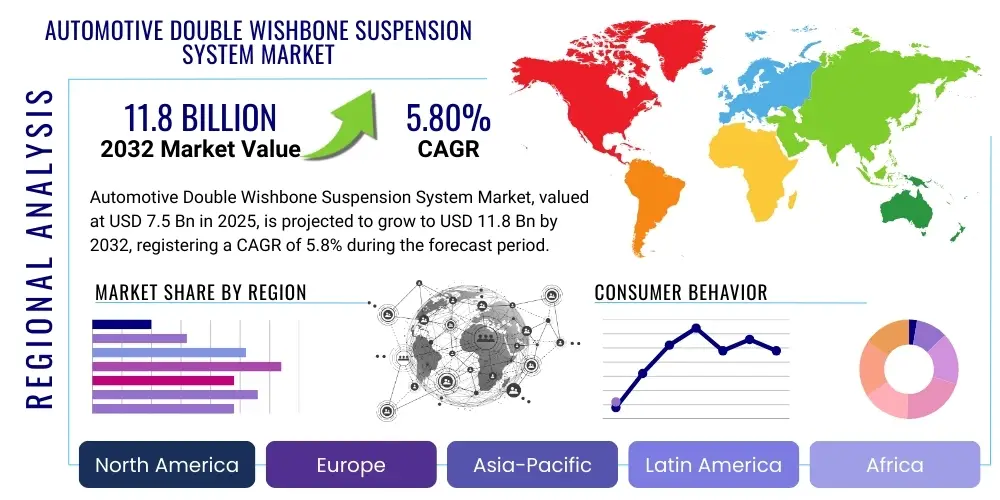

Automotive Double Wishbone Suspension System Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427719 | Date : Oct, 2025 | Pages : 254 | Region : Global | Publisher : MRU

Automotive Double Wishbone Suspension System Market Size

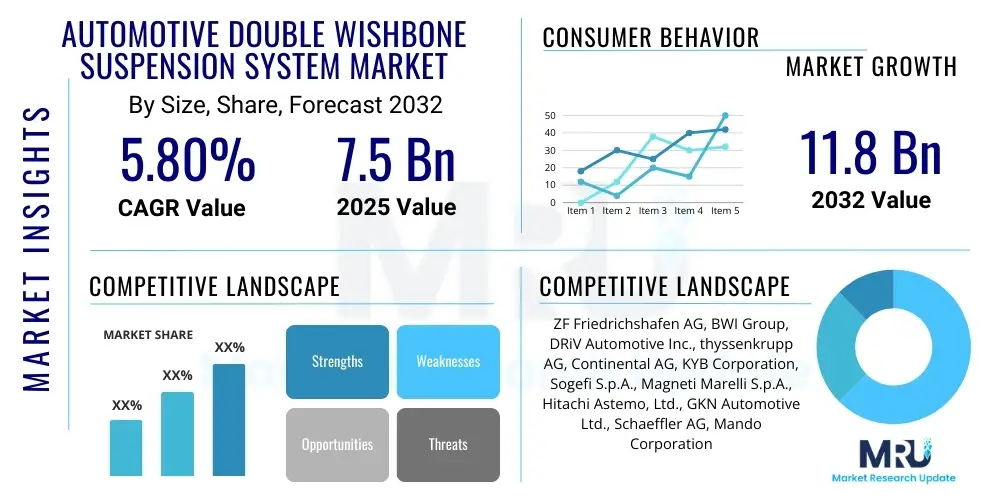

The Automotive Double Wishbone Suspension System Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2025 and 2032. The market is estimated at USD 7.5 Billion in 2025 and is projected to reach USD 11.8 Billion by the end of the forecast period in 2032.

Automotive Double Wishbone Suspension System Market introduction

The Automotive Double Wishbone Suspension System Market encompasses the design, manufacturing, and integration of suspension systems characterized by two Y-shaped arms (wishbones) that locate the wheel. This sophisticated mechanical arrangement provides superior control over wheel movement, allowing for precise management of camber angle, caster angle, and toe as the wheel moves through its travel. The inherent design advantages of double wishbone suspension, including its ability to maintain optimal tire contact patch and resist body roll, make it a preferred choice for vehicles where handling, stability, and ride comfort are paramount.

Major applications for double wishbone suspension systems are predominantly found in the premium, luxury, sports, and high-performance automotive segments, including high-end sedans, sports cars, performance SUVs, and certain electric vehicles. Its widespread adoption in these categories is driven by the systems capacity to deliver exceptional dynamic performance, enhancing both driver engagement and passenger comfort. The design flexibility also allows engineers to fine-tune suspension characteristics for specific vehicle applications, balancing agile handling with refined ride quality.

The primary benefits of double wishbone suspension include enhanced vehicle handling, superior cornering stability, improved tire grip, and reduced unsprung weight when engineered with lightweight materials. These systems effectively isolate road imperfections, minimizing vibrations transmitted to the cabin and contributing to a smoother, more controlled ride. Driving factors for market growth include the increasing global demand for luxury and performance vehicles, stringent safety regulations requiring better vehicle dynamics, and continuous advancements in materials and manufacturing processes that improve system efficiency and durability.

Automotive Double Wishbone Suspension System Market Executive Summary

The Automotive Double Wishbone Suspension System Market is experiencing robust expansion, propelled by several converging business trends. A significant trend is the sustained growth in global demand for premium and luxury vehicles, segments where double wishbone suspension is a standard feature due to its superior performance attributes. Furthermore, the burgeoning electric vehicle (EV) market presents a unique opportunity; the substantial weight of EV battery packs necessitates sophisticated suspension systems capable of managing increased mass while maintaining desired ride and handling characteristics, making double wishbone an ideal solution. Advancements in lightweight materials, such as aluminum alloys and composites, are enabling the development of more efficient and performance-oriented systems, contributing to their wider adoption.

Regional trends indicate strong market penetration in developed economies, particularly North America and Europe, which boast significant markets for high-performance and luxury vehicles. These regions are also hubs for automotive innovation and manufacturing, fostering continuous research and development in suspension technologies. Asia Pacific, especially China, is emerging as a critical growth engine, driven by rising disposable incomes, increasing sales of premium vehicles, and the rapid expansion of its domestic electric vehicle industry. Emerging markets are also showing increased interest in advanced suspension systems as consumer expectations for vehicle performance and comfort rise.

Segmentation trends highlight the increasing preference for double wishbone systems in sports utility vehicles (SUVs) and electric vehicles, moving beyond their traditional dominance in sports and luxury cars. By vehicle type, passenger cars and SUVs represent the largest segments. From a material perspective, the shift towards lightweight aluminum and composite solutions is accelerating, driven by fuel efficiency standards and the performance demands of modern powertrains, including electric ones. The aftermarket segment is also witnessing steady growth, as enthusiasts seek to upgrade or replace suspension components for enhanced performance or customization.

AI Impact Analysis on Automotive Double Wishbone Suspension System Market

Users commonly inquire about how artificial intelligence can optimize the design, manufacturing, and operational performance of double wishbone suspension systems. Key themes revolve around AIs ability to refine suspension tuning for varying road conditions and driving styles, predict component failure for proactive maintenance, and accelerate the development cycle through advanced simulations. There is also significant interest in AIs potential to integrate these systems seamlessly with other vehicle dynamics controls, creating truly adaptive and intelligent suspension setups that enhance safety and comfort. Concerns often touch upon the complexity of integrating AI, data security, and the reliability of AI-driven decisions in real-time automotive environments.

- AI-driven generative design for optimized component geometry and material usage, leading to lighter and stronger wishbones.

- Predictive maintenance analytics using sensor data to anticipate wear and tear, improving system longevity and safety.

- Real-time adaptive damping control and ride height adjustment, leveraging AI algorithms to respond dynamically to road conditions and driving inputs.

- Enhanced simulation and testing through machine learning, significantly reducing physical prototyping needs and accelerating development cycles.

- Integration with advanced driver assistance systems (ADAS) for improved vehicle stability and control in critical maneuvers.

- Optimized manufacturing processes, including robot-assisted assembly and quality control, ensuring consistent performance.

DRO & Impact Forces Of Automotive Double Wishbone Suspension System Market

The market for automotive double wishbone suspension systems is significantly influenced by a combination of key drivers, formidable restraints, and promising opportunities, all shaped by various impact forces. A primary driver is the escalating global demand for premium and luxury vehicles, where consumers expect superior ride comfort and dynamic handling capabilities that double wishbone systems inherently provide. The increasing integration of Advanced Driver Assistance Systems (ADAS) and the progression towards autonomous driving also necessitate highly stable and responsive suspension systems to ensure optimal sensor performance and passenger comfort, further bolstering demand. Furthermore, advancements in lightweight materials like aluminum and composites allow for the reduction of unsprung mass, improving overall vehicle performance and fuel efficiency, aligning with industry trends for efficiency and sustainability.

However, several restraints pose challenges to market expansion. The high manufacturing cost and complexity associated with double wishbone systems, compared to simpler alternatives like MacPherson struts, limit their adoption primarily to higher-end vehicles. Packaging constraints, particularly in smaller or compact vehicle platforms, can also make it challenging to integrate the larger physical footprint of a double wishbone setup. Additionally, the rise of alternative suspension technologies, such as multi-link and air suspension systems, especially in certain mass-market segments or for specific vehicle applications, could potentially divert market share, requiring continuous innovation from double wishbone system manufacturers to maintain competitiveness.

Opportunities for growth are abundant, particularly with the rapid electrification of the automotive industry. Electric vehicles, with their heavy battery packs, benefit immensely from the load-bearing capacity and precise control offered by double wishbone suspension, enhancing range, handling, and passenger comfort. The ongoing quest for autonomous vehicle technologies also opens doors for highly sophisticated, electronically controlled double wishbone systems that can adapt in real-time to optimize passenger experience and safety in a driverless environment. Moreover, the aftermarket segment continues to present opportunities for upgrades and performance enhancements, catering to enthusiasts seeking improved handling and ride quality. These impact forces collectively dictate the trajectory and evolution of the automotive double wishbone suspension market, demanding strategic adaptation and innovation from industry players.

Segmentation Analysis

The Automotive Double Wishbone Suspension System Market is broadly segmented based on various critical attributes, providing a detailed understanding of its dynamics across different applications and product characteristics. These segments allow for a granular analysis of market trends, consumer preferences, and technological advancements, helping stakeholders identify specific growth areas and develop targeted strategies. Key segmentation categories include vehicle type, material type, sales channel, and end-use application, each reflecting distinct market drivers and competitive landscapes.

- By Vehicle Type: Passenger Cars, Sports Cars, Luxury Sedans, Performance SUVs, Electric Vehicles

- By Material Type: Steel, Aluminum Alloys, Carbon Fiber Composites, Other Advanced Materials

- By Sales Channel: Original Equipment Manufacturer (OEM), Aftermarket

- By End-Use: Performance Vehicles, Luxury Vehicles, Off-Road Vehicles, Special Purpose Vehicles

Automotive Double Wishbone Suspension System Market Value Chain Analysis

The value chain for the Automotive Double Wishbone Suspension System Market begins with the upstream segment, which primarily involves the procurement of raw materials and the manufacturing of basic components. This stage includes suppliers of steel, aluminum alloys, and composite materials, as well as manufacturers specializing in bushings, bearings, springs, and dampers. These raw material and component providers are crucial as the quality and cost of their offerings directly influence the final products performance and price. Innovation in material science, particularly in lightweight and high-strength alloys, is a significant driver at this stage, aiming to enhance suspension performance while reducing vehicle weight and improving fuel efficiency.

Moving downstream, the value chain encompasses the sophisticated assembly and integration of these components into complete double wishbone suspension modules. This is typically carried out by specialized suspension system manufacturers or Tier 1 automotive suppliers. These companies leverage advanced engineering, design capabilities (including CAD/CAE software), and precision manufacturing processes to produce robust and performance-tuned suspension systems. They often work in close collaboration with Original Equipment Manufacturers (OEMs) to develop bespoke suspension solutions tailored to specific vehicle models, considering factors such as vehicle weight, expected performance, and desired ride characteristics.

The final stages of the value chain involve the distribution channels, which can be direct or indirect. Direct channels involve the sale of complete suspension systems directly from the Tier 1 suppliers to automotive OEMs for integration into new vehicle production lines. Indirect channels, predominantly forming the aftermarket segment, involve the distribution of replacement parts or performance upgrade kits through a network of distributors, wholesalers, retailers, and independent service garages to end-users. This aftermarket segment caters to vehicle owners looking to replace worn-out components or enhance their vehicles performance with specialized suspension setups. The efficiency and reach of these distribution networks are vital for ensuring product availability and customer satisfaction across both OEM and aftermarket sectors.

Automotive Double Wishbone Suspension System Market Potential Customers

The primary potential customers for the Automotive Double Wishbone Suspension System Market are automotive Original Equipment Manufacturers (OEMs), particularly those specializing in premium, luxury, sports, and performance vehicle segments. These manufacturers consistently integrate double wishbone systems into their vehicle designs due to the superior handling, stability, and ride comfort these systems offer. Brands like Mercedes-Benz, BMW, Porsche, Audi, Ferrari, and Lamborghini are prominent examples, where the high-performance attributes of double wishbone suspension align perfectly with their brand image and customer expectations. The growing segment of high-end electric vehicle manufacturers also represents a significant customer base, as they require robust suspension solutions to manage the substantial weight of battery packs while maintaining agile driving dynamics and luxury ride quality.

Beyond the new vehicle production market, the aftermarket segment constitutes another vital group of potential customers. This includes independent automotive workshops, specialized tuning shops, and individual performance enthusiasts who seek to upgrade or replace their vehicles existing suspension systems. These customers are driven by a desire for enhanced driving performance, improved aesthetics, or customization options that go beyond standard factory specifications. Performance-oriented aftermarket brands and parts suppliers cater to this segment by offering a wide range of double wishbone components, from complete kits to individual wishbones, bushings, and adjustable dampers, allowing for personalized vehicle tuning.

Furthermore, niche markets such as motorsport teams, custom vehicle builders, and specialized off-road vehicle manufacturers also represent potential customers. Motorsport applications demand the ultimate in precision and durability, making double wishbone systems a natural fit for racing cars and rally vehicles where every millisecond counts and dynamic control is paramount. Custom builders often opt for double wishbone setups to achieve specific ride characteristics or packaging requirements for unique vehicle projects. Even certain military or specialized utility vehicle manufacturers may utilize bespoke double wishbone designs for enhanced ruggedness and controlled handling over challenging terrains, demonstrating the versatility and broad appeal of this advanced suspension technology across diverse automotive applications.

Automotive Double Wishbone Suspension System Market Key Technology Landscape

The technology landscape for the Automotive Double Wishbone Suspension System Market is characterized by continuous innovation aimed at enhancing performance, durability, and integration capabilities. A fundamental technological pillar is the widespread adoption of advanced Computer-Aided Design (CAD) and Computer-Aided Engineering (CAE) tools, including Finite Element Analysis (FEA) and Multi-Body Dynamics (MBD) software. These tools enable engineers to simulate various load conditions, optimize component geometry for strength and weight, and predict system behavior under diverse driving scenarios, significantly reducing the need for costly and time-consuming physical prototyping. This digital twin approach allows for rapid iteration and refinement of designs, ensuring optimal performance from the outset.

Material science plays a pivotal role in the evolution of double wishbone systems. There is a growing emphasis on lightweight materials such as high-strength steel alloys, aluminum alloys, and carbon fiber composites. These materials are crucial for reducing unsprung mass, which directly translates to improved ride comfort, better handling, and enhanced fuel efficiency or extended range for electric vehicles. The development of advanced forging, casting, and composite manufacturing techniques is also critical, enabling the production of complex, high-precision components that meet stringent performance and safety standards. Innovations in surface treatments and coatings further enhance component durability and corrosion resistance, extending the lifespan of suspension systems.

Moreover, the integration of active and semi-active suspension technologies represents a significant advancement. Electronically controlled dampers, adaptive air springs, and active anti-roll bars are being combined with double wishbone layouts to create intelligent suspension systems. These systems utilize sensors and Electronic Control Units (ECUs) to continuously monitor road conditions, vehicle speed, steering input, and driver commands, adjusting damping forces and ride height in real-time. This allows for dynamic optimization of both ride comfort and handling characteristics, providing a bespoke driving experience. The convergence of these mechanical advancements with sophisticated electronics and software defines the cutting edge of double wishbone suspension technology, paving the way for highly adaptive and predictive vehicle dynamics.

Regional Highlights

- North America: A leading market driven by high demand for luxury vehicles, performance cars, and SUVs. Significant investment in R&D and a robust aftermarket for upgrades.

- Europe: A hub for automotive innovation and premium vehicle manufacturing. Strict emissions regulations and a strong driving culture foster demand for high-performance and efficient suspension systems.

- Asia Pacific: The fastest-growing region, propelled by rising disposable incomes, expanding luxury vehicle sales, and the rapid adoption of electric vehicles, particularly in China and Japan.

- Latin America: Emerging market with increasing penetration of premium vehicle brands and a growing demand for enhanced vehicle performance and safety features.

- Middle East & Africa: Gradual growth fueled by luxury vehicle imports and increasing infrastructure development, leading to higher demand for robust suspension systems.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Automotive Double Wishbone Suspension System Market.- ZF Friedrichshafen AG

- BWI Group

- DRiV Automotive Inc. (Tenneco)

- thyssenkrupp AG

- Continental AG

- KYB Corporation

- Sogefi S.p.A.

- Magneti Marelli S.p.A.

- Hitachi Astemo, Ltd.

- GKN Automotive Ltd.

- Schaeffler AG

- Mando Corporation

Frequently Asked Questions

What are the primary benefits of double wishbone suspension?

Double wishbone suspension offers superior control over wheel alignment, leading to enhanced handling, improved road holding, reduced body roll during cornering, and a more comfortable ride by maintaining an optimal tire contact patch across various road conditions. It provides a high degree of tunability for specific vehicle dynamics.

Which types of vehicles commonly use double wishbone systems?

Double wishbone suspension is predominantly found in luxury sedans, high-performance sports cars, premium SUVs, and many modern electric vehicles. Its complex design and superior performance make it ideal for applications where ride quality and dynamic driving characteristics are paramount.

How does double wishbone suspension compare to MacPherson struts?

Compared to MacPherson struts, double wishbone systems offer greater control over wheel geometry (camber, caster, toe) throughout suspension travel, allowing for better handling and tire grip. While MacPherson struts are simpler and more compact, double wishbones provide a more sophisticated and tunable solution, albeit at a higher cost and with greater complexity.

What role do materials play in double wishbone design?

Materials are crucial for optimizing double wishbone systems. Lightweight materials like aluminum alloys and carbon fiber composites reduce unsprung mass, improving vehicle responsiveness and fuel efficiency. High-strength steel is used for durability, while advanced polymers in bushings enhance noise, vibration, and harshness (NVH) characteristics and longevity.

How is double wishbone suspension evolving with electric vehicles?

For electric vehicles, double wishbone suspension is evolving to manage the increased weight of battery packs, optimize energy efficiency, and integrate with advanced electronic controls. It allows for precise tuning to balance the heavy EV chassis with agile handling and smooth ride comfort, often incorporating active damping for real-time adjustments.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager