Automotive Coatings Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429785 | Date : Nov, 2025 | Pages : 257 | Region : Global | Publisher : MRU

Automotive Coatings Market Size

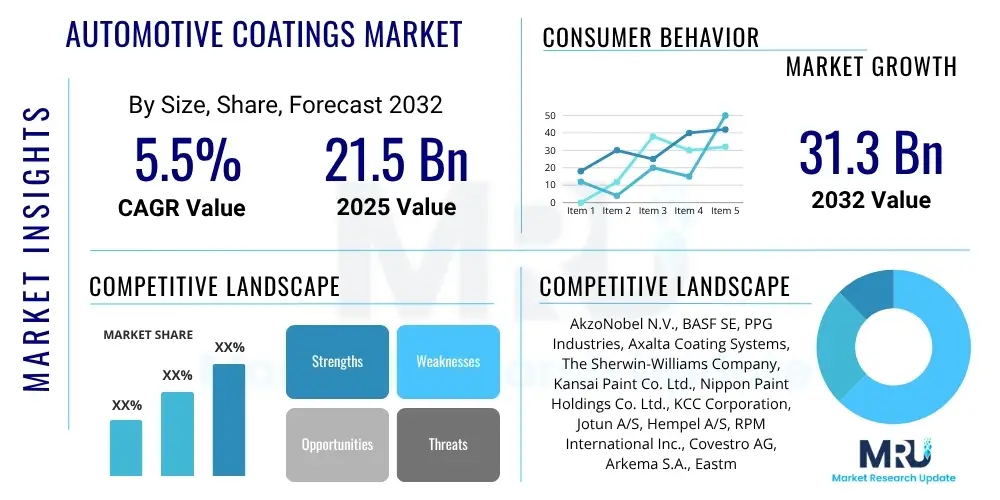

The Automotive Coatings Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.5% between 2025 and 2032. The market is estimated at USD 21.5 billion in 2025 and is projected to reach USD 31.3 billion by the end of the forecast period in 2032.

Automotive Coatings Market introduction

The Automotive Coatings Market encompasses a diverse range of specialized products applied to vehicles for aesthetic appeal, protection, and enhanced functionality. These coatings are crucial for maintaining the structural integrity of automotive components by providing robust barriers against corrosion, abrasion, and environmental elements such as UV radiation, extreme temperatures, and chemical exposure. Beyond their protective attributes, automotive coatings are integral to vehicle aesthetics, offering a wide spectrum of colors, gloss levels, and textures that contribute significantly to a vehicle's perceived quality and brand identity. The product portfolio includes electrophoretic deposition (E-coat) for fundamental corrosion protection, primer coats for surface preparation, basecoats for color application, and clearcoats for ultimate gloss and durability.

Major applications for automotive coatings span both the Original Equipment Manufacturer (OEM) segment and the refinish aftermarket. In OEM applications, coatings are applied during the vehicle manufacturing process, demanding high efficiency, consistency, and adherence to stringent quality standards for large-scale production. The refinish market, conversely, focuses on repair and customization, requiring versatility, color matching accuracy, and ease of application for smaller batches. The inherent benefits of these coatings, such as prolonged vehicle lifespan, improved resale value, and enhanced safety through better visibility or specialized functional layers, underscore their indispensable role in the automotive industry. As consumer expectations for vehicle appearance and durability continue to rise, the importance of advanced coating technologies becomes even more pronounced, driving continuous innovation in the sector.

The market is significantly driven by several key factors. Firstly, the escalating global automotive production, particularly in emerging economies, directly translates to increased demand for coatings. Secondly, advancements in coating technology, including the development of low-VOC (Volatile Organic Compound) and environmentally friendly solutions, are propelled by increasingly stringent environmental regulations worldwide. Thirdly, the growing consumer preference for premium, customized, and durable vehicles necessitates high-performance coatings that offer superior scratch resistance, self-healing properties, and a wider range of aesthetic options. The rapid expansion of the electric vehicle (EV) market also presents a substantial growth catalyst, as EVs require specialized coatings for battery protection, thermal management, and lightweight designs, further shaping the market's trajectory towards innovative and sustainable solutions.

Automotive Coatings Market Executive Summary

The Automotive Coatings Market is experiencing robust growth, primarily fueled by the accelerating global automotive production, a sustained consumer demand for aesthetically pleasing and durable vehicles, and the imperative for environmentally compliant coating solutions. Business trends indicate a strong emphasis on research and development to innovate in sustainable technologies, such as waterborne, high-solids, and powder coatings, aiming to mitigate environmental impact while enhancing performance. Strategic collaborations, mergers, and acquisitions are also prominent as key players seek to expand their product portfolios, strengthen their market presence, and gain access to advanced technologies and new geographic markets. Furthermore, the industry is witnessing a shift towards digitalization in manufacturing processes, enabling greater efficiency, precision, and customization capabilities.

Regional trends highlight Asia Pacific as the dominant and fastest-growing market segment, primarily driven by the burgeoning automotive manufacturing sectors in countries like China, India, and Japan, coupled with a rapidly expanding middle class and increasing disposable incomes. Europe and North America, while more mature, are characterized by stringent environmental regulations that foster innovation in eco-friendly coatings and a strong demand for premium and specialized vehicle finishes. These regions are also at the forefront of adopting advanced application techniques and smart coating technologies. Latin America and the Middle East and Africa are emerging as promising markets, buoyed by expanding industrialization, growing vehicle parc, and governmental initiatives to bolster domestic automotive production, albeit with varying levels of economic stability and regulatory frameworks.

Segment trends within the Automotive Coatings Market reveal significant shifts. The waterborne technology segment is projected to grow substantially due to its low VOC content, aligning with global environmental compliance efforts. Similarly, powder coatings are gaining traction for their superior durability, reduced waste, and efficiency. From a product type perspective, clearcoats continue to hold a dominant share, crucial for providing the final layer of protection and gloss, while basecoats are increasingly focused on color innovation and special effect pigments. The OEM segment remains the largest application area, driven by mass production requirements, but the refinish segment is also witnessing consistent growth, fueled by vehicle repairs, maintenance, and the growing trend of vehicle personalization and customization, particularly with high-performance and specialty finishes.

AI Impact Analysis on Automotive Coatings Market

The impact of Artificial Intelligence (AI) on the Automotive Coatings Market is a subject of growing interest, with common user questions often revolving around how AI can enhance efficiency, improve product quality, and drive innovation in coating formulations and application processes. Users are keen to understand AI's capability in optimizing material selection, predicting coating performance, and ensuring consistent application quality, especially in complex manufacturing environments. There is also a significant focus on AI's potential to accelerate the development of sustainable and smart coatings, address customization demands, and optimize supply chain logistics. Concerns frequently include the initial investment costs, the need for specialized data infrastructure, data privacy issues, and the reskilling of the workforce to adapt to AI-driven processes within the industry.

AI's transformative potential lies in its ability to analyze vast datasets related to material properties, environmental conditions, and application parameters, leading to more informed and rapid decision-making. By leveraging machine learning algorithms, manufacturers can predict optimal coating compositions, identify potential defects before they occur, and fine-tune robotic application systems for unparalleled precision. This not only significantly reduces waste and rework but also accelerates the development cycle for new products, allowing companies to respond more swiftly to evolving market demands and regulatory changes. Furthermore, AI can contribute to predictive maintenance of coating equipment, minimizing downtime and maximizing operational efficiency, thereby translating into substantial cost savings and improved productivity across the value chain.

Moreover, AI is poised to revolutionize the personalization and customization aspects of automotive coatings. By processing customer preferences, design trends, and performance requirements, AI systems can assist in creating bespoke coating solutions, ranging from unique color formulations to specialized functional layers tailored for specific vehicle models or end-user needs. This level of customization, previously resource-intensive, becomes more scalable and economically viable with AI. The integration of AI also facilitates better quality control through real-time monitoring and analysis of coating thickness, adherence, and finish quality, ensuring that every vehicle meets the highest standards. Ultimately, AI fosters an environment of continuous improvement and innovation, positioning the automotive coatings market for a future driven by data-centric insights and intelligent automation.

- Optimized formulation development and accelerated material selection through predictive modeling.

- Enhanced predictive quality control and early defect detection in coating application processes.

- Increased manufacturing efficiency and throughput via AI-driven process optimization and automation.

- Facilitated personalized coating solutions and aesthetic customization based on data insights.

- Improved supply chain management, inventory optimization, and demand forecasting for raw materials.

- Accelerated research and development of sustainable, low-VOC, and smart coating innovations.

- Data-driven insights for understanding market trends, consumer preferences, and competitive landscapes.

- Predictive maintenance for coating robots and equipment, minimizing downtime and operational costs.

DRO & Impact Forces Of Automotive Coatings Market

The Automotive Coatings Market is propelled by a confluence of robust drivers, significant opportunities, and is influenced by various impact forces, while also contending with notable restraints. A primary driver is the consistent increase in global automotive production, particularly in emerging economies, which directly correlates with higher demand for both OEM and refinish coatings. The growing consumer inclination towards enhanced vehicle aesthetics, coupled with increasing expectations for superior durability and corrosion protection, further fuels market expansion. Additionally, the stringent environmental regulations globally, aimed at reducing volatile organic compound (VOC) emissions, are compelling manufacturers to invest heavily in the development and adoption of eco-friendly, low-VOC coating technologies, thereby stimulating innovation and market growth.

Conversely, the market faces several significant restraints. Volatility in the prices of key raw materials such as resins, pigments, and solvents directly impacts manufacturing costs and profit margins, creating uncertainty for market players. The high capital expenditure required for research and development activities, particularly for developing advanced and environmentally compliant coating solutions, can be a barrier for smaller enterprises. Moreover, the automotive coatings industry is subject to a complex and evolving regulatory landscape regarding environmental compliance, product safety, and manufacturing processes, which necessitates continuous investment in compliance measures and can pose operational challenges. Intense competition among a few dominant global players also contributes to pricing pressures and limits market entry for new participants.

Opportunities for growth are abundant within this dynamic market. The burgeoning demand for electric vehicles (EVs) presents a significant avenue, as EVs require specialized coatings for battery protection, thermal management, and lightweight components, diverging from traditional internal combustion engine vehicle needs. The development of smart coatings, incorporating functionalities like self-healing, anti-corrosion monitoring, and temperature regulation, offers substantial differentiation and value addition. Furthermore, customization trends in the automotive industry, where consumers seek unique finishes and personalized aesthetics, open new niches for specialty coatings. Geographically, the expansion of automotive manufacturing bases in developing regions provides untapped market potential, driving demand for both volume and technologically advanced coatings, while the ongoing shift towards advanced coating application techniques also presents avenues for efficiency and performance enhancements.

Segmentation Analysis

The Automotive Coatings Market is intricately segmented across several dimensions, providing a granular view of its diverse landscape and enabling a deeper understanding of specific market dynamics. These segmentations are critical for analyzing consumer preferences, technological adoption rates, and regional demand patterns, allowing stakeholders to tailor strategies effectively. The market is typically broken down by coating type, the chemical composition of the resin, the underlying application technology employed, the category of vehicle being coated, and the specific application segment (OEM or Refinish). Each segment exhibits unique growth drivers, competitive landscapes, and regulatory influences, making a comprehensive analysis of these divisions essential for strategic market positioning and product development.

Understanding these segments is vital for identifying emerging trends and investment opportunities. For instance, the shift towards sustainable coating technologies is predominantly evident across the technology segment, favoring waterborne and powder coatings. Similarly, innovations in resin chemistry directly impact the performance and durability of coatings across all types, from primers to clearcoats. Vehicle type segmentation helps in understanding the specific demands of passenger cars versus commercial vehicles, including heavy-duty trucks and buses, which often require different performance characteristics due to varying operational environments and regulatory standards. The distinction between OEM and refinish applications highlights differences in volume requirements, quality specifications, and distribution channels, necessitating distinct business approaches and product offerings from manufacturers.

The segmentation analysis also allows market participants to track the evolution of consumer preferences, such as the increasing demand for matte finishes or highly scratch-resistant clearcoats, and how these trends translate into demand for specific product types and technologies. Furthermore, it aids in assessing the competitive intensity within particular niches. Companies often specialize in certain segments, leveraging proprietary technologies or strong regional presence. By meticulously dissecting these segments, market reports provide a roadmap for navigating the complexities of the automotive coatings industry, highlighting areas of high growth potential, identifying competitive threats, and informing strategic decisions related to product innovation, market entry, and partnership opportunities.

- By Type:

- Primer: Provides adhesion to the substrate and corrosion protection.

- Basecoat: Delivers color, aesthetic appeal, and special effects.

- Clearcoat: Offers protection against UV, scratches, and environmental damage; provides gloss.

- E-coat (Electrophoretic Deposition): First layer for corrosion resistance and uniform coverage.

- By Resin:

- Polyurethane: Known for flexibility, durability, and resistance to abrasion.

- Epoxy: Offers excellent adhesion and corrosion resistance, often used in primers.

- Acrylic: Provides good color retention, gloss, and weatherability.

- Others: Includes alkyds, polyesters, and hybrid resin systems for specialized properties.

- By Technology:

- Waterborne: Low VOC content, environmentally friendly, increasing adoption.

- Solventborne: Traditional technology, high gloss, robust performance, higher VOC.

- Powder: Zero VOC, high durability, efficient application, minimal waste.

- UV-cured: Rapid curing, high scratch resistance, energy efficient, specialized applications.

- By Vehicle Type:

- Passenger Cars: Largest segment, focus on aesthetics, durability, and customization.

- Commercial Vehicles: Emphasis on robust protection, corrosion resistance, and longevity.

- By Application:

- OEM (Original Equipment Manufacturer): Applied during initial vehicle manufacturing, high volume.

- Refinish: Used for vehicle repair, restoration, and customization in the aftermarket.

Value Chain Analysis For Automotive Coatings Market

The value chain for the Automotive Coatings Market is a multi-tiered structure beginning with the sourcing of fundamental raw materials and culminating in the application of finished coatings on vehicles. At the upstream end, the chain involves a complex network of chemical suppliers providing essential components such as resins, pigments, solvents, and various additives like hardeners, catalysts, and rheology modifiers. These suppliers play a critical role in determining the quality, performance, and environmental compliance of the final coating products. Innovations in raw material science, particularly those focused on bio-based or recycled content, are crucial at this stage, influencing downstream product development and sustainability initiatives across the industry.

Moving downstream, these raw materials are processed and formulated by coating manufacturers who leverage advanced chemical engineering and formulation expertise to create specific coating products for diverse applications. This stage involves significant research and development investment to meet evolving customer demands for durability, aesthetics, and regulatory requirements, such as lower volatile organic compound (VOC) emissions. Manufacturers often differentiate themselves through proprietary technologies, strong brand recognition, and a comprehensive product portfolio. Quality control and stringent testing are integral here to ensure the coatings meet the rigorous specifications of the automotive industry, which demands exceptional performance under various environmental conditions and usage scenarios.

The distribution channel plays a pivotal role in connecting manufacturers with their end-users. Direct distribution is common for large-volume OEM customers, where manufacturers often establish direct supply agreements and on-site support due to the scale and complexity of automotive assembly lines. For the refinish market, an indirect distribution model is prevalent, involving a network of wholesalers, distributors, and independent retailers who supply body shops, collision repair centers, and individual customers. These indirect channels provide essential logistical support, inventory management, and technical assistance, ensuring timely availability of a wide range of products across geographically dispersed markets. This dual approach to distribution is crucial for addressing the distinct needs of the OEM and aftermarket segments, optimizing market reach and customer service.

Automotive Coatings Market Potential Customers

Potential customers for products within the Automotive Coatings Market predominantly comprise key players across the entire automotive ecosystem, categorized primarily into original equipment manufacturers (OEMs) and the expansive automotive aftermarket. Original Equipment Manufacturers represent the largest segment of buyers, including global automotive giants such as Toyota, Volkswagen, General Motors, Ford, and Hyundai-Kia, alongside luxury vehicle manufacturers like BMW, Mercedes-Benz, and Audi. These OEMs require high volumes of coatings for new vehicle production, demanding strict quality control, consistent supply, and innovative solutions that integrate seamlessly with their automated assembly processes. Their purchasing decisions are heavily influenced by factors such as coating performance, cost-effectiveness, environmental compliance, and the ability to enhance brand aesthetics and vehicle longevity.

The automotive aftermarket, encompassing the refinish sector, constitutes another significant customer base. This segment includes a vast network of independent body shops, authorized service centers, collision repair facilities, and custom paint shops that utilize coatings for vehicle repair, restoration, and personalization. Unlike OEM buyers, these customers typically require a wider variety of products in smaller quantities, emphasizing ease of application, color matching accuracy, and rapid curing times to minimize vehicle downtime. The aftermarket also extends to distributors and retailers who supply these refinish products, acting as intermediaries to ensure widespread availability and technical support. The demand in this segment is influenced by factors such as accident rates, vehicle aging, and evolving consumer trends in vehicle aesthetics and customization.

Beyond these primary segments, other potential customers include manufacturers of specialty vehicles such as buses, trucks, recreational vehicles (RVs), and agricultural or construction equipment, all of which require robust, durable coatings tailored to their specific operational environments and performance criteria. Additionally, manufacturers of automotive components and parts (e.g., wheels, bumpers, interior trim) also represent a customer group for specialized coatings. Fleet operators, requiring long-lasting and easy-to-maintain finishes for their commercial vehicles, also contribute to market demand. The diverse needs and distinct purchasing criteria across these various customer groups necessitate a broad product portfolio and customized service offerings from automotive coating suppliers to effectively capture market share.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 21.5 billion |

| Market Forecast in 2032 | USD 31.3 billion |

| Growth Rate | 5.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | AkzoNobel N.V., BASF SE, PPG Industries, Axalta Coating Systems, The Sherwin-Williams Company, Kansai Paint Co. Ltd., Nippon Paint Holdings Co. Ltd., KCC Corporation, Jotun A/S, Hempel A/S, RPM International Inc., Covestro AG, Arkema S.A., Eastman Chemical Company, Wacker Chemie AG, DIC Corporation, Beckers Group, Fujikura Kasei Co. Ltd., Somar Corporation, Diamond Vogel |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Automotive Coatings Market Key Technology Landscape

The Automotive Coatings Market is defined by a rapidly evolving technological landscape, driven by the dual imperatives of enhanced performance and stringent environmental compliance. A cornerstone of this evolution is the increasing prominence of waterborne coating technologies. These systems utilize water as the primary solvent, drastically reducing volatile organic compound (VOC) emissions compared to traditional solventborne coatings. This shift aligns directly with global environmental regulations and consumer preferences for more sustainable products, while still offering excellent aesthetic qualities, durability, and corrosion resistance. Continuous advancements in resin chemistry and additive formulations are further improving the performance characteristics of waterborne systems, making them increasingly competitive with their solventborne counterparts in terms of hardness, gloss, and application flexibility.

Another significant technological advancement is the widespread adoption and innovation in powder coatings. These coatings are applied as a free-flowing, dry powder that is electrostatically charged and then cured under heat to form a hard finish. The key advantages of powder coatings include zero VOC emissions, excellent durability, superior chip and scratch resistance, and high material utilization efficiency due to reclaimable overspray. While historically used more for underbody parts and components, new developments are extending their application to exterior body panels, especially in OEM lines, offering a highly sustainable and high-performance alternative. The ongoing research focuses on lowering cure temperatures and expanding the color and effect range to meet diverse design requirements.

Beyond eco-friendly formulations, the market is also witnessing a surge in smart and functional coatings designed to offer more than just protection and aesthetics. This includes self-healing clearcoats that can autonomously repair minor scratches, anti-corrosion coatings with enhanced barrier properties or active corrosion inhibitors, and thermal management coatings that help regulate vehicle temperature. UV-cured coatings are also gaining traction for their ultra-fast curing times, significantly boosting production line efficiency and reducing energy consumption, particularly in specific OEM and refinish applications requiring rapid turnaround. Furthermore, advanced multi-layer systems, including sophisticated pigment technologies for deeper colors and special effects, are continuously being refined to deliver superior aesthetics and longer-lasting finishes, catering to the premium segment of the automotive market and enhancing vehicle personalization options.

Regional Highlights

- North America: This region represents a mature yet robust market for automotive coatings, characterized by a significant presence of established automotive manufacturers and a strong aftermarket segment. The demand is largely driven by a consistent emphasis on high-performance coatings, advanced durability, and aesthetic customization, particularly for premium vehicles. Stringent environmental regulations in the U.S. and Canada also drive innovation towards low-VOC and sustainable coating solutions, making it a key region for technological adoption.

- Europe: Europe stands as a hub for automotive innovation, with a strong focus on environmental sustainability and high-quality, luxury vehicle production. The market here is significantly influenced by stringent EU regulations on emissions and hazardous substances, accelerating the adoption of waterborne, high-solids, and powder coating technologies. Germany, France, and Italy are leading countries, demonstrating high demand for advanced functional coatings and specialized finishes that enhance vehicle performance and aesthetic appeal.

- Asia Pacific (APAC): The APAC region is the largest and fastest-growing market for automotive coatings globally, primarily driven by the massive automotive production volumes in countries such as China, India, Japan, and South Korea. Rapid urbanization, increasing disposable incomes, and the burgeoning middle class contribute to a surging demand for new vehicles. This region is a hotbed for both OEM and refinish market growth, with a growing focus on cost-effective yet high-performance and environmentally compliant coating solutions to meet expanding market needs.

- Latin America: This region presents an emerging market with considerable growth potential, fueled by increasing foreign investments in automotive manufacturing and an expanding vehicle parc. Countries like Brazil and Mexico are key contributors to regional demand, driven by both domestic consumption and export markets. While economic volatility can be a factor, the long-term outlook remains positive, with a growing need for durable and cost-efficient coatings suitable for diverse climatic conditions and local market preferences.

- Middle East and Africa (MEA): The MEA market for automotive coatings is relatively nascent but shows promising growth, particularly with rising investments in automotive assembly plants and a gradual increase in vehicle ownership. Demand is influenced by the need for coatings that can withstand harsh climatic conditions, including high temperatures and sand abrasion. The region is witnessing a gradual adoption of advanced coating technologies, often driven by international automotive brands establishing a local presence and bringing global quality standards.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Automotive Coatings Market.- AkzoNobel N.V.

- BASF SE

- PPG Industries

- Axalta Coating Systems

- The Sherwin-Williams Company

- Kansai Paint Co. Ltd.

- Nippon Paint Holdings Co. Ltd.

- KCC Corporation

- Jotun A/S

- Hempel A/S

- RPM International Inc.

- Covestro AG

- Arkema S.A.

- Eastman Chemical Company

- Wacker Chemie AG

- DIC Corporation

- Beckers Group

- Fujikura Kasei Co. Ltd.

- Somar Corporation

- Diamond Vogel

Frequently Asked Questions

What are the primary types of automotive coatings?

Automotive coatings typically comprise E-coat for corrosion protection, primer for surface preparation, basecoat for color and aesthetics, and clearcoat for gloss, durability, and UV resistance, forming a multi-layer system.

How do environmental regulations impact the automotive coatings market?

Environmental regulations, particularly those targeting VOC emissions, significantly drive the market towards sustainable alternatives like waterborne, high-solids, and powder coatings, promoting eco-friendly product development and adoption.

What is the role of automotive coatings in electric vehicles (EVs)?

For EVs, coatings are crucial for protecting sensitive battery components, enhancing thermal management, reducing vehicle weight with lightweight substrates, and providing corrosion resistance tailored to new materials and operating conditions.

Which region is leading the growth in the automotive coatings market?

The Asia Pacific region is currently leading the growth in the automotive coatings market, primarily due to robust automotive manufacturing, increasing vehicle sales, and rising disposable incomes in countries like China and India.

What are smart coatings in the automotive industry?

Smart coatings are advanced materials that offer enhanced functionalities beyond basic protection and aesthetics, such as self-healing properties for scratch repair, anti-corrosion monitoring, and active temperature regulation for improved vehicle longevity and performance.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager