Automotive Engine Cover Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429548 | Date : Nov, 2025 | Pages : 242 | Region : Global | Publisher : MRU

Automotive Engine Cover Market Size

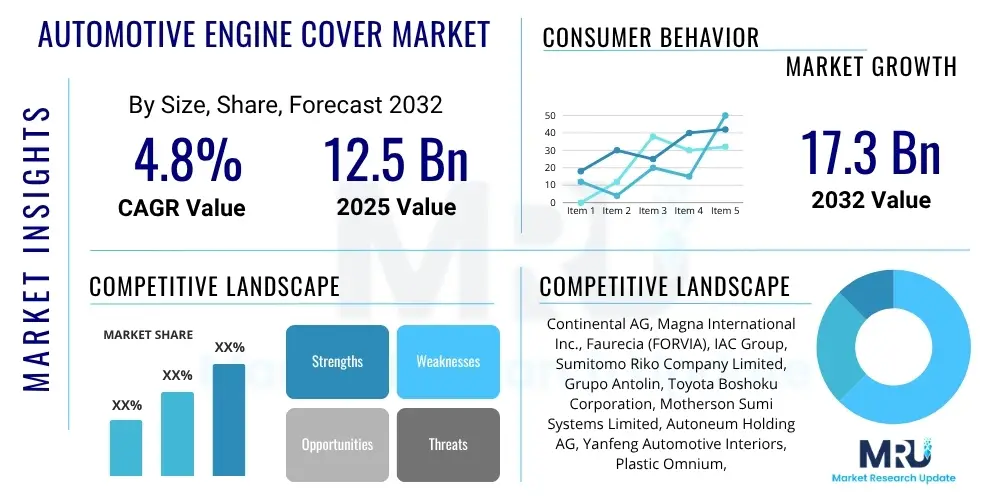

The Automotive Engine Cover Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2025 and 2032. The market is estimated at USD 12.5 Billion in 2025 and is projected to reach USD 17.3 Billion by the end of the forecast period in 2032.

Automotive Engine Cover Market introduction

The Automotive Engine Cover Market encompasses the production and supply of protective and aesthetic components placed over internal combustion engines, and increasingly, power electronics in electric vehicles. These covers serve multiple critical functions, including aesthetic enhancement, noise, vibration, and harshness (NVH) reduction, and protection of engine components from dust, debris, and heat. The market's expansion is intrinsically linked to the growth of global automotive production, consumer demand for refined vehicle interiors, and stringent regulatory requirements for noise emissions.

Product descriptions for engine covers vary significantly based on material, design, and vehicle application. They can be made from various materials such as plastics (e.g., polypropylene, ABS), composites (e.g., fiberglass, carbon fiber), and light metals (e.g., aluminum). Major applications span across passenger vehicles, including sedans, SUVs, and luxury cars, as well as light and heavy commercial vehicles. The primary benefits include improved acoustic comfort inside the cabin, thermal management for engine longevity, and a cleaner, more organized under-hood appearance, contributing to brand perception and resale value.

Key driving factors for market growth include the steady increase in global vehicle manufacturing, particularly in emerging economies, alongside a rising consumer preference for advanced, quieter, and aesthetically pleasing vehicles. Furthermore, the continuous focus by automotive manufacturers on light-weighting vehicles to improve fuel efficiency and reduce emissions, coupled with the evolution of material science to offer more durable and versatile cover solutions, further propels the market forward. The shift towards electric vehicles also presents new opportunities for covers designed for battery packs and electric motors.

Automotive Engine Cover Market Executive Summary

The Automotive Engine Cover Market is experiencing dynamic shifts driven by evolving business trends focused on advanced material science, manufacturing efficiency, and sustainability. Key business trends include the increasing adoption of lightweight and high-performance composite materials to meet fuel efficiency standards and enhance vehicle dynamics. There is also a significant trend towards modular designs that allow for easier assembly, maintenance, and customization, alongside an emphasis on incorporating recycled content in manufacturing processes to address environmental concerns and meet consumer expectations for sustainable products. Furthermore, strategic collaborations between material suppliers and OEMs are becoming crucial for developing innovative, cost-effective, and regulation-compliant engine cover solutions.

From a regional perspective, Asia Pacific remains the dominant market due to its robust automotive production volumes, particularly in countries like China, India, and Japan, which cater to both domestic and export markets. This region is witnessing rapid urbanization and a growing middle class, fueling demand for a wide range of vehicles that incorporate advanced engine covers for aesthetic and functional benefits. Europe, characterized by stringent noise emission regulations and a strong presence of premium and luxury vehicle manufacturers, shows consistent demand for high-quality, acoustically optimized engine covers. North America exhibits a mature market with steady growth, driven by consumer preferences for SUVs and light trucks that often feature sophisticated engine bay designs.

Segmentation trends highlight the increasing prominence of plastic and composite materials over traditional metals due to their lightweight properties, design flexibility, and cost-effectiveness. The acoustic engine cover segment is experiencing significant growth as manufacturers prioritize NVH reduction to enhance cabin comfort and comply with noise abatement standards. Moreover, the OEM channel continues to account for the largest share of the market, as engine covers are typically installed during vehicle assembly. However, the aftermarket segment is also expanding, driven by vehicle customization trends, replacement demands, and the availability of diverse upgrade options. The burgeoning electric vehicle sector is also creating new segments for covers designed specifically for electric powertrains and battery components, focusing on thermal management and safety.

AI Impact Analysis on Automotive Engine Cover Market

Common user questions regarding AI's impact on the Automotive Engine Cover Market frequently revolve around how artificial intelligence can revolutionize design processes, enhance manufacturing efficiency, optimize material selection, and potentially integrate smart functionalities into engine covers. Users are keen to understand if AI can predict performance under various conditions, improve aerodynamic properties, or even reduce production costs. There is also significant interest in AI's role in creating more sustainable engine cover solutions through optimized material usage and waste reduction. Overall, the key themes are efficiency, innovation, customization, and sustainability, with expectations that AI will introduce unprecedented levels of precision and intelligence into this traditional component sector.

- AI-powered generative design tools can optimize engine cover geometries for lightweighting, NVH reduction, and thermal management, potentially reducing material usage by up to 30%.

- Predictive analytics in manufacturing can enhance quality control, identifying defects in real-time during molding processes and minimizing scrap rates.

- AI algorithms can analyze vast datasets of material properties to recommend optimal materials for specific performance requirements, balancing cost, weight, and durability.

- Robotics and automation, often AI-driven, are improving the precision and speed of engine cover assembly and finishing processes, leading to higher output.

- AI can facilitate the development of "smart" engine covers integrated with sensors for real-time monitoring of engine health, temperature, or potential issues, enhancing predictive maintenance capabilities.

- Supply chain optimization using AI can predict demand fluctuations, manage inventory more efficiently, and mitigate risks associated with raw material sourcing.

- Customization and personalization of engine covers can be streamlined using AI to adapt designs quickly based on specific OEM or aftermarket requirements, offering greater flexibility.

DRO & Impact Forces Of Automotive Engine Cover Market

The Automotive Engine Cover Market is shaped by a confluence of driving factors, restraints, opportunities, and pervasive impact forces that dictate its growth trajectory and competitive landscape. A primary driver is the relentless increase in global vehicle production, fueled by rising disposable incomes and urbanization, particularly in emerging economies. Coupled with this is the escalating consumer demand for quieter, more comfortable, and aesthetically pleasing vehicles, which directly necessitates the use of effective engine covers for NVH reduction and visual appeal. Stringent government regulations concerning vehicular noise emissions and pedestrian safety also compel manufacturers to integrate advanced engine cover solutions. Moreover, the industry's continuous pursuit of light-weighting vehicles to improve fuel efficiency and reduce carbon emissions often leads to the adoption of advanced, lightweight materials for engine covers, further stimulating market demand.

However, the market faces several significant restraints. The volatile prices of raw materials, especially plastics and composites derived from crude oil, can directly impact production costs and profit margins for manufacturers. The inherent design complexity involved in creating engine covers that effectively manage heat, noise, and aesthetics while fitting within constrained engine compartments also poses a challenge. Furthermore, the durability requirements for engine covers, which must withstand extreme temperatures, vibrations, and chemical exposure, necessitate robust materials and manufacturing processes, potentially increasing costs. Additionally, intense cost pressures from Original Equipment Manufacturers (OEMs) often push suppliers to innovate while maintaining competitive pricing, which can be challenging in a market sensitive to material costs.

Opportunities for growth are abundant, particularly with the global automotive industry's pivot towards electric vehicles (EVs). While traditional engine covers for internal combustion engines will see continued demand, the EV segment presents new requirements for covers protecting battery packs, electric motors, and power electronics, focusing on thermal management, safety, and acoustic dampening for electric powertrain whine. The development and adoption of advanced materials, such as bio-composites and smart polymers, offer avenues for innovative, lighter, and more sustainable engine cover solutions. Customization and personalization trends, both in the OEM and aftermarket segments, also present significant growth potential, allowing manufacturers to cater to specific consumer preferences and vehicle aesthetics. Furthermore, the integration of sensors and smart functionalities into engine covers for diagnostic purposes or enhanced thermal management could unlock new value propositions, transitioning them from passive components to active system contributors.

Segmentation Analysis

The Automotive Engine Cover Market is comprehensively segmented to provide a detailed understanding of its various facets, enabling stakeholders to identify key growth areas and market dynamics. These segments categorize the market based on the material composition of the covers, the type of vehicle they are designed for, and the sales channel through which they reach the end-user. Each segment reflects unique demand characteristics, technological requirements, and competitive landscapes, driven by factors such as cost-effectiveness, performance criteria, regulatory compliance, and aesthetic considerations.

- By Material Type:

- Plastic: Includes polypropylene (PP), acrylonitrile butadiene styrene (ABS), polyamide (PA), and other engineering plastics. This segment dominates due to lightweight, cost-effectiveness, and design flexibility.

- Composite: Encompasses fiberglass, carbon fiber, and natural fiber composites. Offers superior strength-to-weight ratio and enhanced NVH characteristics, often used in premium and performance vehicles.

- Metal: Primarily aluminum or steel. Used in heavy-duty commercial vehicles or specific applications requiring high heat resistance and structural rigidity, though less common due to weight.

- By Vehicle Type:

- Passenger Cars: Covers sedans, hatchbacks, SUVs, luxury cars, and sports cars. This is the largest segment, driven by high production volumes and diverse aesthetic/performance needs.

- Commercial Vehicles:

- Light Commercial Vehicles (LCVs): Includes vans and pickup trucks, where durability and functionality are key.

- Heavy Commercial Vehicles (HCVs): Encompasses trucks and buses, focusing on robustness and thermal management.

- By Sales Channel:

- OEM (Original Equipment Manufacturer): Refers to engine covers supplied directly to automotive manufacturers for installation in new vehicles. This is the primary channel.

- Aftermarket: Includes sales of engine covers for replacement, repair, or customization purposes through independent retailers, repair shops, and online platforms.

Value Chain Analysis For Automotive Engine Cover Market

The value chain for the Automotive Engine Cover Market begins with upstream activities focused on the sourcing and processing of raw materials. This segment involves suppliers of various plastics such as polypropylene and ABS, composite materials like fiberglass and carbon fiber, and metals such as aluminum. Manufacturers also rely on suppliers for specialized components like fasteners, acoustic insulation foams, and heat shields. The quality and availability of these raw materials directly influence the cost, performance, and sustainability of the final engine cover product. Research and development activities at this stage are crucial for innovating new materials that offer improved lightweighting, NVH performance, and cost efficiency.

Midstream activities involve the manufacturing and assembly of the engine covers. This stage typically includes processes such as injection molding for plastic covers, compression molding or resin transfer molding for composite covers, and stamping or forming for metal covers. Manufacturers employ advanced techniques to ensure precision, durability, and aesthetic finish. Integration of acoustic dampening layers and heat shields occurs here. Quality control and testing are integral to ensure compliance with automotive industry standards for temperature resistance, vibration dampening, and chemical exposure. Efficiency in manufacturing processes, including automation and lean production, is critical for cost optimization and meeting OEM supply demands.

Downstream activities primarily involve the distribution and sales of engine covers. The predominant distribution channel is direct sales to Original Equipment Manufacturers (OEMs), where engine covers are integrated into new vehicle assembly lines. This requires strong logistical capabilities, just-in-time delivery, and close collaboration with automotive manufacturers. The indirect channel serves the aftermarket, supplying engine covers through a network of distributors, wholesalers, independent repair shops, and online retail platforms for replacement, repair, or customization purposes. Effective inventory management and a robust supply chain are essential to ensure product availability across both direct and indirect channels. Post-sales services, including warranty and technical support, also form part of the downstream value chain, enhancing customer satisfaction and brand loyalty.

Automotive Engine Cover Market Potential Customers

The primary potential customers and end-users of automotive engine covers are diverse, reflecting the broad applications of these components across the automotive sector. Original Equipment Manufacturers (OEMs) represent the largest customer base, as they require engine covers for every new vehicle manufactured. This includes global automotive giants producing passenger cars, luxury vehicles, sports cars, and a wide array of commercial vehicles. OEMs are intensely focused on sourcing engine covers that meet stringent specifications for durability, lightweighting, NVH reduction, thermal management, and aesthetic integration, often driving innovation in design and materials.

Beyond OEMs, the automotive aftermarket forms a significant segment of potential customers. This includes independent repair shops and service centers that purchase engine covers for replacement during vehicle maintenance or repair. Damage from accidents, wear and tear, or specific component failures necessitates the replacement of engine covers, creating consistent demand. Additionally, specialized vehicle customization centers and performance tuning shops represent a growing customer segment, seeking aftermarket engine covers for aesthetic upgrades or performance enhancements, often opting for premium or custom-designed covers made from advanced materials like carbon fiber.

Furthermore, parts distributors and wholesalers act as crucial intermediaries, supplying engine covers to both the independent aftermarket and smaller OEMs. These entities require a broad inventory of engine covers for various vehicle makes and models. The rise of e-commerce platforms has also made engine covers accessible directly to individual vehicle owners who undertake DIY repairs or seek personal vehicle modifications, forming another layer of potential customers who prioritize convenience, price, and product availability. The evolving landscape of electric vehicles is also creating new customer segments focused on specialized covers for electric powertrains and battery components, requiring solutions for different thermal and safety parameters.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 12.5 Billion |

| Market Forecast in 2032 | USD 17.3 Billion |

| Growth Rate | 4.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Continental AG, Magna International Inc., Faurecia (FORVIA), IAC Group, Sumitomo Riko Company Limited, Grupo Antolin, Toyota Boshoku Corporation, Motherson Sumi Systems Limited, Autoneum Holding AG, Yanfeng Automotive Interiors, Plastic Omnium, Flex-N-Gate Corporation, Kautex Textron GmbH & Co. KG, Kirchhoff Automotive GmbH, Hutchinson SA, Polytec Holding AG, Aisin Seiki Co. Ltd., Mitsubishi Chemical Holdings Corporation, Rochling Group, BASF SE |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Automotive Engine Cover Market Key Technology Landscape

The Automotive Engine Cover Market is driven by continuous technological advancements aimed at enhancing functionality, reducing weight, and improving sustainability. Key technologies employed include advanced material science, particularly in polymer and composite development. Injection molding remains a dominant manufacturing process for plastic engine covers, benefiting from continuous innovation in mold design and processing parameters to achieve complex geometries and tight tolerances. For composite covers, technologies like compression molding, resin transfer molding (RTM), and sheet molding compound (SMC) are widely utilized to produce lightweight yet structurally robust components with excellent acoustic properties. These processes are increasingly optimized for faster cycle times and reduced material waste.

Lightweighting technologies are paramount in the development of engine covers, as automotive manufacturers strive to meet stringent fuel efficiency and emission standards. This involves the use of advanced lightweight plastics and fiber-reinforced composites, as well as design optimization techniques such as topology optimization, often facilitated by CAD (Computer-Aided Design) and CAE (Computer-Aided Engineering) software. These simulation tools allow engineers to predict material performance, analyze stress points, and optimize the cover's structure to achieve maximum strength with minimum material. Furthermore, the integration of advanced acoustic materials, such as multi-layered foams, felts, and damping pads, is crucial for effectively reducing Noise, Vibration, and Harshness (NVH) levels, thereby enhancing cabin comfort.

The technology landscape also encompasses modular design principles, which allow for easier assembly, disassembly, and maintenance, contributing to the overall serviceability of the vehicle. Surface treatment technologies, including various painting, coating, and texturing methods, are employed to enhance the aesthetic appeal and durability of engine covers, protecting them from environmental factors and chemical exposure. Looking ahead, emerging technologies include the integration of smart materials and sensors into engine covers for real-time monitoring of engine parameters or thermal conditions, potentially enabling predictive maintenance and enhanced safety features. Research into bio-based and recycled materials is also gaining traction, aligning with the industry's broader sustainability goals and aiming to reduce the environmental footprint of automotive components.

Regional Highlights

- North America: This region represents a mature and stable market for automotive engine covers, driven by a robust automotive manufacturing sector and a high demand for premium vehicles. The market is characterized by a strong emphasis on aesthetic appeal, NVH reduction, and the incorporation of advanced materials. The increasing popularity of SUVs and light trucks, which often feature larger engine compartments and a greater focus on under-hood aesthetics, further contributes to market stability and incremental growth.

- Europe: Europe is a key market propelled by stringent environmental regulations concerning noise emissions and a high concentration of luxury and performance vehicle manufacturers. The focus here is heavily on sophisticated acoustic dampening solutions and lightweight composite materials to meet both regulatory compliance and consumer expectations for refined driving experiences. The rapid transition to electric vehicles in this region also opens new avenues for specialized covers for EV powertrains and battery modules.

- Asia Pacific (APAC): APAC stands as the largest and fastest-growing market for automotive engine covers globally, primarily due to the immense scale of vehicle production in countries like China, India, Japan, and South Korea. Rapid economic development, a burgeoning middle class, and increasing vehicle ownership are key drivers. The region is witnessing a significant shift towards advanced materials and higher-quality engine covers, moving beyond basic functionality to encompass improved aesthetics and NVH performance across all vehicle segments.

- Latin America: This region is an emerging market with growing automotive production capacities, particularly in Mexico and Brazil. The demand for engine covers is steadily increasing, driven by expanding vehicle sales and increasing domestic manufacturing. While cost-effectiveness remains a crucial factor, there is a gradual adoption of more advanced and aesthetically pleasing engine cover solutions as consumer preferences evolve.

- Middle East and Africa (MEA): The MEA region is a developing market with growth primarily influenced by expanding automotive sales and assembly operations, particularly in countries like South Africa and the UAE. The market for engine covers is largely dependent on vehicle imports and the establishment of local manufacturing facilities. Demand is influenced by general automotive market growth, with an increasing focus on durability and basic aesthetic improvements.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Automotive Engine Cover Market.- Continental AG

- Magna International Inc.

- Faurecia (FORVIA)

- IAC Group

- Sumitomo Riko Company Limited

- Grupo Antolin

- Toyota Boshoku Corporation

- Motherson Sumi Systems Limited

- Autoneum Holding AG

- Yanfeng Automotive Interiors

- Plastic Omnium

- Flex-N-Gate Corporation

- Kautex Textron GmbH & Co. KG

- Kirchhoff Automotive GmbH

- Hutchinson SA

- Polytec Holding AG

- Aisin Seiki Co. Ltd.

- Mitsubishi Chemical Holdings Corporation

- Rochling Group

- BASF SE

Frequently Asked Questions

What drives the demand for automotive engine covers?

Demand is driven by increasing global vehicle production, consumer preference for quieter and aesthetically pleasing vehicles, stringent noise emission regulations, and the automotive industry's focus on lightweighting for fuel efficiency.

How do engine covers contribute to vehicle performance?

Engine covers primarily contribute by reducing Noise, Vibration, and Harshness (NVH) for improved cabin comfort, protecting engine components from debris, and aiding in thermal management, which can indirectly support engine longevity and efficiency.

What materials are commonly used for engine covers?

Common materials include plastics (like polypropylene, ABS), composites (such as fiberglass, carbon fiber), and occasionally light metals (like aluminum), chosen for their balance of weight, cost, durability, and acoustic properties.

What is the impact of electric vehicles on the engine cover market?

Electric vehicles present new opportunities for specialized covers designed for battery packs, electric motors, and power electronics, focusing on thermal management, safety, and acoustic dampening of electric powertrain whine, rather than traditional engine protection.

Which region dominates the automotive engine cover market?

The Asia Pacific (APAC) region dominates the automotive engine cover market due to its high volume of vehicle production and growing automotive industry, particularly in countries such as China, India, and Japan.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager