructure in countries like China and India. North America and Europe will remain substantial, mature markets, while Latin America, the Middle East, and Africa are expected to show steady growth.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager