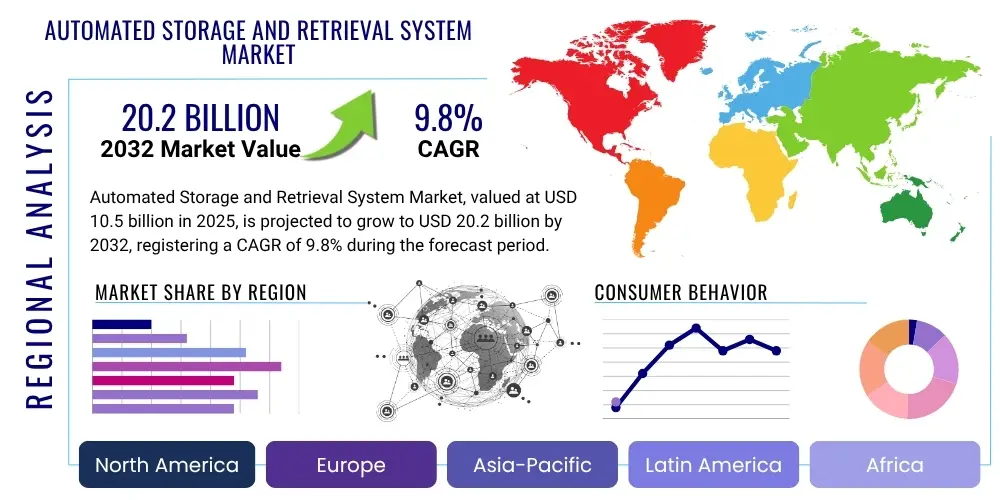

Automated Storage and Retrieval System Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428452 | Date : Oct, 2025 | Pages : 249 | Region : Global | Publisher : MRU

Automated Storage and Retrieval System Market Size

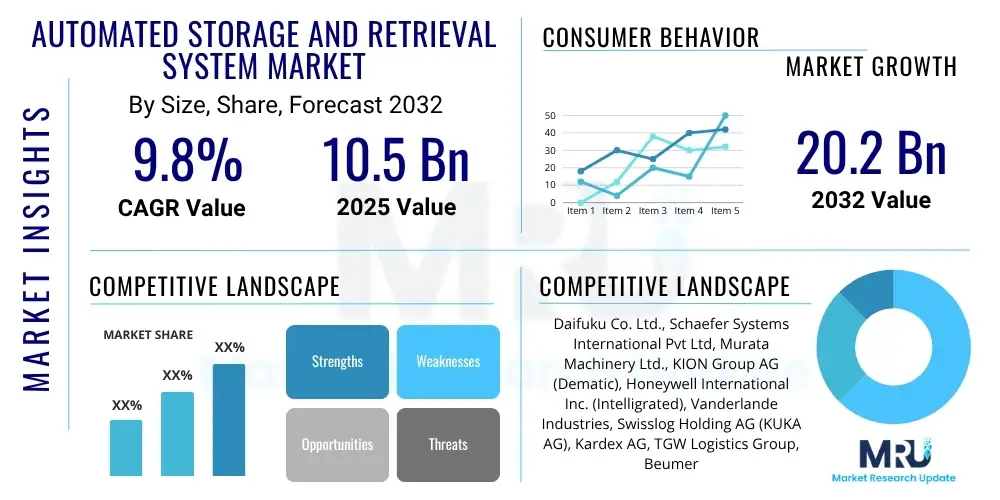

The Automated Storage and Retrieval System Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 9.8% between 2025 and 2032. The market is estimated at USD 10.5 billion in 2025 and is projected to reach USD 20.2 billion by the end of the forecast period in 2032.

Automated Storage and Retrieval System Market introduction

The Automated Storage and Retrieval System ASRS market is experiencing robust growth driven by the escalating demand for streamlined logistics and optimized warehouse operations across various industries. ASRS refers to computer-controlled systems that automatically place and retrieve loads from defined storage locations, offering significant improvements in efficiency, accuracy, and space utilization within warehouses and distribution centers. These sophisticated systems are integral to modern supply chain management, enabling faster throughput, reducing manual labor dependency, and enhancing inventory control, all of which are critical in today's fast-paced global economy. The fundamental principle behind ASRS is to minimize human intervention in repetitive and strenuous tasks, thereby improving safety and reducing operational costs.

The product description of an ASRS typically includes a variety of system types, such as unit-load ASRS for large items like pallets, mini-load ASRS for cartons or totes, carousels (vertical and horizontal) for smaller parts, and increasingly, robotic ASRS solutions utilizing autonomous mobile robots. Major applications span a broad spectrum of end-user industries including e-commerce and retail, automotive, food and beverage, pharmaceuticals, general manufacturing, and cold storage facilities. The primary benefits of implementing ASRS solutions include optimized storage density, reduced labor costs, increased picking accuracy, enhanced operational speed, and improved worker safety by minimizing the need for manual handling in hazardous environments. These systems are crucial for managing high-volume inventories and navigating the complexities of omnichannel fulfillment.

The market's expansion is predominantly driven by several key factors. The exponential growth of the e-commerce sector, characterized by rising customer expectations for rapid delivery and a vast product assortment, necessitates highly efficient and scalable storage solutions. Furthermore, increasing labor costs and persistent labor shortages in warehousing push businesses towards automation to maintain operational viability. The global emphasis on supply chain resilience and efficiency, especially in the wake of recent disruptions, further accelerates ASRS adoption. Finally, advancements in robotics, artificial intelligence, and IoT technologies are continuously enhancing ASRS capabilities, making them more adaptable, intelligent, and cost-effective, thereby fueling market demand and innovation.

Automated Storage and Retrieval System Market Executive Summary

The Automated Storage and Retrieval System ASRS market is poised for significant expansion, reflecting critical shifts in global business trends. The overarching move towards Industry 4.0, characterized by digitalization, automation, and data-driven decision-making, is a primary driver. Companies are investing heavily in advanced logistics solutions to optimize their supply chains, respond to rapidly evolving consumer demands, and enhance competitive advantage. A key business trend is the increasing integration of AI and machine learning into ASRS for predictive maintenance, optimized routing, and enhanced inventory intelligence, leading to smarter, more adaptive systems. Furthermore, there is a growing demand for modular and scalable ASRS solutions that can adapt to fluctuating business volumes and allow for phased implementation, making automation more accessible to a wider range of enterprises, including small and medium-sized businesses.

Regionally, the Asia Pacific APAC market is anticipated to maintain its dominance and exhibit the highest growth rate, fueled by rapid industrialization, burgeoning e-commerce sectors, and substantial investments in manufacturing and logistics infrastructure, particularly in China, Japan, and India. North America and Europe, as mature markets, are characterized by high adoption rates of advanced ASRS technologies, with a strong emphasis on integrating sophisticated software and robotic solutions to achieve higher levels of automation and efficiency. Latin America, the Middle East, and Africa are emerging as high-potential markets, driven by increasing foreign investments, expanding retail networks, and a growing recognition of the benefits of modern warehousing techniques to support economic development and regional trade initiatives.

Segment-wise, the market is witnessing significant developments. The mini-load ASRS segment is experiencing strong growth due to the proliferation of e-commerce and the need for efficient handling of smaller items and order fulfillment for individual units. Robotic ASRS, encompassing both shuttle systems and increasingly autonomous mobile robots AMRs, is gaining traction due to its flexibility, scalability, and ability to handle a diverse range of inventory types. The hardware component segment continues to dominate, but the software and services segments are projected to grow at a faster pace, reflecting the increasing importance of intelligent control, data analytics, and comprehensive lifecycle support for ASRS installations. End-user industries such as e-commerce, 3PL (third-party logistics), and general manufacturing remain the largest contributors to market revenue, consistently investing in automation to meet operational demands and customer expectations.

AI Impact Analysis on Automated Storage and Retrieval System Market

User inquiries concerning AI's influence on the Automated Storage and Retrieval System market primarily revolve around how AI enhances operational efficiency, optimizes resource allocation, and improves decision-making capabilities. Common questions address the tangible benefits of AI in ASRS, such as predictive maintenance, dynamic routing, and intelligent inventory management, alongside concerns regarding implementation complexity, data security, and the potential impact on human employment. Users also express curiosity about AI's role in making ASRS more adaptive and responsive to fluctuating demands, thereby improving overall supply chain resilience. The core expectation is for AI to transform ASRS from purely automated systems into intelligent, self-optimizing ecosystems that can learn and adapt.

- AI-driven predictive maintenance significantly reduces downtime by forecasting equipment failures, enabling proactive servicing and maximizing system availability.

- Optimized routing and task allocation for shuttles and robots, powered by AI algorithms, enhance throughput and reduce energy consumption within the ASRS.

- Real-time inventory intelligence and demand forecasting capabilities, enabled by AI, improve stock accuracy, minimize stockouts, and optimize storage locations.

- Adaptive learning capabilities allow ASRS to dynamically adjust to changing warehouse layouts, product types, and order patterns, increasing operational flexibility.

- Enhanced decision-making for system control and material flow management, improving overall warehouse performance and responsiveness.

- Improved safety protocols through AI-powered anomaly detection and collision avoidance systems for robots and human interaction zones.

- Integration of machine vision and AI for quality control, item identification, and error detection during picking and packing processes.

- Potential for fully autonomous operations, reducing reliance on manual oversight and increasing operational consistency and speed.

DRO & Impact Forces Of Automated Storage and Retrieval System Market

The Automated Storage and Retrieval System market is significantly shaped by a confluence of powerful drivers, persistent restraints, compelling opportunities, and the broader impact forces defining competitive landscapes. The primary drivers fueling market expansion include the exponential growth of e-commerce, which necessitates rapid and accurate order fulfillment; the rising cost of labor and a shortage of skilled warehouse workers, pushing businesses towards automation; and the increasing demand for optimizing storage space due to rising real estate costs. Furthermore, the global emphasis on supply chain resilience, coupled with the need for enhanced operational efficiency and accuracy, consistently propels the adoption of ASRS solutions across diverse industrial sectors. These drivers collectively create a compelling business case for investment in advanced automation technologies.

Despite the strong growth trajectory, several restraints challenge the widespread adoption of ASRS. The most significant is the high initial capital investment required for implementing these sophisticated systems, which can be prohibitive for small and medium-sized enterprises. The complexity of integrating ASRS with existing warehouse management systems WMS and enterprise resource planning ERP software often poses a significant hurdle, demanding specialized technical expertise and substantial upfront planning. Furthermore, the operational inflexibility of some fixed-layout ASRS, making it difficult to adapt to future changes in product mix or inventory demands, can deter potential adopters. The ongoing maintenance costs and the need for specialized technical personnel to manage and service these complex systems also represent notable restraints for companies considering automation.

Opportunities for market growth are abundant and diverse. Emerging economies in Asia Pacific and Latin America present vast untapped potential as industrialization and e-commerce penetration continue to accelerate. The development of modular and scalable ASRS solutions, coupled with flexible financing options, can mitigate the high initial investment barrier, making these systems accessible to a broader range of businesses. Ongoing advancements in software capabilities, particularly in AI, machine learning, and IoT, are creating opportunities for more intelligent, predictive, and adaptable ASRS solutions. Moreover, the increasing focus on sustainable and energy-efficient warehouse operations opens avenues for ASRS that minimize environmental impact. The growing trend of customization to meet specific industry requirements also offers significant market expansion opportunities for solution providers.

Segmentation Analysis

The Automated Storage and Retrieval System ASRS market is extensively segmented to reflect the diverse technological offerings, component structures, and end-user applications across the global industrial landscape. This granular segmentation provides a comprehensive view of market dynamics, growth trajectories within specific niches, and strategic opportunities for manufacturers and service providers. Understanding these segments is crucial for analyzing market trends, competitive positioning, and future investment areas. The market's complexity necessitates a clear breakdown by the types of systems, the underlying components that constitute these systems, and the varied industries that leverage ASRS for operational efficiency and competitive advantage.

- By Type

- Unit-load ASRS (for pallets and large loads)

- Mini-load ASRS (for totes, cartons, and smaller items)

- Carousel ASRS (Vertical Carousels, Horizontal Carousels)

- Vertical Lift Modules VLMs

- Robotic ASRS (Shuttle-based systems, Autonomous Mobile Robot AMR based systems)

- By Component

- Hardware (Storage racks, Robotic cranes, Conveyors, Shuttles, Pick and place robots)

- Software (Warehouse Management System WMS, Warehouse Control System WCS, Execution Systems WES)

- Services (Installation, Maintenance, Consulting, Aftermarket Support)

- By End-user Industry

- E-commerce and Retail

- Automotive

- Food and Beverage

- General Manufacturing

- Healthcare and Pharmaceuticals

- Chemicals

- Semiconductor & Electronics

- Logistics & 3PL

- Others (Aerospace, Defense, etc.)

Value Chain Analysis For Automated Storage and Retrieval System Market

The value chain for the Automated Storage and Retrieval System market begins with a robust upstream segment, encompassing the critical suppliers of raw materials and specialized components essential for ASRS manufacturing. This includes providers of high-grade steel and aluminum for racking structures, precision motors, sensors, controllers, and advanced robotics modules from specialized electronics and automation component manufacturers. Research and development activities also form a crucial part of the upstream, focusing on innovation in robotics, software, and material handling technologies. The quality and reliability of these upstream inputs directly impact the performance and longevity of the final ASRS solution. Strong relationships with reliable component suppliers are vital for maintaining product quality, managing costs, and ensuring timely production.

Further down the value chain, the core activities involve the design, engineering, manufacturing, and assembly of ASRS solutions. This phase is dominated by ASRS manufacturers and system integrators who combine various components into a cohesive, functional system tailored to specific client requirements. System integrators play a pivotal role, often acting as intermediaries who design, install, and customize ASRS solutions, integrating them seamlessly with existing warehouse infrastructure and software systems like WMS and ERP. This requires extensive expertise in mechanical engineering, software development, and project management. The value addition at this stage is significant, transforming disparate components into a unified, high-performance automation solution.

The downstream segment primarily focuses on the distribution, implementation, and post-sales support of ASRS. Distribution channels typically involve a mix of direct sales to large corporations and indirect sales through a network of third-party integrators, value-added resellers VARs, and strategic partners, especially for smaller projects or specific regional markets. Post-installation services, including training, maintenance, and ongoing technical support, are crucial for ensuring the long-term operational efficiency and reliability of ASRS installations. The direct channel allows ASRS manufacturers to maintain close client relationships and offer highly customized solutions, while indirect channels provide broader market reach and specialized local expertise, particularly in complex integration projects. Both channels are essential for market penetration and customer satisfaction, emphasizing the importance of a comprehensive service offering throughout the entire product lifecycle.

Automated Storage and Retrieval System Market Potential Customers

The Automated Storage and Retrieval System market caters to a diverse range of potential customers, primarily businesses and organizations that operate large-scale warehouses, distribution centers, and manufacturing facilities where efficient material handling and inventory management are paramount. These end-users are driven by the need to optimize operational costs, enhance throughput, improve order accuracy, and effectively utilize storage space in an increasingly competitive global environment. The demand for automation spans across various industries, each with unique challenges and requirements, making ASRS a versatile solution for numerous business models. Identifying and understanding these customer segments is critical for solution providers to tailor their offerings and marketing strategies effectively to meet specific industry needs.

Key segments of end-users or buyers of ASRS products include the burgeoning e-commerce and retail sector, which requires rapid, high-volume order fulfillment and returns processing to meet consumer expectations for quick delivery. Third-party logistics 3PL providers are significant customers, as they manage complex supply chains for multiple clients and seek to leverage automation for greater efficiency and competitive differentiation. The automotive industry utilizes ASRS extensively for managing parts inventory, work-in-process materials, and finished goods, supporting just-in-time manufacturing principles. Furthermore, the food and beverage industry, with its stringent requirements for hygiene and temperature control, finds ASRS invaluable for managing perishable goods, while the pharmaceutical and healthcare sectors rely on these systems for secure, accurate, and regulated storage of critical supplies and medicines.

General manufacturing, encompassing a wide array of industrial production, also represents a substantial customer base, using ASRS for storing raw materials, components, and finished products, thereby optimizing production lines and space. Other significant potential customers include cold storage facilities that benefit from automated systems to reduce human exposure to harsh conditions and optimize energy consumption. The semi-conductor and electronics industry, with its high-value, sensitive components, utilizes ASRS for precise inventory control and protection. Essentially, any business facing challenges related to high labor costs, limited storage space, increasing order volumes, or the need for improved inventory accuracy and operational speed is a prime candidate for adopting Automated Storage and Retrieval Systems, underscoring the broad applicability and growing necessity of these solutions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 10.5 billion |

| Market Forecast in 2032 | USD 20.2 billion |

| Growth Rate | CAGR 9.8% |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Daifuku Co. Ltd., Schaefer Systems International Pvt Ltd, Murata Machinery Ltd., KION Group AG (Dematic), Honeywell International Inc. (Intelligrated), Vanderlande Industries, Swisslog Holding AG (KUKA AG), Kardex AG, TGW Logistics Group, Beumer Group, Fives Group, Toyota Industries Corporation (Raymond Corp.), Bastian Solutions LLC (Toyota Advanced Logistics), System Logistics S.p.A. (Krones Group), Modula S.p.A., Ferretto Group S.p.A., MECLOG, Interroll Holding AG, Egemin Automation Inc. (KION Group), stow Group |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Automated Storage and Retrieval System Market Key Technology Landscape

The Automated Storage and Retrieval System ASRS market is underpinned by a rapidly evolving and sophisticated technology landscape that integrates advanced robotics, intelligent software, and pervasive connectivity to deliver highly efficient and adaptable warehousing solutions. At its core, ASRS relies on precision mechanical engineering for components such as robotic cranes, shuttles, and conveyor systems, ensuring accurate and swift movement of goods. However, it is the convergence of digital technologies that truly elevates ASRS capabilities, transforming them into smart, autonomous, and integrated systems. Modern ASRS leverage state-of-the-art sensor technologies, including LiDAR, vision systems, and RFID, for real-time item identification, precise positioning, and obstacle detection, enhancing both operational accuracy and safety within the warehouse environment.

A crucial technological aspect is the robust control system architecture, which often comprises a Warehouse Management System WMS, a Warehouse Control System WCS, and sometimes a Warehouse Execution System WES. These software platforms are the brains of the operation, orchestrating inventory, managing material flow, optimizing storage locations, and dispatching tasks to ASRS hardware. The integration of the Internet of Things IoT allows for seamless communication between various ASRS components, enabling real-time data collection on system performance, inventory levels, and environmental conditions. This vast dataset forms the foundation for advanced analytics and machine learning algorithms, which are increasingly being deployed to optimize operational parameters, predict maintenance needs, and adapt to changing demand patterns, making the systems more resilient and responsive.

The continued advancement in robotics is also a significant driver. This includes more agile and collaborative robots, as well as Autonomous Mobile Robots AMRs, which offer greater flexibility and scalability compared to traditional fixed ASRS. AMRs, often working in conjunction with fixed ASRS, can transport items to and from workstations, enhancing overall warehouse fluidity. The adoption of artificial intelligence and machine learning is making ASRS predictive and proactive, moving beyond mere automation to intelligent automation. This encompasses capabilities such as dynamic path planning, predictive maintenance, automated decision-making for inventory placement and retrieval, and self-learning algorithms that continuously optimize performance based on operational data. These technological advancements are not only improving the efficiency and reliability of ASRS but also expanding their applicability to more complex and dynamic warehousing scenarios, further solidifying their role in the future of logistics.

Regional Highlights

- North America: This region is a mature market for ASRS, characterized by high labor costs, a strong focus on automation to enhance supply chain efficiency, and significant investments in e-commerce infrastructure. The United States and Canada are leading adopters, especially in the automotive, retail, and pharmaceutical sectors, driven by technological innovation and the need for rapid fulfillment.

- Europe: Europe represents another key market with high adoption rates, particularly in countries like Germany, the UK, France, and Italy. Strict labor regulations, increasing wages, and a strong manufacturing base encourage automation. The region is a hub for ASRS innovation, emphasizing energy efficiency, sustainability, and integration with Industry 4.0 initiatives.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing region, fueled by rapid economic development, booming e-commerce, and significant investments in logistics and manufacturing in countries such as China, Japan, India, and South Korea. The region's vast consumer base and expanding industrial output create immense demand for scalable and efficient warehousing solutions.

- Latin America: This emerging market is experiencing increasing industrialization and e-commerce penetration, leading to growing demand for ASRS, particularly in Brazil and Mexico. Investments in infrastructure and manufacturing are driving the adoption of automation to improve efficiency and competitiveness in the regional supply chain.

- Middle East and Africa (MEA): The MEA region is witnessing gradual but steady growth in ASRS adoption, primarily driven by large-scale infrastructure projects, diversification of economies, and increasing e-commerce activities in countries like UAE, Saudi Arabia, and South Africa. Investments in modern warehousing and logistics are essential to support regional trade and economic expansion.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Automated Storage and Retrieval System Market.- Daifuku Co. Ltd.

- Schaefer Systems International Pvt Ltd

- Murata Machinery Ltd.

- KION Group AG (Dematic)

- Honeywell International Inc. (Intelligrated)

- Vanderlande Industries

- Swisslog Holding AG (KUKA AG)

- Kardex AG

- TGW Logistics Group

- Beumer Group

- Fives Group

- Toyota Industries Corporation (Raymond Corp.)

- Bastian Solutions LLC (Toyota Advanced Logistics)

- System Logistics S.p.A. (Krones Group)

- Modula S.p.A.

- Ferretto Group S.p.A.

- MECLOG

- Interroll Holding AG

- Egemin Automation Inc. (KION Group)

- stow Group

Frequently Asked Questions

What is an Automated Storage and Retrieval System ASRS?

An ASRS is a computer-controlled system that automatically places and retrieves items from specified storage locations, optimizing warehouse space and improving operational efficiency by reducing manual labor.

What are the primary benefits of implementing ASRS?

Key benefits include enhanced storage density, reduced labor costs, increased picking accuracy, faster throughput, improved worker safety, and better inventory control, leading to overall operational efficiency.

Which industries primarily utilize ASRS?

ASRS solutions are predominantly used in e-commerce and retail, automotive, food and beverage, pharmaceuticals, general manufacturing, and third-party logistics 3PL due to their diverse operational needs.

What is the estimated market size and growth rate for ASRS?

The ASRS market is estimated at USD 10.5 billion in 2025, projected to reach USD 20.2 billion by 2032, exhibiting a Compound Annual Growth Rate CAGR of 9.8% during the forecast period.

How does AI impact the future of ASRS?

AI integration enhances ASRS with capabilities such as predictive maintenance, optimized routing, real-time inventory intelligence, and adaptive learning, leading to smarter, more efficient, and resilient warehousing operations.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Automated Storage and Retrieval System Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Shelf based picking, Bin based picking, Robotic picking), By Application (Automotive, Metals & Heavy Machinery, Food & Beverages, Chemicals, Healthcare, Semiconductors & Electronics, Retail, Aviation, E-Commerce, Others), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

- Automated Storage and Retrieval System (ASRS) Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Unit Load, Mini Load, Vertical Lift Module, Carousel, Mid Load, Autostore), By Application (Automotive, Chemicals, Aviation, Electronic & Semiconductor, E-Commerce, Food & Beverages, Healthcare, Metals and Heavy Machinery, Others), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager