Aluminum Foil Packaging Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430659 | Date : Nov, 2025 | Pages : 255 | Region : Global | Publisher : MRU

Aluminum Foil Packaging Market Size

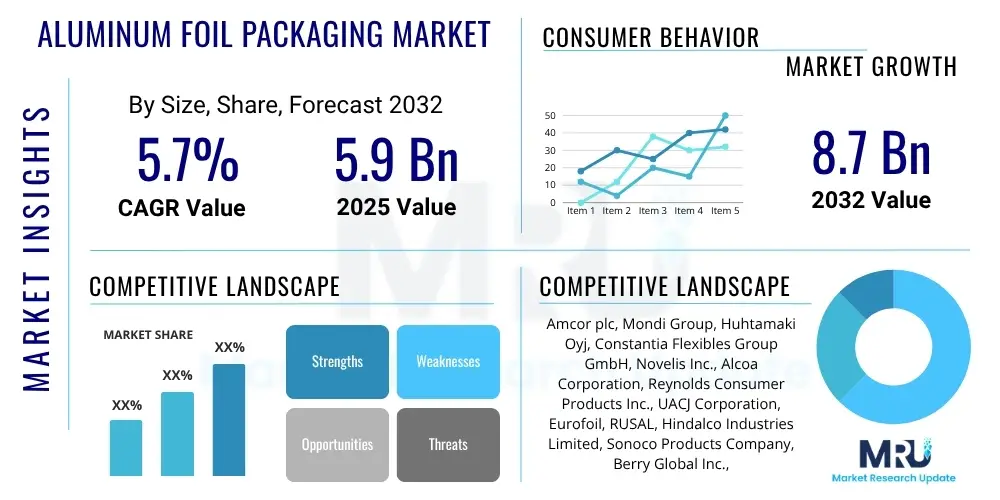

The Aluminum Foil Packaging Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.7% between 2025 and 2032. The market is estimated at USD 5.9 Billion in 2025 and is projected to reach USD 8.7 Billion by the end of the forecast period in 2032.

Aluminum Foil Packaging Market introduction

The Aluminum Foil Packaging Market encompasses the production and distribution of packaging solutions utilizing aluminum foil as a primary material. Aluminum foil is a thin sheet of aluminum, known for its exceptional barrier properties against light, moisture, oxygen, and microorganisms, making it ideal for preserving product freshness and extending shelf life. Its versatility allows it to be used in various forms, including flexible pouches, semi-rigid trays, and rigid containers, often laminated with other materials like plastics or paper for enhanced performance and structural integrity.

Major applications span across the food and beverage industry, where it is extensively used for confectionery, dairy products, baked goods, and ready-to-eat meals, owing to its ability to maintain aroma and flavor. In pharmaceuticals, it provides crucial protection for tablets, capsules, and sterile medical devices, ensuring product integrity and safety. Other significant sectors include cosmetics and personal care, where it protects sensitive formulations, and industrial applications for insulation and barrier needs. The key benefits of aluminum foil packaging include its lightweight nature, excellent thermal conductivity, impermeability, non-toxicity, and recyclability, contributing to sustainable packaging initiatives.

Driving factors for market growth include the increasing consumer demand for convenience foods, the rising global pharmaceutical industry, growing awareness regarding food safety and preservation, and the continuous innovation in sustainable and lightweight packaging solutions. The superior barrier properties of aluminum foil remain a critical differentiator, ensuring product quality and minimizing spoilage, which is particularly vital in a world striving for reduced food waste.

Aluminum Foil Packaging Market Executive Summary

The Aluminum Foil Packaging Market is poised for substantial growth, driven by evolving consumer lifestyles and stringent food safety regulations globally. Business trends indicate a strong focus on sustainable packaging solutions, with manufacturers investing in advanced recycling technologies and circular economy initiatives for aluminum foil. Strategic partnerships and mergers and acquisitions are common as companies seek to expand their product portfolios, enhance technological capabilities, and strengthen their regional presence. Innovation in flexible packaging and barrier laminates is also a key trend, allowing for more efficient use of materials and improved product protection.

Regionally, Asia Pacific is anticipated to be the fastest-growing market, propelled by rapid urbanization, increasing disposable incomes, and the expansion of the food and beverage and pharmaceutical sectors in countries like China and India. North America and Europe, while mature, continue to show steady growth, driven by demand for premium and convenient packaging, along with a strong emphasis on sustainability and product innovation. Latin America and the Middle East & Africa are also emerging as significant markets, supported by economic development and improving infrastructure for packaged goods distribution.

Segment trends highlight the dominance of flexible packaging applications due to their cost-effectiveness, versatility, and reduced material usage, especially in food and pharmaceutical industries. Pharmaceutical packaging, in particular, is witnessing robust growth owing to the critical need for product protection and tamper-evidence. Innovations in thickness reduction without compromising barrier properties, as well as the development of smart packaging features, are shaping the competitive landscape across all segments, addressing both cost efficiency and consumer engagement.

AI Impact Analysis on Aluminum Foil Packaging Market

Users frequently inquire about how Artificial Intelligence (AI) can revolutionize the aluminum foil packaging sector, focusing on operational efficiency, supply chain optimization, and product innovation. Key themes revolve around leveraging AI for predictive maintenance in manufacturing, enhancing quality control through automated inspection, optimizing material usage to reduce waste, and personalizing packaging designs. There is a strong expectation that AI will lead to more sustainable practices, faster time-to-market for new packaging solutions, and improved responsiveness to dynamic market demands, ultimately transforming the industry’s productivity and competitive edge.

- AI-driven predictive maintenance optimizes machinery uptime and reduces operational costs in foil production and conversion.

- Automated quality inspection systems using AI enhance defect detection, ensuring higher product standards and reducing material waste.

- Supply chain optimization through AI algorithms improves inventory management, logistics, and demand forecasting for raw materials and finished products.

- AI assists in designing more efficient and sustainable packaging solutions by simulating material performance and optimizing structural integrity.

- Personalized and smart packaging features, enabled by AI, can enhance consumer engagement and provide real-time product information or freshness indicators.

- Robotics and AI in packaging lines increase automation, leading to higher throughput and reduced labor costs.

- Data analytics powered by AI helps identify market trends, consumer preferences, and operational bottlenecks, informing strategic decision-making.

DRO & Impact Forces Of Aluminum Foil Packaging Market

The Aluminum Foil Packaging Market is propelled by several robust drivers, including the escalating demand from the food and beverage sector for extended shelf life and enhanced product safety, particularly for convenience foods and packaged meals. The burgeoning pharmaceutical industry also significantly contributes to growth, requiring high-barrier packaging for sensitive medications. Furthermore, the inherent benefits of aluminum foil, such as its lightweight nature, excellent barrier properties against moisture and oxygen, and its recyclability, align well with modern consumer preferences for convenience and sustainability. Innovations in packaging design and functionality, including portion control and easy-opening features, further bolster market expansion.

However, the market faces notable restraints, primarily the volatility in raw material prices, particularly aluminum, which can impact manufacturing costs and profit margins. Environmental concerns regarding the energy-intensive production of primary aluminum and the challenges associated with recycling multi-layer laminate structures also pose significant hurdles. Competition from alternative packaging materials like plastics, glass, and paper, which may offer cost advantages or specific aesthetic benefits, further limits market growth. Additionally, stringent regulatory frameworks concerning food contact materials and environmental impact necessitate continuous compliance and adaptation.

Opportunities for growth are abundant, particularly in the development of more sustainable and eco-friendly aluminum foil packaging solutions, such as those incorporating recycled content or designed for easier end-of-life processing. Emerging economies, especially in Asia Pacific and Latin America, present vast untapped potential due to their rapidly expanding consumer bases and increasing adoption of packaged goods. The integration of smart packaging technologies, such as QR codes and RFID for traceability and consumer interaction, also offers a lucrative avenue for innovation. Moreover, strategic collaborations across the value chain to enhance recycling infrastructure and promote circular economy principles will unlock new market potential.

Segmentation Analysis

The Aluminum Foil Packaging Market is comprehensively segmented based on various factors including type, application, end-use, and thickness, allowing for a detailed understanding of its diverse landscape. Each segmentation provides unique insights into market dynamics, demand drivers, and competitive strategies. The primary goal of this segmentation is to categorize the market into manageable groups, enabling stakeholders to identify niche opportunities, understand specific consumer needs, and tailor product offerings effectively.

- By Type:

- Rolled Foil

- Converted Foil

- Laminated Foil

- By Application:

- Food & Beverage

- Pharmaceuticals

- Cosmetics & Personal Care

- Industrial

- Others (Tobacco, etc.)

- By End-use:

- Flexible Packaging

- Semi-rigid Packaging

- Rigid Packaging

- By Thickness:

- Less than 10 Microns

- 10-20 Microns

- More than 20 Microns

Value Chain Analysis For Aluminum Foil Packaging Market

The value chain for the Aluminum Foil Packaging Market begins with upstream activities involving the extraction and processing of raw materials. This primarily includes the mining of bauxite ore, followed by its refining into alumina, and subsequently the smelting of alumina to produce primary aluminum ingots. These ingots are then hot-rolled and cold-rolled into large coils of aluminum sheet, which are further processed into thin aluminum foil by specialized rolling mills. This initial stage is capital-intensive and subject to commodity price fluctuations, forming the foundation of the entire value chain.

Downstream activities involve the conversion of raw aluminum foil into various packaging formats. Converters laminate the foil with other materials like paper, plastic films, or coatings to enhance barrier properties, printability, and mechanical strength. These converted materials are then supplied to packaging manufacturers who produce a wide array of final products, including flexible pouches, blisters, lidding, containers, and wraps. These finished packaging solutions are ultimately distributed to a diverse range of end-user industries such as food and beverage, pharmaceuticals, cosmetics, and industrial sectors.

Distribution channels for aluminum foil packaging products can be direct or indirect. Direct sales typically involve large manufacturers selling directly to major brand owners or large industrial customers, facilitating bulk orders and customized solutions. Indirect channels involve distributors, wholesalers, and retailers who procure packaging materials from manufacturers and supply them to smaller businesses or end-users. The choice of distribution channel often depends on the scale of the customer, the complexity of the product, and geographical reach. The entire value chain relies heavily on efficient logistics and strong supplier-customer relationships to ensure timely delivery and quality control.

Aluminum Foil Packaging Market Potential Customers

Potential customers for aluminum foil packaging are diverse and span across multiple industries, primarily driven by the need for product preservation, safety, and convenience. The largest segment of end-users are within the food and beverage industry, including manufacturers of confectionery, dairy products, baked goods, snack foods, ready meals, processed meats, and beverages. These entities rely on aluminum foil's superior barrier properties to maintain freshness, extend shelf life, and protect against external contaminants, ensuring product quality from production to consumption.

The pharmaceutical industry represents another critical customer base, utilizing aluminum foil for blister packs, strip packs, and sachets for medicines. This sector demands stringent packaging solutions to protect sensitive drugs from moisture, light, and oxygen, thereby ensuring efficacy and patient safety. Similarly, the cosmetics and personal care industry leverages aluminum foil for lotions, creams, and other delicate formulations, where its barrier qualities prevent degradation and contamination, preserving product integrity and shelf appeal.

Beyond consumer goods, industrial applications also constitute significant buyers, including sectors requiring insulation, electrical components, or chemical packaging. Furthermore, the growing trend of e-commerce and home meal kits is expanding the customer base, as these services necessitate robust, lightweight, and protective packaging to withstand transit and maintain product quality. Ultimately, any business requiring high-performance barrier packaging for perishable, sensitive, or high-value goods is a potential customer for aluminum foil packaging.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 5.9 Billion |

| Market Forecast in 2032 | USD 8.7 Billion |

| Growth Rate | 5.7% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Amcor plc, Mondi Group, Huhtamaki Oyj, Constantia Flexibles Group GmbH, Novelis Inc., Alcoa Corporation, Reynolds Consumer Products Inc., UACJ Corporation, Eurofoil, RUSAL, Hindalco Industries Limited, Sonoco Products Company, Berry Global Inc., SIG Combibloc Group AG, Flexpak Inc., Raviraj Foils Limited, Hangzhou Dingsheng Aluminium Industries Co. Ltd., AWL Aluminium-Werke Wutöschingen AG & Co. KG, Guala Closures S.p.A., Carcano Antonio S.p.A. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Aluminum Foil Packaging Market Key Technology Landscape

The Aluminum Foil Packaging Market is continuously evolving with significant advancements in manufacturing and conversion technologies aimed at enhancing product performance, sustainability, and cost-efficiency. A primary area of technological focus is advanced lamination techniques, which involve combining aluminum foil with various polymer films and paper to create multi-layer structures. These laminates offer optimized barrier properties against gases, moisture, and light, while also improving mechanical strength and heat sealability. Innovations in adhesive chemistry and extrusion lamination are crucial for achieving thinner, yet more robust, flexible packaging solutions.

Another critical technological aspect is the development of sustainable coatings and surface treatments for aluminum foil. These coatings can impart enhanced corrosion resistance, improve printability, or provide specialized release properties, often replacing less eco-friendly alternatives. Efforts are also concentrated on creating thinner gauge foils that maintain high barrier performance, reducing overall material consumption and environmental impact. This thin-gauge technology not only contributes to sustainability but also offers economic benefits by lowering material costs and transport weight.

Furthermore, the integration of smart packaging technologies is gaining traction. This includes the incorporation of QR codes, RFID tags, and NFC chips directly into or onto the packaging, enabling enhanced traceability, anti-counterfeiting measures, and interactive consumer engagement. These technologies allow for real-time monitoring of product conditions, supply chain visibility, and personalized marketing experiences. The adoption of digital printing technologies is also revolutionizing the market, allowing for shorter production runs, customization, and greater flexibility in design, catering to the increasing demand for personalized and localized packaging solutions.

Regional Highlights

- North America: A mature market characterized by high demand for convenience packaging and pharmaceutical applications, with a growing emphasis on sustainable and recyclable solutions.

- Europe: Driven by stringent environmental regulations and a strong focus on circular economy initiatives, fostering innovation in recycled content and sustainable packaging designs.

- Asia Pacific (APAC): The fastest-growing region due to rapid urbanization, increasing disposable incomes, and the expanding food and beverage and pharmaceutical industries in countries like China, India, and Japan.

- Latin America: An emerging market experiencing steady growth, fueled by economic development, rising consumer spending, and the adoption of modern retail formats.

- Middle East and Africa (MEA): Demonstrating growth with increasing industrialization, improving infrastructure, and rising demand for packaged food and personal care products.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Aluminum Foil Packaging Market.- Amcor plc

- Mondi Group

- Huhtamaki Oyj

- Constantia Flexibles Group GmbH

- Novelis Inc.

- Alcoa Corporation

- Reynolds Consumer Products Inc.

- UACJ Corporation

- Eurofoil

- RUSAL (United Company Rusal)

- Hindalco Industries Limited

- Sonoco Products Company

- Berry Global Inc.

- SIG Combibloc Group AG

- Flexpak Inc.

- Raviraj Foils Limited

- Hangzhou Dingsheng Aluminium Industries Co. Ltd.

- AWL Aluminium-Werke Wutöschingen AG & Co. KG

- Guala Closures S.p.A.

- Carcano Antonio S.p.A.

Frequently Asked Questions

What is aluminum foil packaging used for?

Aluminum foil packaging is primarily used for preserving food, pharmaceuticals, and cosmetics due to its excellent barrier properties against moisture, oxygen, and light, extending product shelf life and maintaining freshness.

Is aluminum foil packaging sustainable?

Yes, aluminum foil is highly recyclable, contributing to a circular economy. Its lightweight nature also reduces transportation energy, and ongoing innovations are focused on improving its sustainability profile through recycled content and design for recycling.

What are the key drivers for the aluminum foil packaging market?

The key drivers include increasing demand from the food and beverage industry for convenience and food safety, the expanding pharmaceutical sector requiring high-barrier packaging, and growing consumer preference for sustainable and lightweight solutions.

How does AI impact the aluminum foil packaging industry?

AI impacts the industry by enhancing operational efficiency through predictive maintenance, improving quality control with automated inspection, optimizing supply chain logistics, and enabling the development of smarter, more sustainable packaging designs.

Which region leads the aluminum foil packaging market?

The Asia Pacific region is anticipated to be the fastest-growing market due to rapid urbanization, rising disposable incomes, and the significant expansion of the food and beverage and pharmaceutical sectors within countries like China and India.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Aluminum Foil Packaging Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Rigid Aluminium Packaging, Semi-rigid Packaging, Flexible Packaging), By Application (Aerosols Packaging, Tubes Packaging, Cans, Dishes, Lids, Aluminium Pouches, Other), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

- Full Automatic Tablet Packing Machine Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Blister Packaging Equipment, Strip Packaging Equipment, Aluminum foil packaging machine, Automatic Pouch Packing Machine, Fill & Sealing Machine, Other), By Application (Clothing production, The other), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager