Automotive Hydraulics System Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429628 | Date : Nov, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Automotive Hydraulics System Market Size

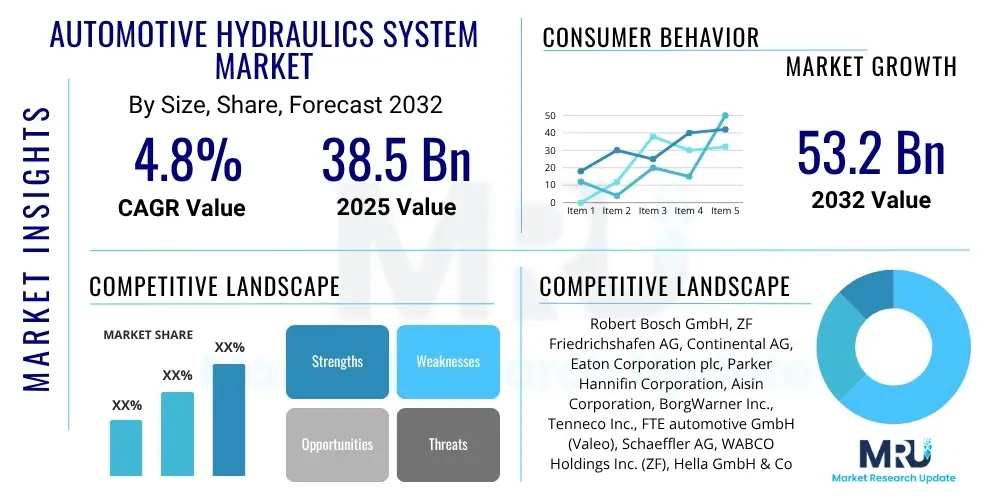

The Automotive Hydraulics System Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2025 and 2032. The market is estimated at USD 38.5 Billion in 2025 and is projected to reach USD 53.2 Billion by the end of the forecast period in 2032.

Automotive Hydraulics System Market introduction

The Automotive Hydraulics System Market encompasses the design, manufacturing, and supply of hydraulic components and systems specifically tailored for vehicular applications. These systems are crucial for transmitting power, multiplying force, and ensuring precise control across various automotive functions. Key components typically include hydraulic pumps, actuators, valves, reservoirs, hoses, fittings, and specialized hydraulic fluids, all engineered to operate reliably under varying pressures and temperatures within a vehicle's operational environment. Their primary applications span critical areas such as braking, steering, clutch engagement, suspension systems, and increasingly, in transmission control mechanisms. The inherent benefits of hydraulic systems, including their robustness, high power density, and ability to handle significant loads with precision, make them indispensable in modern vehicles, contributing significantly to both safety and performance.

The market's sustained growth is largely driven by several fundamental factors. A continuous increase in global vehicle production, particularly in emerging economies, directly fuels the demand for these essential components. Furthermore, stringent safety regulations imposed by various governments worldwide necessitate the adoption of advanced braking and stability control systems, many of which rely heavily on hydraulic technology. The rising consumer demand for enhanced vehicle comfort, improved handling characteristics, and sophisticated driving aids also contributes to the integration of advanced hydraulic solutions. As vehicles become more complex and feature-rich, the role of reliable and efficient hydraulic systems in ensuring optimal functionality and driver experience remains paramount, despite the ongoing shift towards electric and hybrid powertrains which introduce new considerations for hydraulic system design and integration. This robust foundational demand, coupled with continuous innovation, underscores the market's trajectory.

Automotive Hydraulics System Market Executive Summary

The Automotive Hydraulics System Market is undergoing significant evolution, driven by a confluence of business trends, regional dynamics, and segment-specific shifts. Business trends indicate a strong emphasis on lightweighting, system integration, and the development of electronically controlled hydraulic systems that offer enhanced precision and efficiency. Manufacturers are increasingly focusing on modular designs and material innovation to reduce overall vehicle weight and improve fuel economy, while simultaneously responding to the long-term industry shift towards electrification, which influences the design and integration of hydraulic components in hybrid and electric vehicles. Strategic partnerships and mergers are also prevalent as companies seek to consolidate market share and leverage specialized expertise.

Regionally, the Asia Pacific market is demonstrating robust growth, primarily fueled by expanding automotive manufacturing bases in countries like China and India, coupled with rising disposable incomes driving vehicle sales. North America and Europe, while more mature, remain significant markets, characterized by demand for advanced, high-performance, and safety-critical hydraulic systems, particularly within premium and commercial vehicle segments. Latin America and the Middle East and Africa are also witnessing gradual expansion, albeit with varying paces, often driven by infrastructure development and increasing vehicle parc. Segment-wise, braking systems continue to dominate the market due to their universal application and critical safety function, consistently seeing innovation in areas like ABS and ESP. However, the steering and transmission segments are also experiencing notable advancements, including the gradual adoption of electro-hydraulic power steering and sophisticated hydraulic clutch actuation, pushing the boundaries of traditional hydraulic applications and contributing to overall market dynamism.

AI Impact Analysis on Automotive Hydraulics System Market

Users frequently inquire about how Artificial Intelligence (AI) can revolutionize the traditionally mechanical domain of automotive hydraulic systems, focusing on questions related to enhanced safety, predictive maintenance, and efficiency improvements. Common concerns revolve around the integration challenges of complex AI algorithms with physical hydraulic components, the reliability of AI-driven control systems, and the potential for cybersecurity vulnerabilities in connected hydraulic systems. Expectations are high regarding AI's ability to optimize system performance, extend component lifespan, and contribute to the capabilities of autonomous vehicles by providing more responsive and adaptive hydraulic control. The underlying theme is a strong interest in understanding how AI can make hydraulic systems "smarter" and more resilient in a rapidly evolving automotive landscape.

- AI enables advanced predictive maintenance for hydraulic components by analyzing operational data, anticipating failures, and scheduling proactive servicing.

- AI algorithms optimize hydraulic fluid flow and pressure in real-time for adaptive suspension and braking systems, enhancing vehicle stability and comfort.

- Integration of AI with Advanced Driver-Assistance Systems (ADAS) and autonomous driving platforms allows for more precise and responsive hydraulic actuation in critical safety functions.

- AI-powered diagnostics improve troubleshooting efficiency, reducing vehicle downtime and maintenance costs.

- Machine learning models can analyze sensor data to detect anomalies and potential malfunctions, improving the overall reliability and safety of hydraulic systems.

- AI supports the development of next-generation electro-hydraulic systems, allowing for finer control and energy recuperation.

DRO & Impact Forces Of Automotive Hydraulics System Market

The Automotive Hydraulics System Market is shaped by a complex interplay of drivers, restraints, opportunities, and various impact forces that collectively define its trajectory. Key drivers include the consistent growth in global vehicle production, particularly in emerging markets, which inherently increases the demand for essential hydraulic components across all vehicle types. Stringent global safety regulations mandating features like Anti-lock Braking Systems (ABS) and Electronic Stability Programs (ESP) further propel market expansion, as these technologies heavily rely on advanced hydraulic architectures. Additionally, the increasing consumer preference for vehicles offering enhanced comfort, improved handling, and reliable performance continues to drive innovation and adoption of sophisticated hydraulic solutions in steering, suspension, and transmission systems. The expansion of commercial vehicle fleets and off-highway equipment also represents a significant, steady demand generator for robust hydraulic systems.

However, the market faces notable restraints, primarily stemming from the accelerating shift towards electric vehicles (EVs) and hybrid electric vehicles (HEVs). While some hydraulic systems remain essential, EVs reduce reliance on conventional hydraulic power steering and braking boost mechanisms, often replacing them with electro-mechanical equivalents. The inherent complexity of designing and integrating modern hydraulic systems, coupled with ongoing maintenance requirements and associated costs, can also deter adoption in certain segments or vehicle types. The continuous development and increasing prevalence of fully electro-mechanical alternatives for functionalities traditionally handled by hydraulics present a long-term challenge, pushing hydraulic system manufacturers to innovate and justify their continued relevance through superior performance and cost-effectiveness. The fluctuating prices of raw materials, such as steel, aluminum, and specialized rubbers, also impact manufacturing costs and market stability.

Despite these challenges, significant opportunities abound for the Automotive Hydraulics System Market. The ongoing research and development into advanced, lightweight hydraulic fluids and materials offer avenues for improved system efficiency, reduced weight, and enhanced environmental performance. The integration of traditional hydraulic systems with smart electronic control units (ECUs) and sensor technology creates possibilities for more intelligent, responsive, and adaptive systems that can seamlessly interact with vehicle dynamics control. Expanding into high-growth emerging markets, where vehicle penetration is still increasing and basic vehicle features are in demand, presents a substantial opportunity for market players. Furthermore, the development of compact and modular hydraulic systems designed for specialized applications or space-constrained vehicle architectures can unlock new market niches. These opportunities, when strategically pursued, can ensure the continued vitality and relevance of hydraulic technology within the evolving automotive landscape.

Segmentation Analysis

The Automotive Hydraulics System Market is comprehensively segmented to provide a detailed understanding of its diverse components, applications, and end-user landscapes. This segmentation allows for precise market analysis, enabling stakeholders to identify key growth areas, competitive dynamics, and emerging trends across various categories. The market is typically broken down by component type, by the specific vehicle application, by the overall vehicle type, and by the distribution or sales channel through which these systems reach their end-users. Each segment reflects unique demand characteristics, technological requirements, and competitive pressures, contributing to the overall market complexity and strategic planning for participants. Analyzing these distinct segments offers granular insights into market opportunities and challenges, facilitating targeted product development and marketing strategies.

- By Component:

- Brake Master Cylinder

- Brake Caliper

- Hydraulic Hose

- Hydraulic Pump

- Hydraulic Accumulator

- Hydraulic Cylinders

- Hydraulic Filters

- Hydraulic Valves

- Others (Reservoirs, Fittings)

- By Application:

- Braking System (ABS, ESP, Traction Control)

- Steering System (Power Steering, Electro-Hydraulic Power Steering)

- Clutch System

- Suspension System (Adaptive Suspension)

- Transmission System

- By Vehicle Type:

- Passenger Cars (Sedans, SUVs, Hatchbacks)

- Commercial Vehicles (Light Commercial Vehicles, Heavy Commercial Vehicles)

- Off-Highway Vehicles

- By Sales Channel:

- OEM (Original Equipment Manufacturer)

- Aftermarket

Value Chain Analysis For Automotive Hydraulics System Market

The value chain for the Automotive Hydraulics System Market begins with the upstream suppliers of raw materials and primary components, which are foundational to the manufacturing process. This segment involves companies supplying specialized metals like steel, aluminum, and cast iron for housings and pistons, high-grade rubbers and elastomers for seals and hoses, plastics for reservoirs, and chemical companies providing hydraulic fluids. These suppliers are critical for ensuring the quality, durability, and performance of the final hydraulic systems. Their technological advancements in material science directly influence the efficiency, weight reduction, and cost-effectiveness of hydraulic components. Strong relationships with reliable upstream suppliers are paramount for maintaining consistent production quality and managing cost fluctuations, which are significant impact forces on the overall market.

Moving downstream, the value chain progresses through the manufacturing and assembly of hydraulic components by Tier 1 and Tier 2 suppliers, who then integrate these into complete systems. Tier 1 suppliers, such as Bosch, ZF, Continental, and Eaton, play a crucial role by designing, producing, and delivering integrated hydraulic modules directly to Original Equipment Manufacturers (OEMs). These OEMs, including major automotive brands like Toyota, Volkswagen, Ford, and Daimler, are the primary purchasers of these sophisticated systems for integration into their vehicles. Post-manufacturing, the distribution channel is bifurcated into direct sales to OEMs and an extensive aftermarket network. Direct sales involve long-term contracts and close collaboration between Tier 1 suppliers and vehicle manufacturers to ensure seamless integration and specific design requirements are met. This direct channel accounts for a significant portion of the market, particularly for new vehicle production.

The indirect distribution channel primarily serves the aftermarket, catering to replacement and maintenance needs for existing vehicles. This involves a network of independent distributors, wholesalers, retailers, and service centers that provide hydraulic components and fluids to individual consumers, repair shops, and fleet operators. Companies like Gates and Parker Hannifin are significant players in both direct OEM supply and the aftermarket. This complex network ensures that spare parts and maintenance supplies are readily available globally, supporting the longevity and continued operation of vehicles. The efficiency and reach of both direct and indirect channels are vital for market penetration and customer satisfaction, with pricing strategies, logistical capabilities, and brand reputation being key determinants of success in each segment.

Automotive Hydraulics System Market Potential Customers

The primary potential customers for automotive hydraulic systems are the large-scale vehicle manufacturers, often referred to as Original Equipment Manufacturers (OEMs). These include global automotive giants producing passenger cars, commercial vehicles such as trucks and buses, and specialized off-highway vehicles like construction and agricultural machinery. OEMs integrate these hydraulic systems directly into their vehicle designs during the manufacturing process, making them the most significant buyers. Their purchasing decisions are driven by factors such as system performance, reliability, cost-effectiveness, compliance with safety standards, and the supplier's ability to innovate and provide integrated solutions. Establishing long-term supply agreements with these major automotive players is crucial for any market participant seeking to secure substantial market share.

Beyond the OEM segment, the aftermarket represents a substantial and consistent customer base for automotive hydraulic systems. This includes independent repair shops and garages that require replacement parts for maintenance and repairs of existing vehicles. Fleet operators, managing large numbers of commercial vehicles, also constitute a significant customer segment in the aftermarket, demanding durable and readily available hydraulic components to minimize downtime and operational costs. Individual vehicle owners, while typically not direct buyers of raw hydraulic systems, are the ultimate end-users whose needs drive demand for replacement parts through the aftermarket distribution channels. The demand in the aftermarket is primarily influenced by the aging vehicle parc, the severity of driving conditions, and the quality and availability of replacement parts from reputable suppliers. Aftermarket sales are critical for providing ongoing revenue streams and brand visibility post-vehicle sale.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 38.5 Billion |

| Market Forecast in 2032 | USD 53.2 Billion |

| Growth Rate | 4.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Robert Bosch GmbH, ZF Friedrichshafen AG, Continental AG, Eaton Corporation plc, Parker Hannifin Corporation, Aisin Corporation, BorgWarner Inc., Tenneco Inc., FTE automotive GmbH (Valeo), Schaeffler AG, WABCO Holdings Inc. (ZF), Hella GmbH & Co. KGaA, Hitachi Astemo, Inc., Mando Corporation, Brembo S.p.A., Advics Co. Ltd., JTEKT Corporation, Nexteer Automotive Group Limited, Eberspacher GmbH, Denso Corporation |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Automotive Hydraulics System Market Key Technology Landscape

The Automotive Hydraulics System Market is characterized by a dynamic technology landscape continually evolving to meet demands for improved performance, safety, and efficiency while adapting to emerging automotive trends. A significant technological advancement is the widespread adoption of electronically controlled hydraulic systems, where sensors and electronic control units (ECUs) precisely regulate hydraulic pressure and flow. This allows for features like Anti-lock Braking Systems (ABS), Electronic Stability Programs (ESP), and advanced active suspension systems that offer superior vehicle control and safety. These intelligent systems leverage intricate algorithms to optimize hydraulic responses, providing enhanced driver assistance and improving overall vehicle dynamics, which is crucial for modern vehicles.

Another pivotal area of innovation lies in the development of lightweight and durable materials for hydraulic components. Manufacturers are increasingly utilizing advanced composites, high-strength alloys, and engineering plastics to reduce the overall weight of hydraulic systems, contributing to better fuel economy and reduced emissions. This lightweighting trend is critical in supporting the broader automotive industry's push for vehicle efficiency. Concurrently, advancements in hydraulic fluid formulations are enhancing system performance, extending component lifespan, and improving environmental compatibility. New-generation hydraulic fluids offer better thermal stability, reduced friction, and improved resistance to degradation, leading to more reliable and longer-lasting systems.

Furthermore, the integration of hydraulic systems with broader vehicle architectures, particularly in hybrid and electric vehicles, is driving technological change. This includes the development of regenerative braking hydraulic systems that capture and convert kinetic energy into usable power, improving energy efficiency. The emergence of electro-hydraulic power steering systems, which combine the reliability of hydraulics with the flexibility of electric motors, is also a key development. These technologies are often coupled with sophisticated sensor-based monitoring systems that provide real-time diagnostic data, enabling predictive maintenance and ensuring optimal operational integrity. The ongoing research into steer-by-wire and brake-by-wire concepts, while not purely hydraulic, still influences the evolution of hydraulic backup and actuation mechanisms, pushing the boundaries of traditional hydraulic applications.

Regional Highlights

- Asia Pacific (APAC): This region dominates the automotive hydraulics system market, driven by high volume vehicle production in countries like China, India, Japan, and South Korea. Rapid urbanization, increasing disposable incomes, and supportive government policies for the automotive sector fuel consistent demand. The growing adoption of advanced driver-assistance systems and stricter safety regulations also contribute to market expansion.

- Europe: A mature market characterized by stringent safety and emission norms, pushing manufacturers towards advanced and highly efficient hydraulic systems. Germany, France, and the UK are key contributors, focusing on premium and luxury vehicle segments, and increasingly on hybrid and electric vehicle technologies that require specialized hydraulic solutions. Innovation in electro-hydraulic systems is a prominent trend.

- North America: This region maintains a strong market share due to high vehicle sales, a significant presence of leading automotive manufacturers, and a robust aftermarket. The demand for heavy-duty commercial vehicles and SUVs, which rely extensively on hydraulic systems for braking, steering, and suspension, further supports market growth in the United States and Canada. Technological integration and efficiency are key drivers.

- Latin America: Expected to show steady growth, primarily influenced by expanding automotive manufacturing capabilities in countries like Brazil and Mexico. Economic stabilization and increasing vehicle penetration contribute to rising demand for both OEM and aftermarket hydraulic components, though market maturity is lower compared to developed regions.

- Middle East and Africa (MEA): This region is experiencing nascent but growing demand, primarily driven by increasing vehicle parc, infrastructure development projects requiring commercial and off-highway vehicles, and improving economic conditions in key countries. The market is largely dependent on vehicle imports and aftermarket servicing, offering opportunities for suppliers focusing on cost-effective and reliable solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Automotive Hydraulics System Market.- Robert Bosch GmbH

- ZF Friedrichshafen AG

- Continental AG

- Eaton Corporation plc

- Parker Hannifin Corporation

- Aisin Corporation

- BorgWarner Inc.

- Tenneco Inc.

- FTE automotive GmbH (Valeo)

- Schaeffler AG

- WABCO Holdings Inc. (ZF)

- Hella GmbH & Co. KGaA

- Hitachi Astemo, Inc.

- Mando Corporation

- Brembo S.p.A.

- Advics Co. Ltd.

- JTEKT Corporation

- Nexteer Automotive Group Limited

- Eberspacher GmbH

- Denso Corporation

Frequently Asked Questions

What are the primary applications of hydraulic systems in automobiles?

Automotive hydraulic systems are primarily used in braking (ABS, ESP), steering (power steering), clutch engagement, suspension, and transmission control to transmit force and ensure precise operation.

How is the shift towards electric vehicles impacting the automotive hydraulics market?

The transition to electric vehicles (EVs) presents both challenges and opportunities. While some traditional hydraulic functions are being replaced by electro-mechanical systems (e.g., power steering, brake boost), hydraulics remain crucial for critical applications like braking, especially for advanced regenerative braking systems.

What are the key drivers for growth in the automotive hydraulics market?

Key drivers include increasing global vehicle production, stringent safety regulations mandating hydraulic-based safety features, rising demand for vehicle comfort and advanced features, and the expanding commercial vehicle sector.

Which region holds the largest share in the Automotive Hydraulics System Market?

The Asia Pacific region currently holds the largest market share, driven by robust automotive manufacturing, increasing vehicle sales, and developing economies like China and India.

What technological advancements are shaping the future of automotive hydraulics?

Future advancements include electronically controlled hydraulic systems, lightweight material adoption, advanced fluid formulations, integration with AI for predictive maintenance, and regenerative braking hydraulics for improved efficiency in hybrid and electric vehicles.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager