Automotive Electric Vacuum Pump Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430971 | Date : Nov, 2025 | Pages : 251 | Region : Global | Publisher : MRU

Automotive Electric Vacuum Pump Market Size

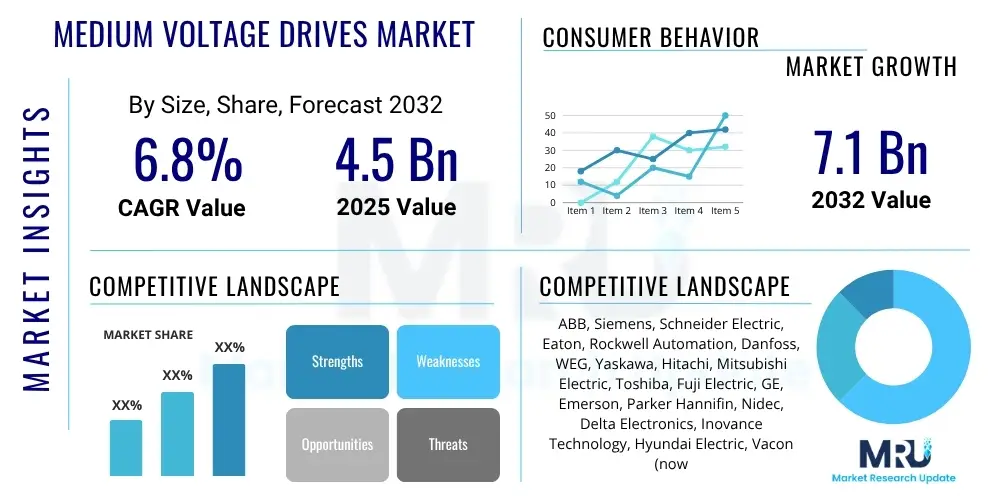

The Automotive Electric Vacuum Pump Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at USD 1.85 Billion in 2025 and is projected to reach USD 2.92 Billion by the end of the forecast period in 2032.

Automotive Electric Vacuum Pump Market introduction

The Automotive Electric Vacuum Pump market encompasses the global industry dedicated to the research, development, manufacturing, and distribution of electrically operated vacuum pumps specifically engineered for integration into modern automotive platforms. These sophisticated electromechanical devices play a pivotal role in ensuring the optimal functioning of critical vehicle systems that require a stable and precisely controlled vacuum pressure, irrespective of the engine's operational status. The market's expansion is intrinsically linked to the ongoing paradigm shifts within the global automotive industry, particularly the accelerating trend towards vehicle electrification, the heightened emphasis on enhancing fuel efficiency, and the increasingly stringent global regulations pertaining to vehicle safety and environmental emissions. By providing an independent and efficient vacuum source, these pumps are becoming an indispensable component for contemporary and future vehicle architectures.

Fundamentally, an electric vacuum pump is designed to generate and maintain a vacuum in various sealed automotive systems, effectively replacing or supplementing the vacuum traditionally generated by the internal combustion engine. Typically, these units comprise a high-efficiency electric motor, a robust pump mechanism—often a vane or diaphragm type—a durable housing, and an integrated electronic control unit (ECU). The innovative design allows for on-demand operation, meaning the pump activates only when vacuum is required, thereby significantly minimizing energy consumption and reducing parasitic losses on the engine. This distinct operational advantage, coupled with their compact dimensions and flexible mounting options, enables seamless integration into diverse vehicle designs, from conventional gasoline and diesel cars to advanced hybrid and battery-electric models. The precise control offered by the ECU ensures consistent performance across varying driving conditions and vehicle loads.

The major applications for automotive electric vacuum pumps are primarily concentrated in safety-critical and performance-enhancing vehicle subsystems. Foremost among these is the brake booster system, where a consistent vacuum is absolutely essential for power-assisted braking, significantly enhancing driver safety, reducing stopping distances, and improving overall driving comfort. Beyond braking, these pumps are increasingly employed in turbocharger wastegate control mechanisms, optimizing the performance and responsiveness of forced-induction engines. They are also crucial components within exhaust gas recirculation (EGR) systems, contributing significantly to the reduction of harmful nitrogen oxide (NOx) emissions in both internal combustion and hybrid powertrains. The profound benefits include markedly improved braking performance and responsiveness, substantial gains in fuel economy through reduced engine load, a significant contribution to lower greenhouse gas emissions, and enhanced design flexibility for vehicle manufacturers. The primary driving forces for the market's robust growth are the accelerating global shift towards hybrid and battery electric vehicles, the continuous evolution of automotive safety standards demanding advanced braking functionalities, and the imperative for automakers to comply with increasingly stringent global CO2 emission reduction targets.

Automotive Electric Vacuum Pump Market Executive Summary

The Automotive Electric Vacuum Pump market is currently experiencing a period of dynamic and sustained growth, fundamentally driven by pervasive technological advancements and shifting industrial priorities within the global automotive sector. The overarching trend towards vehicle electrification, encompassing hybrid, plug-in hybrid, and fully battery electric vehicles, serves as the most potent catalyst, as these advanced powertrains necessitate dedicated and independent vacuum sources for critical functions like brake assistance. This fundamental requirement, coupled with the global push for enhanced vehicle safety features and the stringent regulatory mandates aimed at reducing carbon emissions, collectively underpins the robust expansion trajectory of this market. Stakeholders are witnessing a heightened demand for sophisticated, reliable, and energy-efficient vacuum pump solutions across all vehicle segments, underscoring the indispensable role these components now play in modern automotive engineering.

In terms of prevailing business trends, the market is characterized by a strong emphasis on continuous innovation, with leading manufacturers consistently investing in extensive research and development initiatives. This focus is geared towards creating pumps that are not only more compact and lighter but also offer superior energy efficiency, quieter operation, and enhanced durability to withstand demanding automotive environments. There is a discernible trend towards the development of intelligent, integrated solutions that seamlessly communicate and interact with the vehicle's central electronic control units (ECUs), facilitating optimal performance and diagnostic capabilities. Strategic partnerships and collaborative ventures between electric vacuum pump manufacturers and Tier 1 automotive suppliers are becoming increasingly common, fostering the development of holistic braking and powertrain management systems. Furthermore, competitive pressures are driving continuous improvements in manufacturing processes, aiming for greater cost-effectiveness and scalability to meet the escalating global demand.

Regional dynamics play a crucial role in shaping the market's trajectory, with Asia Pacific emerging as a dominant force and exhibiting the most rapid growth. This surge is primarily fueled by the region's prodigious automotive production volumes, particularly in economic powerhouses like China, India, and Japan, alongside proactive governmental policies aggressively promoting the adoption of electric vehicles. Europe and North America also represent significant growth markets, propelled by highly stringent emission regulations, advanced safety mandates, and a robust consumer preference for technologically sophisticated and environmentally friendly vehicles. From a segmentation perspective, passenger vehicles continue to constitute the largest application segment; however, the commercial vehicle sector is projected to demonstrate accelerated adoption rates as fleet operators increasingly electrify their fleets and seek efficiency gains. The increasing integration of advanced driver assistance systems (ADAS) and the progressive evolution towards fully autonomous vehicles further cement the critical and growing importance of highly reliable and independently operated electric vacuum pumps across the entire automotive landscape, ensuring a positive long-term market outlook.

AI Impact Analysis on Automotive Electric Vacuum Pump Market

User queries regarding the impact of Artificial Intelligence (AI) on the Automotive Electric Vacuum Pump market frequently highlight several key areas of interest: how AI can significantly enhance the operational efficiency and reliability of these vital components, and their seamless integration within increasingly complex vehicle intelligence ecosystems. There is considerable user curiosity about AI's potential to enable more sophisticated predictive maintenance strategies, thereby minimizing unexpected failures and extending product lifespans. Furthermore, users are keen to understand if AI can facilitate the dynamic optimization of vacuum pump performance in real-time, adapting to diverse driving conditions and vehicle states, which could lead to substantial improvements in overall vehicle energy management and braking system responsiveness, especially in advanced driver assistance systems (ADAS) and autonomous driving applications. The predominant themes emerging from these discussions underscore a collective expectation for AI to bring a new level of intelligence, precision, and robustness to critical automotive components.

Artificial Intelligence offers transformative opportunities to significantly elevate the operational intelligence and performance capabilities of electric vacuum pumps. By deploying advanced machine learning algorithms, vast datasets pertaining to pump operational parameters, real-time vehicle dynamics, environmental conditions, and historical performance can be meticulously analyzed. This data-driven approach enables the development of highly accurate predictive maintenance models capable of anticipating potential mechanical or electrical failures before they manifest. Such foresight allows for proactive servicing, minimizing vehicle downtime, reducing maintenance costs, and dramatically extending the operational longevity of the pumps. Moreover, AI-powered control systems can dynamically optimize the pump's duty cycle, ensuring that vacuum is generated only when and at the precise intensity required, leading to substantial reductions in energy consumption. This intelligent adaptation to varying driving styles, road surfaces, and vehicle load ensures not only optimal braking feel and safety but also contributes directly to improving fuel efficiency in hybrids and extending the range of battery electric vehicles.

Beyond direct operational enhancements, AI's influence extends broadly across the entire value chain of the Automotive Electric Vacuum Pump market, impacting everything from design and manufacturing to broader vehicle integration and after-sales service. AI-driven generative design and simulation tools can revolutionize the product development cycle, allowing engineers to rapidly explore and validate countless design iterations, optimizing pump architectures for factors such as noise reduction, thermal management, efficiency, and material utilization. In manufacturing, AI can significantly improve quality control through automated visual inspection systems and enhance production line efficiency through predictive analytics for machinery maintenance. Crucially, AI will be instrumental in facilitating the seamless and intelligent integration of electric vacuum pumps into the sophisticated vehicle control networks of ADAS and future autonomous driving platforms. As vehicles evolve towards higher levels of autonomy, the demand for exceptionally reliable, potentially redundant, and intelligently managed braking systems will intensify, with AI serving as the central orchestrator ensuring the continuous safety and optimal performance of these mission-critical components throughout the vehicle's operational lifespan.

- AI-driven predictive analytics enable real-time monitoring of electric vacuum pump health, proactively identifying potential malfunctions and scheduling preventative maintenance, thereby significantly boosting system reliability and extending component lifespan.

- Machine learning algorithms optimize pump operation by dynamically adjusting vacuum generation based on immediate driving conditions, vehicle speed, and driver input, leading to superior energy efficiency and reduced power consumption, particularly beneficial for electric vehicle range.

- AI integration with Advanced Driver Assistance Systems (ADAS) and autonomous driving frameworks ensures highly responsive and precise brake assist functionality, enhancing overall vehicle safety and control in complex scenarios.

- Generative design and simulation tools powered by AI accelerate the research and development process, enabling manufacturers to innovate more efficient, quieter, and durable pump designs by simulating performance under a vast array of conditions.

- Automated quality control and anomaly detection systems using AI in manufacturing processes minimize defects, improve production consistency, and reduce overall manufacturing costs.

- Advanced diagnostic capabilities facilitated by AI can quickly pinpoint issues within the vacuum pump system, streamlining troubleshooting, reducing repair times, and minimizing vehicle downtime for maintenance.

DRO & Impact Forces Of Automotive Electric Vacuum Pump Market

The Automotive Electric Vacuum Pump market is primarily propelled by a confluence of powerful drivers reshaping the global automotive landscape. The most significant factor is the escalating worldwide adoption of hybrid electric vehicles (HEVs), plug-in hybrid electric vehicles (PHEVs), and battery electric vehicles (BEVs). These electrified powertrains often either lack a traditional internal combustion engine as a consistent vacuum source or operate it intermittently, making dedicated electric vacuum pumps indispensable for ensuring reliable brake assist. Concurrently, increasingly stringent global automotive safety regulations, which mandate advanced braking performance, shorter stopping distances, and improved vehicle control under diverse conditions, further accelerate the integration of these pumps. Moreover, the enduring global imperative for enhanced fuel efficiency and a substantial reduction in carbon emissions incentivizes vehicle manufacturers to replace or augment engine-driven components with more energy-efficient electric alternatives, directly contributing to environmental sustainability goals.

Despite the robust growth drivers, the market navigates several notable restraints that pose challenges for manufacturers and adoption rates. A primary restraint is the relatively higher initial manufacturing cost associated with electric vacuum pumps compared to their conventional mechanical, engine-driven counterparts. This cost differential can be a limiting factor, particularly for mass-market vehicle segments or in cost-sensitive emerging economies. Furthermore, the complexity of integrating these sophisticated electric systems into existing or entirely new vehicle architectures presents engineering challenges, requiring extensive design modifications, precise software calibration, and thorough validation processes to ensure seamless operation and compatibility with the vehicle's overall electronic control network. The added weight and space requirements, although often optimized, can also be minor considerations in ultra-compact vehicle designs.

Significant opportunities are continually emerging for market participants, driven by ongoing technological advancements that are leading to the development of more compact, lighter, quieter, and even more energy-efficient pump designs with enhanced durability and advanced diagnostic capabilities. The rapid progression towards autonomous vehicles represents a substantial and future-proof opportunity, as these vehicles will demand highly reliable, potentially redundant, and intelligently controlled braking systems, elevating the criticality of electric vacuum pumps. Moreover, the burgeoning market for hydrogen fuel cell electric vehicles (FCEVs) presents a new frontier for vacuum pump applications, given that FCEVs also operate without an internal combustion engine to generate vacuum. The overall impact forces on the market are a dynamic interplay of relentless regulatory pressures for enhanced safety and stringent environmental performance, intense technological competition fostering continuous innovation, and evolving consumer preferences shifting towards cleaner, safer, and increasingly autonomous transportation solutions. These powerful forces collectively shape the market's trajectory, demanding agile adaptation and proactive innovation from all stakeholders to capitalize on the growth potential.

Segmentation Analysis

The Automotive Electric Vacuum Pump market undergoes comprehensive segmentation to provide a highly granular and insightful view of its multifaceted structure, thereby enabling a detailed understanding of underlying market dynamics, principal growth drivers, and influential regional characteristics. This intricate segmentation is absolutely vital for stakeholders, allowing them to precisely identify the most lucrative opportunities, formulate highly targeted strategic initiatives, and make informed business decisions. The market is methodically categorized across various dimensions, predominantly including product type, vehicle type, specific application, sales channel, and distinct geographic regions. Each defined segment serves to highlight unique market characteristics, ranging from the fundamental technical specifications and operational principles of the vacuum pumps themselves, to their intended end-use environments within different vehicle categories, and the established pathways through which these critical components ultimately reach consumers and vehicle manufacturers.

- By Product Type: This segment distinguishes electric vacuum pumps based on their internal design architecture and the operational stages involved in vacuum generation, reflecting varying levels of performance and efficiency.

- Single Stage: These pumps feature a simpler internal mechanism, typically offering a moderate level of vacuum and are often favored for applications where space and cost considerations are paramount, or where less intense vacuum requirements suffice. They provide a foundational level of performance suitable for many standard braking systems.

- Dual Stage: Characterized by a more complex design involving two vacuum-generating stages, these pumps are engineered to deliver higher vacuum levels and superior efficiency. They are increasingly adopted in vehicles with more sophisticated braking systems, advanced driver assistance features, or powertrains that demand a more robust and consistent vacuum supply for optimal performance.

- By Vehicle Type: This crucial segmentation accounts for the specific design constraints, performance demands, and integration challenges inherent to different automotive platforms. The requirements for an electric vacuum pump can vary significantly based on the vehicle category.

- Passenger Vehicles: This remains the largest and most diverse segment, encompassing sedans, SUVs, hatchbacks, and coupes. Electric vacuum pumps are extensively utilized here to enhance braking safety, improve pedal feel, and contribute to overall vehicle efficiency across various powertrain configurations.

- Commercial Vehicles: Encompasses trucks, buses, and vans, seeing increasing adoption as electrification of commercial fleets accelerates and safety standards become more stringent.

- Electric Vehicles (BEV, HEV, PHEV): This is the fastest-growing and most critical segment. Battery Electric Vehicles (BEVs), Hybrid Electric Vehicles (HEVs), and Plug-in Hybrid Electric Vehicles (PHEVs) inherently require electric vacuum pumps due to the absence or intermittent operation of a traditional internal combustion engine, making these pumps an absolute necessity for fundamental braking functionality.

- By Application: This segmentation categorizes the market based on the primary function and specific vehicle system that the electric vacuum pump serves, highlighting its versatility and criticality across multiple automotive functions.

- Brake Assist: The most dominant and safety-critical application, where the pump supplies the necessary vacuum to the brake booster, significantly reducing the effort required by the driver and ensuring prompt and effective braking.

- Turbocharger: Utilized for precise control of turbocharger wastegates, optimizing exhaust gas flow to the turbine, which is crucial for managing engine power, improving responsiveness, and enhancing fuel economy in turbocharged engines.

- Exhaust Gas Recirculation (EGR): Essential for modulating the flow of exhaust gases back into the engine's combustion chambers. This process helps to reduce combustion temperatures and consequently lowers the emission of harmful nitrogen oxides (NOx), contributing to environmental compliance.

- Others (e.g., HVAC, Fuel Tank Leak Detection): This includes a range of ancillary applications such as operating vacuum-actuated dampers in heating, ventilation, and air conditioning (HVAC) systems, or assisting in diagnostic tests for fuel tank evaporation leak detection systems, showcasing the pump's broad utility.

- By Sales Channel: This segmentation outlines the principal pathways through which electric vacuum pumps are procured and distributed within the automotive industry, differentiating between initial vehicle production and aftermarket support.

- OEM (Original Equipment Manufacturer): This channel involves direct sales and supply agreements with vehicle manufacturers, who integrate these pumps as original components into their new vehicles during the assembly line production process. This is typically characterized by large volume, long-term contracts.

- Aftermarket: This channel encompasses the sale of replacement electric vacuum pumps through a network of independent distributors, wholesalers, automotive parts retailers, and service centers to cater to the maintenance, repair, and replacement needs of existing vehicles once they are on the road.

Value Chain Analysis For Automotive Electric Vacuum Pump Market

The value chain for the Automotive Electric Vacuum Pump market is a complex, multi-stage process that commences with robust upstream activities focused on the sourcing and meticulous processing of foundational raw materials and specialized components. This initial, critical stage involves a diverse ecosystem of suppliers providing high-grade metals, primarily aluminum and steel, which are essential for manufacturing durable pump housings, rotors, and other structural elements that must withstand demanding operational conditions. Furthermore, the procurement of advanced engineering plastics and composite materials is vital for producing lightweight yet robust components like diaphragms, valves, and electrical insulation. A crucial aspect of this upstream segment is the supply of sophisticated electronic components, including high-efficiency brushless DC motors, precision sensors (such as pressure and temperature sensors), microcontrollers, and intricate wiring harnesses, all of which are absolutely integral to the pump's electrical operation, intelligent control, and seamless communication within the vehicle's electronic network. The unwavering emphasis on quality assurance and cost-effectiveness at this fundamental stage profoundly impacts the final product's performance, reliability, and ultimate market competitiveness.

Following the comprehensive upstream activities, the manufacturing and assembly phase constitutes the strategic core of the value chain. Within state-of-the-art production facilities, manufacturers engage in precision engineering processes, including advanced machining, automated assembly lines, and sophisticated robotic integration. Key operations at this stage include the precise winding of electric motors, the intricate assembly of pump mechanisms (e.g., vanes, diaphragms), the seamless integration of electronic sensors and control units, and the precise programming of embedded software. Throughout this entire phase, rigorous quality control and comprehensive testing procedures are strictly enforced to ensure that every single pump adheres to the exceptionally demanding automotive industry standards for performance, operational reliability, acoustic noise levels, and long-term durability. Effective logistics and highly optimized supply chain management are also paramount during manufacturing, facilitating the just-in-time delivery of components and finished products to meet the exacting production schedules of global automotive OEMs.

The downstream segment of the value chain is primarily focused on the efficient distribution and strategic sales of the finished electric vacuum pumps to their ultimate end-users. The most significant distribution channel involves direct sales and long-term supply agreements established with Original Equipment Manufacturers (OEMs). Electric vacuum pump manufacturers cultivate deep strategic partnerships with major global automotive players, supplying their products for direct integration into new vehicle production lines across various segments, including passenger cars, commercial vehicles, and the burgeoning electric vehicle market. This direct OEM channel is characterized by substantial volume orders, customized product specifications, and extremely stringent quality assurance protocols. Concurrently, an equally vital indirect distribution channel caters specifically to the aftermarket segment. This intricate network comprises authorized distributors, regional wholesalers, and a vast array of independent automotive parts retailers, who collectively supply electric vacuum pumps for maintenance, repair, and replacement purposes to service centers, independent garages, and eventually, to individual vehicle owners. Both the direct OEM sales and indirect aftermarket channels are indispensable for achieving broad market penetration, ensuring sustained growth, and providing essential product lifecycle support throughout the operational lifespan of vehicles equipped with these critical components.

Automotive Electric Vacuum Pump Market Potential Customers

The foremost and most substantial segment of potential customers for Automotive Electric Vacuum Pumps comprises global Original Equipment Manufacturers (OEMs). This expansive category includes the world's leading automotive corporations responsible for designing, engineering, manufacturing, and distributing passenger cars, light-duty and heavy-duty commercial vehicles (trucks, buses, vans), and specialized utility vehicles. These OEMs are continuously in pursuit of cutting-edge, highly reliable, and cost-efficient components to integrate into their new vehicle platforms and future model generations. The escalating global trends of vehicle electrification, coupled with increasingly stringent environmental regulations and ever-evolving safety standards, have made the adoption of independent electric vacuum pumps not merely an option but an absolute necessity for maintaining critical vehicle functions. Consequently, OEMs represent the pivotal buying entities, as these pumps become an embedded and integral part of their intricate vehicle architectures, particularly for brake assist systems where traditional engine vacuum is either insufficient, inconsistent, or entirely absent.

Within the broader OEM landscape, a particularly rapidly expanding and strategically vital customer group encompasses manufacturers of various types of electric vehicles, specifically Battery Electric Vehicles (BEVs), Hybrid Electric Vehicles (HEVs), and Plug-in Hybrid Electric Vehicles (PHEVs), alongside emerging developers of hydrogen Fuel Cell Electric Vehicles (FCEVs). For these pioneering vehicle manufacturers, electric vacuum pumps are not merely an enhancement but a foundational and indispensable component, as their advanced powertrains do not naturally generate the consistent vacuum levels required for conventional power braking systems. This specific customer segment places a premium on solutions that offer exceptional energy efficiency to maximize range, possess a compact footprint for optimal packaging, and integrate seamlessly with highly sophisticated electronic control systems. Furthermore, manufacturers specializing in premium or high-performance vehicles, which typically incorporate advanced and often redundant braking systems demanding superior responsiveness and driver feel, also constitute a key customer base for high-quality, precision-engineered electric vacuum pumps that can meet their exacting performance specifications.

Beyond the formidable OEM market, the aftermarket segment represents a substantial, resilient, and steadily expanding base of potential customers for Automotive Electric Vacuum Pumps. This includes a broad ecosystem of independent automotive repair shops, authorized dealership service centers, and a vast network of automotive parts distributors and wholesale suppliers across regional and global scales. As the total global fleet of vehicles equipped with electric vacuum pumps continues to grow exponentially, the inevitable demand for replacement components—whether due to standard wear and tear, component malfunctions, or routine maintenance requirements—will naturally escalate. These aftermarket buyers, ranging from large distributors to local mechanics, prioritize critical factors such as product availability, competitive pricing, broad compatibility across a diverse range of vehicle makes and models, and swift logistical support. Additionally, individual vehicle owners who undertake their own maintenance, or those seeking specific performance upgrades for their vehicles, also form a segment of the aftermarket customer base, further contributing to the pervasive demand and long-term necessity of electric vacuum pump solutions throughout the vehicle's operational lifecycle.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 1.85 Billion |

| Market Forecast in 2032 | USD 2.92 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Robert Bosch GmbH, Continental AG, Hella GmbH & Co KGaA, ZF Friedrichshafen AG, Denso Corporation, Valeo S.A., Aisin Seiki Co Ltd, Magna International Inc, Johnson Electric Holdings Ltd, FTE automotive GmbH, SHW AG, EATON Corporation, Ningbo Tuopu Group Co Ltd, Hitachi Astemo Ltd, GKN Driveline (Melrose Industries PLC), Wabco Holdings Inc (ZF), Rheinmetall AG, Novares Group, Mahle GmbH, BorgWarner Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Automotive Electric Vacuum Pump Market Key Technology Landscape

The technological landscape of the Automotive Electric Vacuum Pump market is characterized by a relentless pursuit of innovation, primarily centered on enhancing operational efficiency, bolstering reliability, and achieving seamless integration within the increasingly sophisticated and interconnected vehicle architectures of today and tomorrow. A fundamental pillar of this evolving landscape is the pervasive adoption of advanced brushless DC (BLDC) motors. These motors stand out for their superior energy efficiency, significantly extended operational lifespan, and remarkably quieter performance when compared to their conventional brushed motor counterparts. These attributes are exceptionally well-suited for the demanding and often noise-sensitive automotive environment, directly supporting the overarching industry objectives of minimizing energy consumption, reducing vehicle weight, and greatly improving overall vehicle acoustics, which are crucial factors for enhancing passenger comfort and extending the crucial range of electric vehicles. The transition to BLDC technology is therefore not merely an upgrade but a strategic alignment with future automotive design principles.

Further solidifying the robust technological foundation is the sophisticated integration of highly advanced electronic control units (ECUs) in conjunction with an array of precision sensors. These ECUs are absolutely vital for exercising precise and dynamic control over the pump's operation, enabling on-demand vacuum generation and variable output capabilities that can be meticulously tailored to specific vehicle requirements and real-time driving conditions. This intelligent control paradigm meticulously minimizes unnecessary energy draw and optimizes overall performance by only activating the pump when and at the intensity absolutely needed. Pressure sensors are continuously deployed to monitor vacuum levels within the system, providing instantaneous feedback to the ECU, while temperature sensors ensure that the pump operates consistently within safe and optimal parameters. Concurrently, significant advancements in material science play a crucial role; the strategic utilization of lightweight yet exceptionally robust engineering plastics and advanced aluminum alloys contributes substantially to reducing the pump's overall mass, aligning perfectly with broader vehicle lightweighting trends that aim to improve both fuel economy in ICEs and the critical range of electric vehicles. These material innovations also concurrently enhance the durability and resilience of the pumps against the harsh and diverse operating conditions encountered in automotive applications.

Looking towards the future, the market's technological evolution is sharply focused on achieving even greater miniaturization, developing highly modular designs, and fostering the creation of deeply integrated systems that can function autonomously or as part of larger vehicle networks. Manufacturers are actively investing in research to develop more compact pump designs that afford greater flexibility for vehicle packaging, which is becoming increasingly challenging as under-hood and chassis space becomes more constrained, particularly in compact and electrified platforms. Ongoing research efforts are also exploring alternative pump mechanisms and novel advanced sealing technologies, all aimed at further refining efficiency, reducing maintenance requirements, and extending service intervals. Crucially, with the accelerating proliferation of advanced driver assistance systems (ADAS) and the progressive march towards fully autonomous driving capabilities, there is an intensifying focus on developing fault-tolerant designs, implementing redundant systems, and incorporating advanced diagnostic features to ensure unparalleled reliability and safety. Connectivity features, often leveraging advanced AI and machine learning algorithms, are also rapidly emerging as key technological differentiators, enabling proactive maintenance, predictive failure analysis, and further optimizing pump performance over its entire lifecycle, thereby unequivocally ensuring that the critical braking system always operates at its absolute peak efficiency and safety.

Regional Highlights

- North America: This region demonstrates consistent and robust growth within the Automotive Electric Vacuum Pump market, predominantly driven by the implementation of stringent federal and state safety regulations, an aggressive and well-supported push for widespread vehicle electrification, and the substantial presence of major global automotive Original Equipment Manufacturers (OEMs) and leading technology innovators. Furthermore, the strong consumer preference for high-performance and luxury vehicle segments, which often integrate advanced braking systems requiring superior vacuum control, significantly contributes to the escalating adoption of sophisticated electric vacuum pump solutions. Continued investments in hybrid and electric vehicle manufacturing infrastructure and advanced component production capabilities further solidify market expansion in this region.

- Europe: Positioned as a leading global market, Europe is profoundly shaped by its pioneering and highly rigorous emission standards, coupled with an early and widespread adoption of hybrid and electric vehicle technologies across its diverse automotive landscape. Key contributing countries include Germany, France, and the UK, all of which benefit from substantial governmental and private sector investments in automotive research and development, particularly focused on advanced driver assistance systems and premium vehicle segments that demand exceptionally reliable and high-performance components. Proactive government incentives aimed at promoting electric vehicle purchases further stimulate and sustain market demand across the continent.

- Asia Pacific (APAC): Undisputedly identified as the fastest-growing market globally, APAC's remarkable expansion is vigorously propelled by its burgeoning automotive production volumes, particularly concentrated in economic powerhouses such as China, India, Japan, and South Korea. This surge is intricately linked with aggressive governmental support and substantial subsidies for electric vehicle adoption, alongside rapidly increasing disposable incomes and accelerated urbanization trends. These factors collectively fuel a burgeoning demand for modern, highly efficient, and intrinsically safe vehicles throughout the region, establishing APAC as a critically important and immensely promising market for both current penetration and future strategic expansion for electric vacuum pump manufacturers.

- Latin America: This region exhibits moderate yet steady growth within the market, influenced significantly by improving macroeconomic conditions, the expansion of the middle-class demographic, and a continuously growing vehicle parc across its diverse nations. While the pace of adoption for advanced automotive technologies might be more gradual compared to highly developed regions, there is an undeniable and persistent shift towards more fuel-efficient and inherently safer vehicles. This evolving consumer preference is creating nascent but incrementally growing opportunities for electric vacuum pump manufacturers. Brazil and Mexico, with their considerable automotive manufacturing bases and expanding internal markets, represent key markets within this dynamic region.

- Middle East and Africa (MEA): Emerging as a market with significant future potential, MEA's growth trajectory is primarily underpinned by ongoing large-scale infrastructure development projects, a steady rise in vehicle sales attributed to consistent population growth, and a gradual but distinct transition towards modern and technologically advanced automotive solutions. The increasing demand for commercial vehicles, particularly crucial for burgeoning logistics and public transport sectors, coupled with a heightened focus on fleet modernization initiatives across various industries, are identified as pivotal contributing factors. Economic diversification efforts and strategic investments in sustainable transport solutions in several countries within the region are also progressively contributing to market development.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Automotive Electric Vacuum Pump Market.- Robert Bosch GmbH

- Continental AG

- Hella GmbH & Co KGaA

- ZF Friedrichshafen AG

- Denso Corporation

- Valeo S.A.

- Aisin Seiki Co Ltd

- Magna International Inc

- Johnson Electric Holdings Ltd

- FTE automotive GmbH

- SHW AG

- EATON Corporation

- Ningbo Tuopu Group Co Ltd

- Hitachi Astemo Ltd

- GKN Driveline (Melrose Industries PLC)

- Wabco Holdings Inc (ZF)

- Rheinmetall AG

- Novares Group

- Mahle GmbH

- BorgWarner Inc.

Frequently Asked Questions

What is an automotive electric vacuum pump and its primary function in modern vehicles?

An automotive electric vacuum pump is an electrically powered device meticulously engineered to generate and maintain a consistent vacuum pressure independently of the engine. Its primary and critical function is to supply this essential vacuum to the brake booster system, thereby enabling power-assisted braking, significantly enhancing vehicle safety, reducing driver effort, and improving overall driving comfort, particularly in vehicles where traditional engine vacuum is insufficient, inconsistent, or entirely absent, such as hybrid and electric models.

Why are electric vacuum pumps considered crucial for the functionality of electric and hybrid vehicles?

Electric and hybrid vehicles, by design, often lack a reliable or consistent engine-driven vacuum source due to their electric powertrains or intermittent engine operation. Electric vacuum pumps are therefore considered fundamental and indispensable components, as they provide the necessary dedicated vacuum supply for critical systems like brake assist, guaranteeing consistently reliable, responsive, and safe braking performance, which is absolutely vital for the overall safety, control, and functionality of these advanced powertrain vehicles.

How do electric vacuum pumps specifically contribute to enhanced fuel efficiency and a reduction in vehicular emissions?

By operating intelligently on-demand and independently from the engine, electric vacuum pumps significantly reduce the parasitic losses that traditional engine-driven pumps impose on the internal combustion engine. This reduction in engine load directly translates into improved fuel economy for conventional and hybrid vehicles, and consequently, a measurable decrease in greenhouse gas emissions. For electric vehicles, they optimize auxiliary power consumption, thereby indirectly contributing to an extended driving range by managing energy use more efficiently.

What are the key technological advancements driving innovation in the electric vacuum pump market today?

Key technological advancements include the widespread adoption of highly efficient brushless DC (BLDC) motors for superior performance and longevity, the integration of sophisticated electronic control units (ECUs) for precise and adaptive operation, advanced sensors for real-time system monitoring, and the strategic use of lightweight, durable materials to enhance efficiency and robustness. Furthermore, there is a strong focus on miniaturization, modular design principles, and seamless integration capabilities with advanced vehicle control systems like ADAS and emerging autonomous driving platforms.

Which geographical region is currently leading and expected to dominate the growth of the Automotive Electric Vacuum Pump market?

The Asia Pacific region, prominently led by countries such as China and India, is currently identified as the fastest-growing market and is projected to continue dominating the growth of the Automotive Electric Vacuum Pump market. This robust expansion is primarily driven by significant increases in regional automotive production volumes, aggressive governmental support and substantial incentives for electric vehicle adoption, rapidly rising disposable incomes, and widespread urbanization, all collectively fostering an immense demand for modern, efficient, and inherently safe vehicle technologies across the region.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager