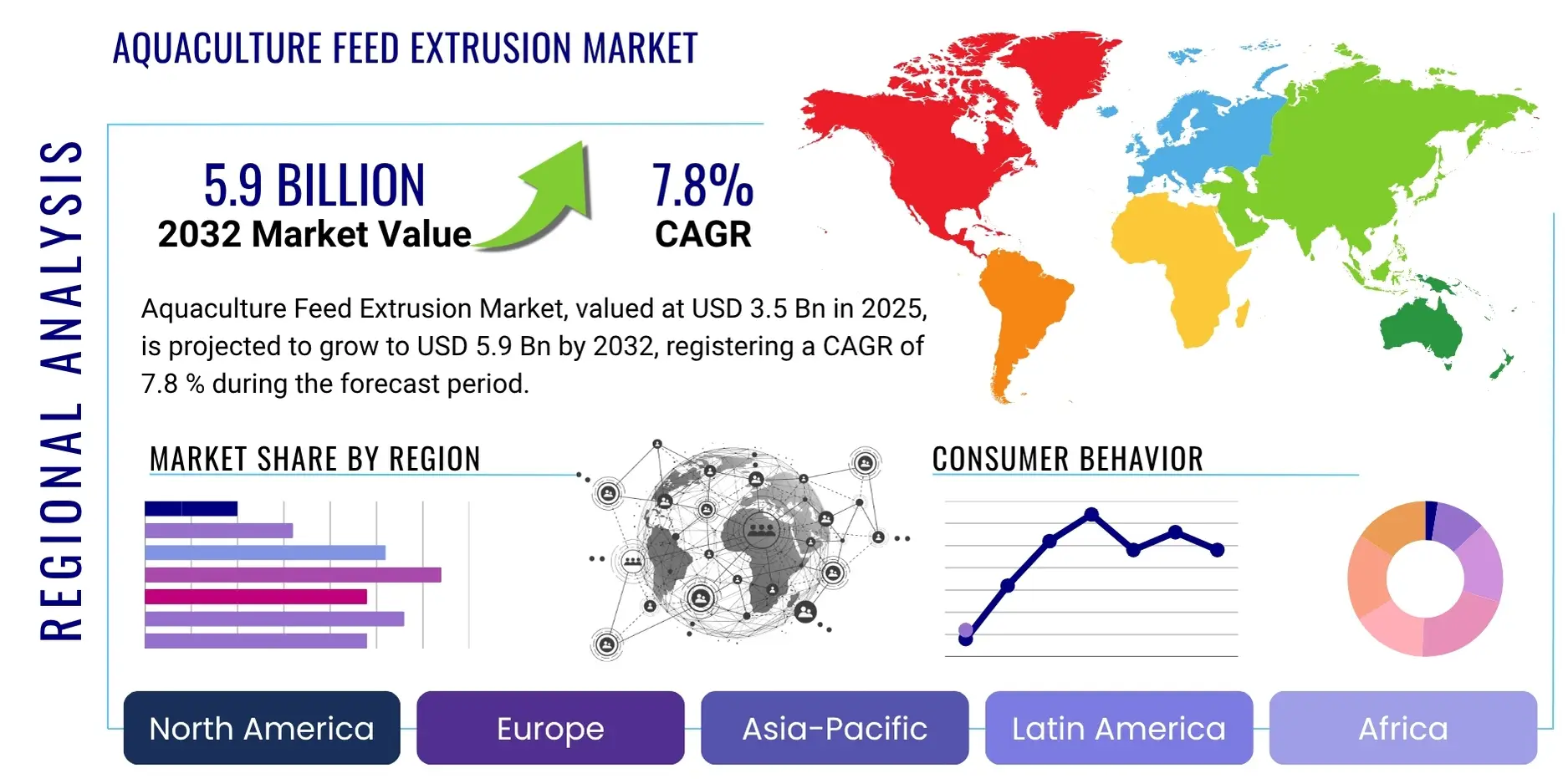

Aquaculture Feed Extrusion Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428097 | Date : Oct, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Aquaculture Feed Extrusion Market Size

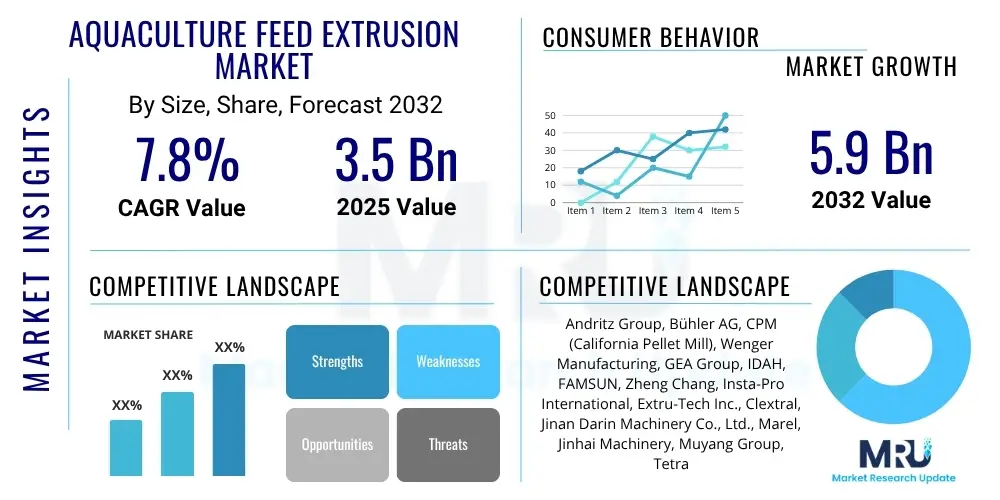

The Aquaculture Feed Extrusion Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2025 and 2032. The market is estimated at USD 3.5 billion in 2025 and is projected to reach USD 5.9 billion by the end of the forecast period in 2032. This growth is primarily driven by the escalating global demand for seafood, which necessitates more efficient and sustainable aquaculture practices, placing a premium on advanced feed technologies capable of optimizing fish growth, health, and feed conversion ratios. Innovations in extrusion technology, enabling the production of diverse feed types with superior nutritional profiles and physical characteristics, further underpin this robust market expansion across various aquatic species and geographic regions, signaling a strong investment outlook for industry participants.

Aquaculture Feed Extrusion Market introduction

The Aquaculture Feed Extrusion Market encompasses the manufacturing and distribution of specialized machinery and technologies used to produce extruded feeds for aquatic animals. These feeds are characterized by their superior physical properties, such as excellent water stability, optimal buoyancy (floating or sinking), and enhanced digestibility, which are crucial for minimizing feed waste, improving water quality, and maximizing nutrient absorption by farmed aquatic species. Extrusion involves a process where raw feed ingredients are subjected to high temperature, pressure, and shear, leading to gelatinization of starches, denaturation of proteins, and expansion of the feed pellet, ultimately creating a porous structure. Major applications of extruded feeds span across various aquaculture sectors, including the rearing of finfish like salmon, tilapia, carp, and catfish, as well as crustaceans such as shrimp and prawns, and other aquatic organisms. The primary benefits of using extruded feeds include improved feed conversion ratios (FCR), reduced environmental impact through lower nutrient discharge, better animal health and growth performance, and greater flexibility in incorporating diverse raw materials. Driving factors for this market include the surging global demand for protein-rich seafood, the imperative for sustainable aquaculture practices, continuous advancements in feed formulation science, and the increasing adoption of intensive aquaculture systems that require high-performance diets to ensure economic viability and ecological responsibility.

Aquaculture Feed Extrusion Market Executive Summary

The Aquaculture Feed Extrusion Market is currently experiencing dynamic growth, propelled by several overarching business trends focused on efficiency, sustainability, and technological integration. The increasing consumer preference for healthy and sustainably sourced seafood is compelling aquaculture operators to adopt high-quality extruded feeds that optimize production while minimizing environmental footprints. This trend is fostering innovation in extruder design, feed ingredient research, and process automation to produce more effective and environmentally friendly aquaculture diets. Regionally, Asia Pacific continues to dominate the market due to its vast aquaculture industry, particularly in countries like China, India, and Vietnam, where the demand for both extruded feed and extrusion equipment is exceptionally high. Europe and North America, while having more mature markets, are characterized by a strong emphasis on high-value species and advanced, precision extrusion technologies. Latin America and the Middle East & Africa regions are emerging as significant growth areas, driven by expanding aquaculture initiatives aimed at enhancing food security and economic development. In terms of segmentation, the market is broadly categorized by extruder type (single-screw and twin-screw), feed type (floating and sinking), and application (fish, shrimp, other aquatic animals). Twin-screw extruders are gaining prominence due to their superior versatility, processing flexibility, and ability to handle a wider range of raw materials for diverse feed formulations, catering to the specific dietary requirements of various aquatic species. This technological shift, coupled with an increasing focus on customized feed solutions, is shaping the competitive landscape and driving strategic collaborations among market players.

AI Impact Analysis on Aquaculture Feed Extrusion Market

The integration of Artificial Intelligence (AI) into the Aquaculture Feed Extrusion Market is anticipated to bring about transformative changes, addressing critical industry challenges ranging from operational efficiency to sustainable resource management. Common user questions revolve around how AI can optimize feed formulation for maximum nutritional value and cost-effectiveness, enhance the precision and consistency of the extrusion process, predict and prevent machinery breakdowns, and ultimately contribute to more environmentally friendly aquaculture practices. Users are keen to understand the practical applications of AI in real-time quality control, inventory management, and even in developing novel feed ingredients. While there is enthusiasm for the potential benefits, concerns also exist regarding the initial capital investment required for AI implementation, the need for specialized skills to operate and maintain AI-powered systems, and the potential for job displacement, underscoring a cautious yet optimistic outlook on AI's disruptive potential. Despite these challenges, the prevailing sentiment suggests that AI will be a pivotal force in driving the next wave of innovation in aquaculture feed production.

- Precision Feed Formulation: AI algorithms analyze vast datasets on nutrient requirements, ingredient availability, and cost fluctuations to optimize feed recipes for specific species, growth stages, and environmental conditions, maximizing efficacy and minimizing waste.

- Process Optimization and Control: AI-powered sensors and machine learning models monitor extrusion parameters (temperature, pressure, moisture) in real-time, automatically adjusting settings to ensure consistent product quality, desired buoyancy, and energy efficiency.

- Predictive Maintenance: AI analyzes machinery performance data to predict potential equipment failures before they occur, enabling proactive maintenance, reducing downtime, and extending the lifespan of extrusion equipment.

- Enhanced Quality Control: Computer vision and AI identify and rectify deviations in pellet size, shape, and density, ensuring high-quality, uniform feed production and reducing manual inspection efforts.

- Supply Chain and Inventory Management: AI optimizes the sourcing of raw materials, manages inventory levels, and forecasts demand, leading to reduced stockouts, minimized spoilage, and more efficient logistics for feed manufacturers.

- Sustainable Ingredient Development: AI can accelerate the discovery and evaluation of novel, sustainable protein sources and other ingredients, aiding in the formulation of feeds that lessen reliance on marine resources and reduce the carbon footprint of aquaculture.

DRO & Impact Forces Of Aquaculture Feed Extrusion Market

The Aquaculture Feed Extrusion Market is shaped by a complex interplay of drivers, restraints, and opportunities, influenced by significant impact forces that dictate its trajectory and sustainability. Key drivers include the ever-increasing global population and its subsequent demand for protein, which directly translates to a greater need for seafood and, consequently, high-quality aquafeed. Advancements in feed formulation and extrusion technology that enable higher feed conversion ratios and improved animal health also act as potent market drivers, encouraging wider adoption. However, the market faces notable restraints, such as the substantial capital investment required for state-of-the-art extrusion equipment, which can be a barrier for smaller players, and the volatility in raw material prices, particularly for ingredients like fishmeal and soy, which can impact production costs and profitability. Opportunities abound in the development of novel and sustainable feed ingredients, the expansion into untapped emerging markets in developing regions with growing aquaculture sectors, and the integration of cutting-edge technologies like IoT, AI, and automation for smart extrusion plants, promising enhanced efficiency and traceability. The primary impact forces influencing this market are technological advancements, which continuously redefine production capabilities and feed quality; environmental concerns, pushing for more sustainable and less polluting feed options; and economic stability, which affects investment in aquaculture infrastructure and consumer purchasing power for seafood products. These forces collectively define the market's growth potential and strategic imperatives for participants.

Segmentation Analysis

The Aquaculture Feed Extrusion Market is meticulously segmented to provide a comprehensive understanding of its diverse components and growth dynamics. This segmentation helps in analyzing market trends, identifying key areas of opportunity, and tailoring strategies to specific industry needs. The market is primarily categorized based on the type of extrusion equipment used, the physical characteristics of the feed produced, the specific aquatic species for which the feed is intended, and the production capacity of the machinery. Each segment plays a crucial role in addressing the varying requirements of aquaculture operations globally, from small-scale farms to large industrial facilities, and catering to the distinct nutritional needs of a wide array of aquatic animals.

- By Extruder Type:

- Single-Screw Extruders

- Twin-Screw Extruders

- By Feed Type:

- Floating Feed

- Sinking Feed

- Slow Sinking Feed

- By Application (Target Species):

- Fish Feed

- Salmon Feed

- Tilapia Feed

- Carp Feed

- Catfish Feed

- Trout Feed

- Other Finfish Feed

- Shrimp Feed

- Mollusk Feed

- Other Aquatic Animal Feed (e.g., Crab, Lobster)

- Fish Feed

- By Capacity:

- Small Capacity (<2 tons/hour)

- Medium Capacity (2-5 tons/hour)

- Large Capacity (>5 tons/hour)

- By End-Use:

- Commercial Aquaculture Farms

- Feed Mills

- Research & Development Institutes

Value Chain Analysis For Aquaculture Feed Extrusion Market

The value chain for the Aquaculture Feed Extrusion Market is a multi-stage process that begins with raw material sourcing and culminates in the delivery of specialized extruded feeds to aquaculture farms. The upstream segment involves the procurement of diverse raw materials essential for aquafeed production. This includes various protein sources such as fishmeal, soy meal, and other plant-based proteins, as well as lipids like fish oil and vegetable oils, carbohydrates from grains, and a range of essential vitamins, minerals, and additives. Key upstream participants are agricultural producers, rendering plants, and chemical manufacturers. Concurrently, the upstream also includes manufacturers of the extrusion machinery itself, who design, produce, and supply the sophisticated equipment necessary for feed processing. These machinery manufacturers, such as Andritz and Bühler, are crucial suppliers, often engaging in extensive R&D to improve extruder efficiency, capacity, and versatility.

Moving through the midstream, the value chain centers on the feed manufacturing process. Here, feed producers acquire the raw materials and utilize extrusion equipment to transform them into high-quality, extruded aquafeed pellets. This stage involves precise ingredient mixing, conditioning, extrusion, drying, cooling, and sometimes coating, to ensure the final product meets specific nutritional and physical specifications for different aquatic species. Quality control and technological expertise are paramount at this stage to produce feeds with optimal digestibility, water stability, and buoyancy. These feed manufacturers often operate large-scale facilities and play a pivotal role in innovating feed formulations to meet evolving demands for sustainable and performance-enhancing diets.

The downstream segment of the value chain focuses on the distribution and ultimate consumption of the extruded aquafeed. Distribution channels can be both direct and indirect. Direct distribution involves major feed manufacturers selling directly to large commercial aquaculture farms, often through dedicated sales teams and logistics networks, facilitating bulk orders and customized solutions. Indirect distribution involves leveraging a network of wholesalers, distributors, and local agents who then supply smaller to medium-sized farms, hatcheries, and retail outlets. This multi-channel approach ensures widespread market penetration. Ultimately, the end-users – aquaculture farms and hatcheries – utilize these extruded feeds to nourish their aquatic livestock, aiming for optimal growth, health, and yield, thereby completing the value chain loop from raw material to consumption and influencing consumer food choices.

Aquaculture Feed Extrusion Market Potential Customers

The primary potential customers and end-users of products within the Aquaculture Feed Extrusion Market are diverse, reflecting the broad scope and varied scale of the global aquaculture industry. Commercial aquaculture farms represent the largest segment of potential customers, ranging from expansive industrial operations focusing on high-value species like salmon, shrimp, and marine finfish, to medium and small-scale farms cultivating species such as tilapia, carp, and catfish. These farms rely heavily on extruded feeds to achieve optimal feed conversion ratios, accelerate growth rates, and maintain the health of their aquatic populations, which directly impacts their profitability and sustainability. Their demand is driven by the need for consistent, nutritionally complete, and physically stable feeds that minimize waste and support intensive farming practices.

Beyond individual farms, integrated feed mills are also significant customers, particularly for extrusion machinery. These mills invest in state-of-the-art extrusion lines to produce their own branded aquafeed products, which they then supply to a wide array of aquaculture operations, often operating on a contract basis or serving a regional market. Their buying decisions are influenced by factors such as equipment efficiency, capacity, versatility to produce various feed types, and the ability to integrate advanced automation and control systems. These feed mills act as crucial intermediaries, translating raw ingredients into high-quality, extruded aquafeed that meets the specific nutritional requirements of different aquatic species and farming methodologies.

Furthermore, government hatcheries, academic research institutions, and aquaculture development organizations constitute another important customer segment. These entities utilize extrusion technology for research purposes, developing new feed formulations, optimizing production processes, and conducting nutritional studies on emerging aquatic species. Their purchasing motivations often include the need for flexible, small-scale extrusion equipment for experimental batches, as well as advanced analytical tools for quality assessment. As the aquaculture industry continues to expand globally and diversify into new species and sustainable practices, the customer base for aquaculture feed extrusion products is poised for continued growth, driven by technological advancements and the escalating demand for aquatic protein sources.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 3.5 Billion |

| Market Forecast in 2032 | USD 5.9 Billion |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Andritz Group, Bühler AG, CPM (California Pellet Mill), Wenger Manufacturing, GEA Group, IDAH, FAMSUN, Zheng Chang, Insta-Pro International, Extru-Tech Inc., Clextral, Jinan Darin Machinery Co., Ltd., Marel, Jinhai Machinery, Muyang Group, Tetra Pak (relevant processing solutions), Sichuan Leader Machinery Co., Ltd., Dalian Highland Co., Ltd., Shandong Luerya Machinery Manufacturing Co., Ltd., Shandong Jinxin Machine Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Aquaculture Feed Extrusion Market Key Technology Landscape

The technological landscape of the Aquaculture Feed Extrusion Market is continuously evolving, driven by the need for greater efficiency, flexibility, and sustainability in feed production. Central to this landscape are advancements in extrusion machinery itself, with twin-screw extruders increasingly becoming the preferred choice over single-screw variants. Twin-screw technology offers superior versatility, allowing for more precise control over temperature, pressure, and shear, which is critical for processing a wider range of raw materials, including those with high fat or high fiber content. This enables the production of diverse feed types with specific buoyancy, water stability, and digestibility characteristics tailored to different aquatic species and life stages. Innovations in screw design, barrel configuration, and die technology are constantly being introduced to enhance throughput, reduce energy consumption, and improve product quality consistency.

Beyond the core extrusion process, the technological landscape includes sophisticated upstream and downstream equipment that complements the extruder. Precision ingredient dosing systems, for instance, utilize highly accurate gravimetric or volumetric feeders to ensure exact mixing ratios of raw materials, which is vital for nutritional consistency and cost control. Post-extrusion, advancements in drying and cooling technologies, such as vacuum dryers and counterflow coolers, are critical for maintaining pellet integrity, preventing nutrient degradation, and extending shelf life. Furthermore, vacuum coating technology allows for the precise application of heat-sensitive ingredients like enzymes, probiotics, and oils onto the feed pellets after drying, without exposing them to high temperatures, thereby preserving their efficacy and enhancing the feed’s nutritional value.

The integration of automation, real-time monitoring, and data analytics represents another significant technological advancement shaping the market. Modern extrusion lines are equipped with advanced sensors and control systems that monitor key parameters throughout the production process, from ingredient intake to final product packaging. Programmable Logic Controllers (PLCs) and Supervisory Control and Data Acquisition (SCADA) systems enable operators to precisely manage and optimize the entire process, minimizing human error and ensuring consistent quality. The adoption of Industry 4.0 principles, including the Internet of Things (IoT) and Artificial Intelligence (AI), is facilitating predictive maintenance, optimizing energy usage, and providing invaluable insights into process performance, paving the way for fully automated, smart feed mills that are more responsive, efficient, and sustainable.

Regional Highlights

- Asia Pacific: This region is the undisputed leader in the Aquaculture Feed Extrusion Market, driven by its vast and rapidly growing aquaculture industry, particularly in countries like China, India, Vietnam, Indonesia, and Thailand. High population density, increasing seafood consumption, and government initiatives supporting aquaculture growth contribute to high demand for both extruded feed and advanced extrusion equipment. The region is a hub for innovation and investment in feed technology.

- Europe: Characterized by a focus on high-value species such as salmon and trout, the European market for aquaculture feed extrusion emphasizes advanced technology, precision feeding, and stringent quality standards. Countries like Norway, Spain, and France are key players, with a strong drive towards sustainable and environmentally friendly feed production practices, leading to adoption of sophisticated, energy-efficient extrusion solutions.

- North America: The market in North America, particularly in the United States and Canada, is driven by a strong emphasis on automation, efficiency, and sustainable aquaculture practices. Demand for extruded feed is robust, with a growing focus on species like salmon, trout, and shrimp. Investment in R&D for novel feed ingredients and process optimization is prominent.

- Latin America: This region is emerging as a significant growth area, primarily fueled by the expanding shrimp and tilapia farming sectors in countries like Ecuador, Brazil, and Mexico. Increasing investments in aquaculture infrastructure, coupled with rising domestic and export demand for aquatic products, are propelling the adoption of modern feed extrusion technologies to enhance productivity and competitiveness.

- Middle East and Africa (MEA): The MEA region represents a developing market with substantial growth potential. Governments in countries like Saudi Arabia, Egypt, and South Africa are investing in aquaculture to bolster food security and diversify their economies. This push is creating a nascent yet rapidly expanding demand for aquaculture feed extrusion solutions, particularly for species like tilapia and marine finfish, focusing on both local production and technological transfer.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Aquaculture Feed Extrusion Market.- Andritz Group

- Bühler AG

- CPM (California Pellet Mill)

- Wenger Manufacturing, Inc.

- GEA Group Aktiengesellschaft

- IDAH Co., Ltd.

- FAMSUN (Jiangsu Muyang Group)

- Zheng Chang Co., Ltd.

- Insta-Pro International

- Extru-Tech Inc.

- Clextral SAS

- Jinan Darin Machinery Co., Ltd.

- Marel hf.

- Jinhai Machinery

- Muyang Group

- Tetra Pak International S.A.

- Sichuan Leader Machinery Co., Ltd.

- Dalian Highland Co., Ltd.

- Shandong Luerya Machinery Manufacturing Co., Ltd.

- Shandong Jinxin Machine Co., Ltd.

Frequently Asked Questions

What are the primary benefits of extruded aquaculture feed?

Extruded aquaculture feed offers significant advantages including improved feed conversion ratios (FCR), enhanced digestibility due to gelatinization, superior water stability reducing nutrient leaching, minimal feed waste, and the flexibility to incorporate a broader range of sustainable ingredients, leading to healthier and faster-growing aquatic animals.

How do single-screw and twin-screw extruders differ for aquaculture feed production?

Single-screw extruders are generally simpler, more cost-effective, and suitable for high-volume production of less complex feeds. Twin-screw extruders, however, offer greater processing flexibility, precise control over cooking conditions, and the ability to handle a wider variety of raw materials, making them ideal for diverse, high-value, and specialized aquafeed formulations for various species.

What role does sustainability play in the Aquaculture Feed Extrusion Market?

Sustainability is a critical driving force, pushing the market towards the adoption of energy-efficient extrusion processes, the development and utilization of novel, environmentally friendly protein sources (e.g., insect meal, algal proteins), and feed formulations that minimize waste and reduce the ecological footprint of aquaculture, addressing consumer and regulatory demands.

Which region is expected to dominate the Aquaculture Feed Extrusion Market?

Asia Pacific is projected to continue its dominance in the Aquaculture Feed Extrusion Market throughout the forecast period. This is attributed to its extensive and rapidly expanding aquaculture industry, large population, increasing seafood consumption, and significant investments in modern feed production technologies across key countries like China, India, and Vietnam.

What are the major challenges faced by manufacturers in this market?

Key challenges for manufacturers include the high initial capital investment required for advanced extrusion machinery, the volatility and rising costs of raw materials (like fishmeal and soy), stringent regulatory requirements pertaining to feed safety and environmental impact, and the constant need for innovation to meet the evolving nutritional demands of diverse aquatic species and optimize feed performance.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager