Automotive Connecting Rod Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428038 | Date : Oct, 2025 | Pages : 241 | Region : Global | Publisher : MRU

Automotive Connecting Rod Market Size

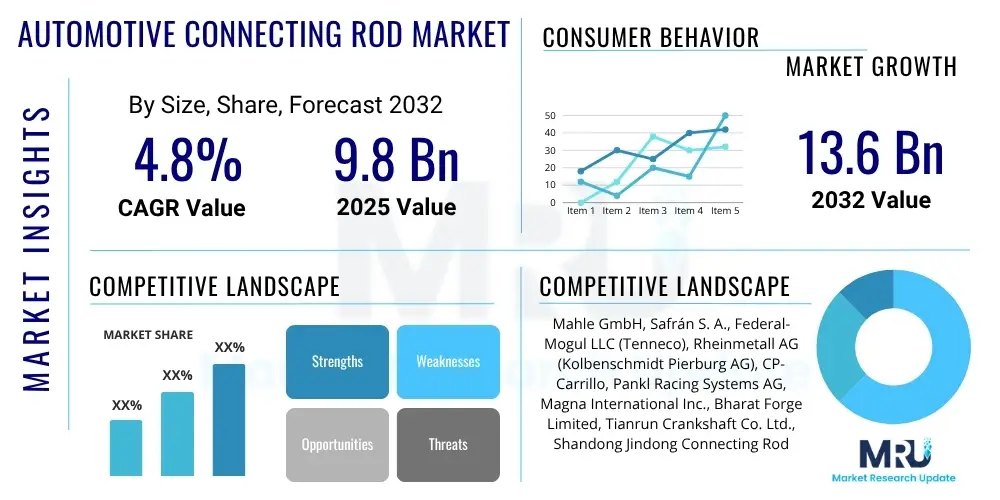

The Automotive Connecting Rod Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2025 and 2032. The market is estimated at USD 9.8 billion in 2025 and is projected to reach USD 13.6 billion by the end of the forecast period in 2032.

Automotive Connecting Rod Market introduction

The automotive connecting rod market is an integral component of the internal combustion engine (ICE) powertrain, facilitating the conversion of the piston's reciprocating motion into the crankshaft's rotary motion. This critical part experiences immense mechanical stress, high temperatures, and dynamic loads, requiring exceptional strength, durability, and precision engineering. Connecting rods are fundamental to the operation of gasoline and diesel engines across various vehicle types, acting as the crucial link that transmits power from the combustion process to the drivetrain, ultimately enabling vehicle propulsion. The market's stability is historically tied to global vehicle production volumes and the continuous technological advancements in engine design, aiming for greater efficiency and reduced emissions.

Connecting rods are primarily manufactured from steel, aluminum, or, in high-performance applications, titanium or composite materials, with different manufacturing processes like forging, powder metallurgy, or casting employed based on performance requirements and cost considerations. They are designed to withstand significant tensile and compressive forces, ensuring reliable power transfer and engine longevity. Their major applications span across passenger cars, where they are optimized for fuel efficiency and smooth operation, to heavy-duty commercial vehicles requiring robust designs for sustained high power output, and even specialized roles in off-highway vehicles and performance racing engines where extreme loads are common.

The primary benefit of a well-engineered connecting rod is its role in ensuring the efficient and reliable operation of an internal combustion engine. Key driving factors for this market include the sustained global demand for conventional and hybrid vehicles, particularly in emerging economies, continuous innovations in engine technology focused on downsizing and turbocharging, and the ongoing need for lightweight components to improve fuel economy and reduce emissions. Furthermore, the robust aftermarket demand for replacement parts and upgrades also significantly contributes to the market's sustained growth, adapting to the diverse needs of the automotive industry.

Automotive Connecting Rod Market Executive Summary

The automotive connecting rod market is experiencing a complex interplay of traditional demand drivers and transformative industry shifts. Despite the accelerating transition towards electric vehicles (EVs), the robust and enduring production of internal combustion engine (ICE) and hybrid vehicles continues to fuel demand for connecting rods globally. Current business trends indicate a strong emphasis on material innovation, with manufacturers exploring advanced steel alloys, aluminum composites, and even carbon fiber reinforced polymers to achieve lighter, stronger, and more durable components. This drive for lightweighting is critical for enhancing fuel efficiency and reducing emissions in line with stringent environmental regulations worldwide. Furthermore, increased automation and precision manufacturing techniques are becoming standard, improving product quality and reducing production costs.

Regionally, the market exhibits varied dynamics. The Asia-Pacific region, led by China and India, remains the largest and fastest-growing market due to high vehicle production volumes, increasing disposable incomes, and expanding middle-class populations. These countries are not only significant manufacturing hubs but also major consumption centers. Europe and North America, while more mature markets, are characterized by a focus on high-performance and premium segments, along with a strong aftermarket for specialized components. Regulatory pressures for emission reduction in these regions also drive innovation towards more efficient engine designs, indirectly impacting connecting rod specifications. Latin America and the Middle East & Africa are emerging as growth regions, propelled by industrialization and rising urbanization leading to increased vehicle sales.

From a segmentation perspective, powdered metal connecting rods are gaining traction due to their cost-effectiveness and good mechanical properties, especially in passenger car applications, while forged steel rods remain the benchmark for high-stress and heavy-duty vehicles. The shift towards smaller, turbocharged engines necessitates connecting rods capable of handling higher cylinder pressures and rotational speeds, thereby influencing design and material choices. Moreover, the aftermarket segment is robust, driven by the need for maintenance, repair, and performance upgrades, offering stable revenue streams. The long-term outlook, however, must consider the eventual decline of ICE vehicle production in favor of EVs, prompting manufacturers to invest in diversified product portfolios and explore applications beyond traditional ICEs, such as in industrial machinery or power generation.

AI Impact Analysis on Automotive Connecting Rod Market

The integration of Artificial Intelligence (AI) across the automotive manufacturing value chain, including the production of critical components like connecting rods, is a topic of significant interest. Common user questions often revolve around how AI can enhance design optimization, improve manufacturing precision, reduce material waste, and streamline supply chain logistics. Users are keen to understand if AI can predict component failures, thereby extending engine life and enabling predictive maintenance, or if it can assist in the development of novel materials that were previously too complex to model manually. There are also inquiries regarding the potential for AI to personalize connecting rod designs for specific engine types or performance requirements, alongside concerns about the initial investment costs, the need for specialized data scientists, and potential job displacement in traditional manufacturing roles.

The key themes emerging from this analysis highlight a strong expectation for AI to drive efficiency, innovation, and cost savings within the automotive connecting rod market. Users anticipate AI's ability to analyze vast datasets from design simulations, material properties, and manufacturing processes to identify optimal parameters for performance and durability. There is also a significant interest in AI's role in quality control, moving beyond manual inspections to automated, vision-based systems capable of detecting microscopic defects at high speeds. This promises to reduce warranty claims and improve product reliability. Furthermore, the market anticipates AI to offer solutions for more robust and resilient supply chains, capable of adapting to global disruptions with minimal impact.

Overall, the prevalent user sentiment is that AI is not just a technological enhancement but a transformative force capable of redefining standards for design, production, and quality in the automotive connecting rod sector. The primary expectations are centered on leveraging AI for predictive analytics, generative design, and intelligent automation. While the benefits are clear, the industry is also grappling with the practicalities of implementation, including data privacy, algorithmic bias, and the upskilling of the workforce. Addressing these concerns will be crucial for the widespread adoption and successful integration of AI into connecting rod manufacturing, ultimately leading to more robust, efficient, and cost-effective engine components.

- AI-driven generative design optimizes connecting rod geometry for strength-to-weight ratio, reducing material usage and improving engine efficiency.

- Predictive analytics powered by AI monitors manufacturing equipment, anticipating maintenance needs and preventing costly downtime.

- AI-enabled vision systems perform rapid, precise quality inspections, identifying micro-cracks and surface imperfections far beyond human capability.

- Smart supply chain management uses AI to forecast demand, optimize inventory levels, and track components, enhancing operational resilience.

- Material science R&D accelerates with AI, simulating new alloy compositions and processing parameters for enhanced performance and durability.

- AI facilitates adaptive manufacturing, allowing production lines to quickly adjust to variations in raw materials or changing design specifications.

DRO & Impact Forces Of Automotive Connecting Rod Market

The automotive connecting rod market is shaped by a confluence of intricate drivers, significant restraints, and emerging opportunities, all under the influence of various impact forces. Drivers for growth include the sustained global demand for new vehicles, especially in rapidly industrializing economies where vehicle ownership is expanding, alongside the continuous advancement in engine technology. Stringent emission regulations globally compel engine manufacturers to develop more efficient and powerful engines, which often translates to a demand for high-strength, lightweight connecting rods capable of handling increased pressures and speeds. The ongoing trend of engine downsizing coupled with turbocharging also necessitates more robust and precisely engineered connecting rods, further driving demand for specialized and advanced components in the market. Furthermore, the robust aftermarket sector consistently provides a steady demand for replacement and upgrade components, contributing significantly to market stability.

However, the market faces considerable restraints. The most significant long-term restraint is the accelerated global shift towards electric vehicles (EVs), which do not utilize internal combustion engines and therefore eliminate the need for connecting rods. While this transition is gradual, it poses an existential threat to the market over several decades. Additionally, the high research and development costs associated with developing new materials and manufacturing processes for high-performance connecting rods can be a barrier, particularly for smaller manufacturers. Volatility in raw material prices, such as steel and aluminum, directly impacts production costs and profit margins. Intense competition among established players and new entrants, especially from Asian manufacturers, also puts downward pressure on pricing, affecting profitability and market share across the value chain. Global economic downturns or geopolitical instabilities can further dampen consumer spending on new vehicles, impacting overall market demand.

Despite these challenges, substantial opportunities exist. The growing demand for high-performance and luxury vehicles, which often feature advanced engine designs requiring premium connecting rods, presents a lucrative niche. Emerging markets, with their burgeoning middle classes and expanding infrastructure, offer significant untapped potential for vehicle sales and, consequently, connecting rod demand. Technological advancements in additive manufacturing (3D printing) for prototyping and specialized, low-volume production, as well as innovations in surface treatments and material composites, open new avenues for product differentiation and performance enhancement. Furthermore, the aftermarket segment, driven by the aging vehicle parc and the trend of vehicle customization, continues to offer resilient growth, allowing manufacturers to leverage their expertise beyond new vehicle production. Diversification into industrial engine applications also presents a viable opportunity for manufacturers to mitigate risks associated with the automotive sector's EV transition.

Segmentation Analysis

The automotive connecting rod market is meticulously segmented to provide a granular understanding of its diverse components and drivers. This segmentation allows for a precise analysis of various product types, materials, vehicle applications, and sales channels, reflecting the multifaceted nature of the automotive industry's demands. Each segment addresses specific performance requirements, cost considerations, and end-user preferences, influencing manufacturing processes and technological advancements within the market. Understanding these distinctions is crucial for stakeholders to identify growth areas, tailor product offerings, and devise effective market penetration strategies in a dynamically evolving landscape. The key segments are defined by the fundamental characteristics of the connecting rod and its end-use environment.

- By Material:

- Steel Connecting Rods: Dominate the market due to their superior strength, durability, and cost-effectiveness, widely used across passenger cars, commercial vehicles, and heavy-duty applications.

- Forged Steel: Preferred for high-stress applications in performance and heavy-duty engines, offering excellent fatigue strength.

- Powdered Metal Steel: Gaining traction for its cost-efficiency and near-net-shape manufacturing capabilities, suitable for high-volume passenger car engines.

- Aluminum Connecting Rods: Valued for their lightweight properties, reducing reciprocating mass and improving engine response and fuel efficiency, often found in high-revving or lightweight performance engines.

- Titanium Connecting Rods: Extremely lightweight and strong, but costly, making them exclusive to ultra-high-performance vehicles and racing applications where weight savings are paramount.

- Composite Connecting Rods: An emerging segment exploring advanced materials like carbon fiber reinforced polymers for extreme lightweighting and unique damping characteristics, primarily in R&D or specialized niches.

- Steel Connecting Rods: Dominate the market due to their superior strength, durability, and cost-effectiveness, widely used across passenger cars, commercial vehicles, and heavy-duty applications.

- By Type of Manufacturing Process:

- Forged Connecting Rods: Produced by shaping metal through localized compressive forces, resulting in superior grain structure and strength, essential for high-stress engine components.

- Powdered Metal (PM) Connecting Rods: Made by compacting metallic powders into a desired shape and then sintering, offering cost advantages and close dimensional tolerances for mass production.

- Cast Connecting Rods: Formed by pouring molten metal into a mold; while cost-effective, they generally offer lower strength compared to forged or PM rods, used in less demanding engine applications.

- By Vehicle Type:

- Passenger Cars: The largest segment, driven by global automotive production, focusing on durability, fuel efficiency, and smooth operation.

- Commercial Vehicles: Includes light commercial vehicles (LCVs) and heavy commercial vehicles (HCVs), requiring robust and high-strength connecting rods to withstand continuous heavy loads and long operational hours.

- Off-highway Vehicles: Covers construction equipment, agricultural machinery, and industrial engines, demanding exceptionally durable and reliable connecting rods for harsh operating environments.

- Two-wheelers: Encompasses motorcycles, scooters, and other two-wheeled vehicles, with connecting rods designed for specific engine sizes and performance characteristics, from commuter bikes to high-performance racing motorcycles.

- By Engine Type:

- Gasoline Engines: Typically operate at higher RPMs, influencing connecting rod design for lighter weight and fatigue resistance.

- Diesel Engines: Characterized by higher compression ratios and torque, demanding stronger, heavier connecting rods to withstand greater stresses.

- By Sales Channel:

- Original Equipment Manufacturer (OEM): Sales directly to vehicle manufacturers for integration into new vehicles, representing the largest volume segment.

- Aftermarket: Sales of replacement and upgrade connecting rods through distributors, independent repair shops, and online retailers, driven by vehicle maintenance, repair, and performance modification needs.

Value Chain Analysis For Automotive Connecting Rod Market

The value chain for the automotive connecting rod market is a complex network involving multiple stages, from raw material extraction to the end-use application in vehicles, encompassing both upstream and downstream activities as well as various distribution channels. The upstream segment of the value chain is predominantly concerned with the sourcing and processing of raw materials, which are critical for determining the strength, durability, and cost-effectiveness of the final product. Key suppliers in this phase include steel mills providing various grades of steel alloys, aluminum manufacturers supplying high-quality aluminum ingots, and, for specialized applications, titanium and composite material producers. These raw material suppliers often engage in extensive research and development to produce materials with enhanced properties, such as improved fatigue strength or reduced weight, directly influencing the performance capabilities of the connecting rods. Additionally, machinery and tooling manufacturers that produce specialized forging presses, powder metallurgy equipment, CNC machines, and heat treatment furnaces are vital upstream contributors, enabling the manufacturing processes with advanced technology.

Further along the value chain, the manufacturing phase involves several critical processes, including forging, casting, or powder metallurgy, followed by precision machining, heat treatment, and surface finishing. Connecting rod manufacturers integrate these processes, often employing advanced techniques like shot peening, nitriding, and balancing to enhance the component's performance and longevity. Quality control is paramount at every stage to ensure the rods meet stringent automotive industry standards for dimensional accuracy, material integrity, and structural soundness. These manufacturers then supply finished connecting rods directly to engine assemblers and vehicle original equipment manufacturers (OEMs), who incorporate them into complete engine systems. The relationship between connecting rod manufacturers and OEMs is typically long-term and collaborative, often involving co-development to meet specific engine design requirements and performance targets. This direct channel represents the bulk of the market volume for new vehicle production, emphasizing reliability, consistency, and compliance with strict quality specifications.

The downstream segment of the value chain focuses on distribution and the eventual end-use. For OEMs, connecting rods are direct inputs into engine assembly lines, making the distribution channel primarily direct. However, the aftermarket segment employs a more varied distribution model, involving a network of wholesalers, regional distributors, independent repair shops, and increasingly, online retail platforms. These channels cater to the demand for replacement parts for vehicle maintenance and repair, as well as performance upgrade components for enthusiasts. Indirect distribution, through a network of authorized dealers and parts suppliers, plays a significant role in making connecting rods accessible to the broader service market. The effectiveness of these distribution channels, both direct and indirect, is crucial for ensuring timely delivery and widespread availability, impacting customer satisfaction and market reach. The entire value chain is driven by technological advancements, regulatory compliance, and a continuous pursuit of efficiency and cost optimization, with each stage adding significant value to the final product.

Automotive Connecting Rod Market Potential Customers

The primary potential customers and end-users of automotive connecting rods are predominantly found within the expansive automotive industry and its ancillary services. At the forefront are the global automotive Original Equipment Manufacturers (OEMs), including major passenger car manufacturers like Toyota, Volkswagen, General Motors, Ford, and Hyundai, as well as leading commercial vehicle producers such as Daimler Trucks, Volvo Group, and PACCAR. These OEMs integrate connecting rods into the engines of their new vehicles during the assembly process, representing the largest volume demand for connecting rod manufacturers. Their purchasing decisions are driven by factors such as cost-effectiveness, adherence to strict performance specifications, material innovation, production scalability, and long-term supply agreements, often involving collaborative design and engineering efforts to meet specific engine requirements and fuel efficiency standards. The focus here is on mass production, reliability, and meeting stringent quality control parameters to ensure warranty compliance and vehicle safety.

Beyond new vehicle production, a significant segment of potential customers resides in the automotive aftermarket. This includes a broad spectrum of entities that purchase connecting rods for maintenance, repair, and performance upgrades of existing vehicles. Independent repair shops, authorized service centers, and auto parts distributors form a crucial part of this customer base, sourcing replacement connecting rods for engine rebuilds or repairs due to wear, damage, or malfunction. Their purchasing criteria often prioritize availability, competitive pricing, and compatibility with a wide range of vehicle makes and models. The aftermarket also includes performance engine builders and automotive enthusiasts who seek high-performance connecting rods made from advanced materials like aluminum or titanium, or with specialized designs, to enhance engine power, durability, and reliability for racing or modified vehicles. These customers typically demand higher specifications and are willing to pay a premium for improved performance characteristics.

Furthermore, other industrial sectors also represent potential customers, albeit on a smaller scale compared to the automotive segment. Manufacturers of stationary power generation units, marine engines, and certain types of off-highway industrial equipment utilize connecting rods in their internal combustion engines. These applications often require connecting rods designed for continuous operation under heavy loads and specific environmental conditions, emphasizing extreme durability and robust construction. The purchasing decisions in these sectors are highly influenced by the specific technical requirements of their machinery, longevity, and adherence to industry-specific regulatory standards. Overall, the market for automotive connecting rods is diverse, catering to high-volume OEM demand, essential aftermarket needs, and specialized performance applications across various industrial domains, each with distinct purchasing drivers and product requirements.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 9.8 billion |

| Market Forecast in 2032 | USD 13.6 billion |

| Growth Rate | 4.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Mahle GmbH, Safrán S. A., Federal-Mogul LLC (Tenneco), Rheinmetall AG (Kolbenschmidt Pierburg AG), CP-Carrillo, Pankl Racing Systems AG, Magna International Inc., Bharat Forge Limited, Tianrun Crankshaft Co. Ltd., Shandong Jindong Connecting Rod Co. Ltd., Shaanxi Heavy Duty Automobile Co. Ltd., Wescon Manufacturing Inc., Arrow Precision Engineering Ltd., Faltec Co. Ltd., Ningbo Tianlong Connecting Rod Co. Ltd., Albon Engineering & Manufacturing PLC. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Automotive Connecting Rod Market Key Technology Landscape

The automotive connecting rod market is continuously evolving, driven by the relentless pursuit of improved engine performance, greater fuel efficiency, and enhanced durability, all while adhering to increasingly stringent emission standards. This technological progression encompasses a wide array of innovations across materials science, manufacturing processes, and design methodologies. One of the primary areas of focus is the development and application of advanced materials. While steel remains dominant, particularly in its forged and powdered metal forms, there is significant research into new high-strength steel alloys that offer superior fatigue resistance and tensile strength with reduced weight. Furthermore, lightweight materials such as advanced aluminum alloys and titanium are crucial for high-performance and racing applications, where reducing reciprocating mass directly translates to higher engine speeds and improved responsiveness. The exploration of composite materials, such as carbon fiber reinforced polymers, is also underway, promising revolutionary weight reductions, though their high cost and manufacturing complexities currently limit widespread commercial application in mainstream vehicles.

In terms of manufacturing processes, precision engineering and automation are at the forefront. Advanced forging techniques, including warm and cold forging, are employed to achieve optimal grain structure and mechanical properties, minimizing material waste and improving component integrity. Powder metallurgy (PM) has seen significant advancements, enabling the production of connecting rods with complex geometries and high precision at a competitive cost, making it a favored method for high-volume passenger car applications. CNC machining remains critical for achieving tight dimensional tolerances and surface finishes, ensuring precise fitment and reliable operation. Beyond traditional methods, additive manufacturing (3D printing) is emerging as a valuable tool, primarily for rapid prototyping, complex geometry validation, and the production of highly specialized, low-volume connecting rods, particularly for performance or bespoke engine projects. This technology allows for unprecedented design freedom, enabling the creation of components with optimized internal structures for weight and strength.

Furthermore, surface treatment technologies play a vital role in extending the lifespan and enhancing the performance of connecting rods. Processes such as shot peening are used to induce compressive residual stresses on the surface, significantly improving fatigue strength and resistance to cracking. Nitriding and various coating technologies are applied to improve wear resistance, reduce friction, and enhance corrosion protection, crucial for components operating under extreme conditions within the engine. Advanced simulation and modeling software, including Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD), are extensively used during the design phase to optimize connecting rod geometry for strength, weight, and stress distribution, predicting performance under various operating conditions. The integration of IoT and AI in manufacturing processes allows for real-time monitoring, predictive maintenance of machinery, and intelligent quality control, further ensuring the consistency and reliability of the final product while minimizing production inefficiencies.

Regional Highlights

- Asia Pacific (APAC): The largest and fastest-growing market for automotive connecting rods, driven primarily by high vehicle production volumes in China, India, Japan, and South Korea. This region serves as a global manufacturing hub and experiences significant demand due to rising disposable incomes, rapid urbanization, and expanding middle-class populations increasing vehicle ownership. The presence of major automotive OEMs and a robust supply chain further consolidates its market leadership.

- Europe: A mature market characterized by stringent emission regulations and a strong emphasis on engine efficiency and performance. Countries like Germany, France, and the UK are key players, demanding advanced and lightweight connecting rods for premium and luxury vehicles, as well as a strong presence in the commercial vehicle segment. Innovation in material science and manufacturing processes is a key driver here.

- North America: Exhibits stable demand, primarily driven by the United States with its large automotive industry, robust aftermarket, and significant market for heavy-duty commercial vehicles and performance cars. The preference for larger engine vehicles historically contributes to a consistent need for durable connecting rods, although the transition to EVs is a growing consideration.

- Latin America: An emerging market showing steady growth due to increasing industrialization, infrastructure development, and growing automotive manufacturing capacities in countries like Brazil and Mexico. Economic stability and expanding consumer bases contribute to rising vehicle sales, subsequently boosting the demand for connecting rods in both OEM and aftermarket segments.

- Middle East and Africa (MEA): This region is experiencing nascent growth, influenced by economic diversification, infrastructure projects, and a gradual increase in vehicle sales, particularly in countries with developing economies. While smaller in market share, it presents future growth opportunities as automotive manufacturing and consumption continue to expand across the region.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Automotive Connecting Rod Market.- Mahle GmbH

- Safrán S. A.

- Federal-Mogul LLC (Tenneco)

- Rheinmetall AG (Kolbenschmidt Pierburg AG)

- CP-Carrillo

- Pankl Racing Systems AG

- Magna International Inc.

- Bharat Forge Limited

- Tianrun Crankshaft Co. Ltd.

- Shandong Jindong Connecting Rod Co. Ltd.

- Shaanxi Heavy Duty Automobile Co. Ltd.

- Wescon Manufacturing Inc.

- Arrow Precision Engineering Ltd.

- Faltec Co. Ltd.

- Ningbo Tianlong Connecting Rod Co. Ltd.

- Albon Engineering & Manufacturing PLC

- Wössner GmbH

- Callies Performance Products

Frequently Asked Questions

Analyze common user questions about the Automotive Connecting Rod market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of an automotive connecting rod?

The automotive connecting rod serves as a critical mechanical link within an internal combustion engine, converting the reciprocating (up and down) motion of the piston into the rotary (circular) motion of the crankshaft. It transmits the force generated by the combustion process from the piston to the crankshaft, ultimately powering the vehicle.

What materials are commonly used to manufacture connecting rods, and why?

Connecting rods are most commonly made from steel (forged or powdered metal) due to its exceptional strength, durability, and cost-effectiveness for mass production. Aluminum is used for lightweight, high-performance engines to reduce reciprocating mass, while titanium is reserved for extreme performance applications due to its superior strength-to-weight ratio, despite higher cost.

How does the shift to electric vehicles (EVs) impact the connecting rod market?

The accelerating global shift towards electric vehicles poses a significant long-term restraint on the connecting rod market. As EVs do not rely on internal combustion engines, they do not require connecting rods. This trend necessitates market players to innovate, diversify into hybrid vehicle components, or explore applications in non-automotive sectors to mitigate future declines in demand.

What are the key factors driving growth in the automotive connecting rod market?

Key growth drivers include sustained global vehicle production, particularly in emerging economies, increasingly stringent emission regulations (which necessitate more efficient and lightweight engine components), the trend of engine downsizing and turbocharging, and a robust aftermarket demand for replacement and performance-upgrade parts.

How is AI impacting the design and manufacturing of connecting rods?

AI is increasingly used to optimize connecting rod design through generative design, creating lighter yet stronger components. In manufacturing, AI enables predictive maintenance for machinery, automated precision quality control, and enhances supply chain efficiency, leading to higher quality products, reduced waste, and streamlined production processes.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager