Aluminum Spacers Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428991 | Date : Oct, 2025 | Pages : 255 | Region : Global | Publisher : MRU

Aluminum Spacers Market Size

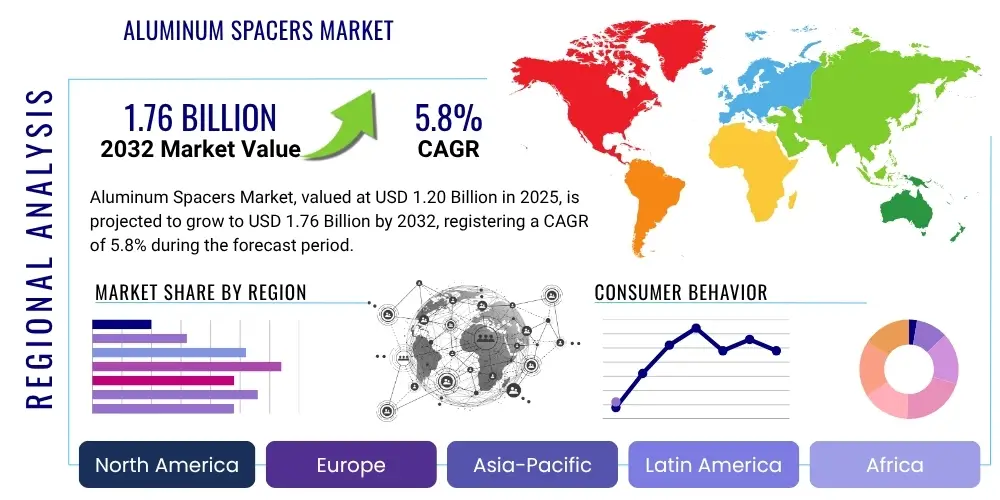

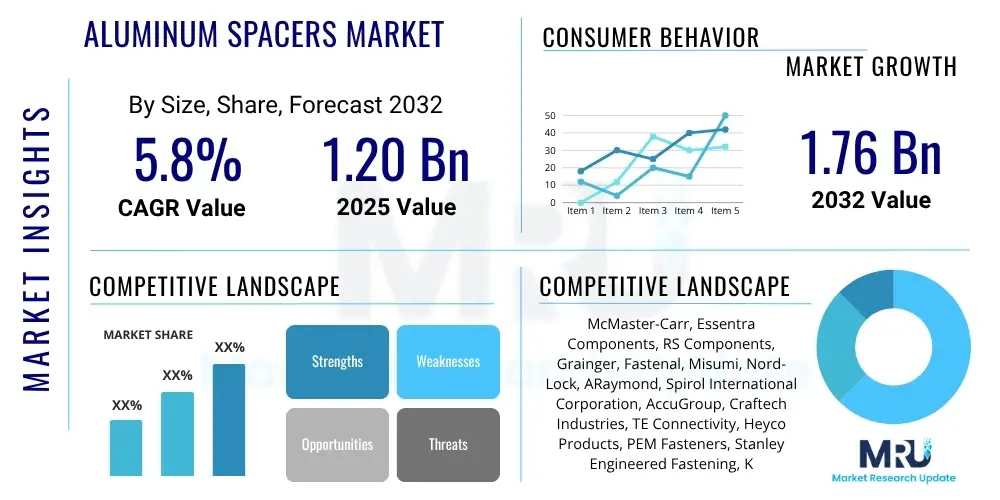

The Aluminum Spacers Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2025 and 2032. The market is estimated at USD 1.20 Billion in 2025 and is projected to reach USD 1.76 Billion by the end of the forecast period in 2032.

Aluminum Spacers Market introduction

The Aluminum Spacers Market encompasses the production and distribution of components designed to maintain a precise distance between two parts, typically for structural support, thermal management, or electrical isolation. Aluminum spacers are fabricated from various aluminum alloys, chosen for their superior strength-to-weight ratio, excellent corrosion resistance, non-magnetic properties, and good thermal and electrical conductivity. These characteristics make them highly versatile across a multitude of industries where performance and reliability are paramount. Their ability to be easily machined, anodized, or coated further enhances their utility, allowing for customization to meet specific application requirements for aesthetics or enhanced durability.

Aluminum spacers serve critical functions in numerous applications, ranging from sophisticated aerospace assemblies to everyday consumer electronics and heavy-duty industrial machinery. In construction, they are vital for window manufacturing, curtain walls, and facade systems, providing structural integrity and thermal breaks. The automotive sector utilizes them for lightweighting initiatives, assembly precision, and thermal management in engine compartments and electronic systems. The burgeoning electronics industry relies on them for PCB mounting, heat dissipation, and ensuring component clearances. Their lightweight nature contributes significantly to reducing overall product weight, leading to improved fuel efficiency in vehicles and lower shipping costs for electronic goods. Moreover, aluminum's recyclability aligns with growing sustainability mandates, presenting an environmentally conscious material choice.

Key driving factors for the Aluminum Spacers Market include the accelerating pace of urbanization and global infrastructure development, which fuels demand in the construction sector. The continuous expansion of the automotive industry, particularly the shift towards electric vehicles, necessitates lightweight and high-performance components. Furthermore, the rapid advancements in electronics and telecommunications, characterized by miniaturization and increased component density, significantly boost the need for precise and effective spacing solutions. The inherent benefits of aluminum, combined with these robust industrial growth trends, position the aluminum spacers market for sustained expansion over the forecast period.

Aluminum Spacers Market Executive Summary

The Aluminum Spacers Market is experiencing robust growth, primarily driven by evolving business trends focused on lightweighting, precision engineering, and sustainable manufacturing practices across diverse industries. There is an increasing emphasis on customization and rapid prototyping to meet specialized application requirements, pushing manufacturers to invest in advanced machining and fabrication technologies. The competitive landscape is characterized by a mix of large global players and specialized regional manufacturers, all vying for market share through product innovation, supply chain efficiency, and competitive pricing strategies. Strategic partnerships and acquisitions are also becoming prevalent as companies seek to expand their product portfolios and geographical reach, consolidating market presence and enhancing operational capabilities in a dynamic global environment.

Regional trends indicate significant market expansion in Asia Pacific, propelled by rapid industrialization, burgeoning construction activities, and the dominance of manufacturing hubs for automotive and electronics. North America and Europe demonstrate stable, mature market growth, with demand primarily stemming from advanced manufacturing sectors like aerospace, automotive, and high-tech electronics, where stringent quality standards and performance requirements are paramount. Emerging economies in Latin America, the Middle East, and Africa are also showing promising growth trajectories, supported by increasing investments in infrastructure development, industrialization initiatives, and growing consumer markets. These regions present substantial opportunities for market players to establish new distribution networks and cater to rising local demand for high-performance components.

Segment trends highlight strong performance across various product types and applications. Threaded and unthreaded spacers continue to be foundational, with custom-designed solutions gaining traction due to specific industry demands for unique geometries and functionalities. From an application perspective, the automotive and construction sectors remain dominant, driven by ongoing demand for lightweight structures and energy-efficient building solutions. The electronics segment is witnessing accelerated growth, fueled by the proliferation of smart devices, IoT components, and data center infrastructure, all requiring precise spacing and thermal management solutions. The industrial machinery and aerospace and defense sectors also contribute significantly, emphasizing durability, reliability, and precision in critical applications. The market is thus diversified across multiple high-growth segments, ensuring resilience and sustained expansion.

AI Impact Analysis on Aluminum Spacers Market

Common user questions regarding AI's impact on the Aluminum Spacers Market frequently revolve around how artificial intelligence can enhance manufacturing efficiency, improve product quality, optimize design processes, and streamline supply chain operations. Users are keen to understand the practical applications of AI in a traditional manufacturing sector like spacer production, wondering if AI can truly deliver significant cost savings, reduce waste, and accelerate time-to-market for customized components. There are also inquiries about predictive maintenance capabilities for machinery, intelligent automation on assembly lines, and the role of AI in material selection and quality inspection. Overall, the themes center on efficiency gains, precision, and smart automation.

The integration of AI technologies is poised to revolutionize the Aluminum Spacers Market by introducing unprecedented levels of precision, efficiency, and adaptability across the entire value chain. AI algorithms can analyze vast datasets from production lines to identify optimal machining parameters, predict equipment failures before they occur, and fine-tune material usage to minimize waste. This leads to substantial reductions in operational costs and enhanced output quality. Furthermore, AI-powered generative design tools are enabling engineers to rapidly explore thousands of design iterations for spacers, optimizing for factors such as weight, strength, and thermal performance, which would be impossible with traditional manual design methods. This acceleration in design cycles and optimization capabilities offers a significant competitive advantage to manufacturers.

- AI-driven predictive maintenance for manufacturing equipment, minimizing downtime and increasing operational efficiency.

- Generative design for optimal spacer geometries, reducing material usage and enhancing performance characteristics.

- Automated optical inspection systems using computer vision for high-precision quality control, detecting microscopic flaws.

- Supply chain optimization through AI-powered forecasting, improving inventory management and logistics for raw materials and finished products.

- Process optimization in extrusion and machining, leading to higher yield rates and reduced energy consumption.

- Real-time monitoring and adaptive control of production parameters for consistent product quality.

DRO & Impact Forces Of Aluminum Spacers Market

The Aluminum Spacers Market is significantly propelled by several robust drivers. A primary driver is the pervasive trend towards lightweighting across the automotive, aerospace, and electronics industries, where aluminum spacers offer a superior strength-to-weight ratio compared to steel. The rapid expansion of the construction and infrastructure sectors globally, particularly in developing economies, is fueling demand for aluminum components in energy-efficient window systems, curtain walls, and modular construction. Furthermore, the continuous miniaturization and increasing complexity of electronic devices necessitate precise, reliable, and thermally efficient spacing solutions, directly boosting the market for aluminum spacers. The inherent corrosion resistance and aesthetic appeal of aluminum also make it a preferred material in various consumer and industrial applications, further solidifying its market position.

However, the market also faces several notable restraints. The volatility of raw material prices, particularly aluminum, poses a significant challenge, impacting manufacturing costs and profitability for spacer producers. Geopolitical tensions and trade policies can disrupt global supply chains, leading to price fluctuations and material availability issues. Intense competition from manufacturers offering alternative materials like plastics, brass, or stainless steel can exert downward pressure on pricing, particularly for standard, off-the-shelf products. Moreover, the high precision required for certain critical applications demands specialized manufacturing equipment and stringent quality control, leading to higher production costs and potentially limiting market entry for smaller players. These factors collectively contribute to a complex operating environment for market participants.

Despite these restraints, substantial opportunities exist for growth and innovation. The increasing demand for custom-designed spacers, tailored to specific performance requirements and unique applications, opens avenues for manufacturers offering specialized engineering and fabrication services. Investing in sustainable manufacturing practices, such as using recycled aluminum and energy-efficient production processes, can attract environmentally conscious customers and align with corporate social responsibility initiatives. Furthermore, the development of smart spacers with integrated sensors or advanced functionalities for specific niche markets, such as IoT devices or specialized machinery, presents a lucrative growth opportunity. Technological advancements in additive manufacturing (3D printing) for aluminum components could also enable faster prototyping and production of complex spacer designs, further expanding market possibilities and driving innovation.

Segmentation Analysis

The Aluminum Spacers Market is comprehensively segmented to provide a granular understanding of its diverse landscape and to identify key growth pockets across various dimensions. This segmentation allows for a detailed analysis of market dynamics, consumer preferences, and technological adoption rates within specific categories. By dividing the market based on product type, application, and end-use industry, stakeholders can gain critical insights into the forces shaping supply and demand. This approach helps in tailoring product development, marketing strategies, and investment decisions to target the most promising segments, ensuring optimized resource allocation and maximized market penetration in an increasingly competitive environment.

Each segment exhibits distinct growth drivers and competitive pressures, reflecting the varying needs and requirements of end-user industries. For instance, the demand for threaded spacers is closely tied to assembly applications requiring secure fastening, while unthreaded spacers are often preferred for simple separation or alignment purposes. Similarly, the automotive sector prioritizes lightweight and vibration-resistant spacers, whereas the electronics industry focuses on precise dimensions and thermal management capabilities. Understanding these nuances through detailed segmentation analysis is crucial for market participants to innovate effectively and strategically position their offerings to capture emerging opportunities. The continuous evolution of technologies and industrial applications further necessitates a dynamic approach to market segmentation, allowing for adaptation to new trends and customer demands.

- By Type

- Threaded Spacers

- Unthreaded Spacers

- Standoffs

- Custom Spacers

- Tubular Spacers

- By Application

- Automotive

- Construction

- Electronics

- Industrial Machinery

- Aerospace & Defense

- Medical Devices

- Consumer Goods

- Telecommunications

- By End-Use Industry

- Building & Construction

- Automotive & Transportation

- Electrical & Electronics

- Industrial

- Aerospace

- Other Manufacturing

- By Region

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East & Africa (MEA)

Value Chain Analysis For Aluminum Spacers Market

The value chain for the Aluminum Spacers Market commences with the upstream activities centered on raw material sourcing and primary aluminum production. This stage involves the extraction of bauxite, its refining into alumina, and subsequent smelting to produce primary aluminum ingots. Key players at this stage are large-scale aluminum producers and extrusion companies that convert ingots into various forms like rods, bars, or profiles, which then serve as the foundational material for spacer fabrication. The quality and purity of these raw materials are paramount, directly influencing the performance and cost-effectiveness of the final aluminum spacers, making supplier relationships and material consistency critical components of the upstream segment.

Moving downstream, the midstream segment involves the core manufacturing processes of aluminum spacers. This includes precision machining, turning, milling, drilling, and cutting of aluminum stock to achieve the exact dimensions and tolerances required by different applications. Advanced manufacturing technologies such as Computer Numerical Control (CNC) machining are extensively utilized to ensure high accuracy and repeatability. Following fabrication, secondary processes like deburring, cleaning, surface finishing (e.g., anodizing, powder coating), and heat treatment are often applied to enhance the spacers' corrosion resistance, hardness, electrical insulation, or aesthetic appeal. Quality control and rigorous inspection are integral to this stage to ensure product specifications are met.

The final stage of the value chain involves distribution channels and reaching the end-users. Direct distribution typically involves manufacturers selling directly to Original Equipment Manufacturers (OEMs) in industries like automotive, aerospace, or electronics, often involving custom orders and long-term contracts. Indirect distribution relies on a network of distributors, wholesalers, and online platforms (e-commerce) that stock a wide range of standard and semi-custom spacers, catering to smaller businesses, MRO (Maintenance, Repair, and Operations) markets, and diverse industrial needs. Effective logistics, inventory management, and customer support are crucial in ensuring timely delivery and satisfying varied customer demands. The choice of distribution strategy often depends on the scale of operations, product complexity, and target market segments.

Aluminum Spacers Market Potential Customers

Potential customers and end-users of aluminum spacers span a wide array of industries, each with specific requirements that drive their purchasing decisions. In the construction sector, prime buyers include manufacturers of windows, doors, curtain walls, and facade systems, who utilize spacers for thermal breaks, structural support, and precise panel alignment. Large construction firms and architectural developers also procure these components for their modular building projects and specialized installations, valuing aluminum's durability and lightweight properties. The growing emphasis on energy-efficient and green building designs further reinforces their demand for high-performance aluminum spacing solutions.

The automotive industry represents a significant customer base, encompassing original equipment manufacturers (OEMs) of passenger vehicles, commercial vehicles, and electric vehicles, as well as their tier-one suppliers. Aluminum spacers are integral to various automotive sub-assemblies, providing crucial spacing for engine components, chassis parts, battery packs in EVs, and interior trim, contributing to overall vehicle lightweighting and improved fuel efficiency. The aerospace and defense sector also heavily relies on aluminum spacers for aircraft structures, instrumentation panels, and satellite components, where stringent weight restrictions, high strength, and corrosion resistance are critical performance factors. These industries demand highly reliable, certified components with impeccable traceability.

Moreover, the electrical and electronics sector is a burgeoning market for aluminum spacers. Manufacturers of printed circuit boards (PCBs), consumer electronics (smartphones, laptops), data center equipment, and industrial control systems are constant buyers. They use spacers for mounting PCBs, ensuring proper airflow for cooling, providing electrical isolation, and maintaining precise clearances between sensitive components. The industrial machinery segment, including manufacturers of automation equipment, robotics, and specialized tools, also procures aluminum spacers for alignment, support, and assembly in their complex mechanical systems. Given the diverse applications, direct sales to OEMs and procurement through industrial distributors are common channels for these varied customer segments, with material quality, dimensional accuracy, and supply chain reliability being key purchasing criteria.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 1.20 Billion |

| Market Forecast in 2032 | USD 1.76 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | McMaster-Carr, Essentra Components, RS Components, Grainger, Fastenal, Misumi, Nord-Lock, ARaymond, Spirol International Corporation, AccuGroup, Craftech Industries, TE Connectivity, Heyco Products, PEM Fasteners, Stanley Engineered Fastening, Komaspec, Hangzhou Wukou Fastener Co Ltd, Wenzhou Jinsheng Fasteners Co Ltd, Shenzhen Jieshi Hardware Co Ltd, Zhejiang Zhengrong Fasteners Co Ltd |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Aluminum Spacers Market Key Technology Landscape

The Aluminum Spacers Market is heavily influenced by advancements in manufacturing and processing technologies, which enable the production of high-precision, high-performance components. Computer Numerical Control (CNC) machining remains a cornerstone, providing unparalleled accuracy and repeatability for turning, milling, and drilling operations. This allows for the creation of intricate geometries and adherence to tight tolerances, essential for critical applications in aerospace and electronics. Automated processes and robotic integration are increasingly being adopted to enhance production efficiency, reduce labor costs, and maintain consistent quality across large production volumes, thereby streamlining the manufacturing workflow and increasing output capacity.

Beyond traditional machining, a range of specialized fabrication and finishing technologies contribute significantly to the market's capabilities. Extrusion technology is crucial for producing aluminum profiles that serve as stock for spacers, offering cost-effective production of uniform shapes. Surface treatment techniques, such as anodizing, chromate conversion coating, and powder coating, are vital for enhancing corrosion resistance, improving wear characteristics, and providing electrical insulation or aesthetic finishes. These treatments extend the lifespan and expand the application versatility of aluminum spacers, allowing them to withstand harsh environmental conditions and meet specific industry standards for durability and performance in diverse end-use scenarios.

Emerging technologies like additive manufacturing (3D printing) are beginning to make inroads into the aluminum spacers market, particularly for prototyping and low-volume production of highly complex or customized designs. While not yet cost-effective for mass production of standard parts, the ability of 3D printing to create intricate internal structures and optimize material usage offers significant potential for future innovation. Furthermore, advanced metrology systems, including optical comparators, laser scanners, and coordinate measuring machines (CMMs), are essential for ensuring the dimensional accuracy and quality assurance of finished spacers. Continuous research into new aluminum alloys with enhanced properties, such as improved strength, fatigue resistance, or thermal performance, also plays a critical role in expanding the market's technological frontier and meeting the evolving demands of advanced industries.

Regional Highlights

The global Aluminum Spacers Market exhibits significant regional disparities in demand, supply, and growth potential, driven by differing industrial landscapes, economic development levels, and regulatory frameworks. Asia Pacific stands out as the dominant region, largely fueled by robust economic growth, extensive infrastructure development projects, and the presence of major manufacturing hubs for automotive, electronics, and construction. Countries like China, India, Japan, and South Korea are leading the charge, benefiting from a large consumer base, rapid urbanization, and government initiatives supporting industrial expansion. This region is characterized by high production volumes and competitive pricing, making it a critical market for both local and international players seeking expansion.

North America and Europe represent mature markets with a strong emphasis on high-precision, high-performance aluminum spacers, particularly for advanced industries such as aerospace, automotive, medical devices, and high-tech electronics. These regions benefit from established manufacturing infrastructure, stringent quality standards, and continuous innovation in engineering and material science. While growth rates might be more moderate compared to Asia Pacific, the demand for custom-engineered solutions and premium-grade aluminum components remains consistently strong, driven by technological advancements and the need for components that meet demanding specifications. Latin America, the Middle East, and Africa are emerging markets, displaying promising growth prospects due to increasing investments in infrastructure, industrialization efforts, and diversification away from traditional industries, creating new opportunities for market penetration and expansion.

- Asia Pacific: Dominant market due to rapid industrialization, large-scale construction activities, and significant growth in automotive and electronics manufacturing in countries like China, India, and Japan.

- North America: Strong demand from the aerospace, automotive, and electronics sectors, driven by technological advancements and stringent quality requirements, particularly in the United States and Canada.

- Europe: Consistent growth in automotive, industrial machinery, and green building construction, with Germany, France, and the UK being key contributors focusing on high-precision and sustainable solutions.

- Latin America: Emerging market with increasing investments in infrastructure and industrial development, fostering growth in construction and automotive sectors in Brazil and Mexico.

- Middle East and Africa (MEA): Growth stimulated by large-scale construction projects, oil and gas industry demands, and diversification efforts across GCC countries and parts of Africa.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Aluminum Spacers Market.- McMaster-Carr

- Essentra Components

- RS Components

- Grainger

- Fastenal

- Misumi

- Nord-Lock

- ARaymond

- Spirol International Corporation

- AccuGroup

- Craftech Industries

- TE Connectivity

- Heyco Products

- PEM Fasteners

- Stanley Engineered Fastening

- Komaspec

- Hangzhou Wukou Fastener Co Ltd

- Wenzhou Jinsheng Fasteners Co Ltd

- Shenzhen Jieshi Hardware Co Ltd

- Zhejiang Zhengrong Fasteners Co Ltd

Frequently Asked Questions

What are the primary uses of aluminum spacers?

Aluminum spacers are primarily used to provide precise spacing between components, offer structural support, facilitate thermal management, and ensure electrical isolation in various assemblies across industries like automotive, construction, electronics, and aerospace. They are critical for maintaining component clearance and integrity.

Why is aluminum a preferred material for spacers over other options?

Aluminum is preferred due to its excellent strength-to-weight ratio, superior corrosion resistance, non-magnetic properties, good thermal conductivity, and ease of machining. These characteristics make aluminum spacers ideal for applications requiring lightweight, durable, and high-performance components, especially compared to heavier steel or less durable plastics.

Which industries are the largest consumers of aluminum spacers?

The largest consumers of aluminum spacers include the automotive industry for lightweighting and assembly precision, the construction sector for windows and structural elements, and the electronics industry for PCB mounting and thermal dissipation. The aerospace and industrial machinery sectors also represent significant demand.

What factors are driving the growth of the Aluminum Spacers Market?

The market's growth is primarily driven by the increasing demand for lightweight materials in various sectors, rapid urbanization and infrastructure development, continuous expansion of the automotive and electronics industries, and the rising emphasis on energy efficiency and precise manufacturing across global industries.

How do technological advancements influence the aluminum spacers market?

Technological advancements, particularly in CNC machining, automated production, and surface treatment methods, enable the creation of highly precise and customized aluminum spacers with enhanced durability and functionality. Emerging technologies like AI-driven design optimization and advanced metrology further contribute to efficiency and quality improvements.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager