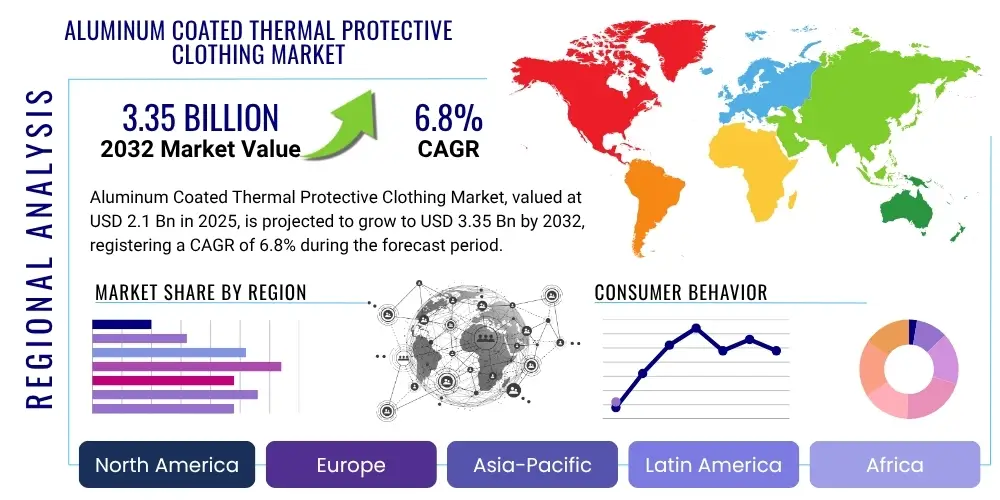

Aluminum Coated Thermal Protective Clothing Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 431046 | Date : Nov, 2025 | Pages : 242 | Region : Global | Publisher : MRU

Aluminum Coated Thermal Protective Clothing Market Size

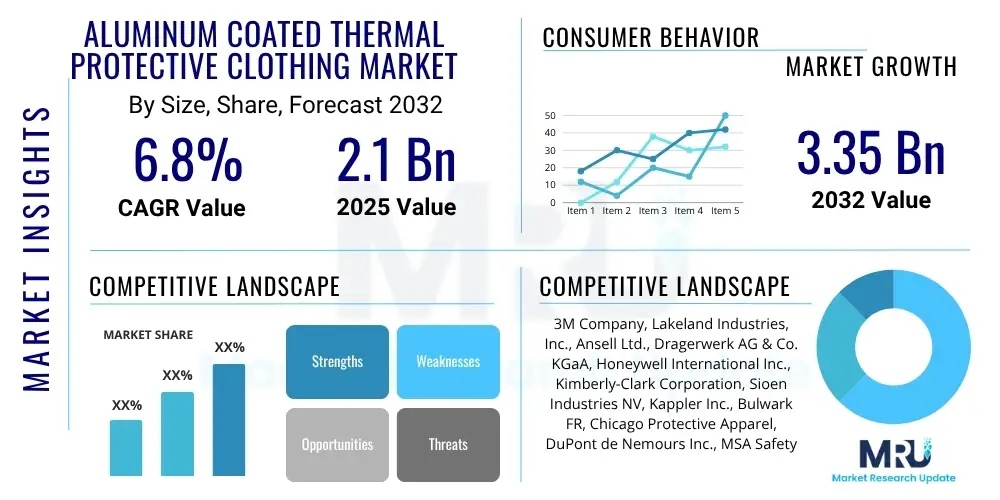

The Aluminum Coated Thermal Protective Clothing Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at USD 2.1 Billion in 2025 and is projected to reach USD 3.35 Billion by the end of the forecast period in 2032.

Aluminum Coated Thermal Protective Clothing Market introduction

The Aluminum Coated Thermal Protective Clothing Market encompasses specialized garments designed to protect workers from extreme heat, radiant heat, molten metal splashes, and other high-temperature hazards. These garments, often constructed with multiple layers of heat-resistant fabrics coated with an aluminum outer layer, reflect radiant heat away from the wearer, significantly reducing heat stress and preventing severe burns. The primary goal is to enhance worker safety in hazardous environments, ensuring compliance with stringent industrial safety regulations and mitigating the risks associated with high thermal exposure.

The product range includes a variety of suits, aprons, gloves, and hoods, tailored for different levels of protection and mobility requirements. Major applications span critical industrial sectors such as firefighting, metallurgy, glass manufacturing, petrochemicals, and aerospace. The inherent benefits of these garments, including superior heat reflection, lightweight comfort in advanced models, and enhanced durability, make them indispensable for safeguarding personnel operating in environments where conventional protective wear is insufficient. The market is primarily driven by an escalating emphasis on occupational safety standards, rapid industrialization in developing economies, and continuous technological advancements in material science that improve garment performance and wearability.

Aluminum Coated Thermal Protective Clothing Market Executive Summary

The Aluminum Coated Thermal Protective Clothing Market is experiencing robust growth, propelled by a global increase in industrial safety mandates and the expansion of high-risk manufacturing sectors. Key business trends indicate a strong focus on innovation, particularly in developing lighter-weight materials, incorporating smart textile functionalities, and offering customizable solutions to meet diverse industrial needs. Manufacturers are also investing in ergonomic designs to improve wearer comfort and mobility, addressing historical limitations of thermal protective gear.

Regionally, the market exhibits dynamic growth patterns. North America and Europe continue to be significant revenue generators due to stringent safety regulations and established industrial infrastructures, alongside a high adoption rate of advanced PPE. The Asia Pacific region is emerging as a dominant growth hub, driven by rapid industrialization, increasing awareness of worker safety, and the expanding presence of manufacturing and heavy industries, especially in countries like China and India. Latin America and the Middle East & Africa also present considerable opportunities, spurred by investments in oil and gas, mining, and construction sectors.

Segmentation trends highlight a strong demand for full-body aluminized proximity suits in specialized applications such as firefighting and molten metal handling, while individual components like gloves and aprons see widespread use across various industrial settings. The metallurgical and firefighting sectors remain the largest end-users, though demand from chemical processing and aerospace industries is steadily increasing. The market is characterized by a competitive landscape, with leading players focusing on product differentiation through material science advancements and strategic partnerships to expand their global footprint and cater to evolving safety requirements.

AI Impact Analysis on Aluminum Coated Thermal Protective Clothing Market

User inquiries regarding the impact of Artificial Intelligence on the Aluminum Coated Thermal Protective Clothing Market frequently revolve around how AI can enhance product design, improve manufacturing efficiency, optimize material selection, and revolutionize safety monitoring. Common themes include the potential for AI-driven predictive maintenance of garments, the integration of smart sensors for real-time hazard detection, and AI's role in creating more adaptive and personalized protective gear. Users are keen to understand how AI can move beyond passive protection to proactive safety measures, making clothing more intelligent and responsive to dynamic work environments, while also addressing concerns about data privacy and the complexity of integrating advanced technologies into traditional PPE.

- AI-driven material science: Optimizing fabric composition and coating properties for enhanced thermal resistance and reduced weight.

- Predictive maintenance: AI algorithms analyzing wear patterns and environmental exposure to recommend timely replacement or repair of protective clothing.

- Smart garment integration: Embedding AI-powered sensors for real-time monitoring of wearer vital signs, environmental conditions (temperature, gas detection), and proximity to hazards.

- Optimized manufacturing processes: AI for quality control, defect detection, and efficiency improvements in the production of aluminized fabrics and garments.

- Personalized fit and design: AI algorithms using body scans and biomechanical data to create custom-fitted protective clothing that maximizes comfort and mobility.

- Enhanced training and simulations: AI-powered virtual reality (VR) or augmented reality (AR) training simulations for proper usage and maintenance of protective clothing.

- Supply chain optimization: AI for forecasting demand, managing inventory, and streamlining logistics for raw materials and finished products.

DRO & Impact Forces Of Aluminum Coated Thermal Protective Clothing Market

The Aluminum Coated Thermal Protective Clothing Market is significantly influenced by a confluence of driving factors, restrictive elements, and burgeoning opportunities, all shaped by various impact forces. The primary drivers include the escalating global focus on occupational safety, enforced by increasingly stringent governmental regulations and international standards for worker protection across high-risk industries. Furthermore, the continuous expansion and modernization of industries such as metallurgy, petrochemicals, and glass manufacturing, particularly in emerging economies, fuel the demand for advanced thermal protective gear. Technological advancements in material science, leading to the development of lighter, more durable, and more comfortable aluminized fabrics, also act as a strong market impetus.

However, the market faces several restraints that could impede its growth. The high initial cost associated with specialized aluminized protective clothing, driven by complex manufacturing processes and advanced materials, can be a barrier to adoption, especially for smaller businesses or in price-sensitive regions. Additionally, the bulkiness and potential for reduced mobility associated with some traditional heavy-duty suits may deter consistent usage. Lack of awareness about the specific benefits and proper maintenance of these advanced PPE in certain regions or among less informed end-users also presents a challenge. The complexity of regulatory compliance across different jurisdictions adds another layer of restraint for manufacturers and distributors.

Opportunities for market expansion are abundant, particularly in the integration of smart technologies into protective clothing, allowing for real-time monitoring and improved responsiveness to hazards. The development of innovative, lightweight, and breathable materials that do not compromise protective capabilities offers a significant avenue for growth. Untapped markets in developing countries, where industrial safety standards are rapidly evolving, present substantial potential. The impact forces at play include the strong bargaining power of buyers, especially large industrial corporations seeking bulk orders and custom solutions, and the moderate bargaining power of suppliers, given the specialized nature of raw materials. The threat of new entrants is relatively low due to high capital requirements and the need for specialized expertise and certifications. The threat of substitutes, while present from other types of flame-resistant or heat-resistant clothing, is limited for applications requiring extreme radiant heat reflection. Competitive rivalry among established players is intense, driving continuous innovation and product differentiation.

Segmentation Analysis

The Aluminum Coated Thermal Protective Clothing Market is comprehensively segmented to provide a detailed understanding of its diverse components and dynamics. This segmentation facilitates a granular analysis of market trends, allowing stakeholders to identify key growth areas and tailor strategies effectively. The market is primarily categorized by the type of clothing, the materials used in its construction, the specific applications it serves, and the end-use industries that procure these specialized garments. Further geographical segmentation offers insights into regional adoption patterns and regulatory influences, painting a complete picture of market demand and supply dynamics across the globe.

- By Type

- Aluminized Proximity Suits

- Aluminized Entry Suits

- Aluminized Firefighting Suits

- Aluminized Aprons

- Aluminized Gloves

- Aluminized Hoods and Balaclavas

- Aluminized Boots and Leggings

- By Material

- Aramid Blends (e.g., Kevlar, Nomex)

- Fiberglass

- Carbon Fiber

- PBI (Polybenzimidazole)

- PBO (Polybenzoxazole)

- Pre-oxidized Carbon Fiber

- Blended Fabrics with High-Performance Polymers

- By Application

- Firefighting and Emergency Services

- Metal Production and Foundry (Steel Mills, Aluminum Smelters)

- Petrochemical and Oil & Gas

- Aerospace and Defense

- Glass Manufacturing

- Chemical Handling

- Welding and Cutting Operations

- Utilities and Electrical Maintenance

- By End-Use Industry

- Manufacturing

- Mining

- Construction

- Emergency Response

- Energy

- Transportation

- By Region

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East and Africa (MEA)

Value Chain Analysis For Aluminum Coated Thermal Protective Clothing Market

The value chain for the Aluminum Coated Thermal Protective Clothing Market is a complex network of interconnected activities, beginning with the sourcing of specialized raw materials and culminating in the delivery and post-sales support of finished protective garments to end-users. Upstream activities involve the procurement of high-performance heat-resistant fabrics such as aramids, fiberglass, and carbon fibers, as well as the specialized aluminum coating materials. Key suppliers in this segment focus on advanced textile manufacturing and chemical processing to produce materials that meet stringent thermal protection standards. Research and development at this stage are crucial for introducing innovative materials that offer improved heat reflection, durability, and reduced weight.

Midstream activities encompass the manufacturing and assembly of the protective clothing. This includes processes like fabric cutting, multi-layer garment construction, precise application of aluminum coatings, and quality control checks to ensure performance and compliance with safety certifications. Manufacturers often specialize in different types of garments, from full proximity suits to gloves and aprons, leveraging advanced sewing and bonding techniques. Downstream analysis focuses on the distribution and sales channels. Products are typically distributed through a mix of direct sales to large industrial clients, specialized industrial safety equipment distributors, and online platforms. Direct sales are common for customized or large-volume orders from major corporations, while distributors serve a broader market of smaller enterprises and provide localized support.

The distribution channel involves both direct and indirect approaches. Direct sales involve manufacturers selling directly to end-users, fostering closer relationships and enabling tailored solutions. Indirect channels rely on a network of wholesalers, retailers, and e-commerce platforms specializing in personal protective equipment (PPE), extending market reach and providing accessibility. After-sales services, including maintenance guidelines, repair services, and product training, are also critical components of the downstream value chain, ensuring the longevity and effectiveness of the protective clothing. Understanding this intricate value chain allows market participants to identify areas for cost optimization, enhance operational efficiency, and capture greater value through strategic partnerships and improved customer service.

Aluminum Coated Thermal Protective Clothing Market Potential Customers

The primary potential customers for Aluminum Coated Thermal Protective Clothing are industries and organizations where workers are regularly exposed to high heat, radiant heat, molten materials, and flash fire risks. These end-users prioritize the safety and well-being of their personnel, often driven by strict regulatory compliance, corporate safety policies, and the severe consequences of thermal injuries. The demand is diverse, spanning heavy industrial sectors to specialized emergency response teams, each requiring specific types and levels of thermal protection tailored to their unique operational hazards.

Key segments of end-user/buyers include fire and emergency services, where firefighters require aluminized proximity and entry suits for structural and industrial fires involving extreme heat. The metallurgical industry, encompassing steel mills, aluminum smelters, foundries, and glass manufacturing plants, represents a significant customer base due to the constant exposure to molten metals and high-temperature processes. Furthermore, the petrochemical and oil & gas sectors, aerospace and defense, and even certain chemical handling and welding operations also constitute vital customer groups. These industries invest in this specialized clothing to protect workers during maintenance, repair, and operational tasks, mitigating risks associated with thermal hazards and ensuring operational continuity while upholding worker safety standards.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 2.1 Billion |

| Market Forecast in 2032 | USD 3.35 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | 3M Company, Lakeland Industries, Inc., Ansell Ltd., Dragerwerk AG & Co. KGaA, Honeywell International Inc., Kimberly-Clark Corporation, Sioen Industries NV, Kappler Inc., Bulwark FR, Chicago Protective Apparel, DuPont de Nemours Inc., MSA Safety Inc., Workrite Uniform Company, Inc., National Safety Apparel, Trelleborg AB, Norafin Industries GmbH, Propper International Inc., Teijin Aramid B.V., PBI Performance Products, Inc., Lion Apparel Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Aluminum Coated Thermal Protective Clothing Market Key Technology Landscape

The Aluminum Coated Thermal Protective Clothing Market is characterized by a dynamic technology landscape driven by continuous innovation in material science and textile engineering aimed at enhancing protection, comfort, and durability. At its core, the technology revolves around the effective combination of heat-resistant base fabrics with highly reflective aluminum coatings. This often involves multi-layer constructions, where an outer aluminized layer reflects radiant heat, an intermediate thermal barrier provides insulation, and an inner moisture-wicking layer ensures wearer comfort and breathability, crucial for mitigating heat stress during prolonged use in extreme conditions.

Key technological advancements include the development of lighter weight yet equally protective fabrics, such as advanced aramid blends, PBI, and carbon fiber composites, which significantly reduce the burden on workers. Innovations in aluminum coating techniques, including vapor deposition and specialized laminations, are improving adhesion, flexibility, and longevity of the reflective surface, making garments more resistant to cracking and delamination. Furthermore, the integration of smart textile technologies, such as embedded sensors for monitoring body temperature, heart rate, and environmental hazards, represents a significant frontier. These smart features enable real-time data feedback, allowing for proactive safety interventions and enhancing overall worker protection in hazardous environments. Ergonomic design principles and advanced garment construction methods are also continually evolving to provide greater mobility, better fit, and reduced physiological strain for the wearer.

Regional Highlights

- North America: This region holds a significant market share, primarily driven by stringent occupational safety regulations, high industrialization rates, and a strong emphasis on worker protection in industries like oil & gas, manufacturing, and emergency services. Technological advancements and the presence of major market players also contribute to its dominance.

- Europe: Europe is another mature market, characterized by advanced industrial sectors and strict European Union safety directives. Countries like Germany, the UK, and France are key contributors, focusing on high-quality, certified protective gear and continuous innovation in materials and design.

- Asia Pacific (APAC): The fastest-growing region, fueled by rapid industrialization, expanding manufacturing bases (especially in metallurgy, automotive, and chemicals) in countries like China, India, and Southeast Asia. Increasing awareness of worker safety and improving regulatory frameworks are propelling demand.

- Latin America: This region presents considerable growth opportunities, particularly in countries with significant mining, oil & gas, and industrial sectors such as Brazil and Mexico. Economic development and a rising focus on industrial safety are driving market expansion.

- Middle East and Africa (MEA): Growth in MEA is largely attributed to the robust oil & gas industry, ongoing large-scale construction projects, and developing industrial infrastructure. Investments in safety equipment are increasing as these regions modernize their industrial operations.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Aluminum Coated Thermal Protective Clothing Market.- 3M Company

- Lakeland Industries, Inc.

- Ansell Ltd.

- Dragerwerk AG & Co. KGaA

- Honeywell International Inc.

- Kimberly-Clark Corporation

- Sioen Industries NV

- Kappler Inc.

- Bulwark FR (a brand of VF Corporation)

- Chicago Protective Apparel

- DuPont de Nemours Inc.

- MSA Safety Inc.

- Workrite Uniform Company, Inc.

- National Safety Apparel

- Trelleborg AB

- Norafin Industries GmbH

- Propper International Inc.

- Teijin Aramid B.V.

- PBI Performance Products, Inc.

- Lion Apparel Inc.

Frequently Asked Questions

What industries primarily use Aluminum Coated Thermal Protective Clothing?

The primary industries utilizing this specialized clothing include firefighting and emergency services, metallurgy (e.g., steel mills, foundries, aluminum smelters), glass manufacturing, petrochemical and oil & gas, and aerospace and defense for protection against extreme heat and radiant energy.

What are the key benefits of using aluminized thermal protective clothing?

Key benefits include superior reflection of radiant heat, excellent insulation against convection and conduction heat, protection from molten metal splashes, enhanced worker safety in hazardous environments, and often lightweight designs for improved mobility and comfort compared to traditional heavy-duty gear.

How do technological advancements influence the market?

Technological advancements drive the market by introducing lighter, more durable, and more flexible materials, improving coating techniques for enhanced reflectivity and longevity, and integrating smart textile features like embedded sensors for real-time monitoring of environmental hazards and wearer vitals, leading to more effective and comfortable protective solutions.

What are the main challenges facing the Aluminum Coated Thermal Protective Clothing Market?

Major challenges include the high manufacturing cost of these specialized garments, which can limit adoption, along with issues related to the bulkiness and restricted mobility of some suits. Additionally, ensuring proper maintenance and increasing awareness about specific product benefits in certain regions remain significant hurdles.

Which regions are expected to show the highest growth in this market?

The Asia Pacific region is anticipated to exhibit the highest growth due to rapid industrialization, expanding manufacturing sectors, and increasing emphasis on occupational safety standards, particularly in emerging economies such as China and India. Latin America and MEA also present strong growth potential.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager