Aerospace Robotics Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427861 | Date : Oct, 2025 | Pages : 251 | Region : Global | Publisher : MRU

Aerospace Robotics Market Size

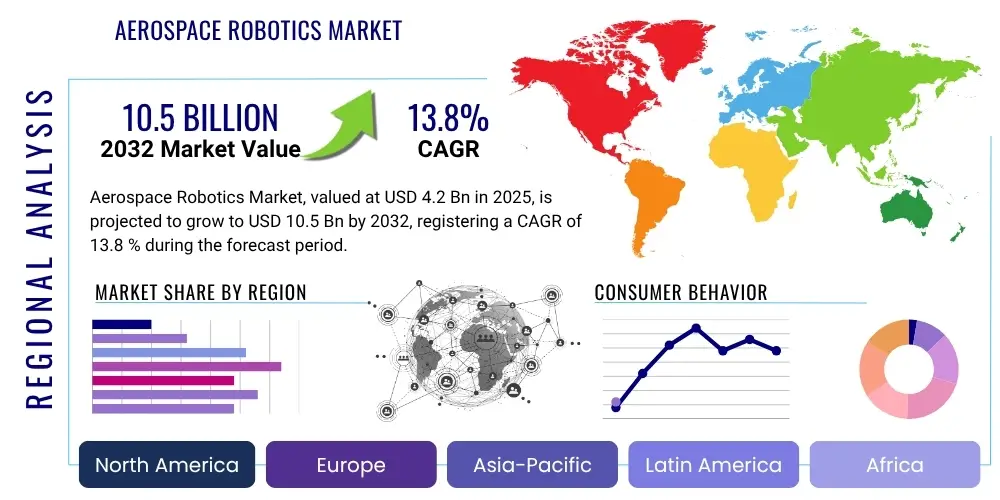

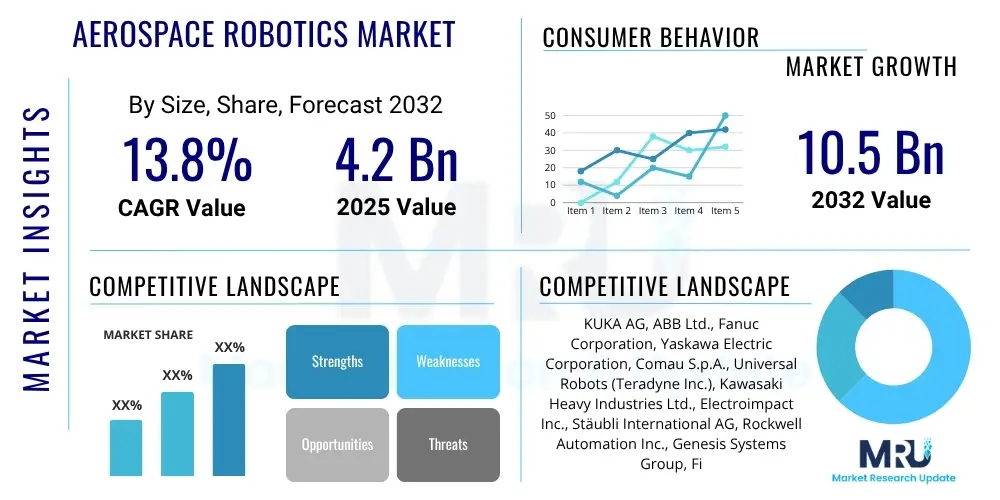

The Aerospace Robotics Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 13.8% between 2025 and 2032. The market is estimated at USD 4.2 Billion in 2025 and is projected to reach USD 10.5 Billion by the end of the forecast period in 2032.

Aerospace Robotics Market introduction

The Aerospace Robotics Market encompasses the design, manufacturing, and integration of robotic systems specifically tailored for applications within the aerospace industry. These advanced robotic solutions are utilized across various stages, from aircraft and spacecraft production to maintenance, repair, and overhaul (MRO) operations, as well as critical tasks in space exploration. The primary objective of deploying aerospace robotics is to enhance operational efficiency, improve precision, ensure worker safety in hazardous environments, and significantly reduce manufacturing and operational costs associated with traditional manual processes. The scope includes a wide array of robotic types, such as articulated robots, SCARA robots, delta robots, and increasingly, collaborative robots (cobots), each designed for specialized functions within the rigorous aerospace domain.

Products within this market range from large-scale gantry robots used for fuselage assembly and precise drilling operations to smaller, highly agile robots equipped with vision systems for detailed inspection and quality control. Major applications span automated riveting, welding, material handling, painting, composite layup, and non-destructive testing (NDT). The inherent benefits of these systems are substantial, offering unparalleled accuracy, repeatability, and speed, which are crucial for meeting stringent aerospace quality standards and production timelines. Furthermore, robotics mitigate human error and exposure to dangerous tasks, leading to improved safety records and reduced waste.

Driving factors propelling the growth of the aerospace robotics market include the surging global demand for new aircraft, advancements in automation technologies, and the increasing complexity of aerospace manufacturing processes that necessitate high-precision solutions. The industry's push towards Industry 4.0 initiatives, which integrate smart manufacturing, IoT, and artificial intelligence into production lines, further accelerates the adoption of robotic systems. Additionally, the growing focus on space exploration and the need for robust, autonomous systems capable of performing tasks in challenging extraterrestrial environments are opening new avenues for specialized aerospace robotics, underscoring their critical role in the future of flight and space endeavors.

Aerospace Robotics Market Executive Summary

The Aerospace Robotics Market is experiencing dynamic growth, propelled by a confluence of technological advancements, increasing automation demands, and the inherent need for precision and efficiency within the aerospace sector. Business trends indicate a strong emphasis on strategic partnerships, mergers, and acquisitions aimed at expanding technological capabilities and market reach. Key players are investing heavily in research and development, particularly in areas like collaborative robotics, artificial intelligence integration for enhanced decision-making, and specialized end-effectors for complex aerospace tasks. There is a discernible shift towards offering integrated solutions that combine robotics with vision systems, advanced software, and data analytics to provide comprehensive automation platforms for aerospace manufacturers and MRO providers. Furthermore, sustainability and reduction of carbon footprint through optimized manufacturing processes, facilitated by robotics, are becoming significant business drivers.

Regionally, North America continues to dominate the market, driven by the presence of major aircraft manufacturers, robust defense spending, and significant investments in space exploration programs. Europe also maintains a strong position, particularly in Western Europe, owing to its advanced manufacturing infrastructure and early adoption of automation technologies within the aerospace and automotive sectors, with Germany, France, and the UK leading the charge. The Asia Pacific (APAC) region is projected to exhibit the highest growth rate, fueled by rapid industrialization, burgeoning domestic aircraft manufacturing capabilities in countries like China and India, and increasing government support for technological advancements. Latin America, the Middle East, and Africa are emerging as promising markets, albeit with slower adoption rates, as they gradually ramp up their aerospace and defense capabilities, creating future demand for robotics solutions.

Segmentation trends highlight the increasing prominence of collaborative robots (cobots) due to their flexibility, ease of integration, and ability to work alongside human operators, addressing safety concerns while boosting productivity in assembly and inspection tasks. Application-wise, drilling and fastening, material handling, and inspection and quality control remain critical segments, witnessing continuous innovation. The end-user segment is largely driven by commercial aircraft manufacturing and MRO, but space exploration is emerging as a high-growth niche, demanding highly specialized and resilient robotic systems for orbital and planetary missions. Component-wise, advancements in robotic arms, sophisticated end-effectors, and intelligent control systems, coupled with integrated software platforms, are crucial for supporting the increasingly complex requirements of aerospace applications, signifying a market that is continually evolving to meet demanding industry standards.

AI Impact Analysis on Aerospace Robotics Market

User questions about the impact of AI on the Aerospace Robotics Market frequently revolve around how AI can enhance robotic capabilities, improve operational efficiency, and address complex challenges unique to the aerospace sector. Key themes include the potential for AI to enable more autonomous decision-making in robots, facilitate predictive maintenance, optimize intricate manufacturing processes, and improve human-robot collaboration. Users are keen to understand if AI can make robots more adaptable to unforeseen circumstances, reduce programming complexities, and contribute to higher quality control standards. Concerns also emerge regarding data security, ethical implications of autonomous systems, the need for robust validation frameworks, and potential workforce displacement, reflecting a desire for balanced insights into AI's transformative potential and its associated risks within this specialized industrial domain.

The integration of artificial intelligence (AI) is set to profoundly revolutionize the Aerospace Robotics Market by transcending traditional automation limits, endowing robotic systems with enhanced cognitive abilities. AI algorithms, particularly machine learning and deep learning, enable robots to process vast amounts of data from sensors, allowing for real-time decision-making, adaptation to dynamic environments, and superior task execution. This intelligence is critical for managing the high variability and precision requirements inherent in aerospace manufacturing, such as identifying microscopic defects during inspection or optimizing complex assembly sequences. Furthermore, AI-powered predictive analytics can forecast equipment failures, schedule proactive maintenance, and minimize downtime for both robotic systems and the aircraft components they produce, significantly improving overall operational efficiency and reducing costs across the value chain.

AI's influence also extends to the development of more sophisticated human-robot collaboration (HRC), fostering environments where robots and human workers can safely and efficiently work side-by-side, sharing tasks and leveraging each other's strengths. This is particularly valuable in aerospace assembly, where dexterity and cognitive flexibility of humans complement the precision and endurance of robots. Moreover, AI is instrumental in accelerating the development of autonomous systems for tasks in extreme environments, such as space exploration or hazardous MRO operations, where human intervention is impractical or unsafe. By enabling robots to learn from experience, perceive their surroundings more accurately, and navigate complex unstructured environments, AI is not merely improving existing robotic functions but fundamentally expanding the scope and capabilities of aerospace robotics, pushing the boundaries of what these systems can achieve.

- Enhanced autonomous decision-making and task execution.

- Predictive maintenance for robotics and aerospace components.

- Optimized manufacturing processes, reducing errors and waste.

- Improved human-robot collaboration (HRC) and safety.

- Advanced defect detection and quality control through machine vision.

- Faster programming and simulation of complex robotic tasks.

- Adaptability to dynamic and unstructured environments.

- Development of highly specialized robots for space exploration.

- Better resource allocation and supply chain optimization.

- Cybersecurity risk mitigation through AI-driven anomaly detection.

DRO & Impact Forces Of Aerospace Robotics Market

The Aerospace Robotics Market is shaped by a complex interplay of Drivers, Restraints, Opportunities, and broader Impact Forces. Key drivers include the escalating global demand for commercial aircraft, which necessitates high-volume and high-precision manufacturing processes, making automation indispensable. The inherent benefits of robotics, such as unparalleled accuracy, repeatability, and speed, directly address the stringent quality and safety standards of the aerospace industry. Furthermore, the imperative to reduce operational costs, enhance worker safety by automating hazardous tasks, and improve overall production efficiency are significant motivators for adoption. The growing focus on space exploration, both governmental and commercial, also fuels demand for specialized robotic systems capable of performing tasks in extreme environments.

However, the market faces several restraints. The high initial capital investment required for purchasing and integrating advanced robotic systems is a substantial barrier for many organizations, particularly smaller and medium-sized enterprises. The technical complexity associated with designing, programming, and maintaining sophisticated aerospace robotics demands highly specialized skills, leading to a shortage of trained personnel. Additionally, the need for extensive customization for diverse aerospace applications can increase costs and implementation timelines. Regulatory hurdles, including certifications and safety standards, particularly for human-robot collaborative environments, add another layer of complexity. Cybersecurity concerns, given the sensitive nature of aerospace data and infrastructure, also pose a significant challenge, requiring robust security measures.

Despite these challenges, numerous opportunities exist to propel market growth. The increasing adoption of collaborative robots (cobots) presents a significant opportunity, offering flexibility and safer human-robot interaction in assembly and MRO tasks. The integration of robotics with additive manufacturing (3D printing) technologies can streamline production of complex aerospace components. Opportunities in predictive maintenance, where robots perform autonomous inspections and repairs, are also expanding. Furthermore, the burgeoning satellite manufacturing sector and the development of next-generation space exploration vehicles offer new avenues for highly specialized robotic applications. Geographically, emerging economies with nascent but growing aerospace industries, particularly in Asia Pacific, present long-term growth prospects for market players.

The market is also influenced by broader impact forces. Rapid technological advancements in AI, machine vision, sensing capabilities, and materials science continually enhance robotic performance and expand their application scope. The global adoption of Industry 4.0 paradigms, emphasizing smart factories, IoT integration, and data-driven manufacturing, strongly encourages robotic deployment. Geopolitical factors, including trade policies, defense budgets, and international collaborations in space programs, can significantly impact market dynamics. Lastly, macroeconomic conditions, such as global economic stability and supply chain resilience, play a crucial role in influencing investment decisions and overall market growth, making the Aerospace Robotics Market highly susceptible to external pressures and technological shifts.

Segmentation Analysis

The Aerospace Robotics Market is meticulously segmented to provide a granular understanding of its diverse components and evolving dynamics. This segmentation typically considers various facets such as robot type, application area, end-user industry, and constituent components, offering a comprehensive view of how different elements contribute to the overall market landscape. Understanding these segments is crucial for stakeholders to identify specific growth areas, tailor product development, and formulate effective market entry strategies. The market is not monolithic; rather, it is a complex ecosystem where specialized robotic solutions address unique challenges within the demanding aerospace domain, from manufacturing highly precise parts to conducting meticulous inspections.

By dissecting the market into these distinct categories, analysis can reveal which robotic technologies are gaining traction, which applications are experiencing the most significant growth, and which end-user sectors are driving demand. For instance, the rise of collaborative robots highlights the industry's need for flexible and safe automation, while the increasing complexity of composite materials in aircraft manufacturing points to a growing demand for advanced material handling and inspection robots. This detailed segmentation not only aids in quantifying market size and forecasting future trends but also provides insights into competitive positioning, technological gaps, and potential strategic alliances, ensuring that market players can navigate the intricacies of the aerospace robotics landscape effectively.

- By Type: Articulated Robots, SCARA Robots, Delta Robots, Cartesian Robots, Collaborative Robots (Cobots), Other Types (e.g., Cylindrical, Gantry)

- By Application: Drilling & Fastening, Welding, Material Handling, Inspection & Quality Control, Painting & Coating, Assembly, Others (e.g., Composite Layup, NDT)

- By End-User: Aircraft Manufacturing (Commercial, Military), Space Exploration (Launch Vehicles, Satellites, Probes), Maintenance, Repair, and Overhaul (MRO), Defense, Research & Development

- By Component: Robotic Arms, End Effectors (Grippers, Tools), Controllers, Sensors (Vision, Force, Torque), Drive Systems (Motors, Gearboxes), Software (AI, Vision Processing, Simulation), Other Hardware

- By Region: North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA)

Value Chain Analysis For Aerospace Robotics Market

The value chain for the Aerospace Robotics Market is intricate, involving a series of sequential activities from raw material sourcing to end-user deployment and post-sales support. It begins with upstream activities focused on the design and manufacturing of core robotic components. This stage involves specialized suppliers providing essential elements such as robotic arms, precision sensors, advanced end-effectors (e.g., grippers, drilling tools, welding torches), sophisticated controllers, and high-performance drive systems. These components often require aerospace-grade specifications, demanding rigorous quality control and certification. Furthermore, software developers contribute critical intellectual property in the form of operating systems, simulation platforms, AI algorithms, and vision processing software that enable the robots to perform complex tasks with precision and autonomy. These upstream suppliers are foundational, as their innovations directly influence the capabilities and reliability of the final robotic systems.

Moving downstream, the value chain encompasses the integration, customization, and deployment of these robotic systems within aerospace manufacturing facilities, MRO centers, or space agencies. This phase is dominated by system integrators who specialize in designing bespoke robotic cells, programming robots for specific aerospace applications, and ensuring seamless integration with existing production lines. These integrators play a crucial role in bridging the gap between standard robotic hardware and the highly specialized requirements of the aerospace industry, offering value-added services such as installation, commissioning, training, and ongoing technical support. End-users, including commercial and military aircraft manufacturers, space exploration entities, and MRO service providers, are at the receiving end, leveraging these integrated solutions to enhance their operational efficiency, product quality, and safety standards.

Distribution channels within the Aerospace Robotics Market are typically characterized by a mix of direct and indirect approaches. Direct sales are common for large-scale projects or strategic partnerships, where leading robot manufacturers directly engage with major aerospace primes to offer customized solutions and extensive support. This direct channel facilitates closer collaboration, allowing for highly tailored robotic deployments that meet precise technical specifications. Indirect distribution, on the other hand, involves a network of authorized system integrators, value-added resellers (VARs), and distributors. These intermediaries are vital for reaching a broader customer base, particularly for smaller projects or specialized applications, by providing localized expertise, integration services, and after-sales support. The complexity of aerospace robotics often necessitates a robust ecosystem of specialized partners and integrators to ensure successful implementation and long-term operational success for end-users, highlighting the importance of both direct engagement and a strong partner network in the market's distribution strategy.

Aerospace Robotics Market Potential Customers

The primary potential customers for the Aerospace Robotics Market are diverse and encompass the entire spectrum of entities involved in aircraft, spacecraft, and related services, all seeking to leverage automation for improved efficiency, precision, and safety. A significant segment comprises commercial aircraft manufacturers, including major global players like Boeing, Airbus, Embraer, and Bombardier. These companies heavily invest in robotics for high-volume production tasks such as fuselage assembly, wing manufacturing, drilling, riveting, and composite layup, aiming to reduce production cycles, lower costs, and ensure consistent quality to meet soaring global demand for new aircraft. Military aircraft manufacturers and defense contractors also form a crucial customer base, utilizing robotics for specialized production, maintenance of advanced fighter jets, and development of unmanned aerial vehicles (UAVs), where precision and security are paramount.

Beyond manufacturing, the maintenance, repair, and overhaul (MRO) sector represents a rapidly growing segment of potential customers. MRO facilities, airlines, and independent service providers are increasingly adopting robotics for tasks like automated inspection of aircraft structures for fatigue cracks and corrosion, precise painting and coating, robotic grinding, and even component repair. These applications enhance the speed and accuracy of maintenance procedures, reduce aircraft downtime, and improve safety for technicians who might otherwise perform tedious or hazardous manual tasks. The MRO sector's drive for efficiency and cost reduction, coupled with the increasing complexity of modern aircraft, makes it a fertile ground for robotic solutions that can automate repetitive and critical inspection and repair processes.

Furthermore, entities engaged in space exploration and satellite manufacturing are emerging as high-value potential customers. This includes national space agencies such as NASA, ESA, JAXA, and commercial space companies like SpaceX, Blue Origin, and Rocket Lab. Robotics are essential for the assembly of launch vehicles, satellites, and spacecraft, where extreme precision and cleanliness are non-negotiable. Moreover, in-space robotics for satellite servicing, asteroid mining, and planetary exploration missions represent a frontier market, demanding highly specialized, autonomous, and resilient robotic systems capable of operating in harsh, extraterrestrial environments. Research and development institutions, universities, and specialized aerospace component manufacturers also represent niche customers, often collaborating with robot manufacturers to develop cutting-edge technologies and test novel applications that will shape the future of aerospace robotics.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 4.2 Billion |

| Market Forecast in 2032 | USD 10.5 Billion |

| Growth Rate | 13.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | KUKA AG, ABB Ltd., Fanuc Corporation, Yaskawa Electric Corporation, Comau S.p.A., Universal Robots (Teradyne Inc.), Kawasaki Heavy Industries Ltd., Electroimpact Inc., Stäubli International AG, Rockwell Automation Inc., Genesis Systems Group, Fives Group, ATI Industrial Automation, Rethink Robotics GmbH, Robotiq Inc., Omron Adept Technologies, Gudel AG, Schunk GmbH & Co. KG, Denso Wave Inc., Nachi-Fujikoshi Corp. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Aerospace Robotics Market Key Technology Landscape

The Aerospace Robotics Market is profoundly influenced by a dynamic and continuously evolving technological landscape, driven by the industry's relentless pursuit of precision, efficiency, and safety. At its core, the advancement of sophisticated robotic arms, ranging from highly robust articulated robots to agile SCARA and Delta robots, forms the backbone of automated aerospace manufacturing. These mechanical platforms are increasingly integrated with advanced sensors, including high-resolution machine vision systems, force-torque sensors, and lidar, enabling robots to perceive their environment with unprecedented accuracy. This enhanced perception is critical for tasks like precise component alignment, defect detection, and adaptive path planning in unstructured or semi-structured environments, which are common in MRO and complex assembly lines. The fusion of sensor data with real-time feedback loops allows for adaptive and intelligent manipulation, moving beyond pre-programmed movements to responsive actions.

The emergence of artificial intelligence (AI) and machine learning (ML) is perhaps the most transformative technological development, elevating robotic capabilities from mere automation to true autonomy and intelligence. AI algorithms are instrumental in enabling robots to perform complex decision-making, optimize process parameters, and learn from experience, significantly reducing the need for extensive manual programming. This is particularly evident in applications such as generative design for robotic paths, predictive maintenance for both robotic systems and aerospace assets, and advanced quality control where AI-powered vision systems can identify minute imperfections that are imperceptible to the human eye. Collaborative robots (cobots) represent another pivotal technology, designed to work safely alongside human operators without physical barriers, thereby enhancing flexibility and efficiency in assembly tasks, small batch production, and complex human-robot interaction scenarios. Their ease of programming and compact footprint make them highly suitable for reconfigurable manufacturing environments.

Furthermore, the integration of Internet of Things (IoT) and digital twin technologies is creating smarter, more connected robotic ecosystems within aerospace factories. IoT enables seamless communication between robots, other machinery, and central control systems, facilitating real-time data collection, monitoring, and analysis for optimized production flow. Digital twin technology creates virtual replicas of physical robotic systems and manufacturing processes, allowing for simulation, testing, and optimization in a virtual environment before physical implementation. This significantly reduces development time and costs while improving operational reliability. Other key technologies include advanced materials for lighter and more precise robotic components, sophisticated control systems with real-time kinematics, and specialized end-effectors designed for handling unique aerospace materials like composites or for executing specific operations such as automated fiber placement (AFP) or automated tape laying (ATL). These technological convergences are not only improving existing robotic applications but also opening new frontiers for automation in aerospace, from deep space missions to fully autonomous aircraft manufacturing lines.

Regional Highlights

- North America: Dominates the market due to the robust presence of leading aircraft manufacturers (Boeing, Lockheed Martin), significant defense spending, and substantial investments in space exploration programs (NASA, SpaceX, Blue Origin). The region benefits from advanced R&D and a strong emphasis on automation and digital manufacturing technologies.

- Europe: A mature market driven by established aerospace giants (Airbus, Dassault Aviation) and leading industrial automation providers. Countries like Germany, France, and the UK are key contributors, focusing on advanced manufacturing techniques, MRO optimization, and collaborative robotics to maintain competitive edge.

- Asia Pacific (APAC): Expected to exhibit the highest growth rate, fueled by rapid expansion of the aviation sector, increasing demand for domestic aircraft manufacturing (e.g., in China and India), and growing investments in advanced production facilities. Government initiatives and the proliferation of Industry 4.0 concepts are accelerating robotic adoption.

- Latin America: An emerging market with growing investments in aerospace manufacturing, particularly in countries like Brazil and Mexico. The region is witnessing gradual adoption of robotics as it aims to enhance its competitive position in the global aerospace supply chain, focusing initially on cost-effective automation solutions.

- Middle East and Africa (MEA): A developing market with increasing focus on diversifying economies beyond oil, leading to investments in aerospace and defense capabilities. While currently a smaller share, strategic initiatives to build localized manufacturing and MRO capabilities are expected to drive future demand for aerospace robotics.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Aerospace Robotics Market.- KUKA AG

- ABB Ltd.

- Fanuc Corporation

- Yaskawa Electric Corporation

- Comau S.p.A.

- Universal Robots (Teradyne Inc.)

- Kawasaki Heavy Industries Ltd.

- Electroimpact Inc.

- Stäubli International AG

- Rockwell Automation Inc.

- Genesis Systems Group

- Fives Group

- ATI Industrial Automation

- Rethink Robotics GmbH

- Robotiq Inc.

- Omron Adept Technologies

- Gudel AG

- Schunk GmbH & Co. KG

- Denso Wave Inc.

- Nachi-Fujikoshi Corp.

Frequently Asked Questions

Analyze common user questions about the Aerospace Robotics market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary benefits of using robotics in the aerospace industry?

Robotics offer unparalleled precision, repeatability, and efficiency in aerospace manufacturing and MRO, significantly reducing human error, enhancing product quality, lowering operational costs, and improving worker safety by automating hazardous tasks.

How is AI impacting the development of aerospace robotics?

AI is transforming aerospace robotics by enabling autonomous decision-making, predictive maintenance, advanced quality control through machine vision, and more efficient human-robot collaboration, leading to smarter, more adaptable, and versatile robotic systems.

What are the main challenges hindering the growth of the Aerospace Robotics Market?

Key challenges include high initial investment costs, the technical complexity of integration and programming, a shortage of skilled personnel, stringent regulatory hurdles for aerospace applications, and ongoing cybersecurity concerns.

Which applications are currently driving the demand for aerospace robotics?

Current demand is primarily driven by applications such as drilling and fastening, material handling, welding, assembly, and inspection/quality control in aircraft manufacturing, as well as emerging needs in space exploration and MRO.

What role do collaborative robots (cobots) play in aerospace?

Cobots are increasingly vital in aerospace for their ability to work safely alongside human operators, offering flexibility and efficiency in assembly, small batch production, and tasks requiring human dexterity combined with robotic precision, without needing extensive safety caging.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager