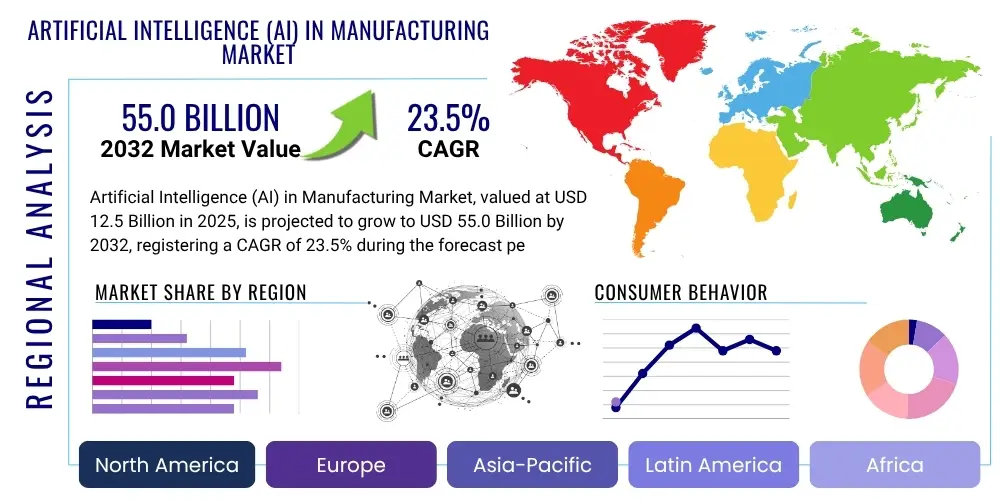

Artificial Intelligence (AI) in Manufacturing Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429052 | Date : Oct, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Artificial Intelligence (AI) in Manufacturing Market Size

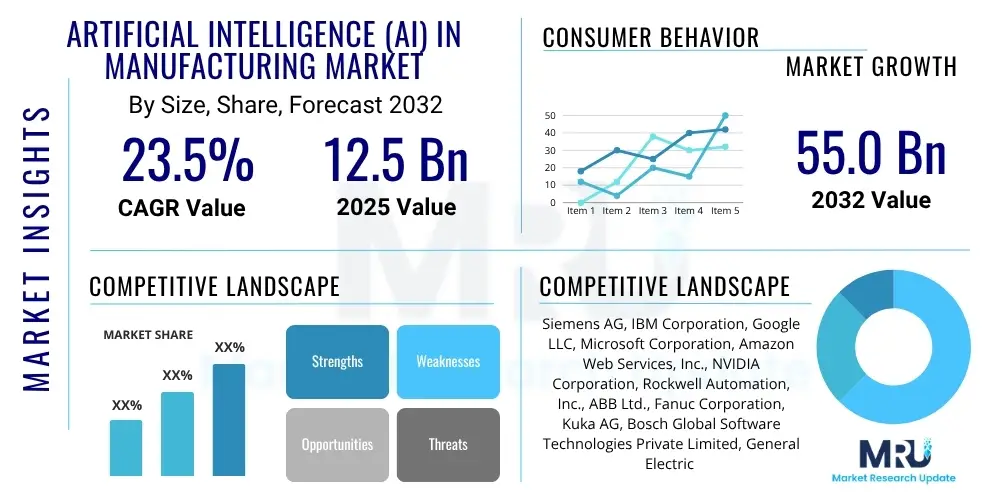

The Artificial Intelligence (AI) in Manufacturing Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 23.5% between 2025 and 2032. The market is estimated at $12.5 Billion in 2025 and is projected to reach $55.0 Billion by the end of the forecast period in 2032.

Artificial Intelligence (AI) in Manufacturing Market introduction

The Artificial Intelligence (AI) in Manufacturing Market encompasses the integration of AI technologies across various stages of the manufacturing process to enhance efficiency, quality, and responsiveness. This includes the application of machine learning, computer vision, natural language processing, and advanced robotics to optimize operations from design and production to supply chain management and customer service. AI-driven solutions are transforming traditional factories into smart, connected, and autonomous environments, facilitating predictive maintenance, automated quality inspection, and intelligent production planning. The market is propelled by the growing adoption of Industry 4.0 initiatives, the proliferation of data from IoT devices, and the increasing demand for automation to counter rising labor costs and improve operational agility. Benefits derived from AI in manufacturing include significant reductions in operational expenditure, enhanced product quality, faster time-to-market, improved worker safety, and the ability to enable mass customization, positioning AI as a critical enabler for competitive advantage in the modern industrial landscape.

Artificial Intelligence (AI) in Manufacturing Market Executive Summary

The Artificial Intelligence (AI) in Manufacturing Market is experiencing robust growth driven by a global push towards digital transformation and the imperative for operational excellence. Business trends indicate a significant shift towards smart factories, characterized by interconnected systems, real-time data analysis, and autonomous decision-making, with cloud-based AI solutions gaining prominence for scalability and accessibility. Regional trends show Asia Pacific as a dominant and rapidly expanding market due to its large manufacturing base and aggressive technology adoption, while North America leads in innovation and R&D investment, and Europe emphasizes sustainable and ethical AI integration within its Industry 4.0 framework. Segment trends highlight the accelerating growth of AI software solutions, particularly those focused on predictive analytics and quality control, alongside a surging demand for AI-powered robotics and automation across diverse manufacturing industries, from automotive to electronics and heavy machinery. The market is witnessing increased collaboration between technology providers and manufacturing firms to develop tailored AI applications that address specific industry challenges and unlock new levels of productivity and innovation.

AI Impact Analysis on Artificial Intelligence (AI) in Manufacturing Market

Users frequently inquire about the transformative capabilities of AI in manufacturing, focusing on how it can enhance efficiency, reduce costs, and improve product quality. Common questions also revolve around the practical implementation challenges, such as data integration, the need for specialized skills, and the return on investment. Concerns regarding job displacement, data security, and the ethical implications of autonomous systems are also prevalent. Overall, there is a strong expectation that AI will revolutionize manufacturing processes, leading to more agile, resilient, and intelligent operations, but with an underlying demand for clear strategies to mitigate potential risks and ensure a smooth transition. The key themes consistently emerging are centered on operational optimization, workforce evolution, and the strategic advantages conferred by data-driven decision-making in a competitive global environment.

- Enhanced Predictive Maintenance: AI algorithms analyze sensor data to forecast equipment failures, minimizing downtime and maintenance costs.

- Improved Quality Control: Computer vision and machine learning identify defects with greater accuracy and speed than manual inspection, reducing scrap and rework.

- Optimized Production Planning: AI analyzes demand, inventory, and production capacities to create efficient schedules, reducing bottlenecks and material waste.

- Streamlined Supply Chain Management: AI predicts supply and demand fluctuations, optimizes logistics, and enhances visibility across the entire supply chain.

- Advanced Robotics and Automation: AI integration enables robots to perform complex tasks, adapt to changing environments, and collaborate with human workers.

- Increased Operational Efficiency: AI-driven insights allow for continuous process optimization, leading to higher throughput and reduced energy consumption.

- Personalized Mass Customization: AI facilitates flexible production lines capable of producing customized products at scale, meeting evolving customer demands.

- Enhanced Worker Safety: AI can monitor hazardous environments and human-robot interactions, alerting to potential risks and preventing accidents.

- Data-Driven Decision Making: Real-time analysis of vast datasets provides actionable insights for strategic planning and continuous improvement.

- Cybersecurity Fortification: AI detects anomalies and potential threats in operational technology (OT) networks, safeguarding sensitive manufacturing data and intellectual property.

DRO & Impact Forces Of Artificial Intelligence (AI) in Manufacturing Market

The Artificial Intelligence (AI) in Manufacturing Market is primarily driven by the overarching imperatives of Industry 4.0, which emphasize automation, data exchange, and interconnected systems. The proliferation of IoT devices in factory settings generates vast amounts of data, creating a rich environment for AI algorithms to identify patterns, predict outcomes, and optimize processes. Furthermore, the global demand for increased production efficiency, reduced operational costs, and improved product quality, coupled with a growing shortage of skilled labor, compels manufacturers to invest in AI-driven solutions. These drivers are significantly pushing the market forward as companies seek competitive advantages through technological innovation and operational resilience. The ability of AI to unlock new levels of precision and responsiveness is a fundamental catalyst for market expansion.

However, the market faces significant restraints, including the substantial initial capital investment required for AI infrastructure, software licenses, and integration services. Many manufacturers, especially small and medium-sized enterprises (SMEs), may find these upfront costs prohibitive. Another critical restraint is the scarcity of a skilled workforce capable of developing, deploying, and managing AI systems within a manufacturing context. This talent gap can hinder adoption and effective utilization of AI technologies. Additionally, concerns around data privacy, cybersecurity risks associated with interconnected systems, and the inherent complexity of integrating diverse AI solutions with existing legacy systems pose considerable challenges, requiring robust planning and sophisticated architectural solutions to overcome. Resistance to change within organizational cultures also serves as a barrier, as adapting to AI-driven workflows often necessitates significant shifts in traditional operational paradigms.

Despite these challenges, the market is rife with opportunities stemming from the potential for predictive maintenance to prevent costly downtimes, the evolution of smart factories that leverage comprehensive AI integration for autonomous operations, and the ability to significantly enhance supply chain resilience through predictive analytics and optimization. AI also offers immense potential for enabling mass customization, allowing manufacturers to cater to individual customer preferences efficiently. The ongoing development of more user-friendly AI platforms and increasing accessibility of cloud-based AI services are further opening doors for broader adoption across various manufacturing sectors and company sizes. Moreover, the focus on sustainable manufacturing practices and energy efficiency presents a fertile ground for AI to optimize resource consumption and reduce environmental impact, offering a dual benefit of cost savings and corporate social responsibility alignment. The convergence of AI with other emerging technologies like robotics, IoT, and digital twins is expected to unlock unprecedented levels of innovation and market growth.

- Drivers: Industry 4.0 Adoption, Proliferation of Data from IoT Devices, Demand for Operational Efficiency, Reduction in Manufacturing Costs, Improvement in Product Quality, Labor Shortages, Need for Predictive Maintenance

- Restraints: High Initial Investment, Lack of Skilled Workforce, Data Privacy and Cybersecurity Concerns, Complexity of Integration with Legacy Systems, Resistance to Organizational Change

- Opportunities: Predictive Maintenance Evolution, Smart Factory Development, Supply Chain Optimization, Mass Customization, Energy Efficiency and Sustainable Manufacturing, Cloud-Based AI Solutions, Emergence of New AI Applications

- Impact Forces: High Bargaining Power of Buyers (demand for tailored solutions), Moderate Bargaining Power of Suppliers (specialized AI vendors), Moderate Threat of New Entrants (high R&D costs, niche focus possible), Moderate Threat of Substitutes (traditional automation, human labor), Intense Competitive Rivalry (numerous tech giants and startups)

Segmentation Analysis

The Artificial Intelligence (AI) in Manufacturing Market is meticulously segmented across various dimensions to provide a detailed understanding of its complex landscape and growth trajectories. These segmentations allow for a granular analysis of market dynamics, identifying key areas of investment, technological adoption, and industry-specific applications. By breaking down the market based on components, technologies, applications, and industries, stakeholders can gain precise insights into market opportunities and competitive positioning. This comprehensive approach ensures that both technology providers and manufacturing end-users can navigate the market effectively, tailoring solutions to specific needs and maximizing the impact of AI integration.

- By Component:

- Software: AI Platforms, AI Solutions (Predictive Maintenance Software, Quality Control Software, Robotics Software, Supply Chain Optimization Software)

- Hardware: Sensors, Cameras, Processors (GPUs, ASICs), Robotics (Collaborative Robots, Autonomous Mobile Robots), Edge Devices

- Services: Consulting Services, Implementation and Integration Services, Support and Maintenance Services, Training and Education Services

- By Technology:

- Machine Learning: Supervised Learning, Unsupervised Learning, Reinforcement Learning, Deep Learning

- Natural Language Processing (NLP)

- Computer Vision

- Context-Aware Computing

- Generative AI

- By Application:

- Predictive Maintenance

- Quality Control and Inspection

- Cybersecurity

- Robotics and Automation

- Supply Chain Optimization: Demand Forecasting, Inventory Management, Logistics Optimization

- Production Planning and Management

- Field Service Management

- Design and Engineering

- By Industry:

- Automotive

- Electronics and Semiconductor

- Heavy Machinery and Metal

- Food and Beverage

- Energy and Power

- Pharmaceuticals and Life Sciences

- Chemicals

- Aerospace and Defense

- Others (Textile, Packaging, etc.)

Value Chain Analysis For Artificial Intelligence (AI) in Manufacturing Market

The value chain for Artificial Intelligence (AI) in Manufacturing begins with upstream activities involving foundational AI research and development, component manufacturing, and data acquisition infrastructure. This segment includes providers of advanced sensors, high-performance processors, cloud computing services, and specialized AI platforms that form the backbone of any AI deployment. These upstream players are critical in supplying the necessary technological components and foundational algorithms that enable AI solutions. Data collection devices such as industrial IoT sensors and high-resolution cameras play a pivotal role in feeding the AI systems with the raw information required for analysis and decision-making, highlighting the importance of robust data generation capabilities in the initial stages of the value chain. Innovation in this segment directly impacts the capabilities and cost-effectiveness of downstream applications.

Moving downstream, the value chain involves AI solution developers and system integrators who customize and deploy AI models for specific manufacturing applications, such as predictive maintenance, quality control, and supply chain optimization. These players translate generic AI capabilities into industry-specific solutions that address unique challenges faced by manufacturers. The final stage involves the end-user manufacturers across various industries like automotive, electronics, and pharmaceuticals, who adopt and utilize these AI solutions within their production processes. The distribution channel for these solutions can be direct, where AI providers sell directly to manufacturers, or indirect, through a network of channel partners, value-added resellers, and system integrators who provide localized support, implementation services, and integration expertise. Indirect channels often play a crucial role in reaching smaller manufacturers and specialized industries, providing tailored solutions and mitigating implementation complexities. Both direct and indirect models are essential for comprehensive market penetration.

Artificial Intelligence (AI) in Manufacturing Market Potential Customers

The primary potential customers for Artificial Intelligence (AI) in Manufacturing solutions are diverse organizations operating within the industrial sector that seek to enhance operational efficiency, reduce costs, improve product quality, and achieve greater agility. This broad category includes large multinational corporations that operate extensive global manufacturing facilities, as well as small and medium-sized enterprises (SMEs) looking to modernize their production lines and gain a competitive edge. These end-users span a wide array of manufacturing verticals, each with unique operational challenges and demands. The core objective across all these potential buyers is to leverage AI to move towards more autonomous, data-driven, and resilient manufacturing processes, ultimately driving profitability and innovation.

Specifically, key end-users and buyers of AI in manufacturing products and services include automotive manufacturers focused on optimizing assembly lines and vehicle quality, electronics and semiconductor companies striving for defect reduction and yield optimization, and heavy machinery and metal fabrication firms aiming to extend equipment lifespan through predictive maintenance. The food and beverage industry utilizes AI for quality inspection, waste reduction, and supply chain freshness, while pharmaceutical companies deploy AI for drug discovery, process optimization, and compliance. Additionally, energy and power generation facilities use AI for grid optimization and equipment reliability. These diverse industries collectively represent the robust and growing customer base for AI in manufacturing, all seeking to harness the power of artificial intelligence to transform their operations and meet the evolving demands of the global market.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $12.5 Billion |

| Market Forecast in 2032 | $55.0 Billion |

| Growth Rate | 23.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Siemens AG, IBM Corporation, Google LLC, Microsoft Corporation, Amazon Web Services, Inc., NVIDIA Corporation, Rockwell Automation, Inc., ABB Ltd., Fanuc Corporation, Kuka AG, Bosch Global Software Technologies Private Limited, General Electric Company (GE Digital), SAP SE, Intel Corporation, Mitsubishi Electric Corporation, Cisco Systems, Inc., PTC Inc., Honeywell International Inc., Yokogawa Electric Corporation, Schneider Electric SE |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Artificial Intelligence (AI) in Manufacturing Market Key Technology Landscape

The Artificial Intelligence (AI) in Manufacturing Market is underpinned by a rapidly evolving technological landscape characterized by significant advancements in several core areas. Machine learning, including deep learning and reinforcement learning, stands as a fundamental pillar, enabling systems to learn from vast datasets for tasks such as predictive maintenance, anomaly detection, and process optimization. Computer vision technologies, utilizing advanced cameras and image processing algorithms, are crucial for automated quality inspection, robotic guidance, and security monitoring. Natural Language Processing (NLP) facilitates human-machine interaction, allowing for intuitive control and data extraction from unstructured text, enhancing collaboration and operational communication. These technologies collectively drive the intelligence behind smart manufacturing operations.

Further enabling the AI in manufacturing ecosystem are sophisticated hardware components and robust infrastructure solutions. High-performance processors like Graphics Processing Units (GPUs) and Application-Specific Integrated Circuits (ASICs) provide the computational power necessary for complex AI models. The Internet of Things (IoT) plays a vital role by providing the network of interconnected sensors and devices that collect real-time data from the factory floor, which is then fed into AI systems for analysis. Cloud computing offers scalable and flexible infrastructure for processing and storing this massive data, while edge AI brings processing capabilities closer to the data source, enabling real-time decision-making without significant latency. The integration of AI with advanced robotics and automation, including collaborative robots (cobots) and autonomous mobile robots (AMRs), is transforming assembly lines and logistics within manufacturing facilities. Digital twins, virtual replicas of physical assets, processes, or systems, are also gaining prominence, using AI to simulate, predict, and optimize real-world operations, thus forming a comprehensive technological framework that supports the continuous innovation and expansion of AI in manufacturing applications.

Regional Highlights

- North America: Leads in AI research and development, characterized by early adoption of advanced manufacturing technologies and substantial investment in smart factories. The region benefits from a strong presence of key technology providers and a robust startup ecosystem driving innovation in AI solutions for industries like automotive, aerospace, and electronics.

- Europe: Driven by robust Industry 4.0 initiatives and a focus on sustainable and ethical AI, Europe is witnessing significant integration of AI across its diverse manufacturing base. Countries like Germany, France, and the UK are investing heavily in automation, predictive analytics, and digital twin technologies to enhance competitiveness and operational efficiency, often supported by government funding and collaborative projects.

- Asia Pacific (APAC): Emerges as the largest and fastest-growing market for AI in manufacturing, propelled by the region's vast manufacturing capacity, rapid industrialization, and increasing adoption of automation, particularly in countries like China, Japan, South Korea, and India. High demand for cost reduction, quality improvement, and the proliferation of smart factory initiatives are key drivers.

- Latin America: An emerging market for AI in manufacturing, with increasing investments in digital transformation initiatives across industries such as automotive, food and beverage, and metals. Countries like Brazil and Mexico are leading the adoption, albeit at a slower pace compared to developed regions, driven by the need to modernize infrastructure and improve global competitiveness.

- Middle East and Africa (MEA): This region is experiencing nascent but growing adoption of AI in manufacturing, primarily driven by economic diversification efforts and investments in industrial infrastructure. Focus areas include optimizing energy production, processing industries, and logistics, with countries like UAE and Saudi Arabia leading the digital transformation efforts.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Artificial Intelligence (AI) in Manufacturing Market.- Siemens AG

- IBM Corporation

- Google LLC

- Microsoft Corporation

- Amazon Web Services, Inc.

- NVIDIA Corporation

- Rockwell Automation, Inc.

- ABB Ltd.

- Fanuc Corporation

- Kuka AG

- Bosch Global Software Technologies Private Limited

- General Electric Company (GE Digital)

- SAP SE

- Intel Corporation

- Mitsubishi Electric Corporation

- Cisco Systems, Inc.

- PTC Inc.

- Honeywell International Inc.

- Yokogawa Electric Corporation

- Schneider Electric SE

Frequently Asked Questions

Analyze common user questions about the Artificial Intelligence (AI) in Manufacturing market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is Artificial Intelligence (AI) in Manufacturing?

AI in manufacturing refers to the application of intelligent technologies like machine learning, computer vision, and robotics to optimize production processes, enhance quality control, streamline supply chains, and enable predictive maintenance across various industrial operations.

What are the primary benefits of implementing AI in manufacturing?

Key benefits include significant improvements in operational efficiency, reduced production costs, enhanced product quality, minimized downtime through predictive maintenance, optimized supply chain management, and increased flexibility for mass customization.

What challenges does AI face in manufacturing adoption?

Challenges include high initial investment costs, a shortage of skilled personnel to deploy and manage AI systems, concerns regarding data security and privacy, and the complexity of integrating AI solutions with existing legacy manufacturing infrastructure.

How does AI impact employment in the manufacturing sector?

AI is transforming manufacturing jobs by automating repetitive tasks, creating new roles requiring specialized AI skills, and shifting human labor towards supervisory, analytical, and collaborative tasks. While some roles may be displaced, new opportunities emerge.

What are the future trends for AI in manufacturing?

Future trends include the widespread adoption of AI-powered digital twins, increased use of generative AI for product design, further integration of edge AI for real-time decision-making, and a growing emphasis on sustainable manufacturing optimized by AI.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager