Atomic Layer Deposition Equipment Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429570 | Date : Nov, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Atomic Layer Deposition Equipment Market Size

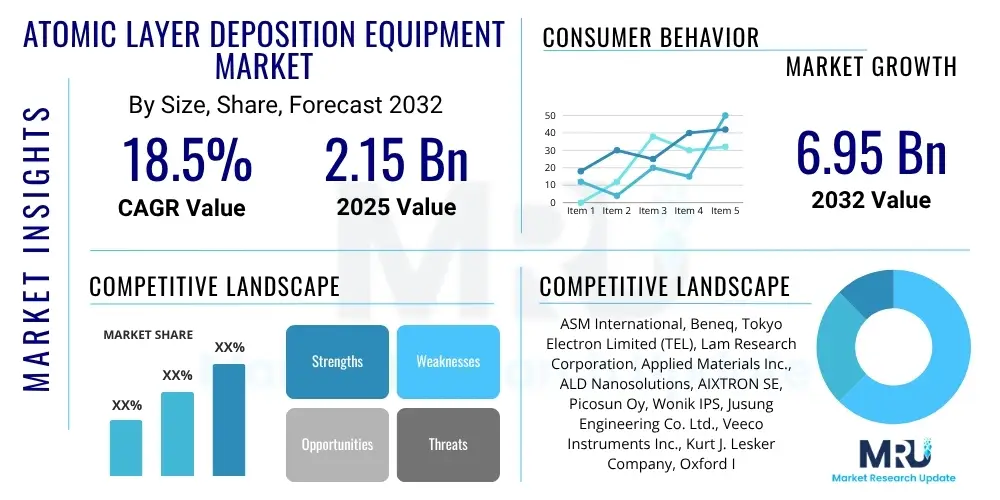

The Atomic Layer Deposition Equipment Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 18.5% between 2025 and 2032. The market is estimated at $2.15 Billion in 2025 and is projected to reach $6.95 Billion by the end of the forecast period in 2032.

Atomic Layer Deposition Equipment Market introduction

The Atomic Layer Deposition (ALD) Equipment Market encompasses advanced systems used to deposit ultra-thin, highly conformal films with atomic-scale precision. ALD is a thin-film deposition technique based on sequential, self-limiting surface reactions, enabling unparalleled control over film thickness and composition. This technology is critical for manufacturing next-generation semiconductor devices, advanced displays, and various other high-performance materials due to its ability to create uniform coatings even on complex, three-dimensional structures. Major applications range from insulating layers and diffusion barriers in semiconductors to protective coatings in medical devices and catalysts.

The primary benefits of ALD equipment include its exceptional conformality, precise thickness control at the angstrom level, excellent film uniformity, and the ability to process at relatively low temperatures, which is crucial for sensitive substrates. These advantages make ALD indispensable for fabricating devices with ever-shrinking feature sizes and increasingly complex architectures. The market is primarily driven by the relentless demand for higher performance and greater miniaturization in electronics, particularly within the semiconductor industry, alongside growing applications in areas such as energy storage, optoelectronics, and advanced packaging.

Atomic Layer Deposition Equipment Market Executive Summary

The Atomic Layer Deposition Equipment Market is experiencing robust expansion, fueled by significant advancements in semiconductor technology and the proliferation of emerging applications requiring ultra-precise thin films. Business trends indicate a focus on strategic collaborations, mergers and acquisitions among key players to expand technological portfolios and market reach, alongside intensive research and development efforts aimed at new precursor chemistries and enhanced reactor designs. Companies are investing heavily in automation and integrated solutions to meet the escalating demands of high-volume manufacturing while ensuring process efficiency and yield.

Regionally, Asia Pacific continues to dominate the market, primarily driven by the substantial presence of semiconductor foundries and memory manufacturers in countries like South Korea, Taiwan, China, and Japan. North America and Europe are also witnessing steady growth, propelled by significant investments in R&D, advanced packaging initiatives, and increasing adoption of ALD in specialized applications such as medical devices and renewable energy. Segment-wise, the memory and logic segments within semiconductors remain the largest contributors, with strong growth also observed in applications for advanced displays, micro-electromechanical systems (MEMS), and power devices, reflecting the diverse utility of ALD technology across critical industries.

AI Impact Analysis on Atomic Layer Deposition Equipment Market

Users frequently inquire about the transformative potential of Artificial intelligence in optimizing ALD processes, predicting material performance, and enhancing equipment intelligence. Key concerns revolve around how AI can reduce operational complexities, improve predictive maintenance, and accelerate the discovery of novel ALD chemistries and film properties. Expectations include leveraging AI for real-time process monitoring, automated recipe generation, and advanced anomaly detection to improve throughput and yield while minimizing human intervention, thereby driving efficiency and cost-effectiveness in the semiconductor manufacturing ecosystem.

- AI-driven optimization of ALD process parameters for enhanced film quality and deposition rate.

- Predictive maintenance algorithms for ALD equipment, minimizing downtime and extending component lifespan.

- Accelerated material discovery through AI-guided computational design of novel ALD precursors and film compositions.

- Real-time anomaly detection and fault diagnosis in ALD chambers, improving process stability and yield.

- Automated recipe generation and self-correction capabilities for adaptive ALD manufacturing.

- Enhanced data analysis for understanding complex ALD reaction mechanisms and surface interactions.

- Integration of AI with in-situ metrology for closed-loop process control and quality assurance.

DRO & Impact Forces Of Atomic Layer Deposition Equipment Market

The Atomic Layer Deposition Equipment Market is influenced by a dynamic interplay of drivers, restraints, opportunities, and broader impact forces. Key drivers include the ever-increasing demand for advanced semiconductor devices, necessitating ultra-thin, high-k dielectric films, and conformal coatings for 3D NAND, DRAM, and logic chips. The miniaturization trend in electronics, coupled with the proliferation of IoT devices, 5G technology, artificial intelligence, and electric vehicles, significantly boosts the need for high-precision film deposition techniques like ALD. Additionally, the expansion of advanced packaging technologies, requiring precise barrier layers and encapsulation, further propels market growth.

However, several restraints challenge market expansion, notably the high capital expenditure associated with ALD equipment, which can be prohibitive for smaller players. The complexity of ALD processes, including the need for specialized precursors and precise temperature control, can also be a barrier to widespread adoption. Limitations related to precursor availability, safety concerns, and the difficulty in scaling certain ALD processes for very large substrates present additional hurdles. Despite these challenges, significant opportunities arise from emerging applications in flexible electronics, quantum computing, medical implants, and advanced optics, which increasingly leverage ALD's unique capabilities for novel material synthesis and device fabrication. Furthermore, the development of new, more efficient, and cost-effective precursors, alongside innovations in reactor design, offers pathways for market expansion and broader industrial penetration.

Impact forces on the market include the rapid pace of technological advancements, driving continuous innovation in ALD equipment performance and capabilities. Global economic conditions and geopolitical factors can influence supply chain stability and investment in semiconductor manufacturing facilities, thereby impacting equipment sales. Environmental regulations and safety standards for handling hazardous precursors also exert pressure on manufacturers to develop greener processes and safer equipment designs. The intense competitive landscape among equipment providers further drives innovation and strategic pricing, shaping market dynamics.

Segmentation Analysis

The Atomic Layer Deposition Equipment Market is extensively segmented to reflect the diverse applications and technological variations within the industry. Understanding these segments is crucial for analyzing market trends, identifying growth opportunities, and strategizing market entry. The primary segmentation dimensions typically include equipment type, application, end-user industry, and geographic region, each offering unique insights into the market's structure and evolution.

- By Equipment Type

- Thermal ALD

- Plasma-Enhanced ALD (PEALD)

- Spatial ALD

- Roll-to-Roll ALD

- Batch ALD

- Area Selective Deposition ALD (ASD)

- By Application

- Logic & Memory Devices (DRAM, 3D NAND, Foundry)

- MEMS & Sensors

- Power Devices

- LEDs & Optoelectronics

- Displays (OLED, Micro-LED)

- Photovoltaics

- Medical & Biomedical

- Advanced Packaging

- Others (e.g., catalysis, protective coatings)

- By End-User Industry

- Semiconductor Industry

- Electronics Industry

- Medical Industry

- Solar Industry

- Research & Development Institutions

- Automotive Industry

- Aerospace & Defense

- By Region

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East and Africa (MEA)

Value Chain Analysis For Atomic Layer Deposition Equipment Market

The value chain for the Atomic Layer Deposition Equipment Market begins with upstream activities involving the research, development, and manufacturing of critical components and specialized precursors. This includes suppliers of high-purity chemical precursors (e.g., metalorganic compounds, halides), high-vacuum components, advanced control systems, and specialized materials required for reactor construction. The quality and availability of these raw materials and components are paramount to the performance and reliability of the final ALD equipment. Innovation in precursor chemistry, particularly for novel materials and processes, remains a significant focus in this upstream segment.

Further along the chain, equipment manufacturers design, assemble, and test the complex ALD systems, integrating various modules like reaction chambers, gas delivery systems, vacuum pumps, and process control software. These manufacturers invest heavily in R&D to enhance deposition uniformity, increase throughput, reduce processing temperatures, and expand the range of materials that can be deposited. The distribution channel primarily involves direct sales teams and dedicated service engineers from the equipment manufacturers who engage directly with large semiconductor fabs and research institutions. For smaller or more niche customers, indirect channels through distributors or system integrators may also be utilized, especially for localized support and customized solutions.

Downstream analysis focuses on the end-users, predominantly semiconductor foundries, Integrated Device Manufacturers (IDMs), memory manufacturers, and various research and development institutions. These customers utilize ALD equipment for a myriad of applications, from depositing high-k gate dielectrics and diffusion barriers to creating encapsulation layers and conformal coatings in advanced logic, memory, and MEMS devices. The effectiveness of the equipment directly impacts the performance, yield, and cost-efficiency of the end-product, making post-sales support, technical expertise, and continuous equipment upgrades critical components of the value chain. The feedback loop from these end-users is vital for driving continuous innovation and improvement in ALD technology.

Atomic Layer Deposition Equipment Market Potential Customers

The primary potential customers for Atomic Layer Deposition equipment are concentrated within high-technology manufacturing and advanced research sectors, particularly those requiring precise material engineering at the nanoscale. Semiconductor manufacturers represent the largest segment of end-users, encompassing integrated device manufacturers (IDMs), foundries, and memory producers who rely on ALD for critical processes like high-k dielectric deposition, gate stack formation, diffusion barriers, and advanced packaging applications in logic, DRAM, and 3D NAND devices. The ongoing drive for miniaturization and performance enhancement in semiconductors ensures a sustained demand from this segment.

Beyond semiconductors, significant demand emanates from manufacturers in the electronics industry for products such as advanced displays (OLED, Micro-LED), MEMS (Micro-Electro-Mechanical Systems) and sensors, power devices, and optoelectronics. These industries leverage ALD for its ability to create uniform, protective, and functional coatings on complex geometries, crucial for device reliability and performance. The medical industry is also emerging as a strong potential customer, utilizing ALD for biocompatible coatings on implants, drug delivery systems, and sterilization barriers on medical instruments, where thin, durable, and precise layers are essential for functionality and patient safety.

Furthermore, research and development institutions, universities, and government laboratories constitute a consistent customer base, acquiring ALD systems for fundamental materials science research, development of new processes, and prototyping novel devices. The solar industry employs ALD for enhancing the efficiency and durability of photovoltaic cells through anti-reflection coatings and passivation layers. Other niche but growing customer segments include industries involved in advanced optics, catalysis, and anti-corrosion coatings, all of whom benefit from the unique capabilities of atomic layer deposition.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $2.15 Billion |

| Market Forecast in 2032 | $6.95 Billion |

| Growth Rate | 18.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | ASM International, Beneq, Tokyo Electron Limited (TEL), Lam Research Corporation, Applied Materials Inc., ALD Nanosolutions, AIXTRON SE, Picosun Oy, Wonik IPS, Jusung Engineering Co. Ltd., Veeco Instruments Inc., Kurt J. Lesker Company, Oxford Instruments, SENTECH Instruments GmbH, Forge Nano Inc., CVD Equipment Corporation, Samco Inc., Encapsulix, Arradiance, Kokusai Electric Corporation |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Atomic Layer Deposition Equipment Market Key Technology Landscape

The Atomic Layer Deposition Equipment Market is characterized by a rapidly evolving technological landscape, driven by the continuous demand for higher performance, greater precision, and broader application versatility. Key technologies at the forefront include Plasma-Enhanced ALD (PEALD), which allows for lower deposition temperatures and enables the use of a wider range of precursors, making it suitable for temperature-sensitive substrates and enhancing film quality. Thermal ALD, the foundational ALD method, continues to be refined for specific applications requiring ultra-high purity and conformal films, often involving advanced precursor delivery systems to maximize efficiency and minimize particle generation. The development of spatial ALD techniques is also prominent, offering higher throughput and suitability for large-area deposition, which is critical for applications like advanced displays and flexible electronics.

Innovations in precursor chemistry represent another vital aspect of the technology landscape, with ongoing research focused on developing safer, more stable, and more reactive precursors that can deposit a wider array of materials, including complex oxides, nitrides, and metals. Advancements in reactor design are crucial, moving towards modular systems, high-aspect-ratio deposition capabilities, and integrated metrology solutions for in-situ monitoring and control. Furthermore, the integration of artificial intelligence and machine learning algorithms is emerging as a significant technological trend, enabling predictive maintenance, process optimization, and accelerated materials discovery, thereby enhancing the overall efficiency and intelligence of ALD equipment. The focus on developing solutions for area-selective deposition (ASD) and atomic layer etching (ALE) further underscores the industry's push towards ultimate precision and control in nanoscale manufacturing.

These technological advancements collectively aim to address existing challenges such as increasing deposition rates without compromising film quality, reducing capital and operational costs, and expanding the material palette achievable through ALD. The continuous refinement of these technologies ensures that ALD remains a critical enabler for next-generation electronic devices and various other advanced material applications, pushing the boundaries of nanoscale engineering. The development of roll-to-roll ALD for flexible substrates and batch ALD for high-volume manufacturing further diversifies the capabilities of this sophisticated deposition technique.

Regional Highlights

- Asia Pacific (APAC): Dominates the global ALD equipment market due to the high concentration of semiconductor manufacturing facilities, especially in South Korea, Taiwan, China, and Japan. Strong governmental support, continuous investments in advanced foundries and memory production, and the presence of leading electronics manufacturers drive significant demand.

- North America: A key region for research and development in ALD technology, driven by robust innovation in the semiconductor industry and academic institutions. Growing adoption in advanced packaging, MEMS, and emerging applications like quantum computing and medical devices contributes to its market expansion.

- Europe: Exhibits steady growth fueled by investments in niche semiconductor applications, automotive electronics, and increasing R&D activities in Germany, the Netherlands, and Finland. Strong focus on sustainable manufacturing and advanced materials also propels ALD adoption.

- Latin America: An emerging market with growing interest in electronics manufacturing and renewable energy, though currently a smaller contributor. Potential for future growth driven by industrialization and technological adoption.

- Middle East and Africa (MEA): A nascent market with limited penetration, primarily driven by investments in research institutions and diversification efforts in industries like oil and gas (for protective coatings) and emerging electronics manufacturing.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Atomic Layer Deposition Equipment Market.- ASM International

- Beneq

- Tokyo Electron Limited (TEL)

- Lam Research Corporation

- Applied Materials Inc.

- ALD Nanosolutions

- AIXTRON SE

- Picosun Oy

- Wonik IPS

- Jusung Engineering Co. Ltd.

- Veeco Instruments Inc.

- Kurt J. Lesker Company

- Oxford Instruments

- SENTECH Instruments GmbH

- Forge Nano Inc.

- CVD Equipment Corporation

- Samco Inc.

- Encapsulix

- Arradiance

- Kokusai Electric Corporation

Frequently Asked Questions

What is Atomic Layer Deposition (ALD) equipment used for?

Atomic Layer Deposition (ALD) equipment is primarily used in the semiconductor industry to deposit ultra-thin, highly conformal films with atomic-scale precision. It is crucial for manufacturing advanced logic and memory devices, MEMS, LEDs, and displays, as well as for protective coatings in medical and industrial applications.

What are the primary advantages of ALD technology?

ALD technology offers exceptional film conformality, precise thickness control at the angstrom level, excellent film uniformity over large areas, and the ability to process at relatively low temperatures. These advantages are vital for fabricating miniaturized, high-performance devices with complex 3D architectures.

Which industries are the major consumers of ALD equipment?

The semiconductor industry is the largest consumer, followed by the electronics industry (for displays, LEDs), medical industry (for biocompatible coatings), solar industry (for photovoltaics), and various research and development institutions. Emerging applications in automotive and aerospace also contribute to demand.

How does AI influence the ALD equipment market?

AI significantly impacts the ALD market by enabling process optimization, predictive maintenance, and accelerated materials discovery. It facilitates real-time monitoring, automated recipe generation, and anomaly detection, leading to improved throughput, higher yields, and reduced operational costs for ALD processes.

What are the key challenges faced by the ALD equipment market?

Key challenges include the high capital cost of ALD equipment, the complexity of ALD processes, limitations in precursor availability and stability, and the difficulties associated with scaling ALD for very large substrates. Ensuring safety in handling hazardous precursors and achieving high throughput while maintaining precision are also ongoing challenges.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager