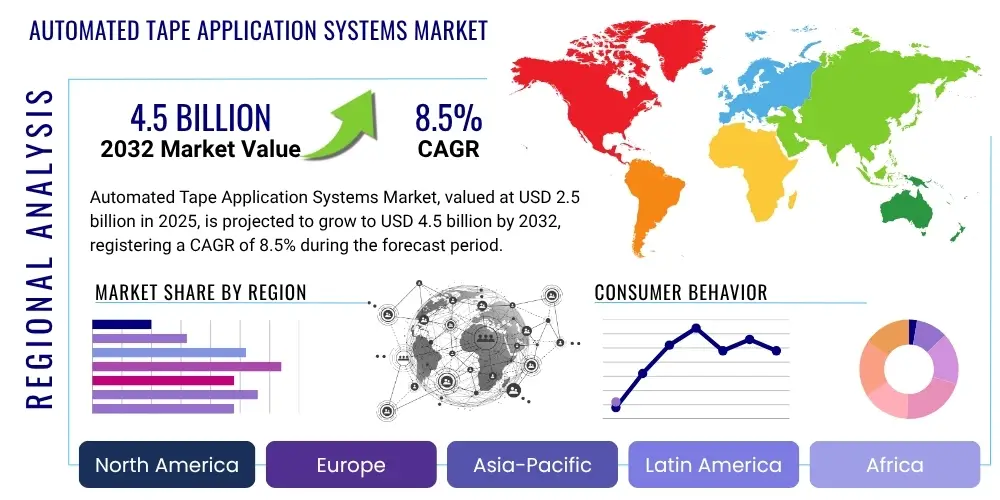

Automated Tape Application Systems Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428844 | Date : Oct, 2025 | Pages : 249 | Region : Global | Publisher : MRU

Automated Tape Application Systems Market Size

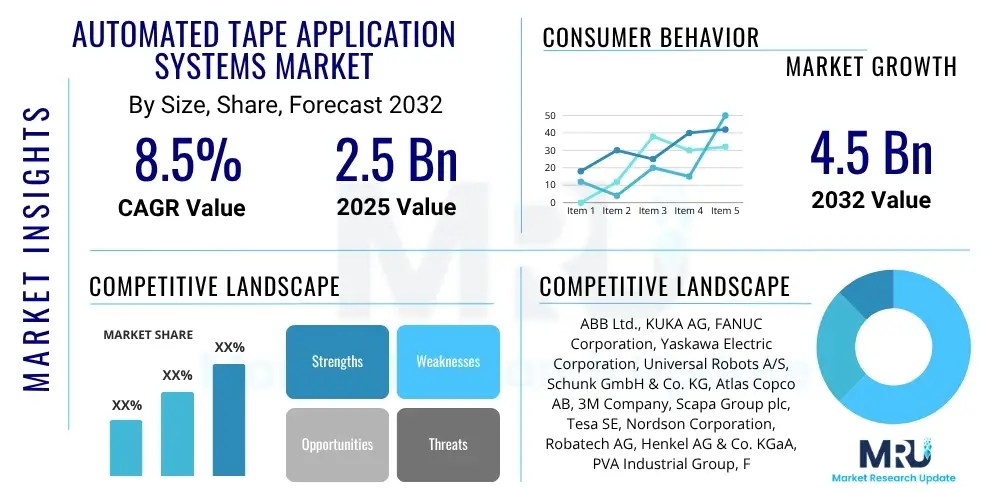

The Automated Tape Application Systems Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2025 and 2032. The market is estimated at USD 2.5 billion in 2025 and is projected to reach USD 4.5 billion by the end of the forecast period in 2032.

Automated Tape Application Systems Market introduction

The Automated Tape Application Systems Market encompasses advanced machinery designed to precisely and efficiently apply various types of adhesive tapes onto surfaces in manufacturing processes. These systems integrate robotics, vision technology, and sophisticated control mechanisms to ensure consistent, high-quality, and rapid tape placement, significantly surpassing the capabilities of manual application. The core product offering includes a range of solutions from semi-automated workstations to fully integrated robotic cells capable of handling complex geometries and high-volume production requirements across diverse industries.

Major applications for automated tape application systems span critical sectors such as automotive manufacturing for component assembly and body-in-white applications, electronics for bonding and shielding in devices, packaging for secure sealing and labeling, and medical device assembly where precision and sterile environments are paramount. The inherent benefits of adopting these systems are multifaceted, including substantial improvements in production efficiency, reduced labor costs, enhanced product quality through consistent application, minimization of material waste, and improved worker safety by automating repetitive or hazardous tasks. These systems are instrumental in modern manufacturing environments striving for optimal operational performance and precision.

Several driving factors are propelling the growth of this market. The global push towards industrial automation and Industry 4.0 initiatives is a primary catalyst, as manufacturers seek to integrate smart technologies for increased productivity and data-driven operations. The escalating costs of skilled labor and increasing demand for higher product quality and consistency further incentivize the adoption of automated solutions. Moreover, the increasing complexity of product designs and the growing use of advanced materials requiring specialized bonding techniques necessitate the precision and control offered by automated tape application systems.

Automated Tape Application Systems Market Executive Summary

The Automated Tape Application Systems Market is currently experiencing robust growth, driven by an overarching global trend towards industrial automation and the continuous pursuit of manufacturing efficiency. Key business trends indicate a strong focus on system integration, enabling seamless connectivity with existing production lines and enterprise resource planning systems, alongside a rising demand for highly flexible and customizable solutions that can adapt to varying product specifications and rapid production changes. Manufacturers are also increasingly prioritizing collaborative robotic systems to enhance human-robot interaction and optimize workstation layouts for specific tasks.

Regionally, the market exhibits diverse growth dynamics. Asia Pacific stands out as the dominant and fastest-growing region, fueled by extensive manufacturing activities, significant investments in factory automation, and rapid industrialization in countries like China, Japan, and South Korea. North America and Europe represent mature markets with a high adoption rate of advanced manufacturing technologies, where the focus is more on upgrading existing infrastructure with smarter, AI-driven systems and addressing labor shortages through sophisticated automation. Latin America and the Middle East and Africa regions are emerging as promising markets, driven by new industrial investments and increasing awareness of automation's benefits.

In terms of segment trends, the fully automated systems segment is projected to maintain its leadership, attributed to its ability to handle high-volume production and complex applications with minimal human intervention. However, semi-automated systems are also seeing steady demand, particularly among small and medium-sized enterprises (SMEs) looking for cost-effective entry points into automation. The automotive and electronics industries remain the largest end-user segments, while packaging and medical sectors are poised for significant expansion, propelled by stringent quality standards and increasing production demands for specialized products. The integration of advanced vision systems and AI-powered controls is becoming a pivotal trend across all segments, enhancing precision, adaptability, and operational intelligence.

AI Impact Analysis on Automated Tape Application Systems Market

Users frequently inquire about how Artificial Intelligence can significantly enhance the precision, efficiency, and adaptability of automated tape application systems, exploring its role in predictive maintenance, real-time quality control, and optimized process flows. There is considerable interest in understanding AI's capacity to learn from production data, leading to self-correction and improved performance over time, as well as its potential to facilitate integration with broader Industry 4.0 ecosystems. Concerns often revolve around the complexity of AI implementation, data privacy, the need for specialized skills, and the return on investment for such advanced technologies.

AI's influence on automated tape application systems is transformative, enabling a new generation of smart, adaptive, and highly efficient machines. By processing vast amounts of operational data, AI algorithms can identify optimal application parameters, predict potential equipment failures before they occur, and dynamically adjust processes in real-time to maintain peak performance and product quality. This level of intelligent automation significantly reduces downtime, minimizes material waste, and ensures unparalleled precision in tape placement, even for the most intricate tasks. AI integration elevates these systems from mere automation tools to intelligent manufacturing assets, capable of continuous learning and improvement.

- Enhanced Precision and Accuracy: AI-powered vision systems detect minute deviations and guide robotic arms for sub-millimeter placement.

- Predictive Maintenance: Machine learning algorithms analyze sensor data to forecast equipment failures, reducing unplanned downtime.

- Process Optimization: AI continuously adjusts application parameters (speed, pressure, temperature) for optimal performance and material usage.

- Real-time Quality Control: AI identifies defects or inconsistencies during application, preventing faulty products from proceeding down the line.

- Adaptive Learning: Systems learn from operational data and past applications to improve performance and adapt to new product variations.

- Seamless Integration: AI facilitates better communication and data exchange with other smart factory components and production planning systems.

- Reduced Material Waste: Intelligent material handling and precise application minimize tape and adhesive waste.

- Improved Energy Efficiency: AI optimizes operational cycles to reduce power consumption of the automated systems.

- Faster Troubleshooting: AI diagnostic tools can quickly identify root causes of operational issues, streamlining maintenance.

- New Application Development: AI allows for rapid prototyping and optimization of new tape application processes for diverse products.

DRO & Impact Forces Of Automated Tape Application Systems Market

The Automated Tape Application Systems Market is significantly influenced by a dynamic interplay of drivers, restraints, opportunities, and broader impact forces shaping its trajectory. Key drivers include the escalating global demand for manufacturing automation, particularly within high-growth industries like automotive, electronics, and medical devices, where precision and efficiency are paramount. The rising cost of labor, coupled with a shortage of skilled manual workers, further compels industries to adopt automated solutions. Moreover, the increasing complexity of product designs and the growing adoption of Industry 4.0 principles, emphasizing smart manufacturing and interconnected systems, are accelerating the integration of these advanced tape application technologies.

However, the market also faces considerable restraints. The high initial capital investment required for automated tape application systems can be a significant barrier for small and medium-sized enterprises (SMEs), limiting their adoption. The complexity of integrating these sophisticated systems into existing manufacturing lines often requires specialized expertise and can lead to operational challenges during the transition period. Furthermore, a perceived lack of skilled personnel capable of operating, maintaining, and programming these advanced robotic systems acts as a bottleneck, necessitating substantial training and development efforts from end-users.

Opportunities for growth are abundant within this market. Emerging markets, particularly in developing economies, present significant untapped potential as industrialization accelerates and manufacturing capabilities expand. The continuous innovation in adhesive tape technologies and advanced materials creates new application possibilities for automated systems, allowing for novel bonding solutions. The development of more flexible, modular, and collaborative robotic solutions (cobots) is lowering the entry barrier and expanding the range of feasible applications, making automation more accessible. The ongoing advancements in software, machine vision, and AI integration are opening avenues for smarter, more adaptable, and highly efficient tape application processes, further fueling market expansion.

Impact forces acting on the market include rapid technological advancements, which constantly introduce more precise, faster, and intelligent systems, rendering older technologies obsolete. Economic factors, such as global economic stability and industrial investment cycles, directly influence capital expenditure on automation equipment. Regulatory standards, especially concerning product quality, safety, and environmental impact, drive the need for consistent and compliant manufacturing processes, thereby increasing the demand for automated solutions that can meet these stringent requirements. Geopolitical shifts and supply chain disruptions can also influence manufacturing strategies, potentially accelerating or decelerating automation adoption depending on the specific circumstances.

Segmentation Analysis

The Automated Tape Application Systems market is meticulously segmented to provide a comprehensive view of its diverse landscape, enabling deeper insights into market dynamics and growth opportunities across various dimensions. This segmentation helps in understanding the specific requirements of different industries and applications, thereby allowing manufacturers and solution providers to tailor their offerings effectively. The market can be broadly categorized based on the level of automation, the type of application, the specific end-user industry, and the key components that constitute these advanced systems.

Understanding these segments is crucial for strategic planning, product development, and market penetration, as each category presents unique demands and growth trajectories. For instance, the demand for fully automated systems is typically driven by high-volume production needs in large-scale manufacturing facilities, while semi-automated solutions cater to smaller operations or specialized tasks requiring human oversight. The varying needs of different end-user industries, from the high-precision demands of electronics to the robust requirements of automotive, also shape the development and adoption of specialized tape application technologies. This detailed segmentation allows for targeted market analysis and provides a granular understanding of where the most significant opportunities and challenges lie.

- By Automation Level:

- Semi-Automated Systems

- Fully Automated Systems

- By System Type:

- Robotic Tape Application Systems

- Gantry-based Tape Application Systems

- Custom-built Tape Application Workstations

- By Application Type:

- Bonding and Assembly

- Masking and Protection

- Sealing and Insulating

- Mounting and Joining

- EMI/RFI Shielding

- Thermal Management

- By End-User Industry:

- Automotive (Interior, Exterior, Powertrain, Electronics)

- Electronics (Consumer Electronics, Industrial Electronics, Semiconductors)

- Medical & Healthcare (Medical Devices, Pharmaceuticals, Diagnostics)

- Packaging (Food & Beverage, Consumer Goods, Industrial Packaging)

- Aerospace & Defense

- General Manufacturing

- Others (Construction, Textile, Renewable Energy)

- By Component:

- Robotic Arms

- Tape Dispensing Units (Applicators)

- Vision Systems (Cameras, Sensors)

- Control Systems (PLCs, HMI)

- Software

- Material Handling Systems

- Safety Systems

Value Chain Analysis For Automated Tape Application Systems Market

The value chain for the Automated Tape Application Systems Market is a complex ecosystem involving multiple stages, from raw material sourcing to the final integration and deployment at the end-user facility. Upstream activities primarily involve the procurement of critical components and raw materials necessary for manufacturing these sophisticated systems. This includes suppliers of high-precision robotic arms, advanced machine vision components such as cameras and sensors, specialized control electronics like Programmable Logic Controllers (PLCs), and the manufacturers of the adhesive tapes and films themselves, which are integral to the system's function. Manufacturers of the automated systems then assemble, test, and often customize these components into a complete, functional unit.

Downstream in the value chain, the focus shifts to the distribution, integration, and servicing of these systems. This involves system integrators who specialize in configuring and installing the automated systems into existing production lines, ensuring seamless operation and compatibility with the client's manufacturing environment. These integrators often provide crucial value-added services such as software development, training, and ongoing technical support. End-users, who are the ultimate beneficiaries, purchase and deploy these systems to enhance their production processes across various industries, realizing benefits such as improved efficiency, consistency, and cost savings.

The distribution channel plays a vital role in connecting manufacturers with end-users. Direct sales from the manufacturer to large industrial clients are common, especially for highly customized or complex installations, allowing for direct communication and tailored solutions. Indirect channels, primarily through a network of distributors, value-added resellers (VARs), and system integrators, are crucial for broader market penetration, particularly for standardized systems or reaching a diverse range of smaller enterprises. These indirect partners often provide localized support, sales expertise, and integration services, acting as a crucial bridge between the technology provider and the end-user.

Automated Tape Application Systems Market Potential Customers

Potential customers for Automated Tape Application Systems are diverse, primarily comprising manufacturing entities across various industrial sectors that require high-precision, repetitive, or high-volume application of adhesive tapes. These end-users are typically seeking to enhance their production efficiency, reduce labor costs, improve product quality and consistency, and address the complexities of modern manufacturing processes. The driving motivation for these buyers often stems from the need to meet stringent industry standards, increase throughput, and adapt to the increasing demand for customization in their products, which manual processes struggle to achieve reliably.

The automotive industry represents a significant segment of potential customers, particularly manufacturers of vehicles and their component suppliers. These companies utilize automated tape application for various tasks, including interior trim assembly, wire harness bundling, sealing applications, mirror and badge attachment, and increasingly for battery pack assembly in electric vehicles. In the electronics sector, manufacturers of consumer electronics, industrial electronics, and semiconductor devices are key buyers, requiring precise tape placement for bonding, shielding, insulation, and heat dissipation in devices such as smartphones, tablets, displays, and circuit boards.

Furthermore, the packaging industry, particularly for food and beverage, pharmaceuticals, and general consumer goods, relies on these systems for efficient carton sealing, labeling, and tamper-evident solutions. The medical and healthcare industry, where sterility, precision, and consistency are critical, also constitutes a growing customer base for applications in medical device assembly, diagnostics, and pharmaceutical packaging. General manufacturing industries encompassing white goods, aerospace, and construction, also increasingly adopt these systems for various assembly and finishing operations, making them a broad and expanding market for automated tape application solutions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 2.5 billion |

| Market Forecast in 2032 | USD 4.5 billion |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | ABB Ltd., KUKA AG, FANUC Corporation, Yaskawa Electric Corporation, Universal Robots A/S, Schunk GmbH & Co. KG, Atlas Copco AB, 3M Company, Scapa Group plc, Tesa SE, Nordson Corporation, Robatech AG, Henkel AG & Co. KGaA, PVA Industrial Group, Fuji Robotics Systems, Automation & Robotics, Inc., Tape Automation Ltd., Promation, Schubert System Elektronik GmbH, Rethink Robotics |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Automated Tape Application Systems Market Key Technology Landscape

The technological landscape of the Automated Tape Application Systems Market is characterized by a continuous evolution of integrated solutions, leveraging advancements in robotics, machine vision, and sophisticated control mechanisms. Central to these systems are high-precision robotic arms, ranging from multi-axis industrial robots capable of heavy loads and complex movements to collaborative robots (cobots) designed to work safely alongside human operators, increasing flexibility in manufacturing cells. These robots provide the dexterity and repeatability necessary for precise tape placement across various surfaces and geometries, which is a significant departure from manual processes.

Machine vision systems are another cornerstone technology, enabling real-time inspection, guidance, and quality control. Equipped with high-resolution cameras and advanced image processing software, these systems can accurately locate target surfaces, identify product variations, and verify the precise placement and integrity of applied tape. This visual feedback loop is crucial for maintaining high quality standards and reducing errors, especially in applications requiring exact alignment or complex patterns. Furthermore, advanced sensors, including proximity sensors, force/torque sensors, and ultrasonic sensors, are integrated to provide additional data for enhanced control, collision avoidance, and adaptive process adjustments.

The control architecture of these systems is highly advanced, incorporating Programmable Logic Controllers (PLCs) and Human-Machine Interface (HMI) panels for intuitive programming, monitoring, and operational management. The increasing integration of the Internet of Things (IoT) allows for seamless data exchange between the tape application system and other factory equipment, facilitating remote monitoring, predictive maintenance, and overall factory floor optimization. Moreover, the growing adoption of Artificial Intelligence (AI) and Machine Learning (ML) algorithms is enhancing system intelligence, enabling features like adaptive learning for process optimization, anomaly detection for quality assurance, and predictive analytics for proactive maintenance, thereby transforming these systems into truly smart manufacturing assets capable of continuous improvement and greater autonomy.

Regional Highlights

- North America: This region is characterized by high adoption of advanced manufacturing technologies and a strong emphasis on automation to combat rising labor costs and ensure high-quality production. The automotive, aerospace, and electronics industries are key drivers. Investments in smart factories and R&D are significant, pushing for further integration of AI and collaborative robotics. The presence of major technology providers and robust manufacturing infrastructure supports consistent growth and innovation.

- Europe: A mature market with a strong industrial base, particularly in Germany, Italy, and France, Europe shows consistent demand for automated tape application systems driven by precision manufacturing needs and stringent quality standards. The focus is on upgrading existing facilities with energy-efficient and highly automated solutions. High labor costs and a commitment to Industry 4.0 initiatives contribute to sustained market growth, with an emphasis on tailored solutions for diverse applications.

- Asia Pacific (APAC): The APAC region stands as the largest and fastest-growing market, primarily due to rapid industrialization, extensive manufacturing activities, and significant investments in factory automation, particularly in countries like China, Japan, South Korea, and India. The burgeoning automotive, electronics, and packaging sectors, combined with the availability of competitive manufacturing ecosystems, fuel the demand for automated tape application systems. Government initiatives promoting smart manufacturing and the increasing establishment of new production facilities further propel market expansion.

- Latin America: This region presents an emerging market for automated tape application systems, driven by increasing industrialization and foreign direct investments in manufacturing sectors, particularly automotive and electronics in countries like Brazil and Mexico. The adoption rates are steadily climbing as local industries seek to improve efficiency and competitiveness against global players. The market here is still in its nascent stages but shows promising growth potential as awareness and affordability of automation solutions increase.

- Middle East and Africa (MEA): The MEA market is relatively smaller but is projected to witness steady growth, primarily influenced by economic diversification efforts, increasing investments in infrastructure, and the development of new manufacturing capabilities, especially in sectors like automotive, construction, and electronics. Countries in the Gulf Cooperation Council (GCC) are leading the adoption of automation technologies to enhance industrial output and reduce reliance on manual labor, creating niche opportunities for automated tape application systems.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Automated Tape Application Systems Market.- ABB Ltd.

- KUKA AG

- FANUC Corporation

- Yaskawa Electric Corporation

- Universal Robots A/S

- Schunk GmbH & Co. KG

- Atlas Copco AB

- 3M Company

- Scapa Group plc

- Tesa SE

- Nordson Corporation

- Robatech AG

- Henkel AG & Co. KGaA

- PVA Industrial Group

- Fuji Robotics Systems

- Automation & Robotics, Inc.

- Tape Automation Ltd.

- Promation

- Schubert System Elektronik GmbH

- Rethink Robotics

Frequently Asked Questions

What are the primary benefits of implementing Automated Tape Application Systems?

The primary benefits include significantly increased production speed and efficiency, enhanced precision and consistency in tape placement, substantial reduction in labor costs, minimized material waste, and improved product quality due to repeatable, error-free application. These systems also contribute to improved worker safety by automating repetitive or ergonomically challenging tasks.

How does AI contribute to the advancement of Automated Tape Application Systems?

AI enhances these systems by enabling features such as real-time adaptive process control, predictive maintenance to minimize downtime, advanced vision-guided robotics for superior accuracy, and continuous learning from operational data. This results in smarter, more efficient, and highly reliable tape application processes that can self-optimize and adapt to changing conditions.

Which industries are the largest end-users of Automated Tape Application Systems?

The automotive and electronics industries are currently the largest end-users, extensively utilizing these systems for various assembly, bonding, shielding, and insulation applications. Other significant and growing end-user sectors include packaging, medical devices, and general manufacturing, all driven by the need for precision and efficiency.

What are the main challenges hindering the adoption of these systems?

Key challenges include the high initial capital investment required for purchasing and installing the systems, the complexity associated with integrating them into existing production lines, and the need for a skilled workforce to operate, program, and maintain the advanced equipment. Overcoming these barriers often requires careful planning and strategic investment.

What future trends are expected to shape the Automated Tape Application Systems Market?

Future trends include increased integration of collaborative robots (cobots) for flexible automation, wider adoption of AI and machine learning for predictive analytics and process optimization, advancements in machine vision for enhanced quality control, and the development of more modular and customizable systems. Emphasis will also be placed on sustainability and energy efficiency, and seamless integration within broader Industry

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager