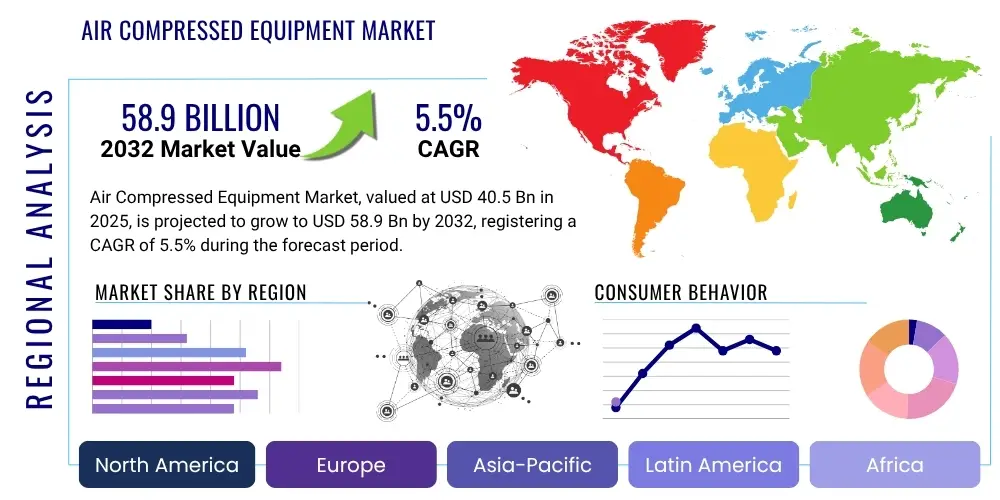

Air Compressed Equipment Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430091 | Date : Nov, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Air Compressed Equipment Market Size

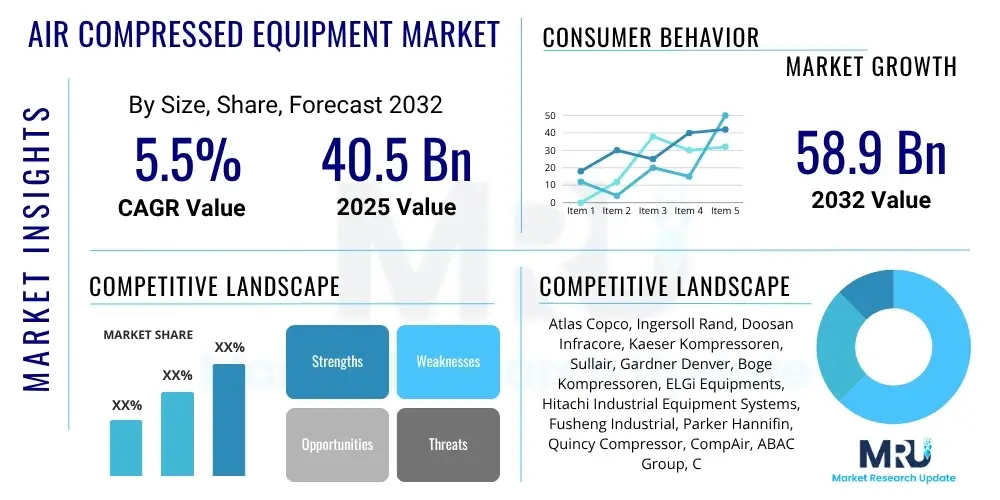

The Air Compressed Equipment Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.5% between 2025 and 2032. The market is estimated at USD 40.5 billion in 2025 and is projected to reach USD 58.9 billion by the end of the forecast period in 2032.

Air Compressed Equipment Market introduction

The Air Compressed Equipment market encompasses a wide array of machinery designed to generate, condition, and utilize compressed air. This equipment primarily includes air compressors, air dryers, air filters, and associated pneumatic tools and accessories. These systems are fundamental to modern industrial operations, converting ambient air into pressurized air that serves as a vital energy source for a multitude of processes. The robust nature and versatility of compressed air make it indispensable across diverse sectors, providing clean, powerful, and controllable energy for various applications.

The products within this market range from small, portable compressors used in automotive repair and construction to large, stationary industrial systems that power entire manufacturing facilities. Major applications span across manufacturing, automotive, construction, energy, and healthcare industries, facilitating tasks such as powering pneumatic tools, operating machinery, material handling, painting, and even providing medical-grade air. The inherent benefits of using air compressed equipment include enhanced operational efficiency, improved safety through the elimination of electrical hazards in certain environments, precise control over processes, and the ability to operate in harsh conditions where other power sources might fail. These advantages underscore the equipment's critical role in driving productivity and innovation across global industries.

Key driving factors for market expansion include accelerating industrialization, especially in developing economies, the increasing demand for automation in manufacturing processes, and stringent regulations concerning energy efficiency and environmental impact that push for more advanced and sustainable compressed air solutions. Furthermore, continuous technological advancements leading to more compact, quieter, and IoT-enabled equipment are significantly contributing to market growth. The need for reliable and efficient power sources in both heavy and light industries ensures a steady and growing demand for air compressed equipment.

Air Compressed Equipment Market Executive Summary

The Air Compressed Equipment market is experiencing robust growth, driven by an expanding global manufacturing base and the pervasive trend towards industrial automation. Key business trends indicate a strong focus on energy-efficient solutions, with manufacturers investing heavily in Variable Speed Drive (VSD) compressors and integrated smart control systems to meet rising operational efficiency demands and comply with stricter environmental regulations. The integration of IoT and Industry 4.0 technologies is transforming the market, enabling predictive maintenance, real-time monitoring, and optimized system performance, thereby enhancing productivity and reducing downtime across various end-use sectors. Sustainability initiatives are also shaping product development, leading to demand for oil-free compressors and equipment with lower carbon footprints.

Regionally, Asia Pacific continues to dominate the market, fueled by rapid industrialization, infrastructure development, and a booming manufacturing sector in countries like China and India. North America and Europe demonstrate mature markets characterized by replacement demand, technological upgrades, and a strong emphasis on advanced, energy-efficient, and environmentally compliant systems. Latin America and the Middle East and Africa are emerging as significant growth hubs, driven by increasing investments in construction, mining, and oil and gas industries, which require robust and reliable compressed air solutions. These regional dynamics highlight diverse growth opportunities and varying demands for technology and product types, necessitating localized market strategies for global players.

Segment-wise, the market sees considerable expansion in oil-free compressors due to their critical applications in sensitive industries such as pharmaceuticals, food and beverage, and electronics, where air purity is paramount. The stationary compressor segment holds a larger share due to its widespread use in continuous industrial operations, while the portable segment is gaining traction in construction and rental markets. Application-wise, manufacturing remains the largest segment, benefiting from increased automation, followed closely by the energy and automotive sectors. The shift towards decentralized production and modular factories also supports the demand for flexible and scalable compressed air solutions, driving innovation in product design and functionality.

AI Impact Analysis on Air Compressed Equipment Market

Users frequently inquire about how Artificial Intelligence (AI) can revolutionize the air compressed equipment market, focusing on aspects like predictive maintenance, energy optimization, operational efficiency, and system reliability. Common questions revolve around the potential for AI to minimize downtime, reduce operational costs through smart energy management, and enhance the overall lifespan of equipment. There is a strong expectation that AI will move beyond basic automation to offer proactive solutions, anticipate failures, and provide intelligent diagnostics, thereby transforming the traditional service and maintenance models. Users seek to understand how AI-driven insights can lead to more sustainable and cost-effective compressed air systems in an increasingly interconnected industrial landscape.

- AI enables predictive maintenance, anticipating equipment failures before they occur and reducing unscheduled downtime.

- Optimized energy consumption through AI algorithms that analyze usage patterns and adjust compressor operation for maximum efficiency.

- Enhanced operational performance via real-time data analysis and intelligent control systems that adapt to varying demand.

- Improved fault detection and diagnostics, allowing for quicker troubleshooting and minimized repair times.

- Facilitates remote monitoring and management of compressed air systems, improving accessibility and responsiveness.

- Supports integration with broader Industry 4.0 ecosystems for seamless data exchange and process optimization.

- Assists in design and engineering of more efficient compressors through advanced simulations and data-driven insights.

DRO & Impact Forces Of Air Compressed Equipment Market

The Air Compressed Equipment market is profoundly influenced by a complex interplay of drivers, restraints, opportunities, and external impact forces. A primary driver is the accelerating pace of global industrialization, particularly in emerging economies, which fuels the demand for robust and efficient industrial machinery, including compressed air systems, across various manufacturing and processing sectors. The increasing adoption of automation and robotics in production lines also significantly boosts the need for reliable compressed air to power pneumatic components and tools. Furthermore, heightened awareness and stringent regulations regarding energy efficiency and environmental sustainability are compelling industries to upgrade to more advanced, eco-friendly, and energy-saving compressed air solutions, thus stimulating market growth. The versatility and widespread applicability of compressed air in diverse end-use industries further solidify its position as an indispensable utility, maintaining consistent demand.

Conversely, the market faces several significant restraints that could impede its growth trajectory. The relatively high initial capital expenditure associated with purchasing and installing advanced air compressed equipment can be a barrier for small and medium-sized enterprises (SMEs) with limited budgets. Operational costs, including substantial electricity consumption and ongoing maintenance requirements, also present a challenge, although technological advancements are gradually mitigating these. Additionally, noise pollution generated by compressors, particularly in urban or confined industrial settings, and the potential for air leakage and pressure drops within older or poorly maintained systems, contribute to inefficiencies and environmental concerns, prompting regulatory scrutiny and the need for continuous system upgrades. The market is also sensitive to global economic downturns, which can reduce industrial investment and slow new project developments.

Opportunities within the market largely stem from technological innovation and expanding application areas. The growing integration of IoT, AI, and cloud-based solutions into compressed air systems offers avenues for enhanced predictive maintenance, remote monitoring, and real-time optimization, creating value-added services and products. The rising demand for oil-free compressors in sensitive industries such as food and beverage, pharmaceuticals, and electronics, driven by strict air purity standards, represents a lucrative niche. Furthermore, the development of customized and modular compressed air solutions tailored to specific industry needs, along with the increasing emphasis on energy recovery systems, presents significant growth prospects. Untapped markets in developing regions, coupled with infrastructure expansion projects globally, also provide substantial opportunities for market players.

Segmentation Analysis

The Air Compressed Equipment market is extensively segmented based on several key parameters, allowing for a detailed understanding of its diverse landscape and consumer needs. This segmentation helps in analyzing market dynamics, identifying specific growth areas, and understanding competitive landscapes. The primary classifications include product type, technology, lubrication type, application, end-use industry, and geographic region. Each segment exhibits unique characteristics and growth drivers, reflecting varying technological preferences, operational requirements, and regulatory environments across different industrial sectors globally. Understanding these distinctions is crucial for manufacturers, distributors, and end-users to navigate the market effectively.

- Product Type

- Air Compressors

- Rotary (Screw, Vane, Lobe)

- Reciprocating (Piston)

- Centrifugal

- Air Dryers

- Refrigerant Air Dryers

- Desiccant Air Dryers

- Membrane Air Dryers

- Air Filters

- Aftercoolers

- Air Receivers

- Pneumatic Tools and Accessories

- Air Compressors

- Technology

- Oil-Lubricated

- Oil-Free

- Lubrication Type

- Stationary

- Portable

- Application

- Manufacturing

- Construction

- Automotive

- Energy

- Food and Beverage

- Healthcare

- Mining

- Oil and Gas

- Semiconductors and Electronics

- Other Industrial Applications

- End-Use Industry

- Industrial

- Commercial

- Residential

- Power Range

- Up to 50 HP

- 51-100 HP

- Above 100 HP

Value Chain Analysis For Air Compressed Equipment Market

The value chain for the Air Compressed Equipment market commences with a robust upstream segment, primarily involving raw material suppliers and component manufacturers. This includes suppliers of metals such as cast iron, aluminum, and steel for compressor casings and internal components, as well as specialized manufacturers providing crucial elements like electric motors, rotors, valves, filters, and electronic control systems. These upstream players are critical in ensuring the quality and reliability of the foundational components, impacting the overall performance and cost-effectiveness of the final product. The competitive landscape at this stage often revolves around material quality, technological sophistication, and supply chain efficiency, directly influencing the manufacturing process downstream.

The midstream of the value chain is dominated by the core manufacturing and assembly processes. Leading manufacturers design, engineer, and assemble various types of air compressors, air dryers, filtration systems, and related pneumatic equipment. This stage involves complex R&D to innovate new technologies, improve energy efficiency, and develop smart features such as IoT integration and remote monitoring capabilities. Quality control, precision engineering, and adherence to international standards are paramount here. Companies often invest heavily in advanced production facilities and skilled labor to produce high-performance, durable, and reliable equipment that meets diverse industrial demands, from heavy-duty manufacturing to sensitive applications requiring oil-free air.

The downstream segment primarily focuses on distribution, sales, installation, and after-sales services, connecting the manufactured equipment with the end-users. Distribution channels are varied, encompassing direct sales teams, authorized distributors, regional dealers, and online platforms. Direct sales are common for large industrial clients requiring customized solutions and extensive technical support, while indirect channels cater to a broader range of customers, often providing localized presence and quicker delivery. Post-sales services, including installation, commissioning, maintenance, spare parts supply, and repair, are critical for customer satisfaction and long-term engagement, forming a significant revenue stream. Effective service networks ensure optimal equipment performance, minimize downtime, and extend product lifecycles, thereby enhancing customer loyalty and market reputation.

Air Compressed Equipment Market Potential Customers

The potential customer base for the Air Compressed Equipment market is remarkably broad and diverse, spanning across nearly all industrial and a growing number of commercial sectors. At its core, any entity requiring a reliable and efficient source of pneumatic power for operations, manufacturing, or maintenance represents a potential customer. This includes large-scale manufacturing facilities that utilize compressed air for assembly lines, automation, and tooling, as well as smaller workshops and service providers that rely on pneumatic tools for repairs and fabrication. The universality of compressed air as an energy medium means that end-users range from highly specialized industries with stringent air quality requirements to general industrial applications where robust and continuous power is essential.

Key end-user industries include, but are not limited to, automotive manufacturing for assembly, painting, and tire inflation; construction for powering jackhammers, drills, and concrete vibrators; energy sectors such as oil and gas for pneumatic instrumentation and process control; and the food and beverage industry for packaging, conveying, and processing, particularly with a focus on oil-free solutions. The pharmaceutical and healthcare sectors are also significant consumers, demanding high-purity compressed air for sterile environments, medical devices, and laboratory applications. Furthermore, mining operations utilize compressed air for drilling and ventilation, while the electronics and semiconductor industry relies on ultra-clean compressed air for sensitive manufacturing processes, highlighting the critical nature of these systems across the economic spectrum.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 40.5 billion |

| Market Forecast in 2032 | USD 58.9 billion |

| Growth Rate | CAGR 5.5% |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Atlas Copco, Ingersoll Rand, Doosan Infracore, Kaeser Kompressoren, Sullair, Gardner Denver, Boge Kompressoren, ELGi Equipments, Hitachi Industrial Equipment Systems, Fusheng Industrial, Parker Hannifin, Quincy Compressor, CompAir, ABAC Group, Chicago Pneumatic, Kobelco Compressors, Cook Compression, Aerzen, Pneutech, Mattei Compressors |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Air Compressed Equipment Market Key Technology Landscape

The Air Compressed Equipment market is continuously evolving, driven by significant technological advancements aimed at enhancing efficiency, reliability, and sustainability. One of the most impactful innovations is the widespread adoption of Variable Speed Drive (VSD) technology in compressors. VSD compressors automatically adjust their motor speed to match air demand, leading to substantial energy savings compared to fixed-speed compressors, which are designed for peak load and often waste energy during partial load operation. This technology is critical in reducing operational costs and meeting stringent energy efficiency standards, making it a preferred choice for industries with fluctuating air requirements.

Another crucial technological trend is the integration of Internet of Things (IoT) and Industry 4.0 principles into compressed air systems. This involves embedding sensors and connectivity into equipment to enable real-time monitoring, remote diagnostics, and predictive maintenance. Data collected from these smart systems, such as pressure, temperature, power consumption, and operating hours, can be analyzed using cloud-based platforms and AI algorithms to optimize performance, prevent failures, and schedule maintenance proactively. This digital transformation not only improves operational uptime and reduces service costs but also provides valuable insights for continuous improvement and energy management across industrial facilities.

Furthermore, advancements in air treatment and filtration technologies are paramount, especially for industries requiring high-purity compressed air. Innovations include more efficient desiccant and refrigerant dryers that achieve lower dew points with reduced energy consumption, as well as advanced filtration solutions that remove sub-micron particles, oil aerosols, and odors more effectively. There is also a growing focus on oil-free compressor technologies, such as water-lubricated or scroll compressors, to meet the strict air quality standards in sectors like food and beverage, pharmaceuticals, and electronics, where even minimal oil contamination is unacceptable. Energy recovery systems, which capture and reuse the heat generated during compression, are also gaining traction, further enhancing the overall energy efficiency and sustainability of compressed air installations.

Regional Highlights

- North America: Characterized by a mature industrial base with a strong emphasis on automation, smart manufacturing, and the replacement of older, less efficient equipment. The region sees significant demand from the automotive, aerospace, and general manufacturing sectors, with a growing focus on energy-efficient and IoT-integrated solutions.

- Europe: Driven by stringent environmental regulations and high energy costs, leading to strong demand for highly efficient, low-noise, and sustainable compressed air solutions. Germany, Italy, and the UK are key markets, with robust manufacturing, automotive, and pharmaceutical industries adopting advanced oil-free and VSD technologies.

- Asia Pacific (APAC): The largest and fastest-growing market due to rapid industrialization, burgeoning manufacturing sectors in China, India, and Southeast Asian countries, and extensive infrastructure development. The region presents immense opportunities for both established and emerging players, particularly in the automotive, electronics, textile, and construction industries, with a mix of demand for both cost-effective and technologically advanced systems.

- Latin America: Experiencing growth driven by investments in mining, construction, and nascent manufacturing industries. Countries like Brazil and Mexico are key contributors, with demand for robust and reliable equipment suited for challenging operational environments. The market is increasingly adopting portable compressors for various project-based applications.

- Middle East and Africa (MEA): Growth is propelled by infrastructure development projects, expansion in the oil and gas sector, and diversification efforts in manufacturing. Saudi Arabia, UAE, and South Africa are significant markets, requiring durable and high-performance compressed air solutions to support heavy industry and large-scale construction, often in harsh climatic conditions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Air Compressed Equipment Market.- Atlas Copco

- Ingersoll Rand

- Doosan Infracore

- Kaeser Kompressoren

- Sullair

- Gardner Denver

- Boge Kompressoren

- ELGi Equipments

- Hitachi Industrial Equipment Systems

- Fusheng Industrial

- Parker Hannifin

- Quincy Compressor

- CompAir

- ABAC Group

- Chicago Pneumatic

- Kobelco Compressors

- Cook Compression

- Aerzen

- Pneutech

- Mattei Compressors

Frequently Asked Questions

What is air compressed equipment and why is it important?

Air compressed equipment generates and conditions pressurized air, serving as a critical power source for various industrial processes. It is vital for operating pneumatic tools, machinery, and automation systems across manufacturing, construction, and other sectors due to its efficiency, safety, and versatility.

What are the primary types of air compressors?

The primary types include rotary compressors (screw, vane, lobe), reciprocating compressors (piston), and centrifugal compressors. Each type is suited for different applications based on air pressure, volume, and operational requirements.

How do energy-efficient technologies impact the air compressed equipment market?

Energy-efficient technologies, such as Variable Speed Drive (VSD) compressors and smart control systems, significantly reduce operational costs and environmental impact. They optimize energy consumption by adjusting output to demand, aligning with sustainability goals and stringent regulations, thus driving market demand for advanced solutions.

What role does IoT play in modern air compressed equipment?

IoT enables real-time monitoring, remote diagnostics, and predictive maintenance for compressed air systems. By collecting and analyzing operational data, IoT integration enhances efficiency, reduces downtime, and allows for proactive issue resolution, contributing to Industry 4.0 initiatives.

Which industries are the largest consumers of air compressed equipment?

The manufacturing industry, encompassing automotive, food and beverage, electronics, and general industrial sectors, represents the largest consumer. Other significant end-users include construction, energy, healthcare, mining, and pharmaceuticals, each relying on compressed air for diverse applications.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager