Automotive Cross Car Beam Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428862 | Date : Oct, 2025 | Pages : 253 | Region : Global | Publisher : MRU

Automotive Cross Car Beam Market Size

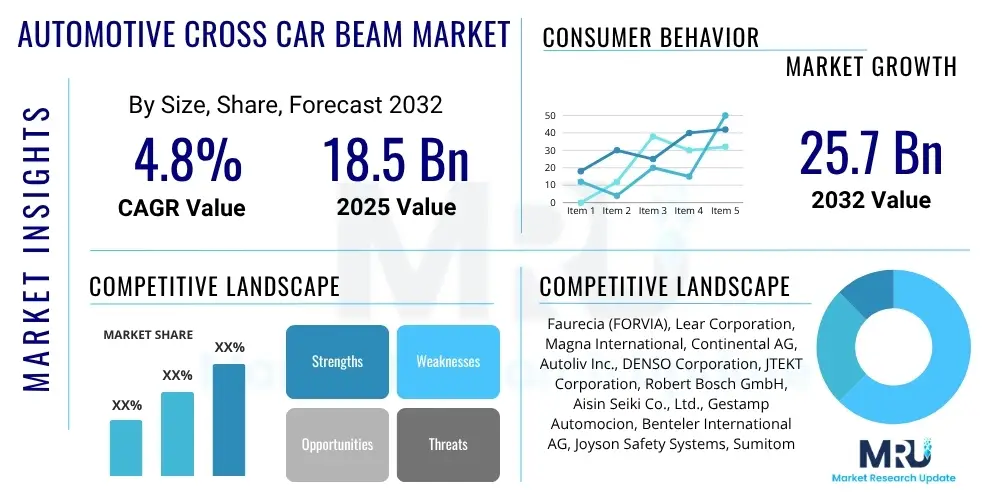

The Automotive Cross Car Beam Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2025 and 2032. The market is estimated at USD 18.5 Billion in 2025 and is projected to reach USD 25.7 Billion by the end of the forecast period in 2032.

Automotive Cross Car Beam Market introduction

The Automotive Cross Car Beam market encompasses the production and supply of a critical structural component found in virtually all modern vehicles. This component, often referred to as the dashboard beam or instrument panel beam, serves as a primary transverse support structure, connecting the vehicle's A-pillars and providing the foundational mounting point for various essential cockpit elements. It plays a pivotal role in ensuring structural rigidity, contributing significantly to occupant safety during frontal or side impacts, and mitigating noise, vibration, and harshness (NVH) within the cabin.

The product itself is a highly engineered part, typically fabricated from high-strength steel, aluminum alloys, or advanced composite materials, with a growing trend towards lightweighting to improve fuel efficiency and reduce emissions. Its major applications span across passenger cars, commercial vehicles, and increasingly, electric vehicles, where unique packaging challenges often influence its design. Key benefits include enhanced crashworthiness by distributing impact forces, providing stable support for the steering column, airbags, HVAC systems, infotainment units, and glove compartments, thereby directly impacting vehicle safety, interior quality, and overall driver and passenger comfort. The market is primarily driven by global vehicle production volumes, increasingly stringent automotive safety regulations mandating robust passive safety features, and the continuous industry push for lightweight yet durable components to meet fuel economy standards and reduce carbon footprints.

Automotive Cross Car Beam Market Executive Summary

The Automotive Cross Car Beam market is currently experiencing dynamic shifts driven by evolving automotive trends, technological advancements, and a persistent focus on safety and efficiency. Business trends indicate a consolidation among Tier 1 suppliers, who are increasingly investing in research and development to offer modular, integrated cross car beam solutions that are lighter, stronger, and easier for OEMs to assemble. There is also a notable emphasis on leveraging advanced manufacturing processes such as hydroforming and high-pressure die casting to optimize material usage and achieve complex geometries, contributing to cost efficiency and performance enhancements. The advent of electric vehicles (EVs) presents both opportunities and challenges, requiring redesigned beams to accommodate battery packaging and unique crash load paths.

Regional trends highlight Asia Pacific as the leading market, fueled by high vehicle production volumes, particularly in China and India, alongside the rapid adoption of advanced manufacturing techniques in countries like Japan and South Korea. Europe and North America are characterized by a strong demand for premium vehicles and stringent safety standards, driving innovation in material selection and advanced occupant protection systems. These regions are also at the forefront of electric vehicle manufacturing, influencing the design and material composition of cross car beams to support new vehicle architectures. The market is geographically diverse, with local production capabilities often being a critical factor in supply chain resilience and cost management.

Segmentation trends reveal a clear trajectory towards lightweight materials, with aluminum and multi-material composites gaining significant traction over traditional steel, particularly in premium and electric vehicle segments. Modular cross car beams are becoming preferred due to their flexibility in integrating various cockpit components, simplifying vehicle assembly, and allowing for greater customization. The demand for cross car beams specifically designed for electric vehicles is growing, as these vehicles often require different structural considerations due to battery placement and redesigned crumple zones. Furthermore, a focus on intelligent integration of sensors and electronics within the beam structure is emerging, reflecting the broader trend towards smarter, more connected vehicle interiors.

AI Impact Analysis on Automotive Cross Car Beam Market

User inquiries about AI's impact on the Automotive Cross Car Beam market often revolve around its potential to revolutionize design, manufacturing processes, and material optimization. Users are keen to understand how artificial intelligence can lead to more efficient, lighter, and safer cross car beams, addressing concerns about cost, performance, and sustainability. Key themes emerging from these questions include the role of AI in predictive modeling for crash scenarios, optimizing material selection for strength-to-weight ratios, enhancing manufacturing precision through automation, and facilitating quicker design iterations. There is an expectation that AI will drive significant advancements in both the conceptualization and production phases of these critical components.

- AI-driven generative design optimizes cross car beam geometries for minimal weight and maximum strength, reducing material usage.

- Predictive analytics enhance quality control in manufacturing by identifying potential defects early, improving production efficiency.

- Machine learning algorithms assist in material selection, identifying the best combinations of alloys or composites for specific performance criteria and cost targets.

- AI-powered simulations enable faster and more accurate crashworthiness testing, accelerating product development cycles.

- Robotics and AI in assembly lines improve precision and reduce labor costs, leading to more consistent product quality.

- Supply chain optimization using AI ensures efficient procurement of raw materials and timely delivery of components to OEMs.

DRO & Impact Forces Of Automotive Cross Car Beam Market

The Automotive Cross Car Beam market is significantly influenced by a confluence of driving forces, inherent restraints, and emerging opportunities, all of which contribute to its overall market dynamics and impact. Key drivers include the consistent growth in global automotive production, particularly in emerging economies, which directly translates to increased demand for essential structural components like cross car beams. Furthermore, the relentless pursuit of enhanced vehicle safety, propelled by increasingly stringent global regulatory standards and consumer expectations, mandates robust and advanced cross car beam designs capable of superior energy absorption and occupant protection. The automotive industry's pervasive trend towards lightweighting, aimed at improving fuel efficiency, reducing emissions, and extending the range of electric vehicles, also serves as a potent driver for innovation in cross car beam materials and manufacturing processes.

Despite these strong drivers, the market faces several restraining factors. The high upfront investment required for research and development into new materials and advanced manufacturing technologies, such as hydroforming or multi-material joining techniques, can be a significant barrier for smaller players. Additionally, the inherent complexity in integrating various cockpit components onto the cross car beam, coupled with the need for precise tolerances and sophisticated assembly processes, adds to manufacturing costs and lead times. Supply chain disruptions, often stemming from geopolitical tensions, natural disasters, or raw material price volatility, can also significantly impede production schedules and impact profitability across the market.

Opportunities for growth are abundant, particularly with the rapid proliferation of electric vehicles, which often necessitate unique cross car beam designs to accommodate battery packaging and enhance structural integrity in new vehicle architectures. The continuous development of advanced materials, including high-strength steels, aluminum alloys, magnesium, and lightweight composites, offers avenues for creating lighter and more performant beams. Furthermore, the adoption of modular platform strategies by OEMs presents an opportunity for suppliers to offer flexible, pre-assembled cross car beam modules that streamline vehicle production and reduce overall vehicle weight. The ongoing automation and digitalization of manufacturing processes, including the use of robotics and Industry 4.0 technologies, also present opportunities for enhanced efficiency, precision, and cost reduction in cross car beam production, allowing for greater innovation and market responsiveness.

Segmentation Analysis

The Automotive Cross Car Beam market is segmented to provide a granular understanding of its diverse landscape, categorizing the market based on material type, product type, vehicle type, manufacturing process, and end-use. This segmentation allows for a detailed analysis of market trends, growth drivers, and competitive strategies within each specific segment. The market's complexity and the varied demands of automotive manufacturers necessitate such a comprehensive breakdown to identify distinct opportunities and challenges.

- By Material Type:

- Steel Cross Car Beam: Traditional, cost-effective, high-strength steel (HSS), ultra-high-strength steel (UHSS).

- Aluminum Cross Car Beam: Lightweight, corrosion-resistant, often used in premium and performance vehicles.

- Magnesium Cross Car Beam: Ultra-lightweight, high strength-to-weight ratio, but higher cost and processing challenges.

- Composite Cross Car Beam: Emerging, multi-material solutions, offers optimal weight reduction and design flexibility.

- By Product Type:

- Single-Piece Cross Car Beam: Conventional design, single unit.

- Modular Cross Car Beam: Integrated design incorporating HVAC, steering column, and other components, pre-assembled.

- By Vehicle Type:

- Passenger Car: Dominant segment, includes sedans, SUVs, hatchbacks.

- Commercial Vehicle: Trucks, vans, buses, often requiring robust designs.

- Electric Vehicle (EV): Specific designs to accommodate battery architecture and weight distribution.

- By Manufacturing Process:

- Stamping: Conventional method, cost-effective for steel.

- Hydroforming: High-pressure fluid forms complex shapes, excellent for lightweight metals.

- Extrusion: Used for aluminum beams, creating uniform cross-sections.

- Casting: Often used for magnesium or complex aluminum geometries.

- Welding & Assembly: Techniques like laser welding for joining multiple components.

- By End-Use:

- OEM (Original Equipment Manufacturer): Direct supply to vehicle manufacturers for new vehicle assembly.

- Aftermarket: Replacement parts, a smaller but significant segment.

Value Chain Analysis For Automotive Cross Car Beam Market

The value chain for the Automotive Cross Car Beam market begins with upstream activities, primarily involving the sourcing and processing of raw materials. This segment includes major producers of high-strength steel, aluminum ingots and sheets, magnesium alloys, and various composite fibers and resins. These material suppliers play a crucial role in providing the foundational elements that determine the final properties and cost of the cross car beam. Innovation in material science at this stage directly impacts the lightweighting and performance capabilities of the final product, with advancements in metallurgy and composite manufacturing continuously driving the evolution of cross car beam design.

Moving downstream, the value chain progresses through Tier 2 and Tier 1 suppliers. Tier 2 suppliers are often specialized in processes such as hydroforming, stamping, extrusion, or casting, transforming raw materials into basic cross car beam structures or sub-components. Tier 1 suppliers, which are often large multinational automotive component manufacturers, then take these structures, integrate additional components like steering column mounts, HVAC ducts, airbag housing, and wire harnesses, to produce complete, often modular, cross car beam assemblies. These Tier 1 suppliers are responsible for advanced engineering, testing, and ensuring the final product meets stringent OEM specifications for safety, performance, and durability. Their capabilities in design, prototyping, and large-scale manufacturing are critical to the market.

The distribution channel for automotive cross car beams is predominantly direct. Tier 1 suppliers typically engage in long-term contracts with Original Equipment Manufacturers (OEMs), supplying cross car beam assemblies directly to vehicle assembly plants worldwide. This direct supply model ensures seamless integration into the vehicle production line and allows for close collaboration on design, quality control, and logistics. Indirect channels, while less prominent for new vehicle production, exist in the aftermarket for replacement parts, where distributors and repair shops procure cross car beams to service older vehicles. The aftermarket segment is smaller but contributes to the overall stability of the value chain by extending the product lifecycle and addressing maintenance requirements over time.

Automotive Cross Car Beam Market Potential Customers

The primary potential customers for Automotive Cross Car Beams are Original Equipment Manufacturers (OEMs) within the global automotive industry. This encompasses a vast array of vehicle manufacturers, ranging from established giants producing millions of vehicles annually to emerging players in the electric vehicle segment. These OEMs directly purchase cross car beams, often as highly engineered and integrated modules, from Tier 1 automotive suppliers for installation in their new vehicle platforms. The decision-making process for OEMs is heavily influenced by factors such as component quality, safety compliance, lightweighting potential, cost-effectiveness, and the supplier's ability to innovate and integrate with complex vehicle architectures.

Specifically, this includes passenger car manufacturers that produce sedans, SUVs, hatchbacks, and luxury vehicles, all of which require tailored cross car beam solutions to meet specific design, safety, and NVH requirements. Commercial vehicle manufacturers, including those producing light trucks, heavy-duty trucks, and buses, also represent a significant customer segment, typically demanding robust and durable cross car beams designed for different load-bearing capacities and operational environments. Furthermore, the rapidly expanding sector of electric vehicle (EV) manufacturers presents a growing base of potential customers, as EVs often require bespoke cross car beam designs to accommodate battery packaging, unique crash structures, and evolving interior layouts, driving demand for innovative and specialized solutions from suppliers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $18.5 Billion |

| Market Forecast in 2032 | $25.7 Billion |

| Growth Rate | 4.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Faurecia (FORVIA), Lear Corporation, Magna International, Continental AG, Autoliv Inc., DENSO Corporation, JTEKT Corporation, Robert Bosch GmbH, Aisin Seiki Co., Ltd., Gestamp Automocion, Benteler International AG, Joyson Safety Systems, Sumitomo Electric Industries, Ltd., ZF Friedrichshafen AG, Hyundai Mobis, Toyoda Gosei Co., Ltd., Plastic Omnium, Yanfeng Automotive Interiors, Eberspächer Group, CIE Automotive |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Automotive Cross Car Beam Market Key Technology Landscape

The Automotive Cross Car Beam market is driven by continuous innovation in material science and manufacturing processes, aiming to achieve optimal performance, weight reduction, and cost efficiency. One of the cornerstone technologies is advanced hydroforming, which utilizes high-pressure fluid to form complex metal shapes with superior dimensional accuracy and structural integrity, allowing for lighter and stronger beams compared to traditional stamping. Alongside this, high-strength steels (HSS) and ultra-high-strength steels (UHSS), coupled with advanced joining techniques such like laser welding and friction stir welding, are crucial for maintaining structural robustness while minimizing weight. The development of advanced aluminum alloys and their application through extrusion and high-pressure die casting also represent significant technological advancements, enabling further lightweighting, particularly in performance-oriented and electric vehicles.

Beyond material processing, the integration of modular design principles has become a key technological trend. This involves designing cross car beams as comprehensive modules that can incorporate various cockpit components such as the steering column, HVAC ducts, airbag modules, and infotainment system supports during the supplier's assembly process. This modular approach simplifies OEM assembly lines, reduces overall vehicle weight, and allows for greater flexibility in vehicle interior design. Furthermore, the application of simulation and modeling software, such as Finite Element Analysis (FEA), is indispensable in the design phase, allowing engineers to predict crashworthiness, stiffness, and vibration characteristics with high accuracy, optimizing designs virtually before physical prototyping.

Robotics and automation play a pivotal role in the manufacturing and assembly of cross car beams, ensuring high precision, repeatability, and efficiency in production. Automated welding, assembly, and quality inspection systems contribute to reduced manufacturing costs and enhanced product consistency. The emerging landscape also includes the exploration of multi-material solutions, where different materials (e.g., steel, aluminum, composites) are strategically combined within a single beam to leverage the specific advantages of each material, such as strength, stiffness, and weight. These hybrid structures often require sophisticated joining technologies that can effectively bond dissimilar materials without compromising structural integrity, pushing the boundaries of current manufacturing capabilities and setting new standards for cross car beam performance.

Regional Highlights

- Asia Pacific (APAC): Dominates the global market, driven by high volume automotive production in China, India, Japan, and South Korea. The region benefits from increasing disposable incomes, rapid urbanization, and a strong push for electric vehicle adoption, which fuels demand for innovative cross car beam solutions. APAC is also a hub for cost-effective manufacturing and advanced technological integration.

- Europe: A significant market characterized by stringent safety regulations and a strong emphasis on premium and luxury vehicles. Countries like Germany, France, and the UK are at the forefront of automotive innovation, driving demand for lightweight materials and advanced modular cross car beam designs. The growing EV market in Europe further stimulates R&D in structural components.

- North America: A mature market with substantial vehicle production, particularly in the USA, Canada, and Mexico. Demand is influenced by consumer preference for larger vehicles (SUVs, trucks) and a continuous focus on enhancing vehicle safety and fuel efficiency. Investments in advanced manufacturing and lightweighting technologies are prevalent in this region.

- Latin America: An emerging market with growing automotive production, especially in Brazil and Mexico. The region benefits from increasing industrialization and foreign investments, leading to a steady demand for cross car beams. Market growth is closely tied to economic stability and vehicle affordability.

- Middle East and Africa (MEA): A developing market with nascent automotive manufacturing capabilities in some countries, alongside significant vehicle imports. Growth is anticipated due to infrastructure development and rising vehicle ownership, although it currently represents a smaller share of the global market.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Automotive Cross Car Beam Market.- Faurecia (FORVIA)

- Lear Corporation

- Magna International

- Continental AG

- Autoliv Inc.

- DENSO Corporation

- JTEKT Corporation

- Robert Bosch GmbH

- Aisin Seiki Co., Ltd.

- Gestamp Automocion

- Benteler International AG

- Joyson Safety Systems

- Sumitomo Electric Industries, Ltd.

- ZF Friedrichshafen AG

- Hyundai Mobis

- Toyoda Gosei Co., Ltd.

- Plastic Omnium

- Yanfeng Automotive Interiors

- Eberspächer Group

- CIE Automotive

Frequently Asked Questions

What is an Automotive Cross Car Beam?

An Automotive Cross Car Beam is a critical structural component spanning the width of a vehicle's dashboard, connecting the A-pillars. It provides essential support for the steering column, instrument panel, HVAC system, airbags, and contributes significantly to vehicle rigidity and occupant safety during collisions.

Why is lightweighting important for Cross Car Beams?

Lightweighting is crucial for Cross Car Beams to improve vehicle fuel efficiency, reduce carbon emissions, and enhance the range of electric vehicles. Lighter beams contribute to overall vehicle weight reduction, directly impacting performance and environmental compliance without compromising safety.

How do Electric Vehicles (EVs) impact the Cross Car Beam market?

EVs impact the market by requiring innovative cross car beam designs to accommodate battery packaging, different crash load paths, and often new interior layouts. This drives demand for advanced lightweight materials and modular solutions tailored to EV specific architectural needs.

What materials are commonly used to manufacture Cross Car Beams?

Common materials include high-strength steel, aluminum alloys, and magnesium. Advanced multi-material composites are also gaining traction for their superior strength-to-weight ratios, offering enhanced performance and further lightweighting capabilities.

What are the key safety trends influencing Cross Car Beam design?

Key safety trends include increasingly stringent global crash test regulations, demand for enhanced occupant protection systems (e.g., advanced airbags), and integration with active safety features. Designs prioritize energy absorption, impact force distribution, and stable mounting for safety-critical components.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager