Aircraft Filters Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430121 | Date : Nov, 2025 | Pages : 257 | Region : Global | Publisher : MRU

Aircraft Filters Market Size

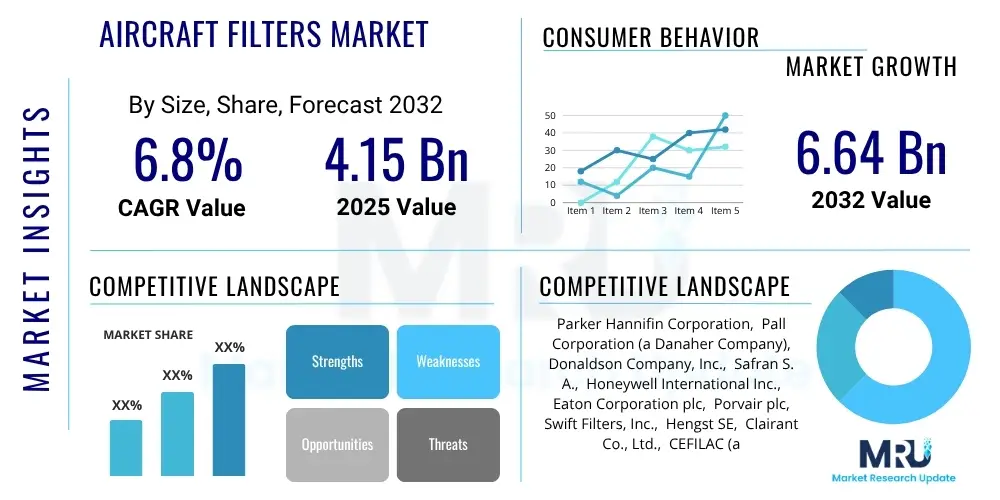

The Aircraft Filters Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at $4.15 Billion in 2025 and is projected to reach $6.64 Billion by the end of the forecast period in 2032.

Aircraft Filters Market introduction

The Aircraft Filters Market represents a critically vital and technologically sophisticated segment within the expansive global aerospace industry, intrinsically dedicated to ensuring the highest echelons of operational integrity, maintaining unparalleled safety standards, and optimizing the performance characteristics of an incredibly diverse array of complex aircraft systems. These highly specialized filtration solutions are engineered with meticulous precision and unwavering reliability to comprehensively eradicate particulate contaminants, eliminate harmful moisture content, neutralize microbial growths, and remove various other deleterious impurities that possess the potential to compromise the fundamental functionality of essential fluids and critical airflows throughout an aircraft’s operational lifespan. The extensive scope of this market encompasses a wide spectrum of diligently designed filters, including those tailored for hydraulic systems that are responsible for the precise control of flight surfaces and the reliable deployment of landing gear, as well as lubricating oils vital for preserving the operational longevity and efficiency of main engines and intricate gearboxes. Furthermore, it incorporates advanced filtration units for aviation fuels that power propulsion systems, sophisticated cabin air recirculation systems paramount for passenger and crew well-being, high-performance engine air intake systems that protect core engine components, and even niche filters for bleed air and auxiliary power units (APUs). The fundamental and overarching mandate of these advanced filters is to rigorously protect extraordinarily sensitive and exceptionally high-value aircraft components from premature wear, corrosive degradation, and potentially catastrophic malfunction, thereby ensuring unwavering adherence to the most stringent international aviation safety protocols and sustaining peak operational performance across the most challenging flight regimes and diverse environmental conditions encountered globally, from arid deserts to polar extremes, and from sea level to high altitudes.

The comprehensive product description for aircraft filters reveals an expansive and highly specialized range of types, each meticulously crafted to fulfill a distinct and absolutely critical function within an aircraft’s complex operational matrix. This extensive range commences with High-Efficiency Particulate Air (HEPA) filters, which are expertly engineered to meticulously purify cabin air, thereby cultivating an exceptionally sterile, healthy, and comfortable environment for both passengers and flight crew by effectively eliminating airborne pathogens, microscopic allergens, fine particulate matter, and various gaseous contaminants. Complementing these essential cabin air purifiers are robust hydraulic filters, which are absolutely critical for preserving the pristine condition and optimal viscosity of hydraulic fluid within systems responsible for governing flight control surfaces, facilitating the reliable deployment and retraction of landing gear, and ensuring the precise operation of braking mechanisms; these filters prevent wear and guarantee uncompromised operational reliability under extreme stress. Fuel filters are diligently designed to meticulously safeguard critical propulsion systems from a myriad of microscopic contaminants, ensuring the delivery of scrupulously clean fuel to the engines, which is paramount for preventing fuel system blockages and maintaining optimal combustion. Oil filters play an indispensable role in significantly extending the operational lifespan of both the main engines and auxiliary power units (APUs) by efficiently removing metallic wear particles, detrimental carbon deposits, and other harmful byproducts of combustion and friction from lubricating oils, thus sustaining peak engine performance and preventing costly damage. Furthermore, sophisticated air intake filters are precisely designed to prevent the ingress of foreign objects, damaging debris, abrasive dust, and other airborne particles into sensitive jet engines during all phases of flight, including high-thrust takeoffs and complex landing maneuvers, which is unequivocally paramount for ensuring engine longevity, optimizing thrust efficiency, and preventing expensive turbine damage. Each individual filter type is painstakingly tailored to meet highly specific operational demands and withstand the unique environmental challenges inherent within particular aircraft systems, reflecting the aerospace industry's uncompromising standards for reliability, durability, and unfailing performance under the most arduous conditions.

The multifaceted and profound benefits derived from the systematic deployment of advanced aircraft filtration systems are extensive, far-reaching, and extend across numerous critical operational domains, directly impacting both safety and economic viability. Foremost among these benefits is the assurance of unparalleled aircraft safety, which is unequivocally achieved by proactively preventing systemic failures that could otherwise severely compromise flight integrity, leading to potentially hazardous situations or even catastrophic events. Beyond this foundational safety imperative, significant and tangible advantages include substantially enhanced operational efficiency, which directly translates into considerable economic benefits for airlines and operators. Effective and consistent filtration markedly reduces the frequency of unscheduled maintenance events, which are notoriously disruptive and expensive, and dramatically extends the operational lifespan of extraordinarily expensive and complex components such as turbine engines, hydraulic pumps, and actuators, thereby deferring capital expenditure. Concurrently, high-efficiency filtration systems demonstrably improve overall fuel economy by meticulously preserving clean fluid pathways and ensuring optimal engine performance, thus reducing operational costs. Moreover, the integral role of cutting-edge aircraft filters is instrumental in assisting aircraft operators and manufacturers in achieving and rigorously maintaining strict compliance with increasingly demanding global environmental and public health regulations. This is particularly relevant concerning mandates for superior cabin air quality, which directly impacts passenger health and comfort, and meticulous emissions control, which addresses broader ecological responsibilities and regulatory penalties. The robust market growth for aircraft filters is fundamentally propelled by the consistent and vigorous expansion of global air travel demand, which necessitates a continuous influx of new aircraft deliveries and a corresponding surge in demand for both Original Equipment Manufacturer (OEM)-installed and aftermarket replacement filters. Concurrently, the progressive aging of the worldwide commercial and military aircraft fleet inherently mandates an elevated frequency of Maintenance, Repair, and Overhaul (MRO) activities, providing a stable, substantial, and recurring source of demand for a comprehensive range of replacement filtration units. Furthermore, relentless innovation in filtration technology, coupled with an intensified industry-wide focus on elevating safety standards, mitigating operational risks, and fostering environmental sustainability, collectively serve to powerfully fuel this market’s consistent and positive growth trajectory, driving continuous demand for more advanced, efficient, reliable, and sustainable filtration solutions across the entire aviation ecosystem, from initial design to end-of-life recycling considerations.

Aircraft Filters Market Executive Summary

The Aircraft Filters Market is presently undergoing a profoundly dynamic period, characterized by the convergence of evolving business trends, significant regional economic shifts, and relentless innovation across various product segments. Current business trends emphatically indicate a strong and growing emphasis on fostering sustainability throughout the aerospace value chain, which is directly translating into intensified research, development, and subsequent adoption of lighter-weight, substantially more durable, and environmentally benign filter materials. These advanced materials not only reduce the ecological footprint but also offer dramatically extended service intervals and contribute to reduced waste generation, aligning with global environmental objectives. The industry is additionally witnessing an increase in strategically crucial collaborations between leading filter manufacturers and prominent aerospace Original Equipment Manufacturers (OEMs), aimed at seamlessly integrating highly advanced filtration systems directly into new aircraft designs from the conceptual stage, thereby ensuring optimal performance, synergistic functionality, and maximum efficiency from the initial rollout. Furthermore, a pivotal trend driving both technological advancement and operational efficiency for airlines and MRO providers is the escalating adoption of intelligent filtration systems. These systems incorporate sophisticated sensors and advanced data analytics capabilities for real-time performance monitoring and sophisticated predictive maintenance, fundamentally transforming how aircraft filters are managed and serviced. The competitive landscape itself is undergoing notable shifts, marked by both strategic consolidation efforts among major established players seeking to broaden their product portfolios and geographical market reach, alongside the emergence of specialized innovators who are introducing highly niche and disruptive filtration solutions.

From a rigorous regional analysis perspective, the Asia Pacific (APAC) market unequivocally stands out as the primary and most vigorous growth engine for aircraft filters. This extraordinary expansion is powerfully fueled by burgeoning regional economies, a rapidly expanding middle-class population, and substantial, sustained investments in new airport infrastructure development and the aggressive enlargement of airline fleets, particularly within economic powerhouses like China, India, and the rapidly developing nations of Southeast Asia. The region's escalating demand for both domestic and international air travel directly translates into an exceptionally robust and continuous need for a comprehensive array of both new and replacement aircraft filters to support an expanding fleet. In contrast, North America and Europe, while representing more mature and established markets, steadfastly maintain their substantial market shares. This endurance is attributable to their extensive existing aircraft fleets, profoundly well-established and sophisticated Maintenance, Repair, and Overhaul (MRO) networks, and consistent, significant defense spending that perpetually drives demand for high-performance military aircraft filters. These technologically advanced regions are also consistently at the forefront of adopting the latest advanced filtration technologies and adhering to the most stringent regulatory standards, further cementing their market positions. Concurrently, emerging markets in Latin America and the Middle East & Africa (MEA) are demonstrating highly promising growth trajectories, propelled by ambitious fleet modernization programs, the strategic establishment of new airline routes, and substantial governmental and private investments in regional aviation hubs, collectively creating fertile new opportunities for filter manufacturers, suppliers, and service providers.

Segmentation trends within the broader aircraft filters market vividly highlight a rapidly growing demand for highly specialized solutions meticulously tailored to address specific operational exigencies and performance criteria. The HEPA filter segment, specifically crucial for cabin air quality, is experiencing particularly heightened growth, driven by an increased global public health awareness and an amplified desire for enhanced passenger comfort and safety, a sentiment notably exacerbated in the wake of recent global health crises. In response, manufacturers are intensely focusing on developing next-generation HEPA filters with improved antimicrobial properties, superior particle capture capabilities, and significantly extended operational lifespans. Simultaneously, filters designed for critical engine and hydraulic systems are witnessing profound innovations aimed at dramatically improving filtration efficiency, substantially reducing overall component weight, and significantly increasing durability through the judicious application of advanced materials science and state-of-the-art manufacturing processes, such as additive manufacturing. The Maintenance, Repair, and Overhaul (MRO) segment continues to represent an absolutely crucial and consistently robust revenue stream, primarily driven by the imperative need to maintain a progressively aging global fleet and the periodic replacement cycles of various safety-critical filter types. Furthermore, pervasive technological integration, exemplified by the seamless incorporation of Internet of Things (IoT) sensors directly into filter elements for real-time condition monitoring, is a cross-cutting and transformative trend influencing all segments. This promises a revolutionary shift towards profoundly more proactive, efficient, and data-driven maintenance paradigms across the entire aircraft filtration ecosystem, ultimately enhancing safety and optimizing operational costs.

AI Impact Analysis on Aircraft Filters Market

Common user questions regarding the profound impact of Artificial Intelligence (AI) on the Aircraft Filters Market frequently revolve around the inherent potential for AI to fundamentally revolutionize existing maintenance practices, significantly enhance filter design methodologies, and ultimately elevate overall operational safety to unprecedented levels within the aerospace sector. Users are particularly keen to comprehend if AI can deliver the capability to accurately predict filter failures with a high degree of precision before they physically manifest, thereby allowing for the proactive optimization of replacement schedules and a dramatic minimization of unscheduled downtime, which is notoriously costly for airlines. There is also substantial and growing interest in understanding precisely how AI technologies can contribute meaningfully to the accelerated development of inherently more efficient, exceptionally durable, and environmentally sustainable filters through the application of advanced material science and sophisticated design optimization algorithms. The overarching themes consistently emerging from these diverse inquiries collectively highlight a strong and pervasive expectation that AI will undeniably usher in a transformative era of 'smart filtration.' In this new paradigm, filtration systems will not only be reactively responsive to emergent issues but will proactively anticipate and effectively prevent potential problems, leading to substantial and demonstrable cost savings, significant operational efficiencies, and profound safety improvements across the entire aviation sector, impacting everything from component longevity to passenger comfort.

Based on this comprehensive analysis of user inquiries and market sentiments, the pivotal themes, prevalent concerns, and aspirational expectations that stakeholders harbor regarding AI's profound influence in this critical domain predominantly center on its unparalleled capacity for sophisticated predictive analytics, highly accurate real-time diagnostics, and exceptionally intelligent design methodologies. Industry stakeholders widely anticipate that AI will facilitate a fundamental shift within the aviation industry, propelling it beyond traditional time-based maintenance protocols to a significantly more sophisticated condition-based or even a truly predictive-based approach. In this advanced maintenance regime, aircraft filters would be replaced precisely when their performance degradation dictates, thereby maximizing their operational useful life, minimizing unnecessary waste, and ensuring optimal resource utilization. Concerns, though outweighed by optimism, often encompass the intricate complexity of seamlessly integrating nascent AI systems into existing, highly regulated aircraft infrastructure, the critical implications of data security and privacy for sensitive operational data, and the imperative need for extremely robust and rigorous validation processes to definitively ensure the unwavering reliability and infallible accuracy of AI models in safety-critical aviation applications. Nevertheless, the predominant and pervasive expectation is that AI will emerge as a truly transformative force, enabling unprecedented levels of efficiency, reliability, and safety in all facets of aircraft filtration, ranging from the optimization of intricate manufacturing processes to the significant extension of filter lifespans in operational aircraft by expertly leveraging vast, complex datasets to derive actionable, intelligent insights. This comprehensive integration promises to redefine industry best practices and unlock new potentials for operational excellence and environmental stewardship.

- Predictive Maintenance Optimization: AI algorithms meticulously analyze vast datasets derived from onboard sensors, historical maintenance records, and real-time operational parameters. This enables them to accurately forecast filter degradation patterns and determine optimal replacement times with high precision, fundamentally shifting maintenance strategies from reactive schedules to highly proactive, condition-based interventions, thereby minimizing unnecessary replacements and preventing costly unscheduled failures.

- Enhanced Design and Material Innovation: AI-driven computational fluid dynamics (CFD) simulations, finite element analysis (FEA), and advanced machine learning techniques are utilized to optimize filter media composition, pore structure, and housing geometry for vastly superior filtration efficiency, substantially reduced pressure drop, increased durability, and lighter overall weight. This sophisticated approach significantly accelerates research and development cycles for the next generation of high-performance filters.

- Real-time Performance Monitoring and Diagnostics: AI systems integrated with intelligent sensors provide continuous, instantaneous feedback on critical filter performance indicators, including differential pressure, contamination levels, and remaining useful life. This enables immediate alerts for critical issues, facilitates precise troubleshooting by maintenance crews, and allows for dynamic adjustments to operational parameters to maintain optimal system health.

- Supply Chain and Inventory Management Efficiency: AI models leverage big data analytics to accurately forecast demand for various filter types based on complex variables such as fleet utilization rates, anticipated MRO schedules, regional operational trends, and seasonal variations. This optimizes inventory levels, ensures the timely availability of crucial spare parts, significantly reduces costly warehousing expenditures, and mitigates risks of stockouts or overstocking.

- Automated Quality Control and Inspection: AI-powered vision systems, often combined with advanced robotics and non-destructive testing techniques, conduct high-speed, highly accurate inspections of manufactured filters at various production stages. This enables the detection of minute manufacturing defects or material inconsistencies that human inspection might overlook, thereby ensuring consistent product quality, adherence to rigorous aerospace standards, and reducing costly recalls.

- Operational Efficiency and Fuel Economy Enhancements: By guaranteeing the sustained optimal performance of filtration systems through AI-driven insights, particularly for engine air intake and fuel systems, AI indirectly but significantly contributes to improved engine efficiency and reduced fuel consumption. Clean air and fluids enable engines to operate at peak thermodynamic levels, minimizing inefficiencies, reducing drag, maximizing thrust, and ultimately decreasing the carbon footprint per flight hour.

DRO & Impact Forces Of Aircraft Filters Market

The Aircraft Filters Market is profoundly influenced by a complex and dynamic interplay of Drivers, Restraints, Opportunities, and broader Impact Forces that collectively shape its growth trajectory, competitive landscape, and strategic direction. Among the primary and most powerful drivers, the sustained and robust global expansion of air passenger and cargo traffic stands out as paramount. This relentless increase in air travel directly necessitates a continuous increase in aircraft fleets—encompassing both substantial new aircraft acquisitions and the extended operational lifespans of existing aircraft—all of which inherently demand a comprehensive range of advanced filtration solutions for both Original Equipment Manufacturer (OEM) installations and the aftermarket. Moreover, the progressive aging of the global commercial and military aircraft fleet unequivocally mandates a consistent and increasing volume of Maintenance, Repair, and Overhaul (MRO) activities. These MRO operations are significant and recurring consumers of replacement filters across all aircraft systems. Additionally, the increasingly stringent and evolving aviation safety regulations, rigorously enforced by international bodies such as the Federal Aviation Administration (FAA) and the European Union Aviation Safety Agency (EASA), compel airlines and aircraft manufacturers alike to adopt even higher-performance, meticulously certified filtration solutions, particularly concerning critical safety systems and cabin air quality. The unwavering industry focus on improving fuel efficiency and effectively reducing operational costs also acts as a potent driver, pushing for innovative, lighter-weight, and substantially more durable filter designs that demonstrably contribute to overall aircraft performance and economic viability.

Conversely, several formidable restraints pose significant challenges to the unbridled expansion of the market. The substantial and often prohibitive costs associated with the intensive research, development, and exceptionally rigorous certification processes for new aerospace filter technologies create significant financial and technical barriers to entry for smaller companies, and can considerably slow down the rate of adoption of crucial innovations. The relatively long operational lifespan of many sophisticated aircraft, coupled with extended filter replacement cycles for critical components, can naturally moderate the overall volume demand for new units in the aftermarket segment, leading to slower revenue generation compared to other fast-moving consumer goods. Furthermore, the market is inherently susceptible to unpredictable fluctuations in the prices of critical raw materials, such as specialized high-performance polymers, advanced composite materials, and unique metallic alloys. These material cost volatilities directly impact manufacturing expenditures and, consequently, the final product pricing, affecting profitability margins across the supply chain. Intense competitive rivalry among a relatively consolidated group of established global players, each vying for market share, can lead to aggressive price pressures, demanding continuous and substantial investment in technological differentiation, product innovation, and sophisticated market penetration strategies, making it exceptionally challenging for new entrants to gain a significant foothold without substantial capital investment and established industry credentials.

However, alongside these inherent challenges, numerous compelling opportunities continually present themselves within the dynamic Aircraft Filters Market, promising future growth and innovation. The burgeoning global trend towards the adoption of sustainable aviation fuels (SAFs) and the active development of electric and hybrid-electric aircraft propulsion systems undeniably open entirely new avenues for highly specialized filtration requirements that differ significantly from traditional combustion engine needs, creating new product categories and market niches. Furthermore, the rapid development and seamless integration of smart filter technologies, incorporating advanced Internet of Things (IoT) sensors and sophisticated Artificial Intelligence (AI) for real-time performance monitoring and predictive maintenance, offer a significant and transformative opportunity to dramatically enhance operational efficiency, substantially reduce unscheduled downtime, and meticulously optimize maintenance schedules for airlines, leading to considerable cost savings. Emerging markets in the rapidly developing regions of Asia Pacific, Latin America, and the Middle East continue to offer substantial organic growth potential due to exponentially increasing air travel demand, ambitious fleet modernization efforts, and continuously expanding MRO infrastructure. Additionally, the relentless pursuit of advanced filter media with demonstrably improved efficiency, reduced weight, and significantly longer service life presents a fertile ground for profound innovation and sustained market leadership. The broader impact forces, encompassing the formidable bargaining power of buyers (large airlines and OEMs demanding cost-effective, high-quality, and certified products) and the specialized bargaining power of suppliers (providers of niche, high-performance materials), the enduring threat of new entrants (high barriers due to extensive certification requirements and immense capital investment), the limited threat of substitutes (due to the inherently safety-critical nature of filtration in aviation), and the intense competitive rivalry among existing established players, collectively ensure a perpetually dynamic and fiercely competitive market landscape that constantly pushes for unparalleled technological advancement and unwavering operational excellence.

Segmentation Analysis

The Aircraft Filters Market undergoes extensive and meticulous segmentation, a critical analytical process that comprehensively categorizes its diverse offerings to precisely reflect the variegated operational needs, specific aircraft types, and distinct end-use applications prevalent across the expansive global aviation industry. This highly detailed breakdown provides a nuanced, granular understanding of complex market dynamics, effectively revealing specific demand patterns, identifying high-growth areas, and pinpointing the underlying drivers within each distinct segment. Such an incisive segmentation approach is absolutely crucial for all market stakeholders, including leading manufacturers, specialized suppliers, and comprehensive MRO (Maintenance, Repair, and Overhaul) providers, as it empowers them to meticulously tailor their product development strategies, refine their marketing campaigns, and optimize their distribution channels to effectively address the unique and often stringent requirements of various market niches. The increasing technological complexity of modern aircraft systems, coupled with ever-tightening regulatory frameworks for aviation safety, environmental performance, and passenger health, further accentuates the paramount importance of a granular market analysis based on these segmentations. By dissecting the market into its fundamental and interconnected components, it becomes strategically possible to identify high-potential growth areas, accurately assess the intensity of competitive forces, and strategically position products to maximize market penetration and ensure sustained profitability.

This comprehensive segmentation allows for an exceptionally precise evaluation of demand generated from different points within the intricate aviation ecosystem, spanning from the initial manufacturing phase of an aircraft through its multi-decade operational life, which involves countless routine maintenance cycles and occasional major overhauls. For instance, the volume, type, and performance specifications for filters required in large commercial aircraft fleets differ significantly from those necessitated for military applications, which frequently demand enhanced ruggedness, survivability, and peak performance under extreme operational conditions. Similarly, the specific filtration needs for hydraulic systems, crucial for flight control, are inherently distinct from those for cabin air quality control, each demanding highly specialized technology, advanced materials, and precise engineering to meet its unique challenges. Understanding these profound distinctions is paramount for manufacturers to innovate effectively and for airlines and MRO providers to select and implement the most appropriate, efficient, and cost-effective filtration solutions that guarantee safety and operational continuity. As the global aviation industry continues its trajectory of innovation and expansion, driven by continuous technological advancements, evolving operational paradigms, and increasing environmental pressures, the demand for highly specialized filters within each of these meticulously defined segments is expected to follow distinct growth patterns, thereby offering diverse and compelling opportunities for market participants to specialize, differentiate their offerings, and gain a sustainable competitive advantage through targeted product development and strategic market positioning.

- By Filter Type: This segment classifies filters based on their intended function and the specific fluid or air they meticulously purify within the aircraft's various critical systems, each designed for precise performance.

- HEPA Filters: High-efficiency particulate air filters primarily utilized for cabin air recirculation systems. They are expertly designed to remove sub-micron particulate matter, microscopic allergens, airborne bacteria, and viruses, thereby ensuring an exceptionally clean, healthy, and comfortable environment for passengers and crew.

- Fuel Filters: These filters are engineered to remove a range of contaminants such as dirt, rust particles, sediment, and free water from aviation fuel. This process is crucial for protecting sensitive fuel pumps, fuel injectors, and vital engine components from abrasive wear and corrosion, thus ensuring optimal combustion and engine reliability.

- Hydraulic Filters: Absolutely essential for maintaining the pristine cleanliness and operational integrity of hydraulic fluid within complex aircraft systems that control flight surfaces, deploy and retract landing gear, and operate braking mechanisms. These filters prevent contaminant-induced wear, guaranteeing reliable and precise hydraulic system operation.

- Oil Filters: Employed extensively in aircraft engines and auxiliary power units (APUs) to efficiently remove metallic wear particles generated during operation, carbon deposits from combustion, and other harmful byproducts from lubricating oil. This action significantly extends engine life, maintains optimal performance, and reduces maintenance requirements.

- Air Intake Filters: Critical components designed to protect jet engines from ingesting foreign objects (FOD), abrasive dust, sand, ice, and other airborne particles during all phases of flight. Their effectiveness is paramount for ensuring engine longevity, preventing erosion, maintaining optimal thrust, and preserving fuel efficiency.

- Cabin Air Filters (Non-HEPA): A broader category of filters used in cabin ventilation systems that may not meet the extremely stringent HEPA standards but still provide significant levels of air purification, removing larger dust particles and odorous compounds to enhance passenger co

Report Attributes Report Details Market Size in 2025 $4.15 Billion Market Forecast in 2032 $6.64 Billion Growth Rate 6.8% CAGR Historical Year 2019 to 2023 Base Year 2024 Forecast Year 2025 - 2032 DRO & Impact Forces - Drivers: Global Air Traffic Growth, Aging Aircraft Fleet MRO Needs, Stringent Safety Regulations, Focus on Fuel Efficiency and Cost Reduction

- Restraints: High R&D and Certification Costs, Extended Filter Replacement Cycles, Volatile Raw Material Prices, Intense Market Competition

- Opportunities: Sustainable Aviation Materials, Integration of Smart Filter Technologies (IoT/AI), Expansion in Emerging Aviation Markets, Electric/Hybrid Aircraft Filtration Requirements

- Impact Forces: Strong Bargaining Power of Major Buyers (Airlines, OEMs), Moderate Bargaining Power of Specialized Suppliers, High Threat of New Entrants (due to capital/certification), Low Threat of Substitutes (safety-critical), High Degree of Competitive Rivalry

Segments Covered - By Filter Type (HEPA Filters, Fuel Filters, Hydraulic Filters, Oil Filters, Air Intake Filters, Cabin Air Filters (Non-HEPA), Others)

- By Aircraft Type (Commercial Aircraft, Military Aircraft, General Aviation)

- By End-Use (Original Equipment Manufacturer (OEM), Maintenance, Repair, and Overhaul (MRO))

Regions Covered North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) Enquiry Before Buy Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy Aircraft Filters Market Key Technology Landscape

The Aircraft Filters Market is consistently being profoundly reshaped by a dynamic and continuously evolving technological landscape, relentlessly driven by the aerospace industry's unwavering pursuit of exceptionally enhanced performance, dramatically increased efficiency, and ultimately superior reliability in highly demanding and safety-critical aerospace applications. A foundational cornerstone of this intensive technological advancement lies squarely in the meticulous development of next-generation filter media. Traditional filtration materials are progressively being supplanted or significantly augmented by innovative compositions and revolutionary designs, including advanced synthetic nanofibers, meticulously engineered electrospun membranes, intricately pleated metallic meshes often enhanced with specialized coatings, and robust ceramic-matrix composites. These cutting-edge materials offer significantly higher filtration efficiencies, demonstrating an unparalleled capability of capturing even the finest particulate matter with extraordinary precision, while simultaneously achieving substantially lower pressure drops across the filter element. This reduction in pressure drop is paramount for minimizing energy consumption across various aircraft systems, thereby contributing to improved fuel efficiency and lower operational costs. Furthermore, these advanced media are rigorously engineered for dramatically extended service intervals, which directly contributes to reduced maintenance costs, decreased aircraft downtime, and a lower environmental footprint, effectively addressing critical operational and economic concerns for airlines and military operators globally.

Regional Highlights

- North America: This region consistently represents a mature yet exceptionally robust and technologically advanced market for aircraft filters, characterized by a substantial installed base of commercial, military, and general aviation aircraft fleets. It boasts a highly developed and innovative aerospace manufacturing sector, coupled with an extensive and sophisticated Maintenance, Repair, and Overhaul (MRO) infrastructure. The United States, in particular, remains a formidable global leader in defense spending, which consistently drives significant demand for cutting-edge, high-performance filtration solutions for its vast military aircraft inventory. Unwavering innovation, stringent adherence to rigorous safety regulations imposed by bodies like the FAA (Federal Aviation Administration), and continuous technological advancements define this dynamic market.

- Europe: The European market for aircraft filters is stable, substantial, and profoundly influenced by extremely strict aviation safety and increasingly demanding environmental regulations, predominantly enforced by EASA (European Union Aviation Safety Agency). These regulations compel the continuous development and adoption of high-efficiency, sustainable, and compliant filter solutions. The region is home to major aerospace manufacturers, most notably Airbus, which acts as a powerful driver for Original Equipment Manufacturer (OEM) demand. Europe also benefits from a well-established and highly efficient MRO network. A strong emphasis on sustainable aviation practices and the integration of advanced materials into filter technology is a prominent characteristic of this mature market.

- Asia Pacific (APAC): Positioned as the most rapidly expanding and dynamic market globally for aircraft filters, APAC's phenomenal growth is vigorously fueled by unprecedented increases in air passenger and cargo traffic, leading to substantial and sustained investments in new aircraft procurement and the rapid development of modern airport infrastructure. This expansion is particularly pronounced in economic powerhouses like China, India, and the rapidly developing nations of Southeast Asia. The escalating number of new aircraft deliveries, coupled with a fast-growing MRO capabilities base, are pivotal drivers for the burgeoning demand for both OEM and aftermarket filtration solutions across the region.

- Middle East and Africa (MEA): The MEA market for aircraft filters shows promising and continuous growth, largely attributable to the strategic establishment and rapid expansion of major global aviation hubs (e.g., Dubai, Doha), significant and aggressive fleet expansion initiatives by prominent regional air carriers, and substantial governmental investments in enhancing defense capabilities across the region. The emergence of new airline ventures, coupled with a thriving tourism sector, contributes significantly to increasing air traffic volumes and, consequently, stimulates a rising demand for aircraft filters across various operational segments, from commercial passenger jets to military platforms.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Aircraft Filters Market.- Parker Hannifin Corporation

- Pall Corporation (a Danaher Company)

- Donaldson Company, Inc.

- Safran S. A.

- Honeywell International Inc.

- Eaton Corporation plc

- Porvair plc

- Swift Filters, Inc.

- Hengst SE

- Clairant Co., Ltd.

- CEFILAC (a SKF Group company)

- Freudenberg Filtration Technologies

- Mann+Hummel Group

- Atlas Copco

- Meggitt PLC (now part of Parker Hannifin)

- Crissair, Inc.

- Kuss Filtration

- Faurecia (now Forvia)

- BOLLFILTER (BOLL & KIRCH Filterbau GmbH)

- Textron Inc. (via subsidiaries)

- Pentair plc

Frequently Asked Questions

What is the primary function of aircraft filters?

Aircraft filters are critical components meticulously engineered to remove harmful contaminants from essential systems such as aviation fuel, hydraulic fluid, lubricating oil, and cabin air. Their primary function is to protect sensitive and high-value aircraft components from premature wear, corrosive degradation, and catastrophic malfunction, thereby ensuring the highest levels of operational safety, optimizing system efficiency, and significantly extending the lifespan of vital aircraft systems while complying with all stringent international aviation regulations and certifications.

Why are HEPA filters crucial for cabin air quality in aircraft?

HEPA (High-Efficiency Particulate Air) filters are absolutely indispensable for maintaining superior and healthy cabin air quality in aircraft by effectively capturing microscopic airborne particles, including fine dust, allergens, bacteria, viruses, and fungi. These advanced filters are designed to remove 99.97% of particles 0.3 microns or larger, significantly enhancing passenger and crew health, comfort, and safety by providing a continuously purified and recirculated cabin environment, mitigating the risk of airborne disease transmission.

How does AI contribute to advancements in aircraft filter maintenance and design?

Artificial Intelligence (AI) is profoundly transforming aircraft filter maintenance through sophisticated predictive analytics, utilizing vast datasets from onboard sensor systems to accurately forecast filter degradation patterns and thereby optimize replacement schedules. This moves maintenance strategies beyond traditional time-based servicing to a proactive, condition-based approach, reducing costly unscheduled downtime. In design, AI enables advanced simulations and material optimization, accelerating the development of more efficient, lighter, and durable filters, leading to enhanced performance and significant cost savings over the operational life of an aircraft.

What are the main types of contaminants targeted by aircraft fuel filters?

Aircraft fuel filters are specifically designed and engineered to target and effectively remove a range of critical contaminants from aviation fuel. These primarily include particulate matter such as rust, dirt, sand, and other solid debris, along with free and emulsified water droplets. Their highly effective removal of these impurities is paramount for preventing severe damage to sensitive fuel pumps, fuel injectors, and other delicate engine components, thereby ensuring clean combustion, optimal engine performance, and uncompromised operational reliability throughout all phases of flight.

What factors determine the replacement frequency for aircraft filters?

The replacement frequency for aircraft filters is determined by several critical and interconnected factors, including the specific filter type, the particular aircraft system it serves, the cumulative aircraft operational hours or flight cycles, and the manufacturer's precise recommendations outlined in maintenance manuals. Increasingly, advanced condition-based monitoring, leveraging embedded sensors and sophisticated predictive analytics, plays a significant and growing role in dictating optimal replacement intervals, ensuring that filters are replaced precisely when their filtration efficiency or structural integrity begins to decline, rather than relying solely on fixed, predetermined schedules, thus optimizing resource utilization and reducing waste.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager