Assembly Fastening Tools Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428004 | Date : Oct, 2025 | Pages : 249 | Region : Global | Publisher : MRU

Assembly Fastening Tools Market Size

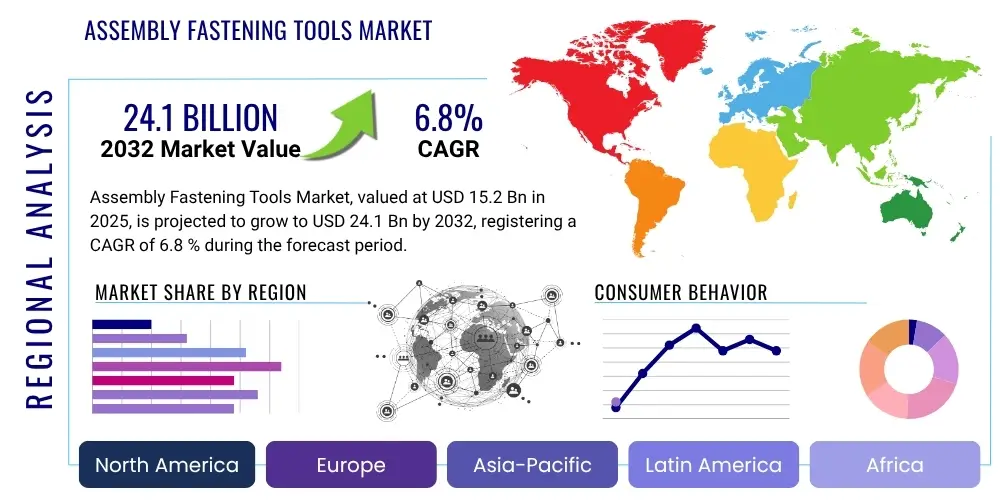

The Assembly Fastening Tools Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at USD 15.2 Billion in 2025 and is projected to reach USD 24.1 Billion by the end of the forecast period in 2032. This growth is underpinned by increasing automation across various industrial sectors and the burgeoning demand for high-precision manufacturing processes. The shift towards electric and smart fastening tools, offering enhanced control and data capabilities, further contributes to this expansion, providing significant value for industries aiming to optimize their production lines.

Assembly Fastening Tools Market introduction

The Assembly Fastening Tools Market encompasses a wide array of devices and equipment designed for joining components through mechanical fasteners. These tools are critical in virtually every manufacturing sector, from automotive and aerospace to electronics and construction, ensuring secure and precise assembly. Products range from manual screwdrivers and wrenches to advanced pneumatic, electric, and hydraulic power tools, including impact wrenches, torque screwdrivers, nutrunners, and riveting tools. Their primary application lies in enhancing assembly line efficiency, improving product quality, and ensuring operator safety and ergonomics. The inherent benefits of these tools include repeatable accuracy, reduced labor costs, increased throughput, and the ability to meet stringent quality standards for diverse material applications. Driving factors for market growth include the global expansion of manufacturing activities, the relentless pursuit of automation and industrial digitalization (Industry 4.0), and the increasing complexity of modern product designs that demand sophisticated fastening solutions. Furthermore, stringent quality regulations across industries, particularly in aerospace and medical devices, necessitate the adoption of advanced, traceable fastening technologies.

Assembly Fastening Tools Market Executive Summary

The Assembly Fastening Tools Market is experiencing robust growth driven by significant business trends such as the widespread adoption of smart manufacturing principles, the growing emphasis on automation in assembly processes, and the increasing demand for ergonomic and precise tools. Companies are heavily investing in research and development to introduce innovative electric and battery-powered tools that offer superior control, portability, and data acquisition capabilities. Regional trends indicate strong growth in Asia Pacific, propelled by the rapid industrialization and expansion of the automotive and electronics manufacturing bases in countries like China, India, and Southeast Asian nations. North America and Europe continue to be key markets, characterized by a demand for high-end, automated fastening solutions and a focus on advanced manufacturing technologies. Segment trends highlight a shift towards electric fastening tools over pneumatic, primarily due to their energy efficiency, lower noise levels, and advanced torque control features. The automotive sector remains a dominant application segment, though aerospace, electronics, and general industrial assembly are also demonstrating substantial demand for specialized fastening tools, including those designed for composite materials and miniature components.

AI Impact Analysis on Assembly Fastening Tools Market

Artificial intelligence is set to profoundly transform the Assembly Fastening Tools Market, ushering in an era of unprecedented precision, efficiency, and predictive capabilities. Users commonly inquire about how AI will enhance tool performance, optimize assembly processes, and improve overall product quality. There is significant interest in AI's role in enabling smarter, self-optimizing assembly lines that can dynamically adjust to variations, reduce defects, and predict maintenance needs before failures occur. Furthermore, concerns often revolve around the initial investment costs, the complexity of integrating AI systems with existing infrastructure, and the potential impact on workforce skills and job roles. Expectations are high for AI to deliver greater process control, actionable insights from fastening data, and more adaptive automation solutions that can handle increasingly complex and customized manufacturing tasks, ultimately leading to higher productivity and lower operational costs in assembly operations.

- AI-powered predictive maintenance for fastening tools, anticipating wear and optimizing service schedules, thereby minimizing downtime and extending tool lifespan.

- Enhanced quality control through AI vision systems and data analytics, detecting assembly defects or inconsistencies in real-time and ensuring fastener integrity.

- Optimization of fastening parameters (torque, speed, angle) using machine learning algorithms, adapting to material variations and environmental conditions for optimal joint quality.

- Integration of AI with robotic assembly systems, enabling more agile and adaptive robotic manipulators to handle diverse fastening tasks with greater precision and flexibility.

- Real-time performance monitoring and diagnostics for smart fastening tools, providing operators with immediate feedback and facilitating data-driven decision-making for process improvement.

- Automated root cause analysis for fastening errors, using AI to identify patterns and suggest corrective actions, significantly reducing rework and scrap rates.

- Personalized operator guidance and training systems powered by AI, assisting human workers with complex assembly sequences and improving skill acquisition.

- Supply chain optimization for fasteners and tools, leveraging AI to forecast demand, manage inventory, and ensure timely availability of necessary components.

- Development of autonomous assembly stations where AI controls entire fastening sequences, from part presentation to final torque verification, with minimal human intervention.

- Design optimization for new products through AI simulations, predicting fastening requirements and potential issues at the design stage, reducing prototyping cycles.

DRO & Impact Forces Of Assembly Fastening Tools Market

The Assembly Fastening Tools Market is profoundly influenced by a complex interplay of drivers, restraints, opportunities, and external impact forces. A primary driver is the accelerating trend of industrial automation and the proliferation of Industry 4.0 technologies, compelling manufacturers to adopt sophisticated, interconnected fastening solutions for enhanced efficiency and precision. The global expansion of manufacturing sectors, particularly in emerging economies, also fuels demand for reliable and high-performance assembly tools. However, the market faces significant restraints, including the high initial capital investment required for advanced automated fastening systems, which can be a barrier for smaller enterprises. The complexity of integrating new digital tools with legacy systems and the need for a skilled workforce capable of operating and maintaining these advanced tools also present challenges. Geopolitical uncertainties, trade disputes, and economic fluctuations can disrupt supply chains and impact manufacturing output, thereby affecting market stability and growth. These external forces necessitate a cautious yet innovative approach from market participants to navigate potential downturns and capitalize on emerging trends.

Opportunities within the market are vast, especially with the growing demand for lightweight materials in industries such as automotive and aerospace, which require specialized fastening tools and techniques for composites and advanced alloys. The increasing focus on ergonomic design and operator safety in assembly lines creates avenues for manufacturers to innovate tools that reduce fatigue and prevent injuries. Furthermore, the rising adoption of electric and battery-powered tools, driven by sustainability initiatives and the desire for reduced noise and emissions, presents a substantial growth opportunity. The impact forces include technological advancements in sensing and control, which enable higher precision and data capture capabilities in fastening tools. Shifting regulatory landscapes regarding product safety and environmental standards also influence tool design and material choices. The competitive landscape is intensified by globalization, leading to a focus on cost-effectiveness, quality, and rapid innovation to maintain market share. Overall, while challenges exist, the underlying drive for manufacturing excellence and efficiency continues to propel the market forward.

Segmentation Analysis

The Assembly Fastening Tools Market is segmented based on several key characteristics, providing a granular view of market dynamics and potential growth areas. This comprehensive segmentation allows for a detailed understanding of varying demands across different product types, power sources, applications, and end-user industries. Such a breakdown is crucial for market players to tailor their product offerings, marketing strategies, and distribution channels to effectively target specific niche markets and capitalize on distinct growth opportunities. Each segment possesses unique requirements regarding precision, speed, durability, and cost-effectiveness, dictating the design and technological features of the tools developed for them. The evolving technological landscape, coupled with industry-specific needs, consistently reshapes the prominence and growth trajectory of these segments, making continuous analysis imperative for strategic planning and market penetration.

- By Product Type:

- Wrenches

- Screwdrivers (Manual, Power)

- Nutrunners (Manual, Power)

- Impact Wrenches

- Riveting Tools

- Torque Tools (Click, Digital, Hydraulic)

- Dispensing Tools

- Other Hand Tools

- By Power Source:

- Electric (Corded, Cordless/Battery-powered)

- Pneumatic

- Hydraulic

- Manual

- Battery

- By Application:

- Assembly and Manufacturing

- Maintenance and Repair Operations (MRO)

- Construction

- Installation

- Disassembly

- By End-User Industry:

- Automotive

- Aerospace and Defense

- Electronics and White Goods

- Heavy Industry (Machinery, Shipbuilding)

- Construction and Infrastructure

- Energy (Oil & Gas, Renewables)

- General Manufacturing

- Medical Devices

- By Torque Range:

- Low Torque (<10 Nm)

- Medium Torque (10-100 Nm)

- High Torque (>100 Nm)

- By Automation Level:

- Manual Tools

- Semi-Automatic Tools

- Fully Automatic Systems

Value Chain Analysis For Assembly Fastening Tools Market

The value chain for the Assembly Fastening Tools Market is a complex ecosystem, beginning with the meticulous upstream analysis of raw material sourcing and component manufacturing. This involves the procurement of high-grade steels, aluminum alloys, plastics, and electronic components essential for tool fabrication. Suppliers of motors, batteries, sensors, and control systems play a critical role in determining the quality and performance capabilities of the final product. Downstream analysis focuses on the distribution and sales channels, which include a multifaceted network comprising direct sales to large industrial clients, specialized distributors, wholesalers, and an expanding e-commerce presence. Manufacturers often maintain direct relationships with major automotive or aerospace companies to provide tailored solutions and ongoing support, leveraging their technical expertise and deep understanding of specific application requirements. This direct channel facilitates customization and long-term partnerships, crucial for high-value sales. The efficiency of this upstream and downstream integration significantly influences manufacturing costs, delivery times, and overall market responsiveness. Effective management of these stages ensures that high-quality components are procured economically and that finished tools reach end-users efficiently.

Distribution channels in the Assembly Fastening Tools Market are bifurcated into direct and indirect routes, each serving distinct market segments and customer needs. Direct channels involve manufacturers selling their tools directly to large-scale industrial customers, often supported by dedicated sales teams, technical support, and service networks. This approach is prevalent for complex, high-value, or customized fastening systems where direct consultation and integration services are paramount. It allows for direct feedback from end-users, fostering innovation and rapid product adaptation. Indirect channels, on the other hand, encompass a broader network of independent distributors, wholesalers, and retailers. These partners extend market reach, particularly to small and medium-sized enterprises (SMEs) and general industrial users who require readily available, standardized tools. E-commerce platforms are increasingly becoming a vital indirect channel, offering convenience, competitive pricing, and global accessibility, especially for standard hand tools and less specialized power tools. The effectiveness of these channels is often determined by the logistics infrastructure, inventory management capabilities, and the ability to provide localized sales and after-sales support, which are critical for customer satisfaction and brand loyalty.

Assembly Fastening Tools Market Potential Customers

The potential customers for Assembly Fastening Tools span a diverse range of industries, reflecting the fundamental need for secure and efficient joining processes across modern manufacturing and maintenance operations. End-users or buyers of these products include large multinational corporations operating complex assembly lines, as well as small and medium-sized enterprises (SMEs) engaged in specialized fabrication and repair work. The automotive industry represents a cornerstone of demand, with manufacturers and their vast supply chains requiring tools for engine assembly, chassis construction, interior fitting, and electric vehicle battery pack integration. Aerospace and defense companies are also significant consumers, demanding ultra-precise and reliable fastening solutions for aircraft, spacecraft, and military equipment, where safety and performance are non-negotiable. This segment often necessitates tools capable of handling advanced materials and providing traceable torque data.

Beyond these major sectors, the electronics and white goods industries rely heavily on assembly fastening tools for intricate component mounting and consumer product assembly, driving demand for miniature and precision tools. The heavy industry, encompassing machinery manufacturing, shipbuilding, and industrial equipment, utilizes robust and high-torque tools for large-scale construction and assembly. Furthermore, the construction and infrastructure sector, along with the energy sector (including oil & gas, and renewables), requires powerful and durable tools for structural assembly and maintenance. General manufacturing across various product categories, from furniture to sporting goods, also constitutes a broad base of potential customers. The growing trend of do-it-yourself (DIY) and professional tradespeople further expands the customer base, particularly for manual and light-duty power tools. Each of these customer segments exhibits unique purchasing criteria, ranging from price and durability to precision, connectivity, and after-sales service, compelling tool manufacturers to offer a diverse product portfolio.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 15.2 Billion |

| Market Forecast in 2032 | USD 24.1 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Atlas Copco AB, Stanley Black & Decker, Inc., Ingersoll Rand Inc., Bosch GmbH, Chicago Pneumatic (Part of Atlas Copco), DEWALT (Stanley Black & Decker), Makita Corporation, Hilti Corporation, Snap-on Incorporated, Apex Tool Group, LLC, Würth Group, Milwaukee Tool (TTI Group), Gedore Tools GmbH, Norbar Torque Tools Ltd., Danaher Corporation (Proto Industrial), Koki Holdings Co., Ltd. (HiKOKI Power Tools), AIMCO, Ltd., Sturtevant Richmont, Desoutter Industrial Tools (Atlas Copco), Mountz Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Assembly Fastening Tools Market Key Technology Landscape

The Assembly Fastening Tools Market is continually shaped by advancements in several key technological areas, driving innovation in tool performance, user experience, and overall manufacturing efficiency. One prominent trend is the widespread adoption of battery-powered electric tools, which offer unparalleled portability, precision, and energy efficiency compared to traditional pneumatic counterparts. These tools are often equipped with advanced brushless motors that extend battery life and reduce maintenance requirements, coupled with sophisticated electronic control systems that allow for precise torque, angle, and speed adjustments. This level of control is paramount in industries where exact fastening specifications are critical, such as aerospace and medical device manufacturing. Furthermore, the integration of smart features, including Wi-Fi or Bluetooth connectivity, enables real-time data logging, tool tracking, and remote diagnostics, facilitating proactive maintenance and ensuring compliance with quality standards. These capabilities are crucial for modern assembly lines that prioritize data-driven process optimization and traceability.

Another significant technological advancement lies in the development of advanced sensor technologies and integrated software solutions. Torque transducers, accelerometers, and gyroscopes embedded within fastening tools provide accurate feedback on the fastening process, allowing for real-time monitoring and verification of joint integrity. This sensor data, when combined with analytical software, can detect anomalies, identify potential issues, and generate detailed reports for quality assurance and compliance. Ergonomic design is also a critical technological consideration, with manufacturers investing in lightweight materials, vibration dampening systems, and optimized tool balance to minimize operator fatigue and reduce the risk of musculoskeletal injuries. The advent of augmented reality (AR) and virtual reality (VR) technologies is starting to influence the market, offering new avenues for operator training, assembly guidance, and complex maintenance procedures. These technologies aim to enhance human-machine collaboration, improve training efficacy, and ultimately boost productivity while maintaining high safety standards on the assembly floor.

Regional Highlights

- North America: A mature market characterized by high adoption of automated and smart fastening solutions, particularly in automotive, aerospace, and general manufacturing. Strong emphasis on high-precision, ergonomic tools and increasing demand for data-driven assembly processes.

- Europe: A leading region in advanced manufacturing and Industry 4.0 adoption, driving demand for electric, pneumatic, and hydraulic fastening tools with advanced torque control. Germany, France, and the UK are key contributors, focusing on energy efficiency and sustainable manufacturing practices.

- Asia Pacific (APAC): The fastest-growing market, propelled by rapid industrialization, expanding manufacturing bases (automotive, electronics, construction) in China, India, Japan, and South Korea. Characterized by high volume production and increasing adoption of automation and smart factory concepts.

- Latin America: Emerging market with growing manufacturing sectors, particularly in Brazil and Mexico, driven by foreign direct investment in automotive and general industrial production. Demand for both cost-effective and moderately advanced fastening tools is observed.

- Middle East and Africa (MEA): Growing market influenced by investments in infrastructure development, oil & gas, and diversification of economies. Demand for robust, durable tools for heavy industry, construction, and maintenance applications is prominent, with increasing interest in advanced solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Assembly Fastening Tools Market.- Atlas Copco AB

- Stanley Black & Decker, Inc.

- Ingersoll Rand Inc.

- Bosch GmbH

- Chicago Pneumatic (Part of Atlas Copco)

- DEWALT (Stanley Black & Decker)

- Makita Corporation

- Hilti Corporation

- Snap-on Incorporated

- Apex Tool Group, LLC

- Würth Group

- Milwaukee Tool (TTI Group)

- Gedore Tools GmbH

- Norbar Torque Tools Ltd.

- Danaher Corporation (Proto Industrial)

- Koki Holdings Co., Ltd. (HiKOKI Power Tools)

- AIMCO, Ltd.

- Sturtevant Richmont

- Desoutter Industrial Tools (Atlas Copco)

- Mountz Inc.

Frequently Asked Questions

Analyze common user questions about the Assembly Fastening Tools market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary factors driving growth in the Assembly Fastening Tools Market?

Growth is primarily fueled by increasing industrial automation, the global expansion of manufacturing industries, rising demand for precision and quality in assembly, and the growing adoption of Industry 4.0 technologies that integrate smart tools into production lines.

How is the market segmented by power source, and which segment is experiencing the fastest growth?

The market is segmented by power source into Electric (corded, cordless), Pneumatic, Hydraulic, and Manual. The Electric segment, especially battery-powered cordless tools, is experiencing the fastest growth due to superior portability, precision, and energy efficiency, aligning with sustainability trends.

What role does AI play in the evolution of assembly fastening tools?

AI significantly enhances tool functionality through predictive maintenance, real-time quality control, optimized fastening parameters, and integration with robotic assembly systems. It drives smarter, more efficient, and adaptive manufacturing processes, ultimately reducing defects and increasing throughput.

Which end-user industries are the largest consumers of assembly fastening tools?

The automotive industry is the largest consumer, followed closely by aerospace and defense, electronics and white goods, and heavy industry. These sectors demand high-precision, reliable, and often specialized fastening solutions for their complex assembly operations.

What are the key technological advancements transforming the Assembly Fastening Tools Market?

Key advancements include battery-powered electric tools with brushless motors and precise electronic controls, integrated sensor technologies for data logging and quality verification, advanced ergonomics for operator safety, and the emerging application of augmented and virtual reality for training and guidance.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager